The functionality of specialized agricultural machinery relies on the intricate design and arrangement of various elements. Understanding these components is essential for maintaining efficiency and ensuring optimal performance in field operations. Each segment plays a critical role in the overall mechanics, contributing to the seamless operation of the equipment.

When examining the configuration of a specific model, it becomes apparent that each piece is tailored to fulfill distinct functions. Knowledge of the layout not only aids in troubleshooting but also enhances the capability to make informed decisions regarding repairs and replacements. This understanding fosters a deeper appreciation for the engineering that supports agricultural practices.

By familiarizing oneself with the individual components, operators can significantly extend the lifespan of their machinery. Detailed insights into the assembly empower users to undertake maintenance with confidence, ensuring that the equipment remains in peak condition throughout its operational life. Investing time in learning about these elements is a crucial step toward successful equipment management.

Understanding John Deere 1200A Bunker Rake

The machinery in question is a vital tool in the maintenance of turf environments, particularly in golf courses and sports fields. Its design is optimized for efficiency, enabling operators to manage large areas with precision and ease. This equipment is engineered to facilitate the cleaning and grooming of various surfaces, ensuring optimal conditions for play and aesthetics.

Key features of this equipment include:

- Efficient Design: The layout promotes smooth operation and maneuverability across diverse terrains.

- Durability: Constructed from high-quality materials, it withstands demanding conditions and frequent use.

- Adaptability: The tool can be customized with different attachments to suit specific tasks, enhancing versatility.

Understanding the functionality of this machine involves recognizing its primary components and their roles:

- Operational Mechanism: This aspect includes the drive system and the method of engagement, ensuring optimal performance.

- Cleaning Mechanism: An essential part that effectively gathers debris and maintains surface quality.

- Control System: The interface that allows users to manage various settings and operational modes.

Comprehending the attributes and functionality of this machine is crucial for maximizing its potential in turf maintenance. Proper usage and regular maintenance will lead to improved performance and longevity, making it a valuable asset in any facility that prioritizes pristine playing conditions.

Overview of Bunker Rake Features

This section delves into the essential characteristics of specialized landscaping machinery designed for effective turf management. The equipment incorporates various components that work synergistically to enhance the efficiency of ground maintenance tasks, particularly in recreational areas. A thorough understanding of these features aids users in maximizing the utility and longevity of their machinery.

The following table outlines key features commonly found in this type of equipment:

| Feature | Description |

|---|---|

| Hydraulic System | Facilitates smooth operation and adjustment of attachments for varying terrain conditions. |

| Adjustable Height | Allows for customization of working height to meet specific grooming needs. |

| Durable Frame | Constructed with robust materials to withstand the rigors of frequent use and harsh environments. |

| Easy Maneuverability | Designed for enhanced control and movement, making it suitable for various landscapes. |

| Multi-functional Attachments | Compatible with a range of tools, increasing versatility in ground care tasks. |

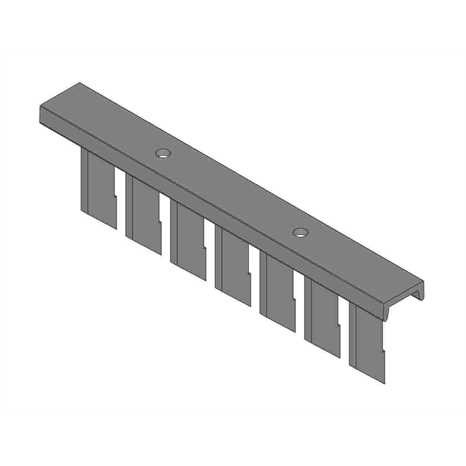

Essential Components of the Rake

Understanding the fundamental elements of this specialized equipment is crucial for optimal performance and maintenance. Each component plays a vital role in the overall functionality, contributing to efficiency and effectiveness in various tasks.

Main Structural Elements

- Frame: The backbone of the apparatus, providing stability and support.

- Wheel Assembly: Facilitates mobility, allowing the machine to navigate different terrains.

- Hitch Mechanism: Ensures proper attachment to the towing vehicle, maintaining a secure connection.

Operational Components

- Working Teeth: These elements engage the ground to gather materials effectively.

- Height Adjustment System: Enables the operator to modify the working depth according to specific requirements.

- Drive System: Powers the movement and operation of the machine, ensuring consistent performance.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure optimal performance and extend the lifespan of any equipment. By implementing a proactive maintenance strategy, operators can minimize downtime and prevent costly repairs. This section provides valuable insights into effective maintenance practices that promote durability and reliability.

Routine Inspections: Conduct frequent checks to identify wear and tear before it escalates into significant issues. Look for signs of corrosion, loose components, and any irregularities in function. Early detection can save both time and resources.

Proper Cleaning: Keeping machinery clean is vital for preventing debris buildup that can hinder operation. Ensure that all moving parts are free of dirt and grime, especially in critical areas that impact performance. Regular washing and servicing will help maintain efficiency.

Lubrication: Apply the appropriate lubricants to all moving parts as per the manufacturer’s recommendations. Proper lubrication reduces friction and wear, enhancing overall functionality and preventing premature failure of components.

Storage Considerations: When not in use, store equipment in a dry, sheltered area to protect it from the elements. Covering machinery helps to prevent rust and degradation from environmental factors, preserving its integrity over time.

Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule provided by the manufacturer. This includes routine service checks, replacement of wear parts, and any specific care instructions. Following these guidelines will ensure that the equipment remains in peak condition.

Identifying Common Replacement Parts

Maintaining equipment in optimal condition is essential for ensuring longevity and efficiency. This section focuses on recognizing essential components that may require attention over time. Understanding these elements can aid in proper upkeep and prevent potential malfunctions.

Key Components to Monitor

When evaluating machinery, several primary elements should be regularly inspected:

- Drive Belts

- Hydraulic Hoses

- Filters

- Spindle Bearings

- Wheels and Tires

Signs of Wear and Tear

Recognizing indicators of degradation can help in timely replacements:

- Cracks or fraying on drive belts

- Fluid leaks from hoses

- Discoloration or blockages in filters

- Unusual noises from bearings

- Uneven tire wear

By keeping a vigilant eye on these components and their condition, operators can ensure that the equipment remains functional and performs efficiently.

Tools Required for Repairs

Proper maintenance and repair of equipment necessitate a specific set of tools to ensure efficiency and effectiveness. Having the right instruments on hand not only simplifies the process but also minimizes the risk of damage to the machinery.

- Wrenches: A variety of wrenches, including adjustable and socket types, are essential for loosening and tightening bolts and nuts.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for removing and securing screws in various components.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating small parts and wires.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specified torque settings.

- Cutting Tools: Utility knives and wire cutters are needed for cutting cables and other materials as necessary.

- Diagnostic Tools: Multimeters and diagnostic scanners help in troubleshooting electrical issues and ensuring proper functionality.

- Safety Gear: Personal protective equipment, including gloves and safety glasses, is crucial to safeguard against potential hazards during repairs.

By utilizing the appropriate tools, one can effectively perform repairs, enhancing the longevity and performance of the equipment.

Wiring Diagram for Electrical Systems

The configuration of electrical systems is crucial for the efficient operation of various machinery. Understanding the connections and relationships between components is essential for troubleshooting and maintaining functionality. This section provides an overview of how these systems are organized, emphasizing the significance of accurate wiring in ensuring optimal performance.

Key Components

In electrical layouts, several key elements must be considered. These include power sources, fuses, relays, and various sensors. Each component plays a vital role in the overall functionality, contributing to the system’s reliability and efficiency. Ensuring that all parts are correctly connected according to the specified configurations is critical for avoiding malfunctions.

Connection Guidelines

Proper connection practices are necessary to prevent electrical issues. It is important to follow the recommended wiring patterns, ensuring that positive and negative terminals are correctly aligned. Additionally, maintaining clean and secure connections can significantly reduce the risk of shorts and improve overall system stability.

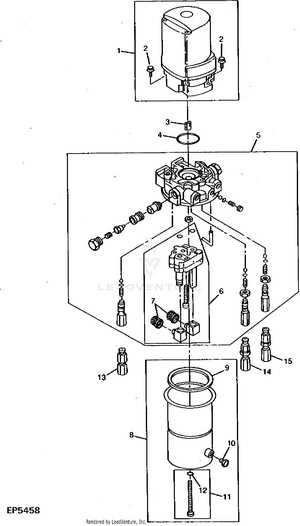

Hydraulic System Components Explained

The hydraulic system is a vital mechanism in various machinery, providing the necessary force to perform different tasks efficiently. This system utilizes fluid under pressure to transmit energy, allowing for precise control and powerful operation of the equipment. Understanding the key elements of this system can help in troubleshooting and maintaining optimal functionality.

Key Elements of the Hydraulic System

At the heart of any hydraulic assembly are essential components that work together seamlessly. These include the hydraulic pump, which generates pressure; hydraulic cylinders, which convert hydraulic energy into mechanical movement; and valves that regulate the flow and direction of the fluid. Each part plays a crucial role in ensuring that the system operates smoothly and effectively.

Importance of Regular Maintenance

To ensure the longevity and reliability of the hydraulic system, regular inspection and maintenance are necessary. This includes checking fluid levels, inspecting hoses for leaks, and ensuring that all components are functioning correctly. A well-maintained hydraulic system not only enhances performance but also minimizes the risk of unexpected failures.

Compatibility with Other John Deere Models

Understanding the interchangeability of components across different machinery models can enhance the efficiency of operations and reduce maintenance costs. Certain models share similarities that can facilitate the use of specific elements, allowing for smoother transitions when repairs or upgrades are necessary.

Here are some notable models that exhibit compatibility:

- Model A: Often features interchangeable components that align with several aspects of functionality.

- Model B: Shares similar mechanisms, allowing parts from one model to fit into another with minimal adjustments.

- Model C: Designed with certain features that mirror those of other machinery, ensuring ease of replacement.

- Model D: Benefits from a compatible design that allows for the incorporation of various components.

When considering compatibility, it is crucial to refer to the manufacturer’s guidelines and consult technical resources to ensure proper fitment and functionality.

Where to Find OEM Parts

When it comes to sourcing original equipment manufacturer components, it’s crucial to identify reliable outlets that can provide the quality and authenticity needed for optimal performance. Numerous avenues exist for acquiring these essential items, each offering unique advantages depending on your requirements.

Authorized Dealers

One of the most dependable methods is to approach authorized dealers. These establishments have direct relationships with manufacturers and ensure that the items they sell meet the highest standards of quality. They often have comprehensive inventories and can provide expert advice on selecting the right components.

Online Marketplaces

In today’s digital age, numerous online platforms offer a wide selection of OEM components. Shopping online allows for easy price comparisons and the convenience of browsing various suppliers from the comfort of your home. However, it’s essential to verify the reputation of the sellers to ensure the legitimacy of the products.

| Source | Advantages |

|---|---|

| Authorized Dealers | High quality, expert advice, direct from manufacturer |

| Online Marketplaces | Convenient, extensive selection, competitive pricing |

Assembly Instructions for Rake Parts

When assembling the components of your landscape maintenance equipment, following a systematic approach ensures optimal functionality and durability. Proper installation not only enhances performance but also prolongs the lifespan of your machinery. The steps outlined below will guide you through the assembly process with clarity and precision.

- Preparation:

- Gather all necessary components and tools.

- Refer to the manufacturer’s manual for specific guidelines.

- Work in a clean, organized space to prevent misplacement of parts.

- Assembling the Frame:

- Start by securing the main frame components using the appropriate fasteners.

- Ensure all joints are tight and free of debris.

- Double-check the alignment of all parts to maintain structural integrity.

- Installing the Operating Mechanism:

- Attach the operating mechanism to the frame, following the specific orientation indicated in the manual.

- Utilize a torque wrench to tighten bolts to the recommended specifications.

- Test the mechanism for smooth operation before proceeding.

- Final Assembly:

- Install any additional accessories, ensuring they are compatible with the main assembly.

- Conduct a thorough inspection of all connections and fastenings.

- Perform a final test of the complete unit to verify that all functions operate correctly.

Following these assembly instructions will help ensure that your equipment operates efficiently, allowing you to achieve the best results in your maintenance tasks.

Upgrading Your Bunker Rake Performance

Enhancing the efficiency of your turf maintenance equipment can lead to significant improvements in productivity and overall results. By implementing strategic upgrades, operators can optimize their machinery for better handling, durability, and performance.

Consider the following modifications to elevate the functionality of your equipment:

- Blade Enhancements: Upgrading to high-quality blades can improve cutting efficiency and longevity. Consider options with advanced materials that resist wear.

- Engine Modifications: Enhancing the power unit can result in increased torque and speed, enabling smoother operations even in challenging conditions.

- Hydraulic System Improvements: Upgrading hydraulic components can enhance responsiveness and efficiency, allowing for better control during use.

- Tire and Wheel Upgrades: Investing in premium tires can improve traction and stability on various terrains, reducing wear and tear on the machine.

Implementing these upgrades can lead to a noticeable enhancement in the overall performance of your machinery, ensuring that it meets the demands of maintaining high-quality landscapes.