The intricate design of agricultural machinery plays a crucial role in enhancing productivity and efficiency. Understanding the various elements that constitute such equipment is essential for proper maintenance and effective repairs. This section delves into the arrangement and functionality of different components, providing valuable insights for operators and technicians alike.

By examining the layout and relationships among the individual parts, users can gain a clearer perspective on how each element contributes to the overall operation of the machine. Familiarity with these components not only aids in troubleshooting but also empowers users to make informed decisions regarding upgrades and replacements.

Furthermore, having a detailed view of the configurations supports the continuous performance of the equipment, ensuring longevity and reliability. Whether you are a seasoned operator or a newcomer to the field, this exploration serves as a valuable resource for maximizing the effectiveness of your machinery.

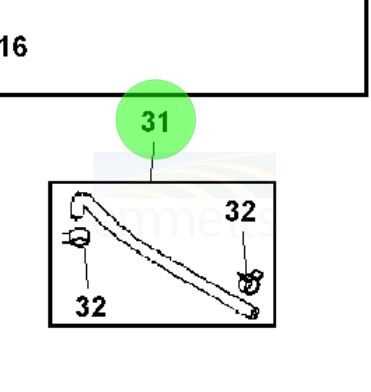

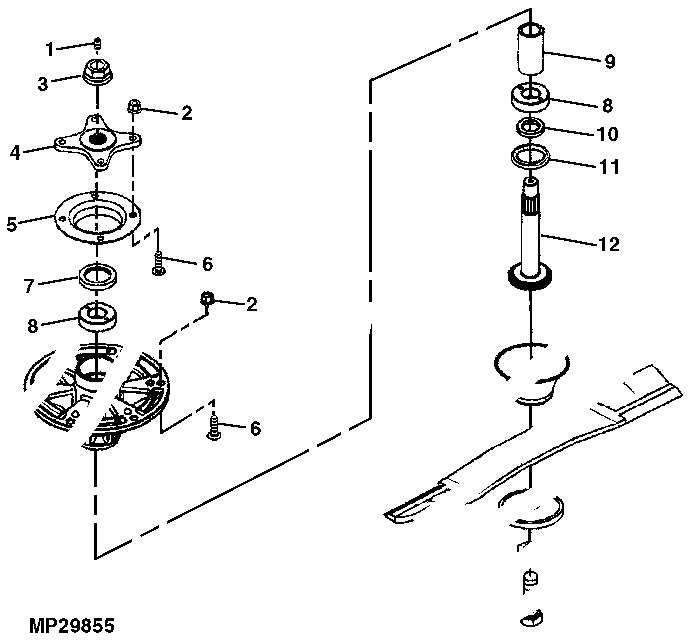

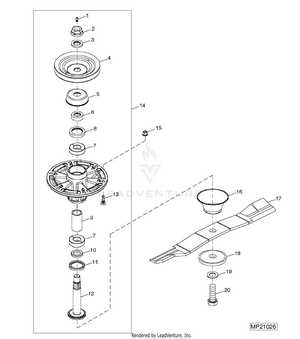

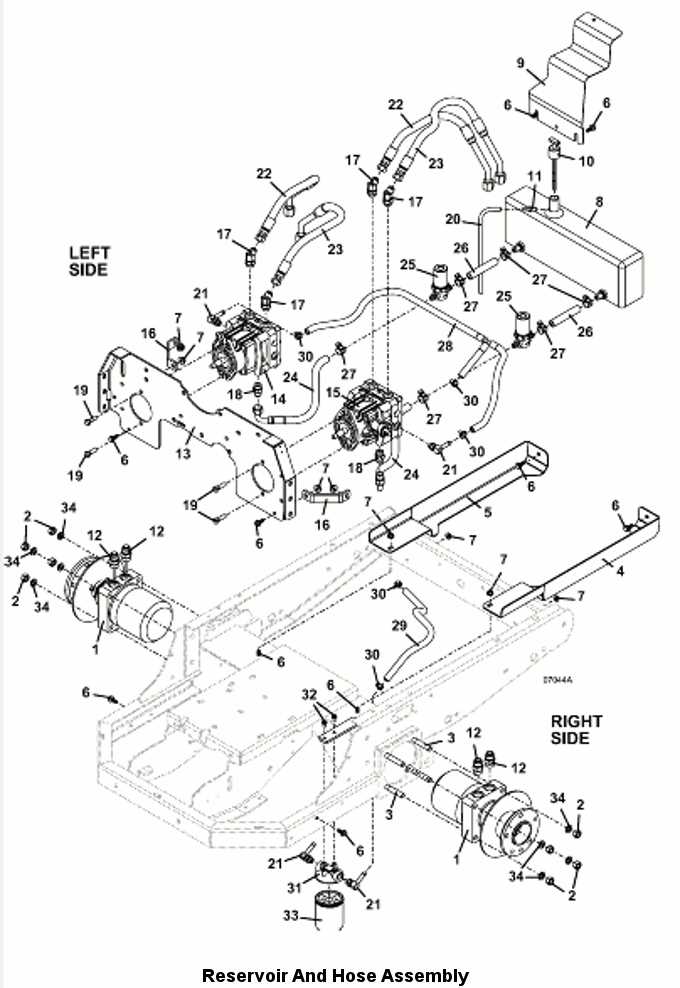

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide a clear overview of how various elements interact, ensuring that technicians can easily identify and replace faulty units. Understanding these illustrations enhances the efficiency of servicing tasks and minimizes the risk of errors during repairs.

Enhancing Understanding

Illustrative guides aid in comprehending the complex relationships between different machine elements. By offering a detailed view of each segment, they help operators visualize assembly and disassembly processes, making it easier to carry out repairs without confusion.

Streamlining Repairs

These graphical tools significantly speed up repair work. Technicians can quickly locate necessary components and understand their arrangement, reducing the time spent searching for information. This efficiency not only helps in completing repairs faster but also contributes to improved productivity in the workshop.

| Benefit | Description |

|---|---|

| Clear Identification | Facilitates easy recognition of components and their functions. |

| Time Savings | Reduces the duration required for repair processes. |

| Reduced Errors | Minimizes mistakes during assembly or replacement tasks. |

| Improved Training | Aids in the education of new technicians by providing visual context. |

Key Components of the 727A

The performance and efficiency of any machinery greatly rely on its fundamental elements. Understanding these essential components can provide insights into the overall functionality and maintenance of the equipment. Each part plays a specific role, contributing to the seamless operation and durability of the system.

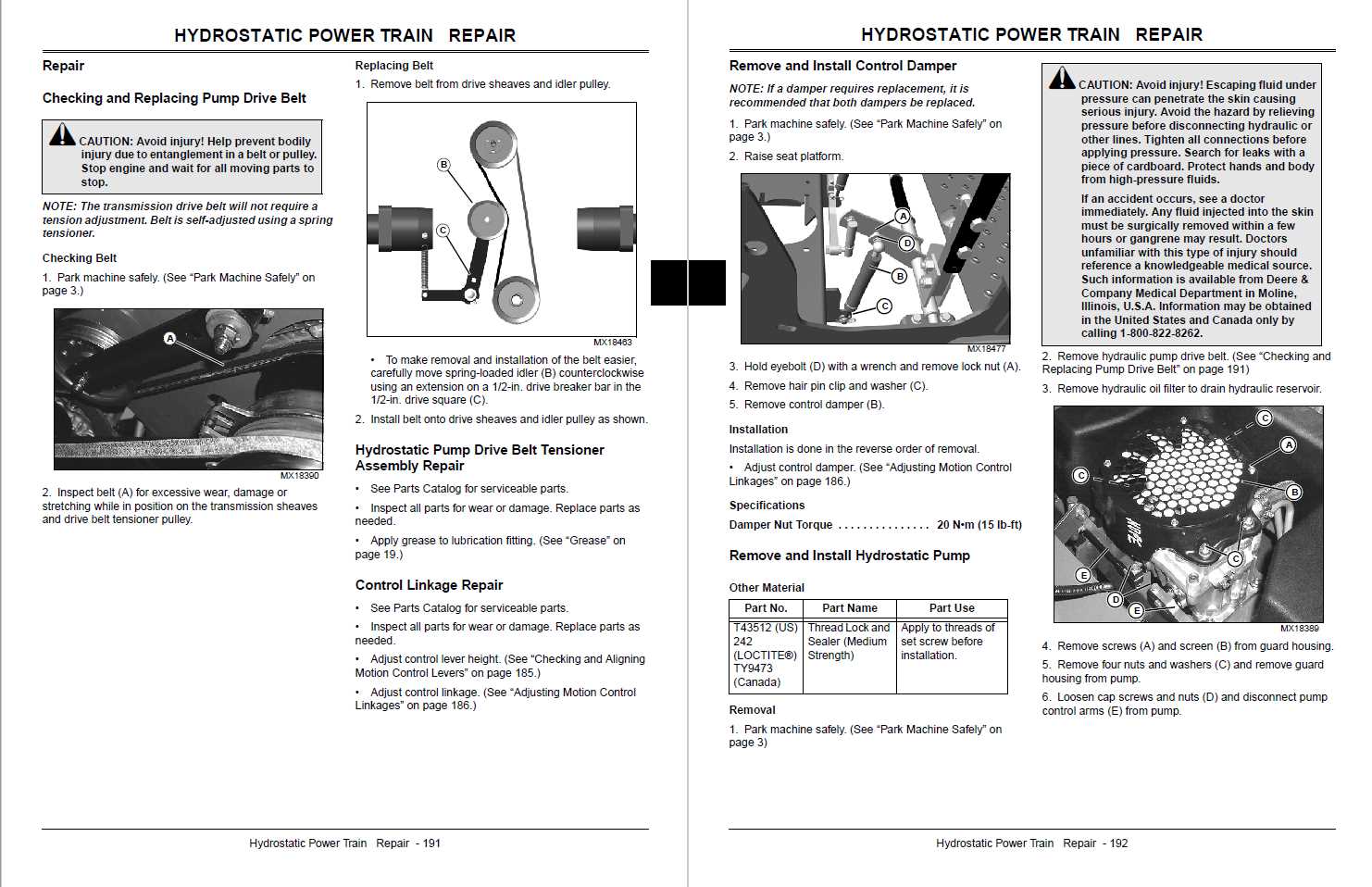

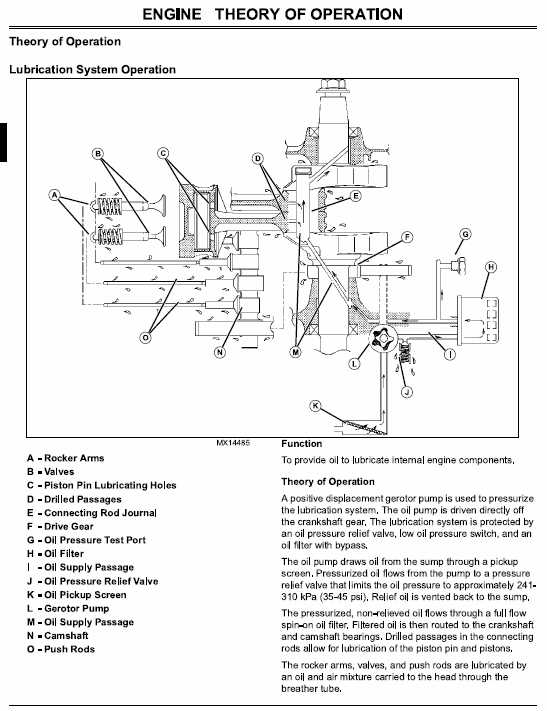

Power and Drive Systems

At the heart of the equipment lies its power and drive systems. These systems are crucial for converting fuel energy into mechanical force, enabling the machine to perform its tasks effectively. Proper functioning of these components ensures smooth operation, allowing for optimal performance across various terrains.

Hydraulic Mechanisms

Hydraulic mechanisms are vital for enhancing the machine’s capabilities. They facilitate lifting, pushing, and pulling actions, making it versatile for multiple applications. Regular inspection and maintenance of these systems are essential to prevent leaks and ensure the efficient transfer of power.

Common Replacement Parts

Maintaining machinery in optimal condition often requires the timely replacement of specific components. Understanding which elements are most prone to wear and tear can enhance the longevity and efficiency of the equipment. This section highlights frequently replaced components that are essential for smooth operation.

One of the most common items needing attention is the filtration system. Regularly changing filters ensures that the engine and hydraulic systems operate efficiently, preventing contaminants from causing damage. Additionally, belts and hoses are critical for the functionality of various mechanisms, and their deterioration can lead to significant performance issues.

Another vital aspect is the battery, which plays a key role in powering electrical systems. Over time, batteries may lose their charge capacity, necessitating replacement to ensure reliable operation. Lastly, tires should be monitored closely; worn-out tires can compromise traction and stability, impacting overall performance on various terrains.

Understanding Part Numbering System

The identification system used for components is crucial for effective maintenance and repairs. This organized structure allows users to easily locate and order necessary elements, ensuring the efficient operation of machinery. A clear understanding of how these numbers are formulated can significantly enhance the repair process.

Structure of Component Identification

Typically, the numbering system consists of several segments that provide essential information about each item. The main features of this system include:

- Category Codes: Initial letters often indicate the type of component, such as hydraulic, electrical, or mechanical.

- Specification Details: Numbers following the category codes usually denote size, capacity, or model variations.

- Version Indicators: Additional letters or numbers may specify updates or modifications made to the original design.

Benefits of a Well-Defined System

Having a structured identification method offers several advantages:

- Efficiency in Ordering: Knowing the exact identification number expedites the process of acquiring replacements.

- Accurate Maintenance: Technicians can easily reference and document repairs when using a standardized identification system.

- Streamlined Inventory Management: Organizations can effectively manage their stock by categorizing components using a clear numbering format.

Visual Representation of Parts

A clear illustration of components is essential for understanding the intricacies of machinery. Such visual aids not only enhance comprehension but also facilitate effective maintenance and repairs. By providing a graphical overview, users can quickly identify each element and its specific function within the system.

Benefits of Illustrative Guides

Illustrative guides serve as valuable tools for both novice and experienced users. They simplify complex information, allowing for quicker recognition and understanding of individual components. This approach minimizes the chances of errors during assembly or disassembly, ensuring that each part is correctly placed and functioning as intended.

Application in Maintenance and Repair

Utilizing visual representations in maintenance procedures can significantly streamline the repair process. Technicians can refer to these guides to locate parts efficiently, reducing downtime and improving productivity. Additionally, having a visual reference fosters a deeper knowledge of the machinery, enabling better troubleshooting and problem-solving capabilities.

How to Use the Diagram Effectively

Understanding a visual representation of components is essential for efficient maintenance and repairs. This tool aids in identifying specific elements and their functions, allowing users to troubleshoot issues and streamline their work processes. Mastering the use of this illustration can enhance one’s ability to operate machinery smoothly.

Identifying Key Components

Begin by familiarizing yourself with the various sections of the illustration. Each part is typically labeled clearly, making it easier to locate essential elements. Pay attention to symbols and color codes that may indicate specific functions or warnings. This initial step is crucial for developing a solid foundation for future tasks.

Planning Maintenance Activities

Once you have a clear understanding of the layout, use the representation to plan your maintenance activities. Create a checklist based on the components highlighted in the visual guide. Prioritize tasks by identifying critical areas that require immediate attention, ensuring that you address potential issues before they escalate.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and care. Implementing effective maintenance practices can significantly extend its lifespan and enhance performance. Below are essential strategies to keep your machinery in optimal condition.

Regular inspections play a crucial role in identifying potential issues before they escalate. Scheduling routine check-ups allows you to monitor vital components and address wear and tear promptly.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 100 hours of operation | Use the recommended oil type for better performance. |

| Air Filter Check | Every 50 hours | Replace if dirty or clogged to ensure proper airflow. |

| Battery Inspection | Monthly | Check for corrosion and clean terminals as needed. |

| Tire Pressure | Weekly | Maintain recommended pressure for optimal traction. |

| Hydraulic Fluid Level | Weekly | Ensure levels are adequate to prevent overheating. |

Utilizing high-quality replacement parts can also enhance the reliability and efficiency of your machinery. Invest in trusted brands to avoid issues associated with inferior components.

Finding Genuine Replacement Parts

Locating authentic components for your machinery is crucial for maintaining its performance and longevity. Ensuring that you use original or high-quality substitutes can significantly impact the overall functionality and reliability of your equipment. Here are some strategies to consider when searching for replacements.

Research Authorized Dealers

One of the best ways to ensure you’re getting genuine components is to work with authorized distributors. These suppliers often have a direct connection to manufacturers and can provide:

- Verification of authenticity

- Access to the latest product updates

- Detailed product information and specifications

Utilize Online Resources

The internet offers a wealth of resources for identifying authentic replacements. Utilize the following tools:

- Official manufacturer websites

- Online forums and communities of equipment owners

- Parts lookup tools available on dealer sites

By leveraging these avenues, you can find the exact components needed for your machinery, ensuring optimal performance and peace of mind.

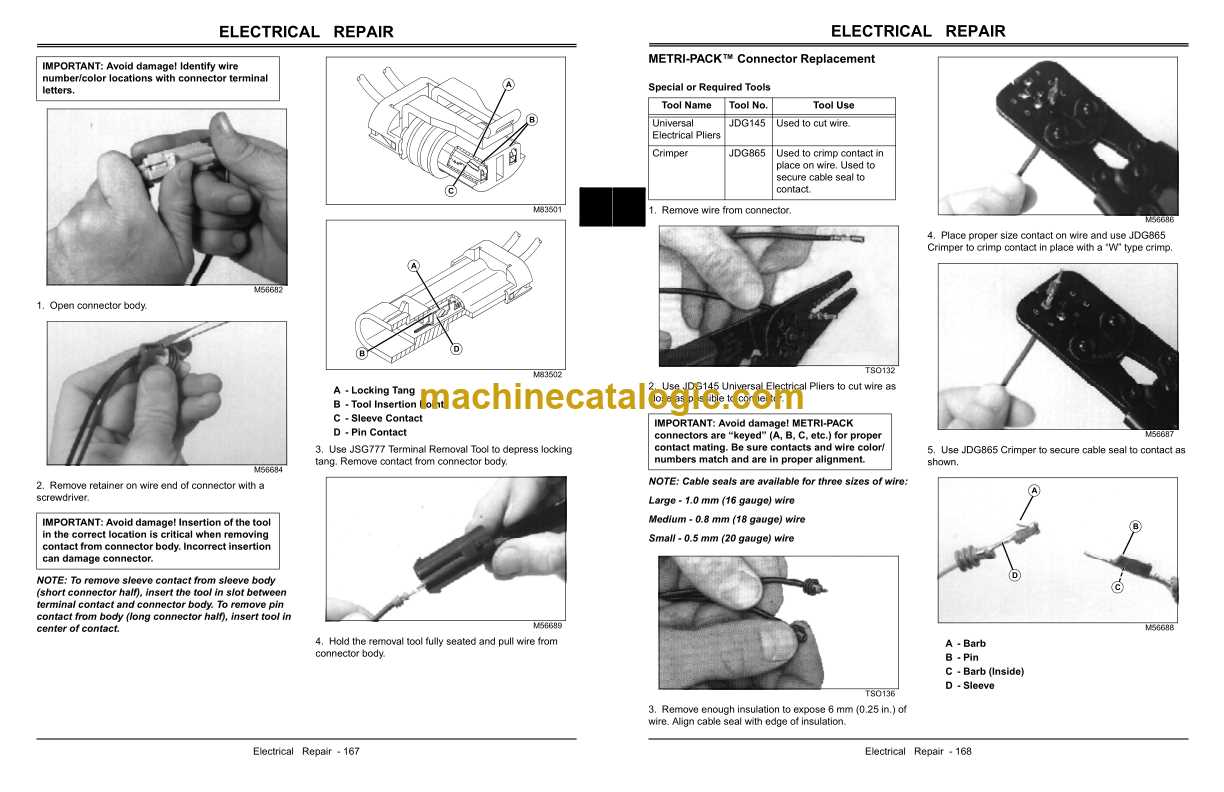

Tools Needed for Repairs

Effective maintenance of machinery requires specific instruments to ensure that all tasks are performed accurately and efficiently. Having the right equipment not only facilitates the repair process but also enhances safety and extends the lifespan of the machinery.

Essential tools include a variety of wrenches and sockets to handle different bolt sizes, ensuring a secure fit during assembly and disassembly. Pliers and screwdrivers are vital for gripping and manipulating smaller components, while a torque wrench is crucial for applying the correct amount of force to fasteners, preventing over-tightening.

Additionally, a reliable lifting mechanism, such as a jack or hoist, is necessary for safely elevating parts for better access. Keeping a set of diagnostic tools on hand, like multimeters and pressure gauges, aids in identifying issues effectively. Finally, having a sturdy workbench and proper storage for tools enhances organization, leading to a more productive repair experience.

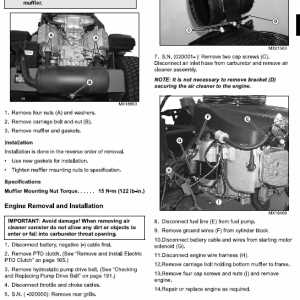

Typical Repair Procedures

This section provides an overview of common maintenance and repair techniques that are essential for ensuring optimal performance and longevity of agricultural machinery. Understanding these procedures can aid operators in performing routine checks and troubleshooting effectively.

Maintenance Checks

- Inspect hydraulic fluid levels regularly to ensure proper operation.

- Examine belts and hoses for wear or damage, replacing them as needed.

- Check tire pressure and tread for any signs of excessive wear.

- Monitor engine performance for any irregularities, including unusual noises or vibrations.

Common Repairs

- Replace filters to maintain clean fuel and air supply.

- Repair or replace damaged components to prevent further issues.

- Lubricate moving parts to reduce friction and wear.

- Calibrate settings to ensure machinery operates within specified parameters.

Sources for Parts Diagrams

Accessing reliable resources for schematics is crucial for effective maintenance and repair tasks. Various platforms provide detailed illustrations that aid in identifying components and their arrangements. These resources are invaluable for both professional technicians and enthusiastic hobbyists looking to enhance their understanding of machinery.

Manufacturers often offer online catalogs featuring comprehensive drawings that detail every element of their equipment. These official websites typically include search functionalities, allowing users to easily locate the specific model they are interested in. Additionally, many distributors and retailers maintain extensive archives of schematics that are accessible to customers, providing another layer of convenience.

Community forums and discussion groups serve as another excellent avenue for obtaining detailed visuals. Enthusiasts frequently share their knowledge and resources, including links to various diagrams. Engaging with such communities can lead to discovering alternative resources and gaining insights from experienced users who can provide helpful advice based on their own experiences.

Customer Support and Resources

Accessing reliable assistance and materials is essential for maximizing the performance and longevity of your equipment. Whether you require technical guidance, replacement components, or maintenance advice, various resources are available to ensure you can effectively manage your machinery.

Technical Assistance

For immediate support, users can reach out to dedicated service teams who are knowledgeable about the equipment’s specifications and functionality. These professionals are equipped to handle inquiries regarding troubleshooting, operational efficiency, and general maintenance tips.

Resource Availability

A wealth of information is accessible online, including user manuals, instructional videos, and FAQs. These resources can enhance your understanding of your equipment and provide practical solutions to common issues. Regularly updating your knowledge through these channels can lead to more effective usage and problem resolution.

| Resource Type | Description | Access Method |

|---|---|---|

| User Manuals | Detailed guides on operation and maintenance | Online download or customer service |

| Video Tutorials | Visual demonstrations of various tasks | Official website or video-sharing platforms |

| FAQs | Answers to common questions and concerns | Company website support section |

| Customer Service | Direct assistance for specific inquiries | Phone, email, or chat support |