In the world of agricultural equipment, the efficiency and functionality of machinery rely heavily on its individual components. Each piece plays a vital role in ensuring that the overall system operates smoothly. By examining the intricacies of these elements, operators can enhance performance and extend the lifespan of their machinery.

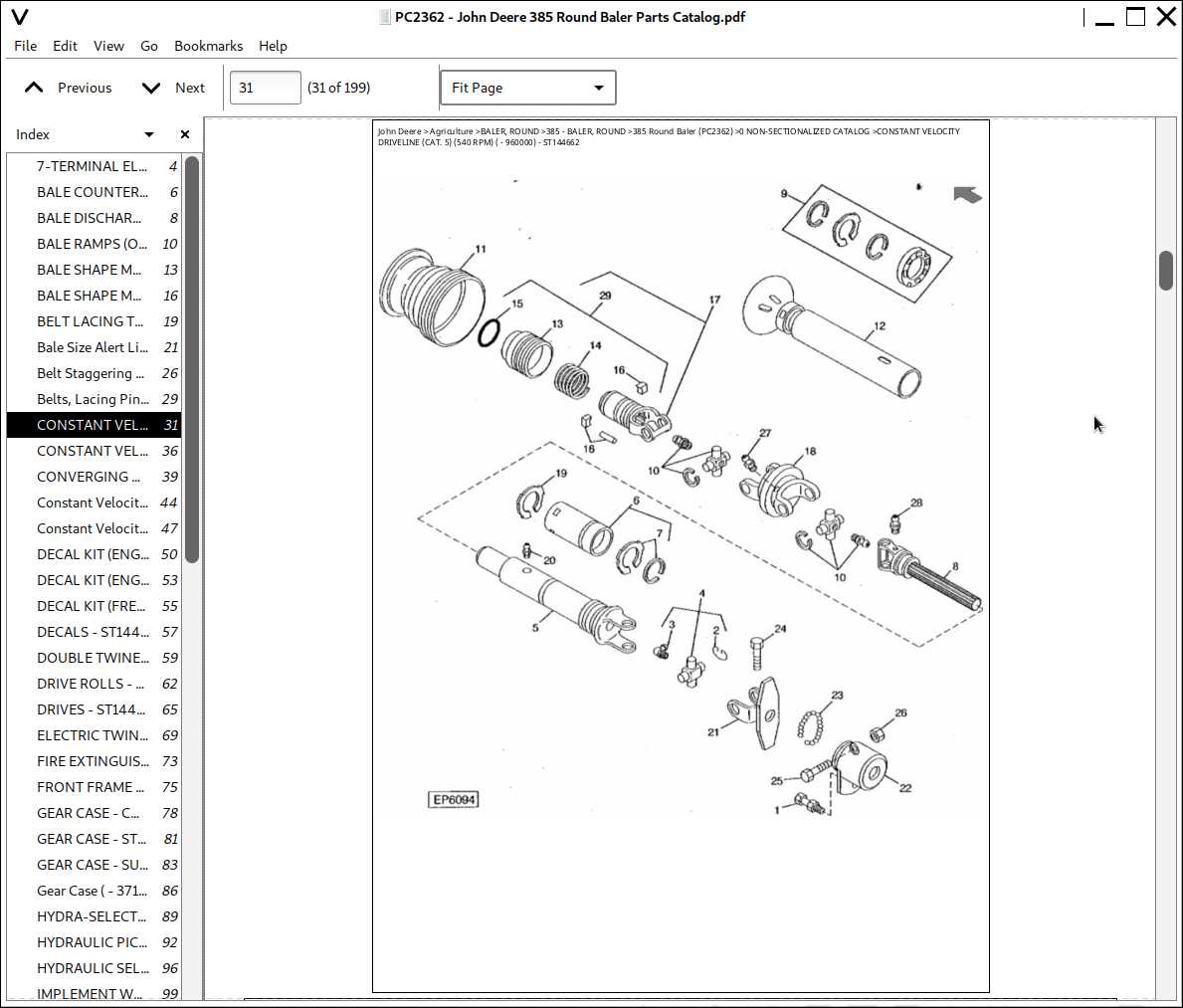

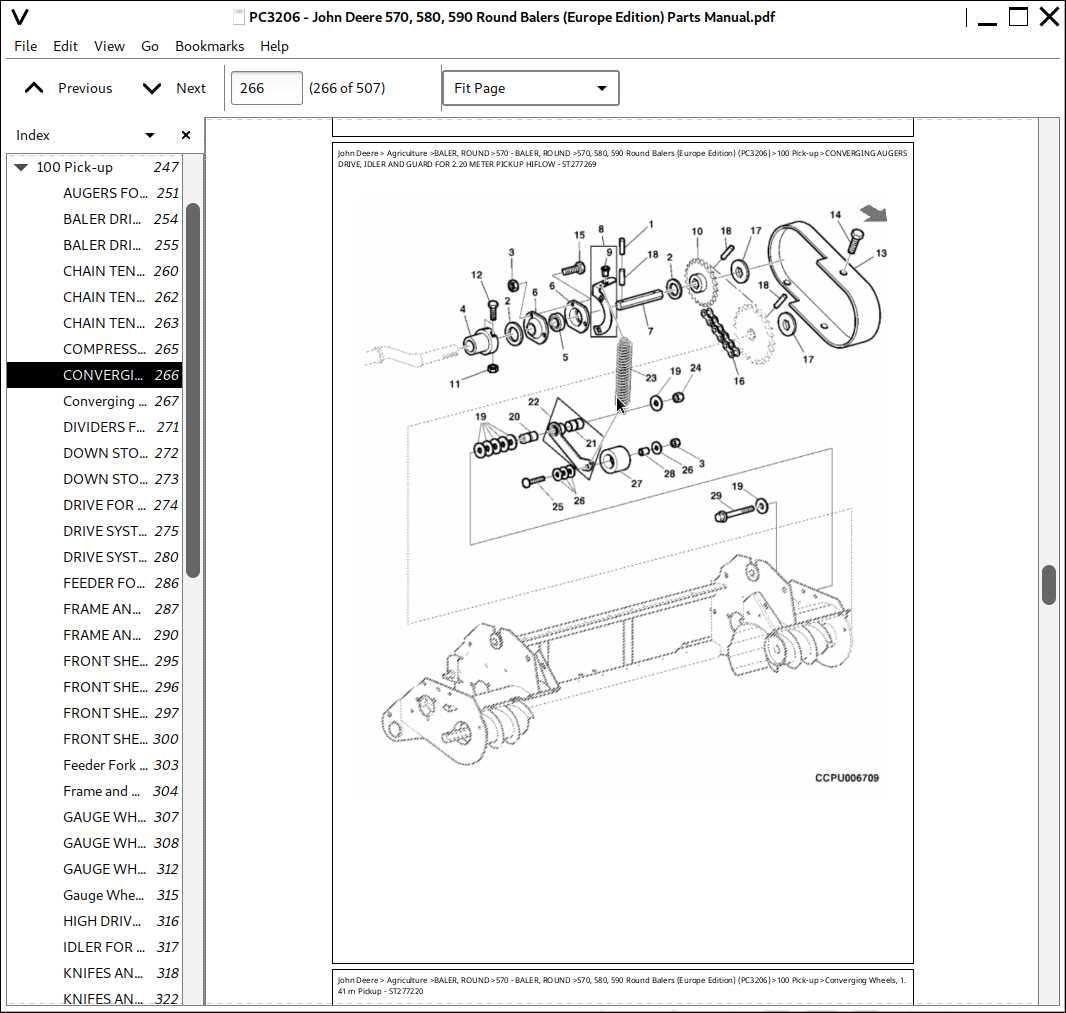

Visual representations of these components can significantly aid in understanding how they interact. When one is equipped with the knowledge of each element’s position and purpose, troubleshooting and maintenance become more straightforward tasks. This guide aims to delve into the essential elements that comprise a crucial piece of farming equipment, offering insights into their arrangement and function.

Ultimately, a comprehensive grasp of machinery construction not only improves operational efficiency but also empowers users to make informed decisions about repairs and upgrades. The following sections will provide a detailed exploration of these components, allowing users to fully appreciate the mechanics at play.

Understanding John Deere 385 Baler

This section explores the essential components and mechanics behind a specific agricultural implement designed for efficient hay and straw processing. By examining its functionality, users can gain insights into maintenance and operation, ultimately enhancing productivity in the field.

Key Components

Central to this machine are several crucial elements that work in harmony to ensure optimal performance. These include the feed mechanism, cutting apparatus, and compression chamber, all of which contribute to the efficient handling of various materials.

Maintenance Tips

Regular upkeep is vital for longevity and reliability. Routine checks on the core mechanisms, timely lubrication, and timely replacement of worn elements can significantly improve the lifespan and efficiency of the equipment.

Importance of Baler Parts Diagrams

Understanding the intricate components of machinery is crucial for efficient operation and maintenance. Visual representations play a key role in simplifying complex structures, enabling users to identify and locate specific elements quickly. This clarity enhances troubleshooting and repair processes, ultimately ensuring optimal functionality.

Benefits of Visual Guides

- Facilitates quick identification of components.

- Improves accuracy in repairs and maintenance.

- Reduces downtime through efficient problem-solving.

- Enhances user understanding of machinery operation.

Long-Term Advantages

- Increases lifespan of equipment through proper care.

- Supports training for new operators.

- Encourages a proactive maintenance approach.

Common Issues with Baler Components

Understanding the typical challenges faced by machinery components is crucial for effective maintenance and operation. Various elements may exhibit problems that can impact overall functionality and efficiency. Identifying these issues early can prevent extensive damage and costly repairs.

Frequent Problems

- Wear and Tear: Continuous use can lead to deterioration of key parts, affecting performance.

- Clogging: Debris accumulation can obstruct movement, leading to decreased productivity.

- Misalignment: Components may shift out of place, resulting in inefficient operation and potential breakdowns.

- Hydraulic Failures: Leaks or malfunctions in hydraulic systems can hinder machine capabilities.

Preventive Measures

- Regular Inspections: Routine checks can help identify wear and potential issues before they escalate.

- Proper Lubrication: Ensuring all moving parts are well-lubricated reduces friction and extends component life.

- Timely Replacements: Swapping out worn parts promptly can maintain overall machinery efficiency.

- Clear Obstructions: Regularly removing debris from operational areas helps prevent clogs and jams.

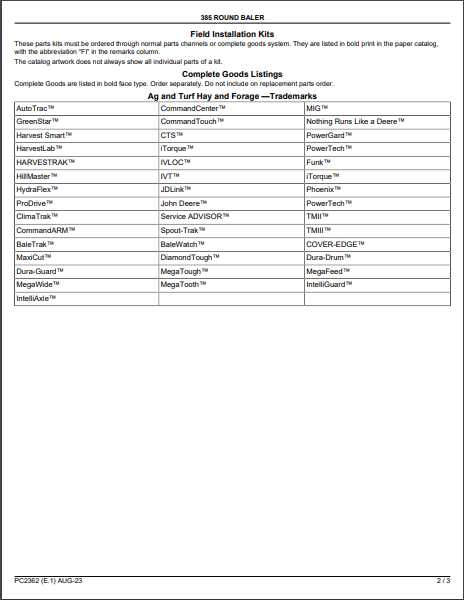

How to Read Parts Diagrams

Understanding schematics is essential for effective maintenance and repair of machinery. These visual representations provide critical insights into the assembly and components of equipment, enabling users to identify and source necessary items with ease.

Identifying Components

When examining a schematic, look for labels and numbers that correspond to specific elements. Each part is typically marked, allowing for quick reference when searching for replacements.

Utilizing the Legend

A legend often accompanies the visual representation, detailing symbols and terminology. Familiarizing yourself with this key can enhance comprehension and streamline the repair process.

| Symbol | Description |

|---|---|

| ⬤ | Component |

| ➔ | Connection |

| ⚙️ | Mechanical part |

Essential Parts of the John Deere 385

Understanding the critical components of this machinery is vital for optimal performance and maintenance. Each element plays a unique role in ensuring efficiency and reliability, making knowledge of these elements essential for operators and technicians alike.

Key Components

Familiarity with the main components can enhance the operation and longevity of the equipment. Below are some of the essential elements that contribute to its functionality:

| Component | Description |

|---|---|

| Feeder System | Ensures a steady supply of material for processing. |

| Compression Chamber | Where the material is compacted into bales. |

| Knots and Twine Mechanism | Secures the bales for transport and storage. |

Maintenance Tips

Regular checks and timely replacements of these components can significantly impact performance. Prioritizing maintenance will ultimately extend the life of the machinery and enhance its efficiency.

Replacement Parts for Optimal Performance

Ensuring machinery operates at peak efficiency relies heavily on the quality and suitability of its components. When specific elements are worn or damaged, it’s crucial to replace them with high-quality alternatives that enhance functionality and extend the equipment’s lifespan.

Choosing Quality Components

Selecting reliable replacements is vital for maintaining effectiveness. Durability and compatibility should guide your choices, as these factors directly influence overall productivity and machine health.

Maintaining Performance

Regular inspections can help identify when replacements are necessary. Staying proactive about component quality not only boosts performance but also minimizes downtime, ensuring your equipment remains ready for demanding tasks.

Maintenance Tips for Baler Longevity

Ensuring the durability of your agricultural machinery requires regular attention and care. By following a few essential practices, you can significantly extend the lifespan of your equipment and improve its overall efficiency.

- Regular Cleaning: Remove debris and buildup after each use to prevent corrosion and damage.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear.

- Inspection: Conduct frequent checks for signs of wear or damage, focusing on belts, bearings, and tension settings.

- Calibration: Ensure that all adjustments are made according to the manufacturer’s specifications to optimize performance.

- Storage: Keep the equipment in a dry, sheltered environment to protect it from the elements when not in use.

By incorporating these practices into your routine, you will help safeguard your machinery, ensuring it performs at its best for years to come.

Where to Find Quality Parts

When it comes to maintaining and repairing your agricultural equipment, sourcing high-quality components is essential for optimal performance. Whether you’re in need of specific elements or looking to upgrade, knowing where to find reliable supplies can make a significant difference.

Online Retailers

Many online platforms specialize in machinery components, offering a vast array of options. Here are some benefits of shopping online:

- Convenience: Browse and order from the comfort of your home.

- Variety: Access a wide selection of brands and models.

- Comparative Pricing: Easily compare prices from different sellers.

Local Suppliers

Visiting nearby suppliers can also yield high-quality components. Consider the following advantages:

- Expert Advice: Get recommendations from knowledgeable staff.

- Immediate Availability: Purchase items on the spot without waiting for shipping.

- Community Support: Build relationships with local businesses that understand your needs.

By exploring both online and local options, you can ensure you find the best components to keep your machinery running smoothly.

Upgrading Components for Efficiency

Enhancing the efficiency of agricultural machinery is crucial for maximizing productivity and reducing operational costs. Upgrading key components can lead to improved performance, lower maintenance needs, and increased output. By investing in high-quality replacements or advanced technologies, operators can ensure that their equipment meets modern standards and expectations.

Identifying Critical Components

Prioritizing which elements to upgrade is essential for effective enhancement. Focus on components that directly impact functionality, such as drive systems, feeding mechanisms, and hydraulic systems. By analyzing performance metrics and identifying bottlenecks, operators can make informed decisions that will yield significant improvements.

Benefits of Modern Upgrades

Incorporating state-of-the-art components not only boosts efficiency but also enhances reliability and longevity. Advanced materials and designs can reduce wear and tear, leading to lower downtime and maintenance costs. Furthermore, upgrades can improve energy consumption, making operations more sustainable while contributing to overall yield increases.

Comparing with Other Baler Models

When evaluating different equipment options, it’s essential to consider how various machines stack up against each other in terms of efficiency, durability, and performance features. Each model brings its own set of advantages and potential drawbacks, making it crucial for users to assess their specific needs against what is available in the market.

Performance and Efficiency

Different machines can vary significantly in terms of their operational efficiency. Some models may excel in speed and output, while others focus on precision and material handling. For instance, certain designs incorporate advanced technology that enhances productivity, allowing for quicker turnaround times and improved overall performance. It’s vital to examine these aspects when selecting equipment that aligns with your operational requirements.

Durability and Maintenance

Longevity is another critical factor to consider. Machines built with robust materials tend to have longer lifespans, reducing the frequency of repairs and maintenance. Furthermore, ease of maintenance plays a role in overall operational costs. Models that allow for straightforward access to key components can significantly reduce downtime and increase efficiency, making them more appealing to operators.

Ultimately, comparing various models involves a careful analysis of features, operational costs, and user requirements to ensure the right choice is made for optimal productivity.