The world of agricultural machinery is vast and complex, requiring a deep understanding of the essential systems that keep these machines running efficiently. This section focuses on the detailed structure of various components, offering insight into how each element works together to maintain optimal functionality in agricultural operations.

Understanding how mechanical systems interact is crucial for anyone involved in maintenance or repairs. By examining the core assemblies and their connections, we can gain a better grasp of the equipment’s inner workings, helping to ensure smooth operation in the field. Proper knowledge of these systems is invaluable for extending the life of machinery and avoiding unnecessary downtime.

Understanding the Structure of John Deere 2032r

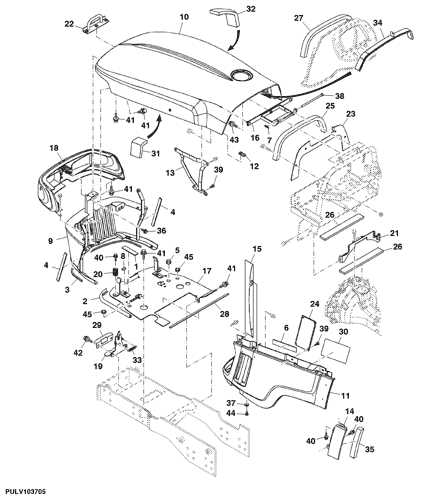

The design of this utility machine combines several essential systems that work together to provide efficient performance. Its overall architecture is engineered for versatility, durability, and ease of maintenance, making it a reliable choice for various tasks. Each component within this machinery is strategically positioned to ensure optimal functionality and easy access when necessary.

By understanding the arrangement and purpose of its various elements, users can better appreciate how the equipment operates and how each section contributes to its efficiency. Whether focusing on the engine, hydraulics, or control systems, every part plays a significant role in ensuring smooth operation across diverse conditions.

Key Components of the 2032r Tractor

The tractor is made up of several essential elements that work together to ensure efficient operation and versatility in a variety of tasks. Each component has a specific role in enhancing functionality, from handling challenging terrain to executing precise agricultural processes.

Engine and Transmission

The engine provides the necessary power for a wide range of applications, allowing the machine to perform under various conditions. Coupled with the transmission system, it ensures smooth transitions and optimal speed control, enhancing productivity.

Hydraulic System and Implements

The hydraulic system is crucial for operating different attachments and implements. It offers flexibility, enabling the tractor to handle tasks like lifting, digging, or grading with ease, contributing to its multifunctional nature.

Hydraulic System Breakdown

The hydraulic system plays a crucial role in providing the power needed for various mechanical functions. This system channels fluid to create pressure, enabling smooth and efficient operation of different components. Understanding its structure and flow is essential for maintaining optimal performance and preventing malfunctions.

At the core of the system is a pump that generates the pressure required to move the hydraulic fluid through various channels. These channels distribute the fluid to actuators, which in turn convert this pressure into mechanical movement. Valves are positioned strategically to control and direct the flow, ensuring precise operation of connected parts.

Maintaining the hydraulic system involves regular inspection of hoses, filters, and seals to avoid leaks or blockages that could compromise the performance. Proper upkeep ensures the longevity and efficiency of the entire system.

Engine Parts Overview

In this section, we will explore the key elements that make up the heart of the engine. These components work together to ensure smooth and efficient operation, each playing a vital role in the overall performance of the machine. Understanding these elements can help with maintenance and troubleshooting, ensuring longevity and reliability.

Main Components

The core of the engine consists of various elements that enable it to function effectively. These include the combustion chamber, pistons, crankshaft, and valves, all working in harmony to convert fuel into mechanical energy. Their interaction is crucial for delivering power to the system.

Additional Elements

Supporting components like the cooling system, oil filters, and fuel injectors ensure that the engine runs smoothly without overheating or wearing down prematurely. Proper care of these elements can prevent common issues and maintain optimal performance over time.

| Component | Function | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Combustion Chamber | Converts fuel into energy through controlled explosions. | ||||||||||||||||||||||||||||||

| Pistons | Move within the cylinders to transfer force to the crankshaft. | ||||||||||||||||||||||||||||||

| Crankshaft | Transforms linear motion from the pistons into rotational motion. | ||||||||||||||||||||||||||||||

| Valves | Regulate

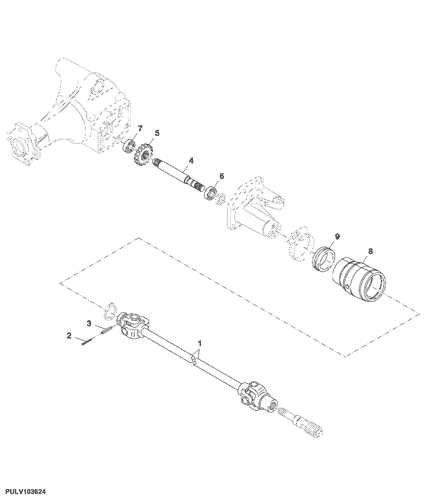

Transmission System ComponentsThe transmission system is a crucial part of any vehicle, responsible for transferring power from the engine to the wheels. It ensures smooth operation, allowing the machine to perform efficiently in various conditions. This section outlines the essential components involved in this process and how they function together to maintain optimal performance.

Each of these components works in unison to keep the system running efficiently, providing the necessary control and power for different operations. Electrical Wiring Diagram

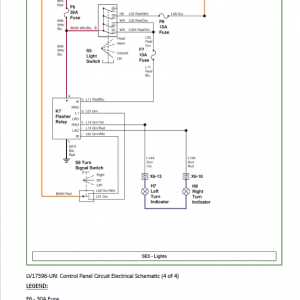

This section provides an overview of the electrical connections and components essential for the optimal operation of the machinery. Understanding the layout and functionality of these elements is crucial for troubleshooting and maintenance. A clear representation of the electrical system ensures that users can effectively navigate through the various wiring paths and connections. Key Components

The primary elements involved in the electrical system include switches, fuses, relays, and connectors. Each component plays a significant role in the efficient operation of the machine. Proper identification and understanding of these parts are vital for ensuring that electrical issues can be diagnosed and resolved quickly. Wiring OverviewA comprehensive overview of the wiring structure illustrates how each component interconnects to form a cohesive electrical system. This knowledge aids users in recognizing potential problem areas and enhances their ability to perform necessary repairs and upgrades. Maintenance Essentials for the 2032r

Proper upkeep is crucial for the longevity and performance of any machinery. Understanding essential maintenance practices helps ensure optimal operation and reduces the risk of unexpected breakdowns. This section will guide you through key procedures that enhance the reliability of your equipment.

Identifying the Cooling System PartsThe cooling system is essential for maintaining optimal operating temperatures in machinery. Understanding its components can help ensure efficient performance and longevity. This section will explore the various elements involved in the cooling mechanism. Key components of the cooling system include:

Each part plays a crucial role in regulating temperature, preventing overheating, and ensuring the overall efficiency of the machine. Fuel System LayoutThe configuration of the fuel delivery mechanism is crucial for the efficient operation of any machinery. This system ensures that the necessary energy source is effectively supplied to the engine for optimal performance. Understanding the arrangement and function of each component helps in maintaining and troubleshooting the system. The primary elements involved include the fuel tank, which stores the liquid energy, and the fuel lines that transport the substance to the engine. Additionally, filters play a vital role in removing impurities, while the pump is responsible for maintaining adequate pressure throughout the system. A proper layout facilitates seamless flow and enhances the reliability of the equipment. In summary, a well-structured fuel system is essential for ensuring the longevity and efficiency of the machine. Regular checks and maintenance of the various components will prevent disruptions and support smooth operations. Steering Mechanism Overview

The steering mechanism is a crucial component in ensuring effective navigation and maneuverability of machinery. It comprises various elements that work together to facilitate precise control and responsiveness during operation. Understanding this system is essential for maintaining optimal performance and enhancing user experience. Key ComponentsThis system typically includes a steering wheel, a series of linkages, and a hydraulic or mechanical actuator. The steering wheel allows the operator to direct the vehicle, while the linkages transfer motion to the wheels. The actuator plays a vital role in providing the necessary force to facilitate smooth turning and stability. Functionality and ImportanceThe functionality of the steering mechanism directly impacts the overall handling characteristics of the equipment. Proper maintenance of this system is vital, as it ensures safety and efficiency during operation. Regular inspections and timely repairs can prevent unexpected failures, leading to a more reliable performance in various tasks. Brake System DiagramThe braking mechanism is essential for ensuring safety and control during operation. This section provides an overview of the components involved in the braking system, highlighting their functions and interconnections. Understanding these elements is crucial for maintenance and troubleshooting. Key ComponentsThe primary parts of the braking system include various components that work together to facilitate effective stopping power. Below is a table outlining these crucial elements along with their descriptions.

Operation OverviewWhen the brake pedal is pressed, hydraulic pressure is generated in the cylinder, which then transfers this force through the brake lines. This action causes the linings to clamp onto the drum or rotor, effectively slowing the vehicle. Regular inspection of these components is vital for optimal performance and safety. Connecting Attachments to the 2032rWhen utilizing your compact utility vehicle, attaching various implements can significantly enhance its versatility and efficiency. Understanding the proper methods for connecting these tools is essential for optimal performance and safety. Begin by ensuring that the vehicle is on a stable surface and powered off. Assess the attachment’s compatibility with your machine, checking for any specific requirements. Alignment is crucial; position the implement so that it aligns with the connection points on the rear or front of the unit. Once aligned, carefully lower the attachment and engage the locking mechanisms. It is important to verify that the connections are secure before operating the vehicle. Regular maintenance of both the machine and attachments will help prevent wear and ensure longevity. Troubleshooting Common IssuesEncountering problems with machinery is a common experience for many operators. Understanding the typical challenges that may arise can help in diagnosing and resolving these issues efficiently. This section aims to highlight some prevalent malfunctions and offer guidance on how to approach them. One frequent concern is difficulty starting the engine. This may be due to several factors, including insufficient fuel, a weak battery, or issues with the ignition system. Checking the fuel level and ensuring the battery is adequately charged are essential first steps in troubleshooting this situation. Another common issue is overheating during operation. This can often result from coolant leaks, a malfunctioning thermostat, or a clogged radiator. Regularly inspecting the cooling system and maintaining proper fluid levels can prevent this problem from escalating. Operators may also face performance drops while in use. This could be attributed to air filter blockages, fuel quality issues, or mechanical wear. Conducting routine maintenance and replacing filters as needed can help restore optimal performance. Finally, unusual noises or vibrations may signal underlying mechanical issues. Regular inspections and prompt attention to any irregular sounds can prevent more significant damage and costly repairs down the line. |