Understanding the intricate details of heavy machinery is essential for effective maintenance and repair. A comprehensive overview of component arrangements can significantly enhance operational efficiency and reduce downtime. This knowledge serves as a foundation for anyone involved in the upkeep of complex equipment.

By examining the structural configuration of vital elements, operators and technicians can identify potential issues before they escalate. A clear representation of each part’s role and position within the system is invaluable, facilitating troubleshooting and ensuring that repairs are carried out swiftly.

In this section, we will delve into the specific layout of essential components, providing insights into their interconnections and functionalities. This understanding not only aids in immediate repairs but also fosters a deeper appreciation for the machinery’s design and engineering.

Understanding John Deere 1200A Parts

The exploration of machinery components is crucial for effective maintenance and optimal performance. Each element plays a significant role in the overall functionality, ensuring seamless operation. Recognizing how these elements interact can enhance longevity and efficiency.

Component identification is essential for troubleshooting and repairs. Familiarizing oneself with the various segments, from power systems to mobility mechanisms, allows for informed decision-making during maintenance tasks.

Maintenance routines can be streamlined by understanding the layout and connection of each unit. This knowledge ultimately contributes to reduced downtime and improved productivity, making the machinery more reliable in demanding environments.

Overview of John Deere 1200A Model

This section provides a comprehensive look at a particular model known for its efficiency and durability in various agricultural applications. Its design caters to the needs of users seeking reliable machinery for diverse tasks.

- Engine specifications

- Operational capabilities

- Maintenance requirements

- Features enhancing productivity

By exploring these aspects, one can appreciate the strengths and advantages this model offers to both professionals and hobbyists alike.

- Introduction to its mechanics

- Typical usage scenarios

- Comparison with other models

- Owner testimonials

Ultimately, understanding this model’s characteristics can help users make informed decisions regarding its use and maintenance.

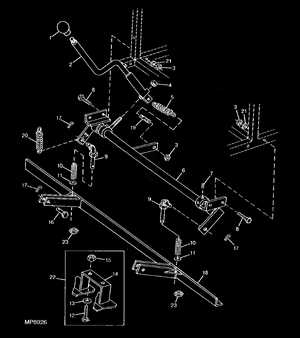

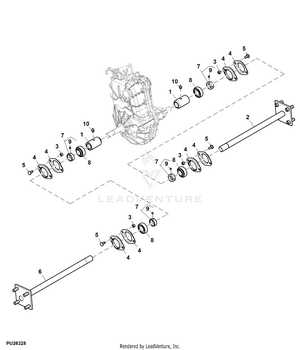

Key Components of the 1200A

This section explores the essential elements that contribute to the functionality and performance of the machine. Understanding these components allows for better maintenance and enhanced efficiency in operation.

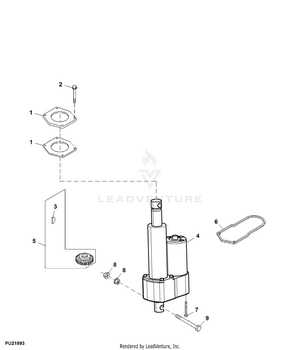

The hydraulic system is crucial, providing the necessary power for various functions. It includes pumps, hoses, and valves that work in harmony to control movement and operations.

The drivetrain encompasses gears and axles, ensuring optimal transfer of power to the wheels. Proper functioning of this system is vital for maneuverability and traction on different terrains.

The cutting assembly plays a significant role in achieving precise results, incorporating blades and adjustment mechanisms that enhance performance and adaptability to diverse conditions.

Finally, the electronic control unit manages all operations, allowing for user-friendly interaction and real-time monitoring of machine performance, ensuring everything runs smoothly.

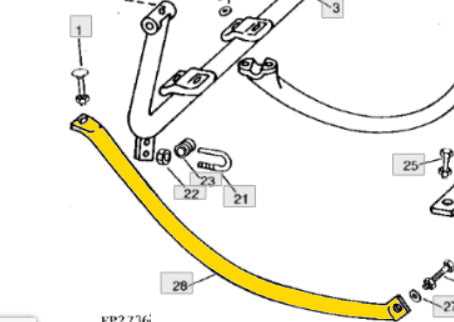

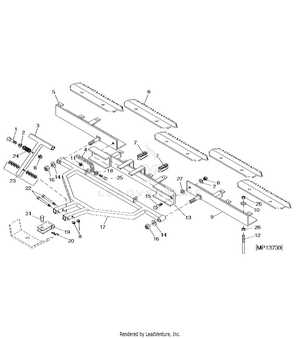

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. They serve as a guide, enabling users to identify individual elements and their relationships within the overall system. This clarity can significantly enhance maintenance and repair processes.

By breaking down complex machinery into manageable sections, these illustrations allow for easier troubleshooting and efficient replacement of worn or damaged items. They foster a deeper understanding of how various parts interact, ultimately leading to better performance and longevity of the equipment.

Moreover, having access to these visual aids can streamline training for new technicians, ensuring they are equipped with the necessary knowledge to handle repairs effectively. This resource is invaluable in minimizing downtime and maximizing productivity in any operational setting.

Where to Find Parts Diagrams

Locating comprehensive visuals that illustrate components can be crucial for maintenance and repairs. Understanding where to source these resources can save time and enhance efficiency.

Online Resources

- Official Manufacturer Websites

- Specialized Retail Platforms

- Community Forums and Groups

Printed Manuals

- Authorized Dealers

- Library Archives

- Second-hand Bookstores

Common Issues with 1200A Parts

In the realm of agricultural machinery, various components often face challenges that can impact performance and longevity. Understanding these frequent complications is essential for maintaining efficiency and ensuring optimal operation. Many users encounter issues that stem from wear and tear, improper installation, or inadequate maintenance practices.

Wear and Tear

One prevalent concern is the natural degradation of components over time. Parts subjected to heavy usage may exhibit signs of fatigue, leading to diminished functionality. Regular inspections can help identify these problems early, allowing for timely replacements and preventing more significant failures.

Improper Installation

Another common issue arises from incorrect assembly or adjustments. When components are not fitted properly, it can lead to misalignment and increased stress on surrounding elements. Following manufacturer guidelines during installation is crucial to avoid such pitfalls, ensuring all pieces function harmoniously together.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular care and attention. Implementing a few key practices can significantly extend its lifespan and enhance efficiency.

- Regular Inspections: Frequently check components for wear and tear. Look for signs of damage or corrosion that may require immediate attention.

- Cleanliness: Keep the machine clean to prevent dirt buildup, which can lead to malfunctions. Regularly wash surfaces and remove debris.

- Lubrication: Ensure moving parts are well-lubricated. This minimizes friction and reduces wear, promoting smoother operation.

- Fluid Levels: Regularly monitor and maintain proper levels of oil, coolant, and other essential fluids. Replenish as needed to avoid overheating or engine damage.

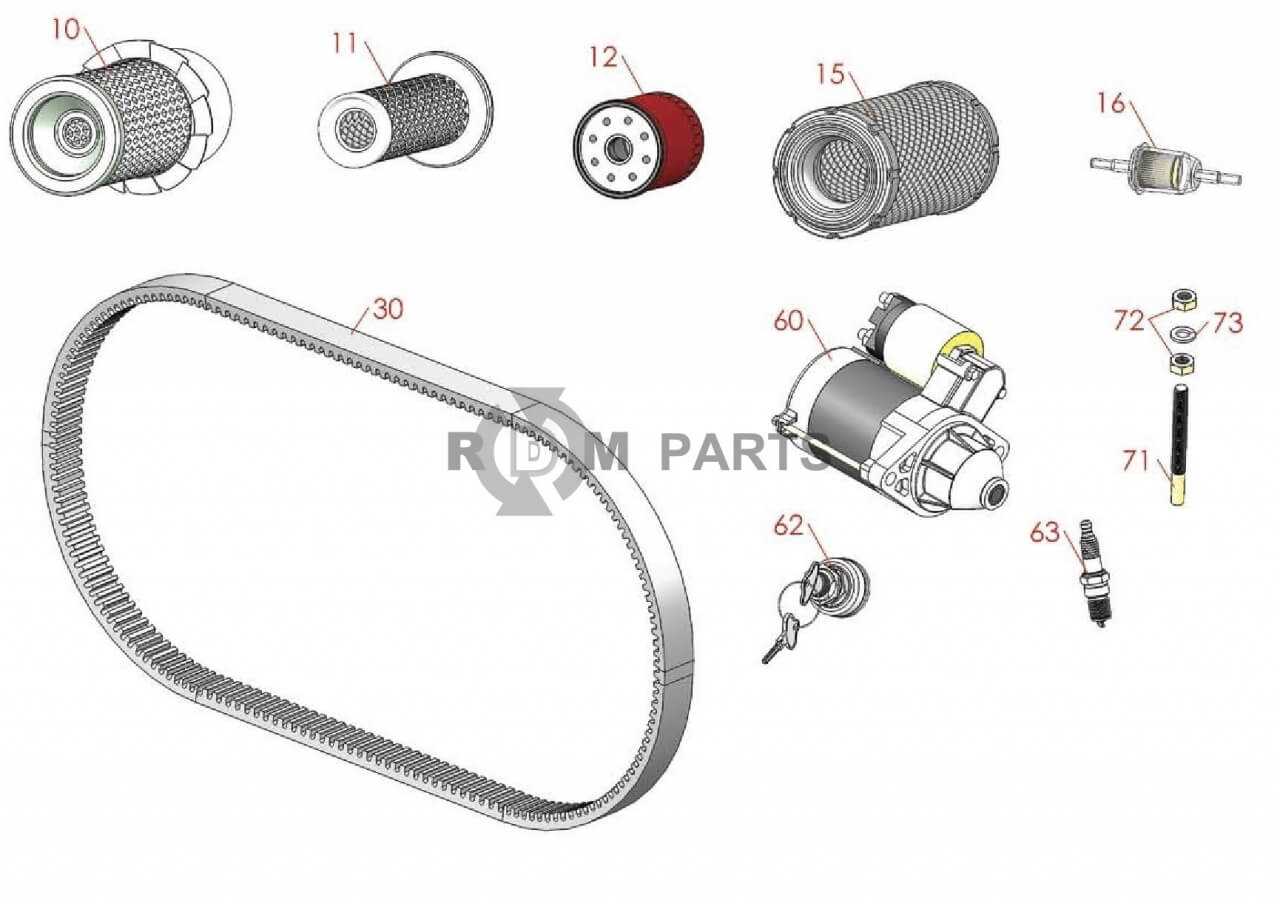

- Filter Replacement: Change air, oil, and fuel filters according to the manufacturer’s recommendations. Clean filters improve efficiency and prevent clogs.

By adhering to these maintenance strategies, you can maximize the performance and longevity of your machinery, ensuring it remains a reliable asset for years to come.

Aftermarket vs. Original Parts

The choice between alternative and manufacturer-specified components can significantly impact performance and longevity. Each option presents unique advantages and disadvantages that users must consider based on their specific needs and budget constraints.

Original components typically ensure compatibility and reliability, often coming with warranties and support from the manufacturer. These items are engineered to meet precise specifications, which can enhance the overall efficiency of the machinery.

On the other hand, alternative components can offer cost savings and a wider selection. Many users find that these options provide similar performance at a reduced price, making them an appealing choice for budget-conscious consumers. However, potential risks include variability in quality and durability.

Ultimately, the decision hinges on a careful evaluation of performance expectations, financial considerations, and the specific application requirements. Balancing these factors will guide users to the most suitable choice for their equipment.

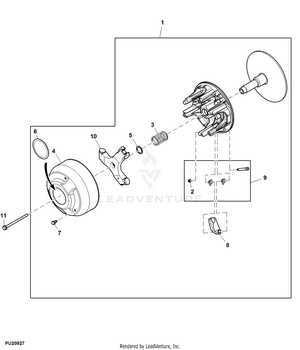

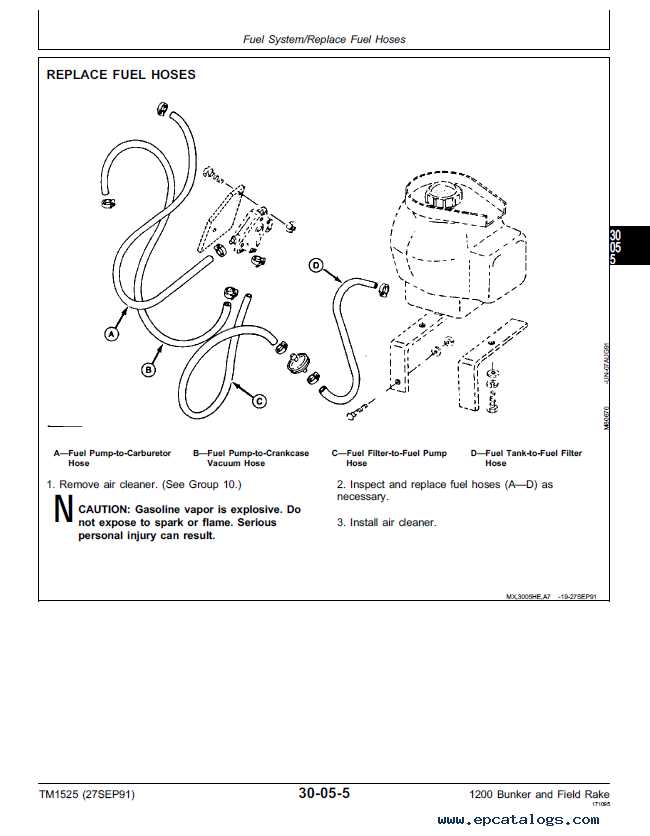

How to Read a Parts Diagram

Understanding a schematic representation of components is crucial for effective maintenance and repair. These visual aids provide a clear layout of individual elements and their interconnections, enabling users to identify and source the necessary components for any project. Mastering the interpretation of such visuals can significantly streamline your workflow and enhance your troubleshooting capabilities.

Identifying Key Symbols

The first step in comprehending these visuals is to familiarize yourself with the common symbols and notations used. Each element typically has a unique representation, which may include numbers or letters indicating specific parts. By recognizing these symbols, you can quickly locate and differentiate between various components within the schematic.

Understanding Component Relationships

Next, focus on how the elements interact with each other. Arrows and lines often illustrate connections, showing how parts fit together within the system. Pay attention to any annotations that describe functions or installation procedures, as these provide valuable context for each component’s role in the overall assembly.

Benefits of Accurate Parts Identification

Proper identification of components plays a crucial role in maintaining equipment efficiency and longevity. When users can accurately recognize the specific elements needed for repairs or replacements, it minimizes downtime and enhances productivity. Understanding the significance of precise identification fosters a more streamlined approach to maintenance and reduces the risk of errors that could lead to costly complications.

Enhanced Operational Efficiency

Identifying the correct elements ensures that replacements fit perfectly and function as intended. This precision not only leads to smoother operation but also contributes to the overall reliability of machinery. Efficiency increases as the need for repeated repairs diminishes, allowing operators to focus on their tasks without frequent interruptions.

Cost-Effectiveness and Resource Management

Accurate identification directly impacts budget management. By selecting the right components the first time, unnecessary expenses related to incorrect purchases or installation can be avoided. Effective resource allocation becomes possible, as funds can be directed toward necessary upgrades and maintenance rather than remedial actions due to misidentification. This strategic approach enhances both short-term savings and long-term sustainability.

Replacement Part Recommendations

When maintaining heavy machinery, selecting the right components is crucial for optimal performance and longevity. Ensuring that you utilize high-quality substitutes can significantly enhance the efficiency and reliability of your equipment.

Genuine Components: Whenever possible, opt for authentic replacements. These items are specifically designed to meet the manufacturer’s standards, ensuring perfect compatibility and durability.

Aftermarket Alternatives: Many aftermarket options provide a cost-effective solution without compromising quality. Research reputable brands that offer robust warranties and positive reviews from other users.

Essential Components to Consider: Focus on critical elements such as filters, belts, and hydraulic components. Regularly replacing these parts can prevent larger issues down the line.

Consulting a professional mechanic or technician can also provide valuable insights into the best choices for your particular machinery.

Resources for Further Assistance

Accessing reliable sources is crucial when seeking support for machinery maintenance and repair. Numerous platforms and tools can help enhance your understanding and provide the necessary information to tackle challenges effectively.

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer Website | Official site offering manuals and technical support. | Visit Here |

| Online Forums | Communities where users share experiences and solutions. | Join Forum |

| Parts Suppliers | Vendors that provide components and accessories with diagrams. | Find Parts |

| YouTube Channels | Video tutorials and demonstrations for practical guidance. | Watch Videos |