Understanding the intricate details of agricultural equipment is essential for optimal maintenance and functionality. This section delves into the various elements that constitute a specific model of farm machinery, highlighting their roles and significance in ensuring efficient operation. By examining the assembly and layout of these components, users can better appreciate the complexity and design of modern farming tools.

In the realm of agricultural implements, each section plays a crucial part in the overall performance of the machinery. Recognizing how these elements interact allows for more informed decision-making regarding repairs and upgrades. With a comprehensive overview, operators can enhance their expertise, ultimately leading to improved productivity and longevity of their equipment.

John Deere 265 Overview

This remarkable piece of machinery is designed for efficiency and versatility, making it an essential tool in various agricultural and landscaping applications. Its robust construction and advanced features cater to the needs of both professional landscapers and dedicated homeowners. The model’s ability to tackle diverse tasks is a testament to its engineering excellence and reliability.

Equipped with a powerful engine, it delivers impressive performance while maintaining fuel efficiency. The user-friendly controls enhance operability, allowing operators to navigate challenging terrains effortlessly. Additionally, the innovative design promotes easy maintenance, ensuring that users can keep it in optimal working condition with minimal effort.

Overall, this exceptional equipment stands out in its category, embodying the perfect blend of power, versatility, and ease of use. Whether for commercial or residential purposes, it proves to be an invaluable asset for any outdoor project.

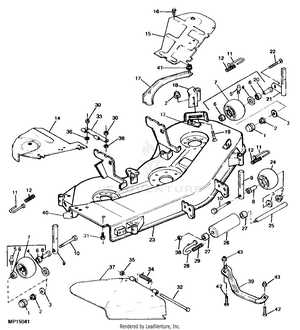

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repairs. Visual representations that outline individual elements and their relationships facilitate a clearer comprehension of how a machine functions. These illustrations serve as essential tools for technicians, providing guidance and enhancing efficiency during servicing tasks.

Enhanced Maintenance Efficiency

Visual aids simplify the process of identifying and accessing specific components. Technicians can quickly locate necessary items, reducing downtime and improving overall productivity. This clarity helps streamline repair workflows, allowing for quicker troubleshooting and problem resolution.

Improved Communication and Training

Visual representations foster better communication among team members. They serve as a common reference point, making it easier for experienced technicians to share knowledge with newcomers. This facilitates a more effective training process, ensuring that all personnel are equipped with the necessary understanding to operate and maintain the machinery.

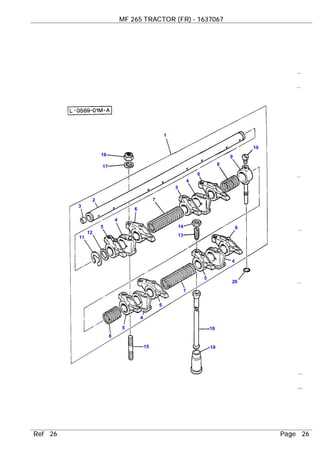

Key Components of John Deere 265

The functionality and efficiency of any machinery rely heavily on its essential elements. Understanding these fundamental components can greatly enhance the user experience and ensure proper maintenance. Each part plays a specific role, contributing to the overall performance and reliability of the equipment.

Primary Elements

- Engine: The powerhouse responsible for driving the entire system.

- Transmission: This component facilitates smooth power transfer between the engine and wheels.

- Hydraulic System: Essential for operating attachments and ensuring optimal functionality.

- Chassis: The framework that supports all other elements, providing stability and durability.

Additional Features

- Control Panel: The interface for the operator, enabling easy management of various functions.

- Cooling System: Maintains the appropriate temperature, preventing overheating during operation.

- Fuel System: Responsible for delivering energy to the engine, crucial for efficient performance.

Understanding the Diagrams’ Symbols

Interpreting the illustrations related to machinery can greatly enhance comprehension of their components and functions. These visuals often include a variety of symbols and markings, each conveying specific information that aids in identifying parts and understanding their relationships within the assembly.

Common Symbols Explained

Many visuals utilize standardized symbols to represent various elements. Familiarity with these symbols can significantly streamline maintenance and repair tasks. Below is a summary of some commonly encountered symbols:

| Symbol | Description |

|---|---|

| ⚙️ | Gear mechanism, indicating a rotating part. |

| Fastener, often used to show bolts and screws. | |

| ️ | Tool symbol, representing maintenance or adjustment requirements. |

| ⚡ | Electrical component, signifying wiring or connections. |

Importance of Understanding Symbols

Grasping the meanings behind these symbols not only facilitates effective repairs but also helps in recognizing the necessary tools and procedures for each task. This knowledge empowers users to work confidently and efficiently, ensuring the longevity and performance of the machinery.

Common Issues and Repairs

Machines often encounter a range of common problems that can affect their performance and longevity. Understanding these issues is essential for efficient maintenance and repair. Identifying the symptoms early on can save time and resources while ensuring that the equipment operates smoothly.

One frequent issue is engine performance degradation, which may manifest as reduced power or unusual noises. This can often be attributed to fuel system problems, such as clogged filters or injector malfunctions. Regularly checking and replacing fuel filters can help mitigate these issues.

Another prevalent concern involves hydraulic system failures. Symptoms such as slow or unresponsive movement can indicate low fluid levels or leaks in the hydraulic lines. Maintaining proper fluid levels and inspecting hoses for wear and damage are vital steps in preventing significant failures.

Electrical faults can also lead to operational challenges, such as starting difficulties or malfunctioning lights. Regularly inspecting wiring and connections can help detect issues before they escalate, ensuring consistent performance.

Lastly, wear and tear on belts and blades can impact cutting efficiency. Periodic inspection and timely replacement of these components are essential for maintaining optimal functionality. Keeping a close eye on these common issues can significantly enhance the reliability and durability of the machinery.

Where to Find Parts

When searching for components for your equipment, it’s essential to explore various resources to ensure you find quality replacements. Many avenues are available to help you locate the necessary items, whether you prefer purchasing new, used, or refurbished parts.

Here are some effective ways to source the components you need:

- Official Dealerships: Authorized dealerships often carry a wide range of original components and can provide expert advice on compatibility.

- Online Retailers: Numerous e-commerce platforms specialize in equipment components, offering detailed descriptions and customer reviews to guide your choices.

- Local Repair Shops: Local mechanics or repair shops may have spare parts on hand or can order them for you, often at competitive prices.

- Manufacturer Websites: Many manufacturers have dedicated sections on their websites where you can browse and order directly.

- Salvage Yards: Salvage or recycling yards may have used components at lower prices, providing a cost-effective option for repairs.

- Forums and Online Communities: Engaging with online forums dedicated to equipment can yield leads on where to find specific components or even direct sales from other enthusiasts.

Utilizing a combination of these resources will help ensure you find the right replacements efficiently and effectively.

Comparing OEM vs. Aftermarket Parts

When it comes to maintaining machinery, choosing the right components can significantly impact performance and longevity. Two primary options available are original equipment manufacturer (OEM) components and aftermarket alternatives. Understanding the distinctions between these choices is essential for making informed decisions regarding repairs and upgrades.

Quality and Performance

Quality can vary greatly between OEM and aftermarket components. Here are some considerations:

- OEM Components: Typically manufactured by the original equipment maker, ensuring precise fit and compatibility.

- Aftermarket Options: Produced by third-party companies, which may lead to variations in quality and performance.

Cost Considerations

Cost is often a deciding factor when selecting between these two types of components:

- OEM Components: Generally come at a premium price due to brand reputation and guaranteed quality.

- Aftermarket Options: Usually more budget-friendly, but prices can vary widely depending on the manufacturer and product specifications.

Ultimately, the choice between OEM and aftermarket components should be based on individual needs, budget, and the desired level of quality and reliability.

Maintenance Tips for Longevity

Ensuring the extended lifespan of machinery requires regular attention and care. By adopting specific maintenance practices, users can significantly enhance performance and reliability, leading to reduced downtime and increased efficiency. Following a structured approach to upkeep is essential for any equipment owner aiming for optimal operation.

Regular Inspections

Conducting frequent inspections allows for early detection of wear and tear. Check vital components such as belts, filters, and fluid levels to prevent potential issues. Establishing a routine maintenance schedule will ensure that all areas are covered, promoting smoother functionality.

Proper Cleaning and Storage

Maintaining cleanliness is crucial for the longevity of any machine. Remove debris and dirt that can cause damage or impede performance. Additionally, proper storage practices, such as protecting equipment from harsh weather conditions, can further extend its lifespan and reliability.

Assembly and Disassembly Guidelines

Proper assembly and disassembly procedures are crucial for maintaining equipment functionality and longevity. Following systematic methods ensures that components fit correctly and operate efficiently, reducing the risk of damage during maintenance tasks. Understanding these practices can significantly enhance performance and safety.

Preparation Steps

Before beginning any assembly or disassembly process, ensure that you have all necessary tools and components at hand. Review the equipment’s manual for specific instructions and safety precautions. It is also advisable to create a clean workspace to avoid losing small parts and to ensure a smooth workflow. Organizing components by type and size can simplify the reassembly process.

Disassembly Process

Start by removing any attachments or accessories that may obstruct access to the main components. Carefully label and store each part as it is removed, making it easier to identify during reassembly. Use appropriate techniques, such as gently tapping or prying, to avoid damaging components. If resistance is encountered, assess the situation to ensure proper removal without exerting excessive force.

In conclusion, adhering to established guidelines when assembling or disassembling machinery is essential for effective maintenance. Taking the time to prepare and follow systematic procedures can lead to successful outcomes and extended equipment life.

Resources for Further Learning

For those seeking to enhance their understanding of machinery and its components, a wealth of resources is available. These materials can provide insights into maintenance, assembly, and operational techniques, facilitating a deeper appreciation of complex systems. Engaging with various educational tools can significantly improve practical skills and theoretical knowledge.

Consider exploring the following types of resources:

| Resource Type | Description |

|---|---|

| Online Courses | Many platforms offer courses focused on machinery operation and repair, providing both video and written content for various skill levels. |

| Manuals | Comprehensive guides are often available online, detailing specific models and their components, which can aid in troubleshooting and maintenance. |

| Forums | Participating in online communities allows enthusiasts to exchange experiences, tips, and advice related to equipment care and usage. |

| Workshops | Hands-on sessions provide practical experience, where individuals can learn directly from experts in a controlled environment. |

Customer Support and Service Options

Accessing reliable assistance and maintenance services is essential for ensuring the optimal performance of agricultural machinery. Various support avenues are available to cater to the needs of users, providing guidance on troubleshooting, maintenance schedules, and operational inquiries.

Available Support Channels

Customers can reach out through multiple channels, including dedicated hotlines, online chat, and email support. These options allow for prompt responses to questions and concerns, facilitating a smoother experience for users. Additionally, many organizations offer extensive online resources, such as FAQs and instructional videos, to help users troubleshoot common issues independently.

Service Centers and Maintenance

For more complex repairs, authorized service centers provide expert assistance. These facilities are staffed with trained technicians familiar with the equipment, ensuring high-quality service. Regular maintenance plans can also be arranged to enhance machinery longevity and performance, allowing users to schedule services conveniently.