In the realm of agricultural machinery, comprehending the various elements that contribute to operational efficiency is crucial. This section aims to elucidate the intricate relationships between different components within a specific model of a well-known manufacturer. By examining these intricacies, users can enhance their understanding of how each piece plays a role in the overall functionality.

Identifying and familiarizing oneself with the specific components allows for more effective maintenance and repairs. Knowledge of how these elements interconnect can lead to better decision-making when it comes to replacements or upgrades. This exploration emphasizes the importance of recognizing the role each component plays in achieving optimal performance.

As we delve into the details, the focus will be on providing a comprehensive overview of the key elements that make up the equipment. Each component will be discussed in a manner that highlights its significance and functionality, ensuring that readers can easily grasp the essential aspects of the machinery.

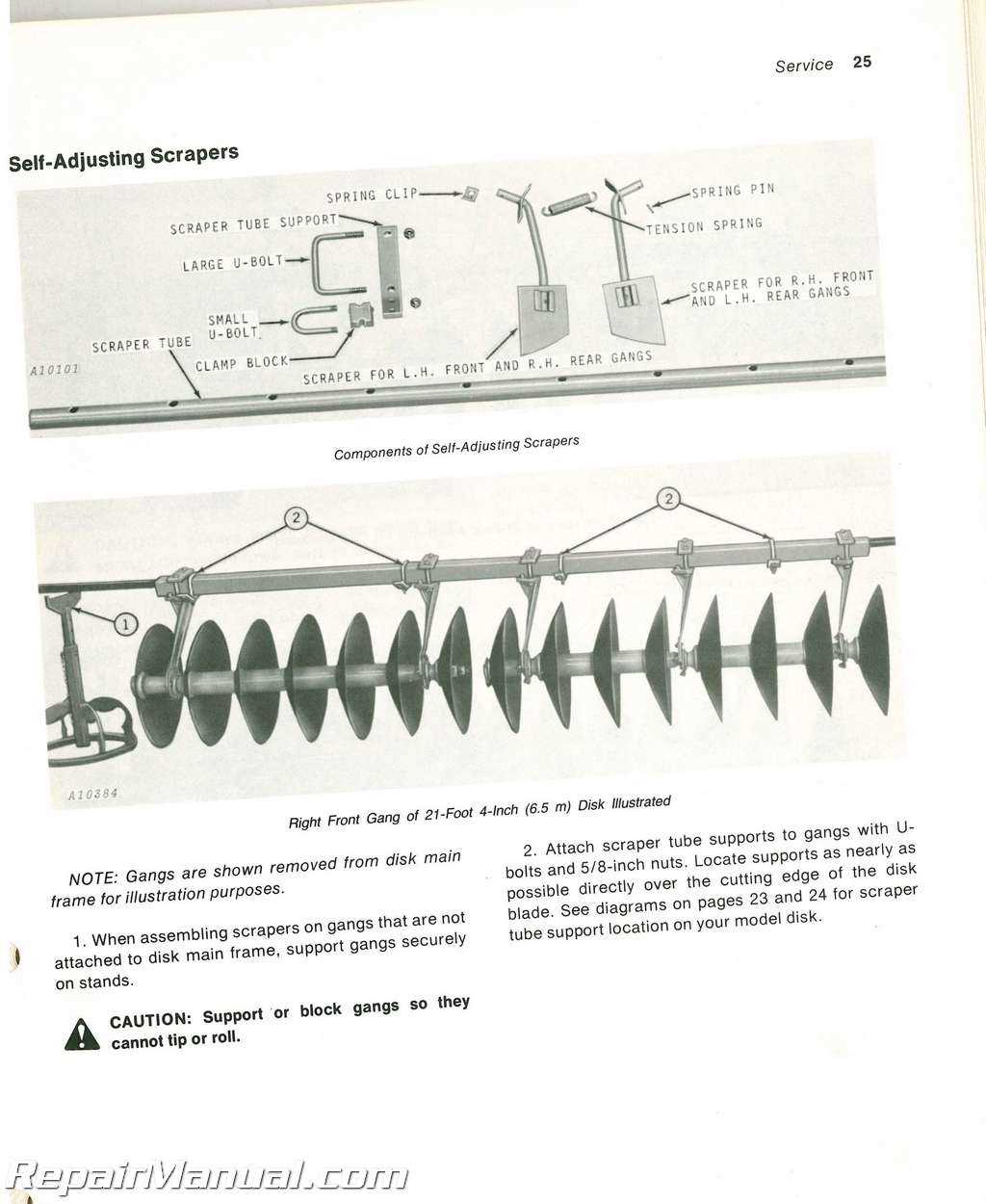

This section delves into the essential components and functionalities of a specific agricultural implement, highlighting its role in enhancing soil preparation and crop yield. By understanding the various elements involved, users can better appreciate the machinery’s efficiency and application in modern farming practices.

Key Features and Functions

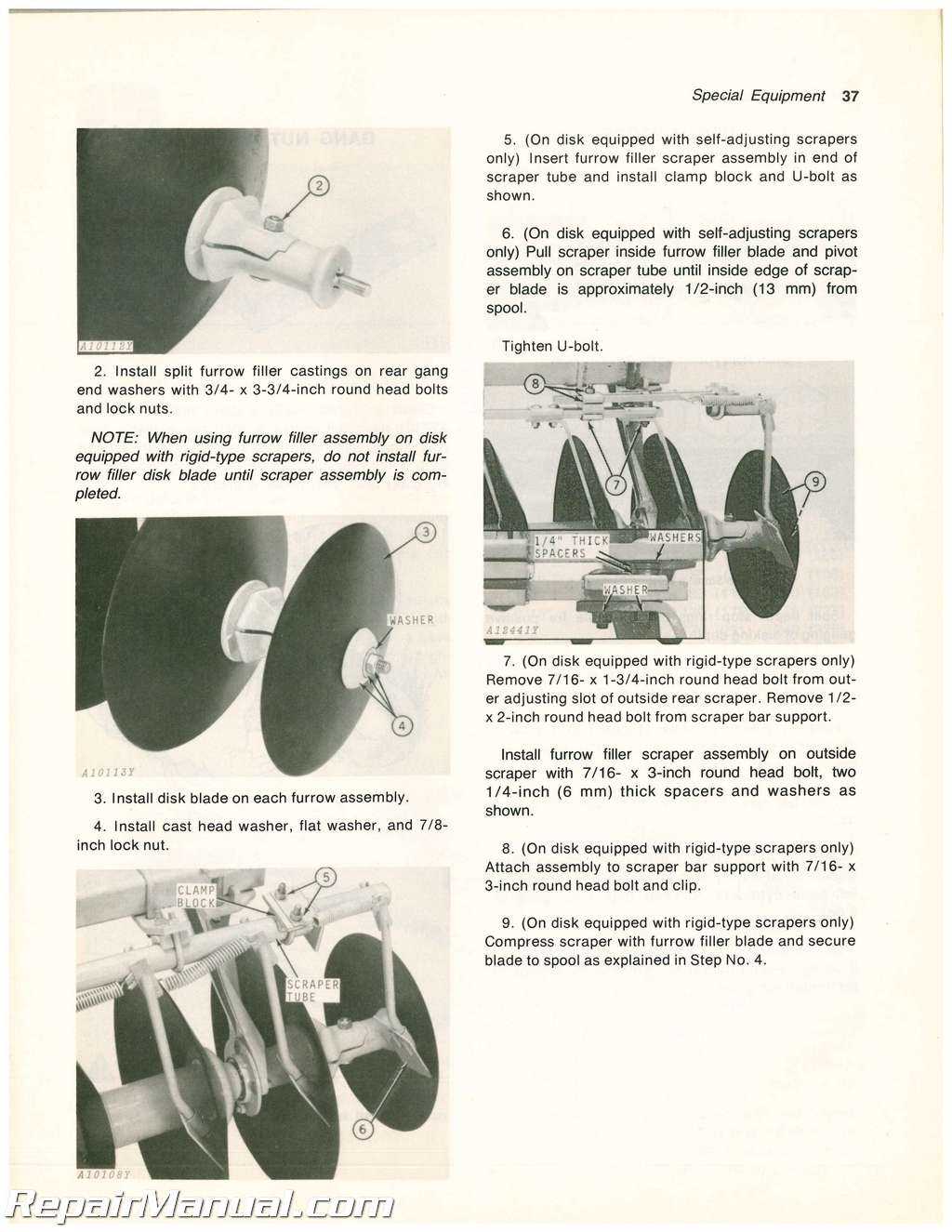

The implement is designed to optimize soil cultivation, providing a smooth and consistent working surface. Its configuration allows for adjustable depth control, enabling operators to tailor the operation according to specific agricultural needs. Each component plays a crucial role in ensuring the implement’s overall performance and longevity.

Component Overview

| Component | Description |

|---|---|

| Frame | Provides structural support and stability during operation. |

| Blades | Cut through soil and crop residue, promoting effective tillage. |

| Hitch | Connects the implement to the towing vehicle, facilitating movement. |

| Axle | Supports the weight of the implement and aids in maneuverability. |

| Depth Control | Allows for adjustments in working depth to meet various soil conditions. |

Key Features of the 220 Disc

This agricultural tool is designed to deliver high performance in soil cultivation, offering durability and precision in fieldwork. Its innovative construction ensures efficiency in a wide range of terrain types, making it a reliable choice for modern farming.

| Feature | Description |

|---|---|

| Heavy-duty Frame | Built with robust materials, the frame provides enhanced stability and supports long-term use even in tough conditions. |

| Adjustable Angle Blades | The blades can be easily adjusted to suit different soil types, ensuring optimal tilling results with minimal effort. |

| High-quality Bearings | Equipped with sealed bearings that reduce maintenance needs and improve operational longevity. |

| Efficient Weight Distribution | The design ensures even weight distribution across the unit, allowing for smoother operation and better soil penetration. |

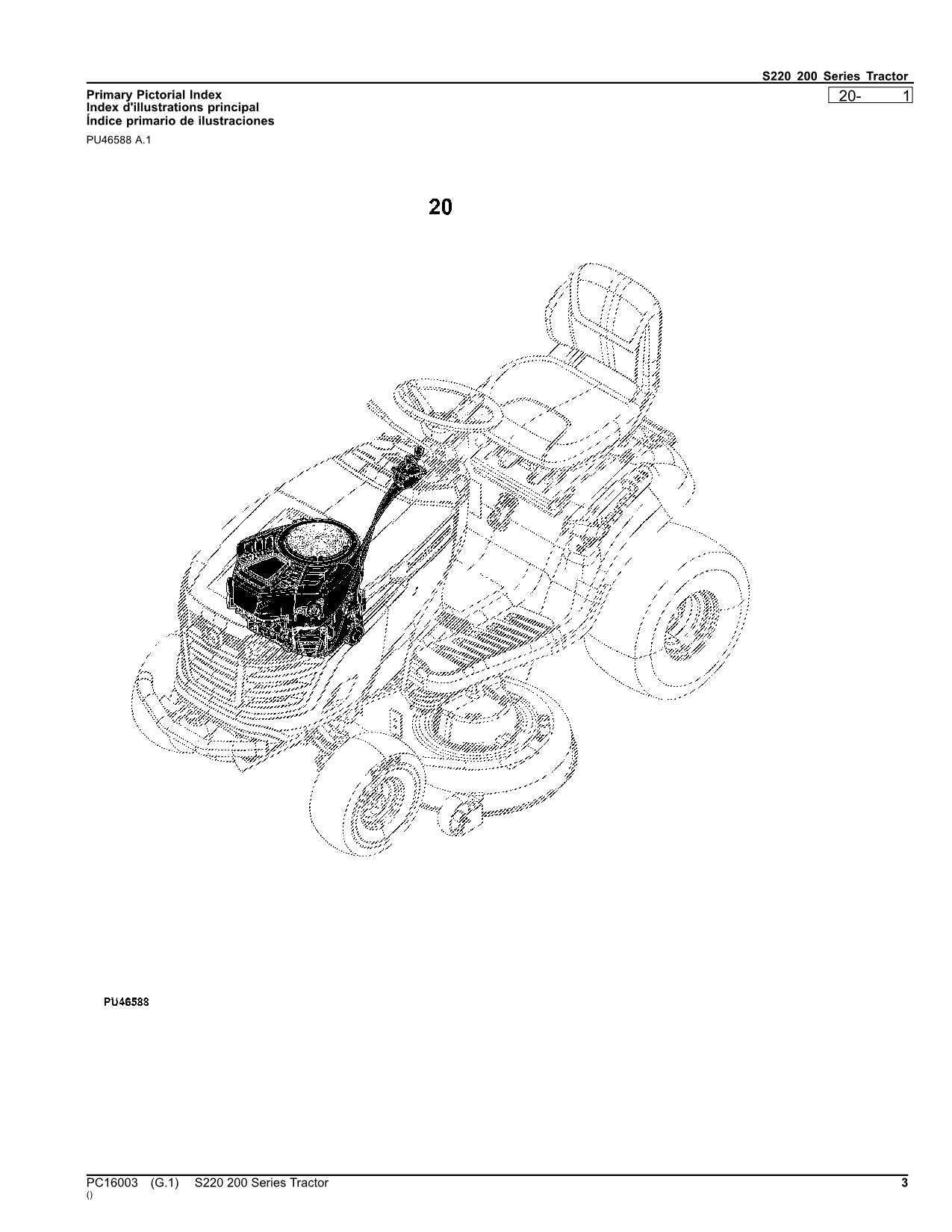

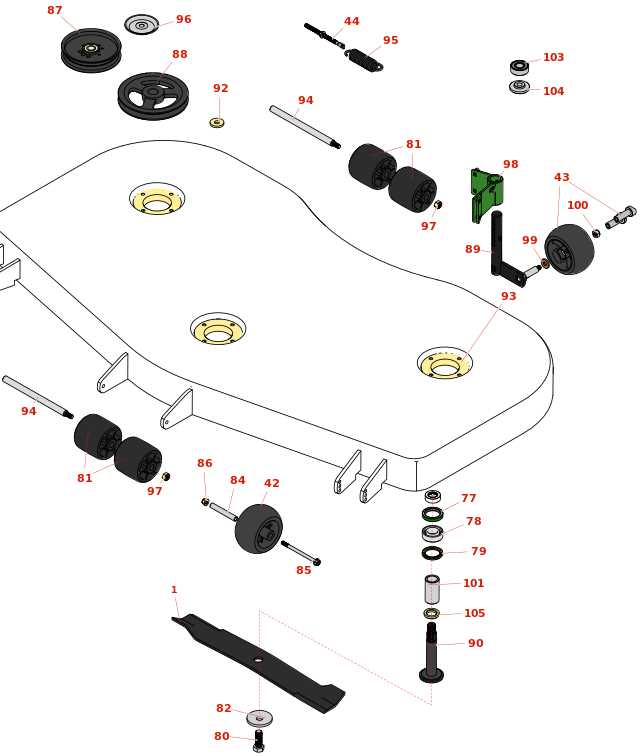

Understanding the Parts Layout

When working with machinery, having a clear grasp of the layout and arrangement of components is essential for effective maintenance and repairs. Each part plays a role in ensuring the smooth operation of the equipment, and knowing their positioning can greatly assist in troubleshooting or replacement processes.

Key Components Overview

- Frame and support structure – This serves as the foundation, holding various elements together securely.

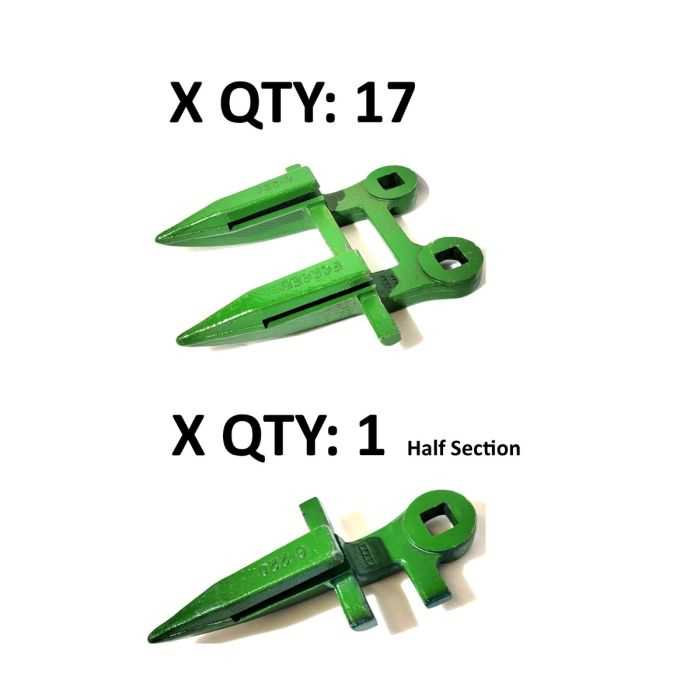

- Blade assemblies – Responsible for handling material, these elements are positioned in a specific sequence to maximize efficiency.

- Adjustment mechanisms – These parts allow for fine-tuning, ensuring optimal performance depending on the task at hand.

Connection and Mounting Points

The connection points between the different elements are crucial for stability. Each joint or fastening position must be properly aligned to avoid unnecessary wear or malfunction. Regular inspection of these areas can prevent potential breakdowns.

- Main Components of the Disc

- Manufacturer and brand reputation

- Availability of components in the market

- Compatibility with older or modified equipment

- Research potential suppliers and their pricing

- Compare warranties and guarantees offered

- Consider bulk purcha

Upgrading vs. Replacing Components

When maintaining agricultural machinery, operators often face the decision between enhancing existing elements or opting for complete substitutions. Each approach has its advantages and challenges, impacting performance, cost, and longevity of the equipment.

Upgrading involves improving specific components, which can lead to enhanced functionality and efficiency without the need for a full overhaul. This method allows for targeted investments that address particular shortcomings, making it a cost-effective solution in many cases. For instance, modern enhancements may improve compatibility with new technologies, increasing overall productivity.

On the other hand, replacing components can ensure that all parts function optimally together, especially if the existing components are significantly outdated or worn out. This approach might involve higher initial costs but can result in better reliability and reduced maintenance needs in the long run. It also provides an opportunity to incorporate the latest advancements in design and technology.

Ultimately, the decision to upgrade or replace should be guided by a thorough assessment of the machinery’s current condition, operational requirements, and budget considerations. Making an informed choice can significantly enhance the efficiency and effectiveness of agricultural operations.

User Experiences and Reviews

This section focuses on the impressions and evaluations shared by users regarding their experiences with the equipment in question. Insights from various individuals provide valuable perspectives on performance, reliability, and overall satisfaction, helping potential buyers make informed decisions.

Performance Insights

Many users highlight the effectiveness and efficiency of the machinery in various agricultural tasks. Users appreciate its ability to handle diverse terrains and its consistent results, which contribute significantly to their productivity. Feedback emphasizes the importance of proper maintenance to sustain high performance over time.

Reliability and Durability

Reviews often mention the robustness of the machinery, with several users reporting minimal issues even after extensive use. The build quality is frequently praised, with many noting that the equipment withstands harsh conditions well. Regular maintenance routines are recommended to ensure longevity and optimal functionality.

The primary structure of this equipment involves several essential elements that work together to ensure smooth operation and optimal performance. These components are designed to interact with the ground, allowing for efficient soil manipulation and ensuring uniform results in the field. Each part plays a crucial role in maintaining balance and functionality during use.

Key Structural Elements

The framework consists of heavy-duty materials that provide stability and durability. This includes both the rotating and stationary parts that are designed to handle various soil conditions. The working components are carefully positioned to distribute pressure evenly, ensuring effective penetration and smooth maneuverability.

| Component | Function | |

|---|---|---|

| Blades | Responsible for cutting and turning the soil. | |

| Bearings | Allow smooth rotation and reduce friction. | |

| Frame |

Importance of Maintenance ProceduresRegular maintenance procedures are essential to ensure the longevity and optimal performance of any agricultural equipment. Proper upkeep helps prevent unexpected breakdowns, reducing the risk of costly repairs and downtime during critical operations. A well-maintained machine operates more efficiently, leading to better productivity and fuel efficiency, which ultimately saves time and resources. Neglecting routine inspections and servicing can lead to wear and tear that might go unnoticed until it results in more severe mechanical issues. By adhering to a structured maintenance schedule, operators can identify and address potential problems before they escalate, ensuring smooth and reliable operation throughout the machine’s lifespan. Common Issues and Troubleshooting

When dealing with agricultural equipment, regular wear and tear can lead to various challenges. Understanding common mechanical problems and knowing how to troubleshoot them is essential for maintaining efficiency in the field. This section provides insights into typical malfunctions and offers practical solutions for quick fixes. One frequent issue is related to the equipment’s performance dropping over time. This can be caused by worn-out components, misaligned assemblies, or improper maintenance. To resolve this, regular inspections and timely replacements are critical to ensure optimal operation. Another common problem involves the uneven distribution of soil or debris, which may result from improper calibration or malfunctioning parts. Correcting these issues often involves realigning the working parts or replacing damaged components to restore balance and improve functionality. Finally, hydraulic failures are a notable concern that can lead to reduced maneuverability or a complete stop in functionality. Regular checks on the hydraulic system, including fluid levels and seals, help prevent these malfunctions and ensure the system operates smoothly. Tools Needed for RepairsWhen performing maintenance or fixing equipment, it’s important to have the right set of instruments at hand. Without the proper tools, even minor tasks can become difficult, increasing the risk of damage or extended downtime. Preparation is key to ensuring that repairs are done efficiently and accurately. Basic Tools

For most maintenance work, a standard set of wrenches, screwdrivers, and pliers will be essential. These common tools can handle a wide range of bolts, screws, and other fasteners, making them versatile in various repair scenarios. A sturdy adjustable wrench is particularly useful for loosening and tightening different sizes of nuts and bolts. Specialized Equipment

In some cases, specialized tools like torque wrenches, Step-by-Step Repair Guide

In this guide, we will walk you through the process of maintaining and fixing agricultural equipment to ensure optimal performance. The steps outlined here will help you address common mechanical issues efficiently, ensuring that your machinery remains operational for a longer time. Initial AssessmentBefore beginning any repairs, it is essential to perform a thorough inspection. Check for any signs of wear and tear, leaks, or other noticeable damages. This evaluation will help you identify the root cause of the malfunction and determine the necessary tools for the job. Component Replacement and AdjustmentOnce the faulty parts have been identified, proceed with replacing them. Be sure to follow the manufacturer’s guidelines for removing and installing new components. If adjustments are needed, such as tightening bolts or realigning mechanisms, use the appropriate tools to complete the task. Proper calibration is key to ensuring smooth operation after the repair. Replacement Parts AvailabilityWhen it comes to maintaining agricultural machinery, having access to spare components is crucial for minimizing downtime and ensuring smooth operation. Many manufacturers and suppliers offer a wide range of substitutes for different mechanical systems, ensuring compatibility and performance. Whether it’s a critical mechanical issue or routine maintenance, these items are essential for keeping equipment functional. The availability of these items is often influenced by production timelines, supplier networks, and specific model requirements. It’s important to ensure that the replacement components you choose are designed to meet the technical specifications of your equipment, guaranteeing longevity and efficiency. Identifying Genuine ComponentsEnsuring that you are using authentic parts is crucial for the longevity and optimal performance of your machinery. Using counterfeit or substandard components can lead to significant wear, malfunctions, and costly repairs. It’s important to recognize the key indicators that set genuine items apart from lower-quality alternatives. Signs of AuthenticityOne of the primary methods to determine whether a component is genuine is through its packaging and markings. Authentic parts often come with specific branding, serial numbers, and certification labels that validate their origin. Additionally, the quality of the material and the precision of craftsmanship are telltale signs of genuine manufacturing. Benefits of Using Authentic ComponentsBy using original components, you guarantee better performance and longer service life. These parts are designed to fit seamlessly into the machinery, reducing wear and tear and improving overall efficiency. The following table outlines some key benefits of genuine parts versus non-authentic ones.

|