In the realm of agricultural equipment, a comprehensive grasp of machinery components is essential for optimal functionality and maintenance. This section aims to explore the intricate relationships between various elements that contribute to the overall performance of these powerful machines.

Insight into machinery can enhance operational efficiency and extend the lifespan of the equipment. By examining individual components, users can identify potential issues before they escalate, ensuring smoother operations and reduced downtime.

Furthermore, a thorough exploration of mechanical systems empowers operators to make informed decisions regarding repairs and upgrades. This knowledge not only fosters a deeper connection with the machinery but also promotes a culture of proactive maintenance.

Understanding the John Deere 650

This section provides an insightful overview of a compact agricultural machine known for its reliability and versatility. Designed to tackle a variety of tasks in farming and landscaping, this equipment has gained popularity among both professionals and enthusiasts. Its robust construction and user-friendly features make it a valuable asset in various applications.

To fully appreciate its functionality, it’s essential to explore the key components and their roles in the machine’s operation. Below is a summary table that highlights significant elements of this equipment and their respective purposes.

| Component | Function |

|---|---|

| Engine | Powers the machine and drives its hydraulic systems. |

| Transmission | Facilitates movement and speed control for various tasks. |

| Hydraulic System | Enables lifting and operating attachments with ease. |

| Chassis | Provides structural integrity and stability during operation. |

| Control Panel | Allows the operator to manage various functions efficiently. |

Understanding these components can enhance the user experience and optimize performance in the field. Regular maintenance and awareness of each part’s function contribute to the longevity and effectiveness of the machine.

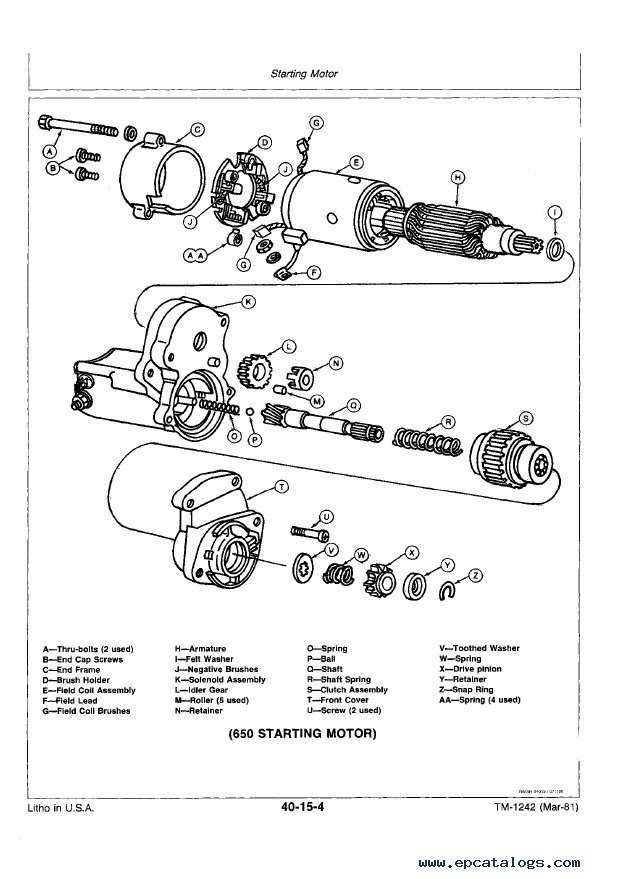

Key Components of John Deere 650

This section explores the essential elements that contribute to the functionality and performance of the equipment. Understanding these components is vital for effective maintenance and operation.

- Engine: The heart of the machinery, responsible for providing the necessary power for various tasks.

- Transmission: This system ensures smooth gear shifting, allowing for optimal speed and torque management.

- Hydraulics: Vital for controlling attachments and implements, enabling versatility in operations.

- Chassis: The structural framework that supports all components and provides stability during use.

- Electrical System: Powers the ignition, lights, and other electronic components, ensuring proper operation.

- Cooling System: Maintains optimal operating temperatures to prevent overheating and enhance efficiency.

Each of these key components plays a crucial role in the overall performance and durability of the machine. Regular inspection and maintenance of these elements can lead to improved efficiency and longevity.

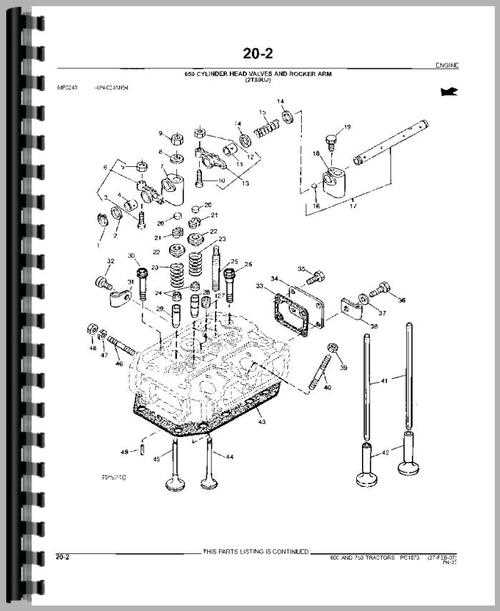

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide clarity and assist users in identifying the necessary elements for effective troubleshooting and servicing. By offering an organized view, these illustrations facilitate a deeper understanding of how various pieces interconnect and function together.

| Benefits | Description |

|---|---|

| Clarity | Enhances understanding of complex assemblies. |

| Efficiency | Speeds up the repair process by allowing quick identification of components. |

| Accuracy | Reduces the likelihood of errors during reassembly. |

| Training | Serves as a valuable educational tool for new technicians. |

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide a detailed look at the various elements involved, helping users identify and locate specific items within a system. Grasping how to interpret these images can significantly enhance troubleshooting skills and efficiency.

Key Elements to Focus On

- Labels: Each part typically has a corresponding label or number that connects it to the list of components.

- Sections: Diagrams are often divided into sections, making it easier to navigate through complex systems.

- Arrows and Lines: These indicate how components are interconnected or how they fit together.

Steps to Analyze the Illustration

- Start by familiarizing yourself with the overall layout.

- Locate the reference key, which explains the symbols used.

- Identify the components relevant to your task, focusing on their positions and connections.

- Cross-reference with the list of elements to ensure accuracy.

Common Issues with John Deere 650

Understanding the typical challenges faced by operators can significantly enhance the performance and longevity of agricultural machinery. Many users encounter various mechanical and operational difficulties that can impact efficiency and productivity. Identifying these issues early can lead to effective troubleshooting and maintenance.

One prevalent concern involves engine performance, where symptoms may include rough idling or difficulty starting. Another frequent problem is related to hydraulic systems, which can manifest as leaks or unresponsive controls. Additionally, wear and tear on transmission components can lead to shifting issues, affecting overall handling and maneuverability.

Regular inspections and timely maintenance are crucial in addressing these common concerns. Keeping an eye on fluid levels, checking for unusual noises, and staying aware of any changes in performance can help in preventing more serious problems down the line.

Where to Find Replacement Parts

Finding suitable components for your machinery is essential to maintain its efficiency and longevity. There are numerous avenues to explore, from online marketplaces to local suppliers, ensuring you can source the necessary items with ease.

Online Marketplaces

Numerous websites specialize in selling aftermarket and original components. Platforms such as eBay and Amazon provide extensive inventories, often featuring competitive pricing. Be sure to check seller ratings to ensure quality and reliability.

Local Dealerships and Distributors

Local dealerships often stock genuine components and can provide expert advice on compatibility. Visiting these establishments allows you to inspect items in person and gain insights from knowledgeable staff.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires consistent attention and care. By following some essential maintenance practices, you can significantly enhance the performance and durability of your equipment. This guide will outline key strategies to help keep your machinery in optimal condition.

Regular Inspections

Conducting frequent inspections is crucial to identify potential issues before they escalate. Check all components for wear and tear, including belts, hoses, and fluid levels. A proactive approach can prevent costly repairs and extend the life of your machinery.

Proper Lubrication

Lubrication is vital for reducing friction and preventing wear on moving parts. Follow the manufacturer’s recommendations for lubricant types and intervals. Regularly inspect lubrication points and ensure they are adequately serviced to maintain peak performance.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Check for leaks, wear, and damage. |

| Oil Change | Every 50 hours | Use recommended oil type. |

| Filter Replacement | Every 100 hours | Replace air and fuel filters as needed. |

| Greasing | Every 25 hours | Ensure all grease fittings are serviced. |

Comparison with Other John Deere Models

This section explores the differences and similarities between various models within the same brand, focusing on features, performance, and user experience. By examining these machines, we can gain insights into their unique attributes and how they cater to different needs in agricultural and industrial settings.

Performance Analysis

When evaluating performance, it’s essential to consider engine efficiency, horsepower, and operational capabilities. Some models may excel in power output, while others offer superior fuel economy, making them suitable for specific tasks.

Feature Comparison

Features such as transmission type, ease of maintenance, and available attachments play a crucial role in usability. Different models may incorporate advanced technology, enhancing overall functionality and operator comfort, tailored to various user preferences.

Expert Recommendations for Repairs

Maintaining machinery is crucial for optimal performance and longevity. Ensuring that repairs are conducted effectively can prevent future issues and enhance efficiency. Here are some expert suggestions for handling repairs with precision.

Regular Maintenance Checks

- Establish a routine for inspections to catch potential problems early.

- Check fluid levels, belts, and hoses regularly.

- Clean filters and replace them as necessary to maintain airflow and efficiency.

Utilizing Quality Components

- Always opt for high-quality components to ensure durability.

- Consider OEM parts for a perfect fit and reliability.

- Research aftermarket options to find reputable suppliers that meet performance standards.

By following these guidelines, operators can ensure that their equipment remains in peak condition, ready to tackle any task at hand.

Upgrading Parts for Enhanced Performance

Enhancing machinery functionality is essential for maximizing productivity and efficiency. By selecting superior components, operators can significantly improve performance and ensure longevity. This section explores various upgrades that can be implemented to achieve optimal results.

| Upgrade Type | Benefits |

|---|---|

| Engine Enhancements | Increased power output and fuel efficiency |

| Transmission Improvements | Smoother operation and faster response times |

| Hydraulic System Upgrades | Enhanced lifting capacity and control |

| Wheel and Tire Options | Better traction and stability on various terrains |

Resources for Further Information

Accessing reliable information is crucial for those seeking to enhance their understanding of machinery components and their specifications. This section highlights various resources that can provide valuable insights, helping users make informed decisions and ensuring the longevity of their equipment.

Online Manuals and Guides

Many manufacturers offer comprehensive manuals and guides available for download on their official websites. These documents typically include detailed descriptions, maintenance schedules, and troubleshooting tips that can be essential for effective operation.

Community Forums and Support Groups

Engaging with online communities can be incredibly beneficial. Forums dedicated to machinery enthusiasts allow individuals to share experiences, seek advice, and access a wealth of shared knowledge. Participating in these discussions can lead to discovering solutions that may not be found in formal publications.

Utilizing these resources can significantly enhance your expertise and ensure that you are well-equipped to handle any challenges that may arise.