Understanding the intricate systems of machinery is essential for effective maintenance and repair. This guide aims to provide insights into the arrangement and functionality of crucial elements within a specific model of a well-known brand. By delving into the structure and relationships of these components, users can enhance their knowledge and proficiency in equipment management.

Each section will meticulously break down various segments, showcasing their roles and interconnections. This examination not only aids in troubleshooting but also fosters a deeper appreciation for engineering precision. Familiarity with these layouts equips users with the tools necessary for optimal operation and longevity of their equipment.

Moreover, having access to detailed illustrations can significantly streamline the repair process. By visualizing how parts work together, individuals can identify issues more efficiently and implement solutions with confidence. Ultimately, this resource serves as a vital reference for anyone looking to maintain their machinery effectively.

Understanding the John Deere 185 Hydro

This section aims to provide insights into a specific model of lawn care equipment renowned for its performance and durability. By exploring its various components, users can better appreciate how each part contributes to the overall functionality of the machine.

Key Features and Benefits

The machine is equipped with an innovative transmission system that enhances maneuverability and ease of use. Its robust engine ensures efficient operation, making it ideal for various landscaping tasks. Understanding these features allows users to maximize productivity and maintain their equipment effectively.

Maintenance and Care

Regular upkeep is crucial for optimal performance. Familiarizing oneself with the essential elements of this model enables users to identify potential issues early. Proper maintenance not only extends the lifespan of the equipment but also ensures a reliable and smooth operation.

Overview of John Deere 185 Model

This section provides a comprehensive look at a well-known lawn maintenance machine designed for efficiency and durability. Renowned for its robust features, this model offers exceptional performance in various mowing conditions.

Engine Performance: Equipped with a powerful engine, this machine ensures smooth operation and reliable cutting power.

Design and Comfort: The ergonomic layout enhances user experience, allowing for easy maneuverability and comfort during prolonged use.

Maintenance: Understanding the maintenance needs is crucial for longevity; regular checks and part replacements contribute to optimal functioning.

In summary, this model stands out in the market for its balance of power, comfort, and reliability, making it a popular choice among homeowners and professionals alike.

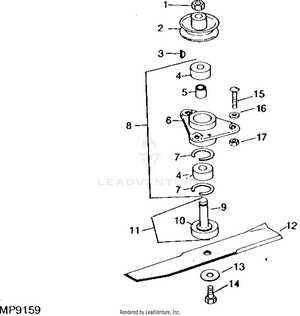

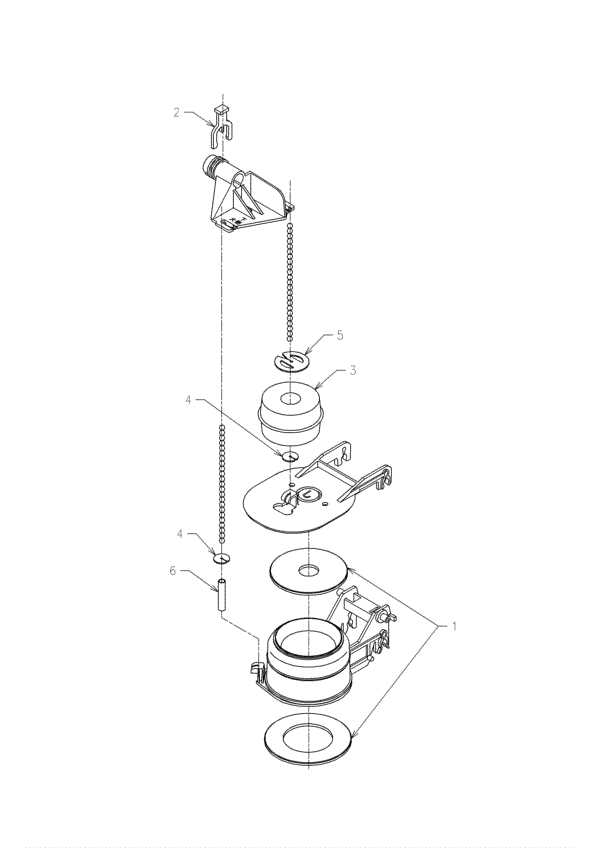

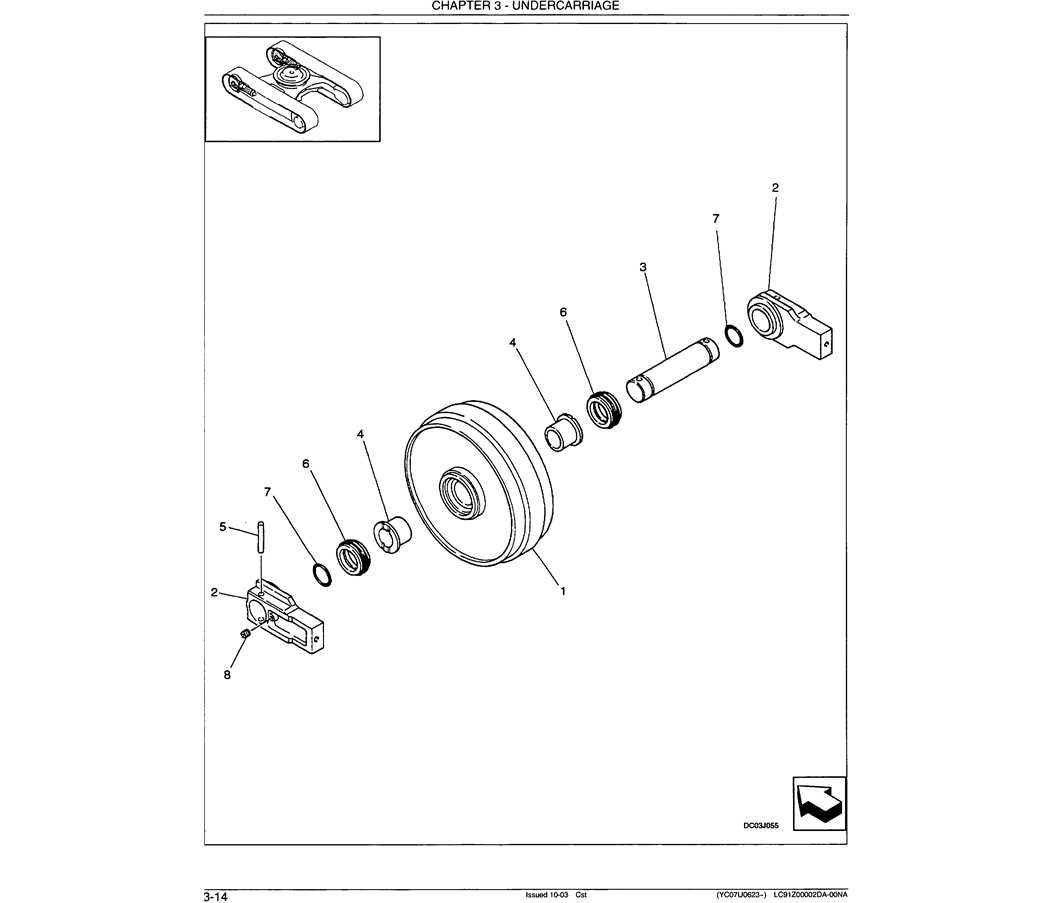

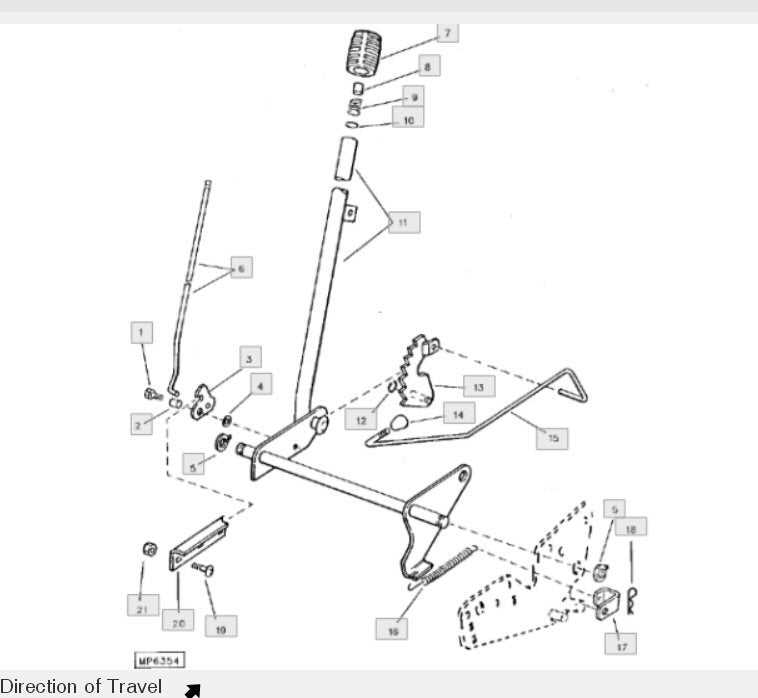

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations of these elements provide invaluable insights that enhance efficiency and reduce errors during servicing. By illustrating how various parts interact, these schematics serve as essential tools for both professionals and enthusiasts alike.

Enhancing Clarity in Maintenance

Clear illustrations allow users to identify specific components quickly, facilitating faster troubleshooting and repairs. This clarity helps in minimizing downtime, as technicians can quickly reference the layout to find and replace faulty elements without unnecessary confusion.

Facilitating Accurate Ordering

When repairs are needed, having a visual reference ensures that the correct components are ordered. This precision is vital in avoiding delays caused by incorrect or incompatible items being procured. Accurate ordering not only saves time but also reduces costs associated with returns and exchanges.

| Benefits | Description |

|---|---|

| Time Efficiency | Reduces downtime through quick identification of components. |

| Cost Savings | Minimizes expenses by ensuring accurate ordering of replacements. |

| Improved Understanding | Enhances knowledge of machinery through detailed visual aids. |

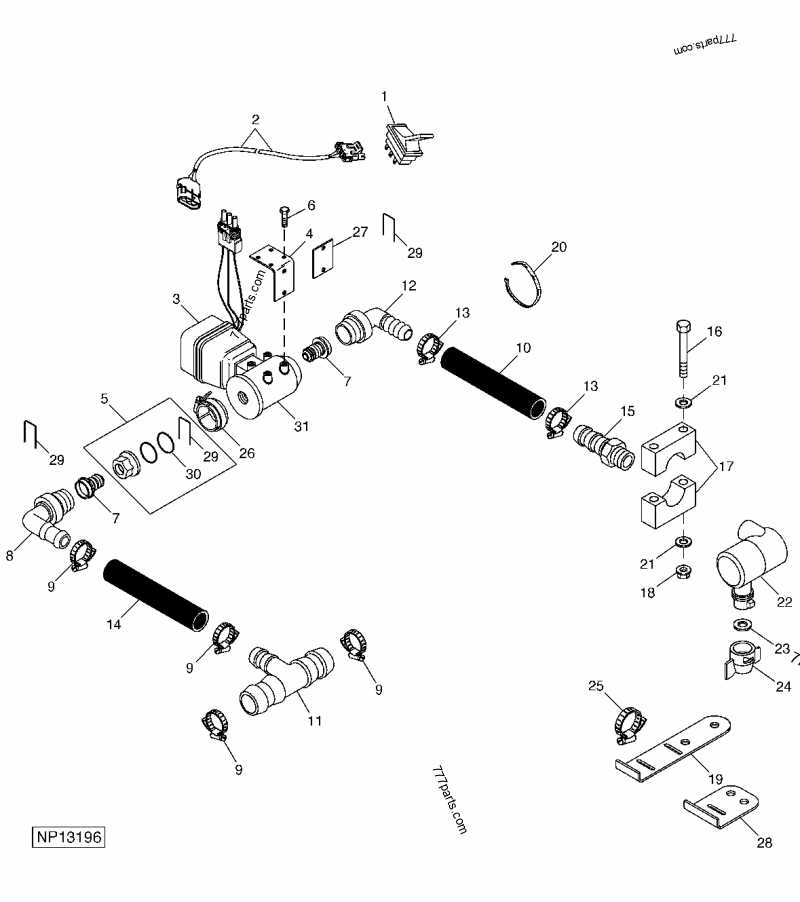

Key Components of the Hydrostatic System

The hydrostatic system is essential for the efficient operation of various machinery, providing seamless control and power transfer. Understanding its core elements is crucial for optimal performance and maintenance.

Pump Mechanism

The pump is the heart of the system, responsible for generating fluid flow. It converts mechanical energy into hydraulic energy, enabling movement and force transmission throughout the machinery.

Motor Assembly

The motor converts hydraulic energy back into mechanical energy, driving the wheels or implements. Its design ensures precision and responsiveness, enhancing the overall functionality of the equipment.

Common Repairs for John Deere 185

Routine maintenance and occasional fixes are essential for keeping this popular mowing machine in optimal condition. Users often encounter specific issues that require attention, ranging from minor adjustments to significant replacements. Understanding common repairs can help enhance performance and extend the lifespan of the equipment.

Engine Troubleshooting

Engine-related problems can manifest in various ways, such as starting difficulties or irregular idling. Regular checks of the spark plug and fuel filter are recommended, along with ensuring that all connections are secure. Addressing these issues promptly can prevent more significant complications down the line.

Transmission Maintenance

The transmission system plays a critical role in performance. Common concerns include slipping or grinding noises, which may indicate low fluid levels or worn components. Regular fluid changes and inspections can help maintain smooth operation and reduce the likelihood of costly repairs.

How to Read Parts Diagrams

Understanding schematic representations is crucial for effective maintenance and repairs. These visual aids offer a detailed breakdown of components, facilitating easier identification and replacement processes.

1. Familiarize Yourself with Symbols: Each illustration employs specific symbols to represent different elements. Recognizing these will enhance comprehension and efficiency.

2. Follow the Flow: Observe how components are interconnected. This will help you grasp the overall functionality and how each piece contributes to the system.

3. Utilize the Legend: Most schematics include a legend that explains symbols and designations. Referencing this section can clarify any uncertainties.

4. Take Notes: As you study the visual, jot down important details. This practice aids retention and ensures you won’t overlook crucial information.

5. Cross-reference with Manuals: Always align your findings with official manuals for accuracy. This additional resource reinforces understanding and provides context.

By mastering these techniques, you’ll ultimately enhance your ability to navigate complex visual guides with confidence.

Essential Maintenance Tips for Longevity

Proper upkeep is crucial for enhancing the lifespan of your equipment. By adhering to a few essential guidelines, you can ensure that your machine operates efficiently and remains in optimal condition for years to come. Regular maintenance not only prevents unexpected breakdowns but also improves performance, making your investment worthwhile.

Here are some fundamental practices to keep your machinery in top shape:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace old oil to ensure smooth operation and reduce wear. |

| Air Filter Cleaning | Every 25 hours | Remove and clean to prevent engine damage from dirt and debris. |

| Blade Sharpening | As needed | Keep blades sharp for efficient cutting and reduced strain on the engine. |

| Tire Inspection | Monthly | Check for wear and maintain proper inflation for stability and safety. |

| Belt Inspection | Every 100 hours | Examine for wear and tension to ensure proper functionality. |

Implementing these practices will significantly extend the life of your equipment, allowing you to maximize its performance and reliability. Regular attention to detail can make all the difference in maintaining a high level of efficiency and safety.

Where to Find Genuine Parts

When seeking authentic components for your machinery, it’s essential to explore reliable sources that ensure quality and compatibility. Accessing original items not only guarantees optimal performance but also prolongs the lifespan of your equipment.

Recommended Sources

- Authorized Dealerships

- Official Manufacturer Websites

- Specialized Retailers

- Industry Trade Shows

Additional Tips

- Verify the authenticity of the seller.

- Check for warranty and return policies.

- Consult user reviews and ratings.

Aftermarket vs. OEM Parts Comparison

When maintaining machinery, the choice between original components and alternative options is crucial. Understanding the benefits and drawbacks of each can significantly impact performance and longevity.

Original equipment components are designed specifically for the machinery, ensuring compatibility and reliability. However, alternative options often present a cost-effective solution with varying quality.

- Quality:

- OEM: Typically manufactured to the exact specifications of the original design, ensuring optimal performance.

- Aftermarket: Quality can vary widely; some may exceed OEM standards, while others may not meet them.

- Cost:

- OEM: Generally more expensive due to brand reputation and warranty coverage.

- Aftermarket: Often more affordable, providing budget-friendly options for repairs and maintenance.

- Availability:

- OEM: May have limited availability depending on the manufacturer.

- Aftermarket: Usually more widely accessible through various suppliers.

- Warranty:

- OEM: Typically comes with a manufacturer’s warranty, offering peace of mind.

- Aftermarket: Warranty terms vary; some products may offer limited guarantees.

Ultimately, the decision hinges on specific needs, budget constraints, and the importance of reliability in machinery performance. Weighing these factors can help users make informed choices that align with their maintenance goals.

Common Issues and Solutions

In the realm of outdoor equipment, various challenges may arise that affect performance and efficiency. Understanding these common problems and their resolutions can significantly enhance the longevity and functionality of your machinery. Here, we explore frequent issues encountered by users and effective strategies to address them.

Frequent Problems

- Engine Starting Issues: Difficulty in starting the engine can stem from fuel supply problems, battery issues, or ignition system failures.

- Hydraulic System Malfunctions: Leaks or pressure loss in the hydraulic system may lead to inadequate operation of attachments.

- Uneven Cutting: An uneven cutting pattern often results from dull blades or improper deck leveling.

- Noisy Operation: Unusual noises may indicate worn-out bearings or loose components within the machine.

Solutions

- Addressing Starting Problems:

- Check the fuel level and quality.

- Inspect the battery connections and charge.

- Examine the ignition system for faults.

- Resolving Hydraulic Issues:

- Inspect hoses for leaks and replace if necessary.

- Check fluid levels and replenish as needed.

- Test the pump functionality and replace if malfunctioning.

- Improving Cutting Quality:

- Sharpen or replace blades regularly.

- Adjust the cutting deck to ensure proper height.

- Minimizing Noise:

- Conduct regular maintenance on bearings and gears.

- Tighten any loose bolts or components.

Tools Required for Repairs

When tackling maintenance tasks, having the right equipment is essential for efficiency and precision. Various tools not only facilitate the repair process but also ensure safety and accuracy.

- Wrenches: A variety of sizes is crucial for loosening or tightening bolts.

- Screwdrivers: Both flathead and Phillips types are necessary for accessing different components.

- Socket Set: Useful for quickly removing nuts and bolts in tight spaces.

- Pliers: Ideal for gripping, twisting, and cutting wires or small parts.

- Jack and Stands: Essential for safely lifting the equipment during repairs.

By gathering these tools, you will be well-equipped to delve into any necessary repairs effectively, ensuring the ultimate performance of your machinery.

Upgrades for Improved Performance

Enhancing the efficiency and capability of your machinery can lead to significant gains in productivity. By focusing on specific improvements, you can optimize performance and ensure longevity in operation. These enhancements often involve replacing outdated components with advanced alternatives that deliver superior results.

Powertrain Enhancements: Upgrading the transmission system can provide smoother operation and increased torque. Consider options like a more responsive drive belt or a high-performance transmission fluid for better power transfer.

Engine Modifications: Replacing the air filter and fuel injectors with high-efficiency models can boost horsepower and fuel economy. Additionally, tuning the engine can help achieve its ultimate potential.

Chassis Improvements: Strengthening the frame and suspension can enhance stability and load-bearing capacity. High-quality shock absorbers and springs can provide better handling and comfort during operation.

Technology Integration: Incorporating modern technology, such as GPS tracking and advanced diagnostics, can streamline operations and maintenance, ensuring optimal performance.

Resources for Further Information

For those seeking to enhance their knowledge and understanding of machinery components and maintenance, a variety of valuable resources are available. These can help users navigate through technical details and ensure effective troubleshooting and repairs.

- Manufacturer Websites: Explore the official pages for detailed specifications and guides.

- Online Forums: Engage with communities of enthusiasts who share insights and experiences.

- Video Tutorials: Utilize platforms that offer visual instructions for maintenance and repairs.

- Service Manuals: Access comprehensive documents that provide step-by-step procedures.

- Parts Retailers: Visit sites specializing in machinery components for sourcing replacement items.

By leveraging these resources, individuals can delve deeper into the intricacies of their equipment and achieve ultimate efficiency in operation and upkeep.