When it comes to maintaining expansive green spaces, having a reliable machine is essential. This equipment is designed to tackle various landscaping tasks efficiently, making it a valuable asset for both professionals and enthusiasts. A thorough comprehension of its components not only aids in proper maintenance but also ensures optimal performance over time.

Identifying the various elements of this machinery can enhance your ability to troubleshoot issues and perform necessary repairs. Each component plays a crucial role in the overall functionality, contributing to the machine’s durability and effectiveness. Recognizing these parts can help in making informed decisions regarding replacements and upgrades.

In this section, we will explore an illustrative guide to the intricate system of components, providing insights into their arrangement and functionality. Whether you’re looking to perform routine maintenance or address specific problems, understanding this layout is fundamental for any owner aiming to maximize the longevity and performance of their equipment.

Understanding John Deere F911 Parts

Grasping the essential components of your machinery is crucial for optimal performance and longevity. Each element plays a significant role in ensuring the efficient operation of the entire system. Familiarity with these individual elements not only aids in maintenance but also empowers users to make informed decisions regarding repairs and replacements.

To effectively manage and maintain your equipment, it’s important to identify the various segments and their functions. This knowledge facilitates troubleshooting, enabling users to pinpoint issues and implement solutions more efficiently. Proper comprehension of these integral sections enhances overall reliability and minimizes downtime.

Moreover, understanding the relationships between different components can lead to more effective upgrades and modifications. By delving into the intricacies of each part, one can achieve the ultimate performance from the machinery, ensuring it operates at peak efficiency for years to come.

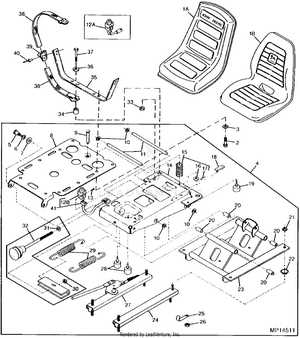

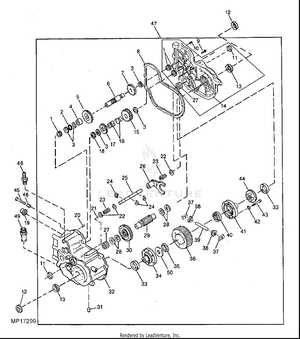

Overview of F911 Parts Diagram

This section provides a comprehensive look at the visual representation of components within the specified model, facilitating a deeper understanding of each element’s function and interrelation. The illustration serves as an essential tool for maintenance and repair, enabling users to identify parts quickly and accurately.

Understanding Component Layout

The layout depicted in the illustration organizes various elements logically, allowing for easy navigation through the intricate assembly. Each segment is labeled clearly, ensuring that users can pinpoint specific pieces without confusion. This clarity is crucial for efficient troubleshooting and repairs.

Importance of Accurate Identification

Correctly identifying individual components not only streamlines the maintenance process but also enhances overall performance. Knowledge of each part’s role ensures that users can make informed decisions during repairs or replacements. Moreover, familiarity with the assembly can significantly reduce downtime and improve operational efficiency.

Key Components of F911 Mower

The functionality and efficiency of a lawn care machine depend heavily on its essential elements. Understanding these components helps in maintaining optimal performance and extending the lifespan of the equipment. Each part plays a vital role, contributing to the overall operation and reliability of the mower.

Engine: The heart of the machine, providing the necessary power for operation. A well-maintained engine ensures smooth functionality and can significantly influence fuel efficiency.

Cutting Deck: This is where the magic happens. The cutting deck houses the blades and is crucial for achieving a clean and even cut. Regular checks can prevent issues such as uneven cutting or damage to the blades.

Transmission: This component facilitates the transfer of power from the engine to the wheels. A reliable transmission system allows for better control and maneuverability, especially on varied terrain.

Wheels: These provide stability and mobility. The quality and condition of the wheels can greatly impact the machine’s ability to navigate different surfaces.

Controls: User-friendly controls ensure that the operator can efficiently manage the mower’s functions. Intuitive designs enhance comfort and minimize the risk of operational errors.

By familiarizing oneself with these fundamental components, users can better appreciate the craftsmanship involved and make informed decisions regarding maintenance and repairs.

Importance of Accurate Diagrams

Accurate illustrations play a vital role in the maintenance and repair of machinery. They serve as essential tools for technicians, providing a visual representation of components and their arrangement. When these visual aids are precise, they enhance understanding and efficiency, minimizing the likelihood of errors during assembly or disassembly.

Clarity in these visual representations ensures that every element is easily identifiable, which is crucial for effective troubleshooting. A detailed illustration helps users quickly locate specific parts, streamlining the repair process and reducing downtime.

Furthermore, well-structured visuals can also aid in training new personnel. By providing a clear reference, they facilitate the learning process, enabling trainees to familiarize themselves with complex systems more effectively. This not only improves individual skills but also enhances overall team productivity.

In conclusion, the precision of these visual tools significantly impacts operational efficiency, safety, and training within mechanical maintenance. Their value cannot be understated, as they contribute to both the accuracy of repairs and the longevity of equipment.

Where to Find Parts for F911

Locating the necessary components for your equipment can be crucial for maintaining its performance and longevity. There are various avenues to explore when seeking replacements or upgrades, ensuring that you have the right items for your needs.

Online Retailers

- Visit specialized websites that focus on outdoor machinery and accessories.

- Explore large e-commerce platforms that offer a wide range of machinery components.

- Check manufacturer websites for direct purchases or recommendations on where to buy.

Local Suppliers

- Identify local dealerships that specialize in agricultural or landscaping equipment.

- Seek out hardware stores that may stock compatible items for your model.

- Attend local trade shows or expos, where vendors often showcase relevant equipment and components.

By leveraging these resources, you can ensure that your machinery remains in optimal working condition, allowing for efficient operation and increased productivity.

Common Issues with F911 Components

When working with specific machinery, various components can present challenges that affect overall performance and reliability. Understanding these common issues can help users maintain their equipment effectively.

Frequent Problems

- Wear and tear on belts leading to reduced efficiency.

- Hydraulic leaks that may impact operation.

- Electrical failures causing starting issues.

Maintenance Tips

- Regularly inspect belts for signs of fraying or cracking.

- Check hydraulic fluid levels and connections frequently.

- Test electrical systems to ensure proper functioning.

Maintenance Tips for F911 Parts

Regular upkeep is essential for ensuring the longevity and optimal performance of your machinery. By following specific guidelines, you can enhance efficiency and prevent premature wear. Proper attention to components not only extends their life but also improves overall functionality.

Routine Inspection

Conducting frequent checks on various elements is crucial. Look for signs of wear or damage, and address issues promptly. This proactive approach helps in identifying potential problems before they escalate, saving time and resources in the long run.

Lubrication and Cleaning

Keep all moving parts well-lubricated to reduce friction and wear. Regular cleaning is equally important, as debris can hinder performance. Establish a cleaning schedule to maintain the integrity of the equipment and ensure it operates smoothly.

Upgrading F911 for Better Performance

Enhancing the efficiency and functionality of your equipment can significantly improve its overall performance. By focusing on key components and implementing upgrades, operators can experience increased reliability, better handling, and improved productivity. This section explores various approaches to optimize your machine and elevate its capabilities.

Key Upgrades to Consider

First and foremost, consider upgrading the engine and transmission systems. A more powerful engine can lead to enhanced torque and speed, while a refined transmission allows for smoother operation and better fuel efficiency. Additionally, incorporating advanced filtration systems can help maintain engine health, leading to longer operational life.

Enhancing Mobility and Stability

Improving mobility is another crucial aspect. Upgrading tires or tracks can enhance grip and traction, allowing for better performance on various terrains. Furthermore, modifying the suspension system can significantly increase stability, making the equipment easier to control during challenging tasks. Implementing these changes not only boosts performance but also contributes to a safer operating environment.

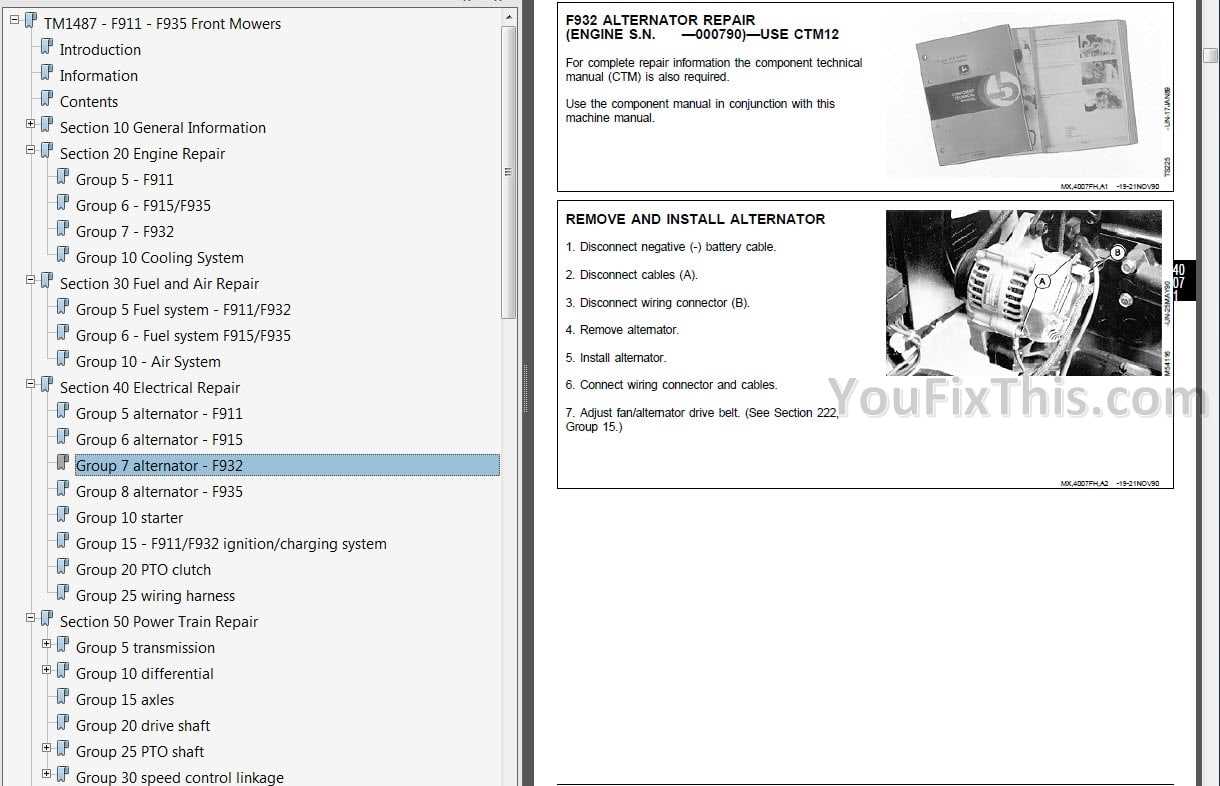

DIY Repairs Using the Diagram

Understanding the layout of components is essential for anyone looking to undertake maintenance or repairs on their machinery. Having a clear visual reference simplifies the process, allowing users to identify parts easily and understand their relationships. This approach not only saves time but also minimizes the risk of errors during repairs.

Benefits of a Visual Reference

- Enhances comprehension of the machine’s structure

- Facilitates quicker identification of malfunctioning components

- Supports effective troubleshooting and problem-solving

- Encourages confidence in performing repairs independently

Steps for Effective Repairs

- Gather the necessary tools and safety equipment.

- Refer to the visual layout to locate the part you need to replace or fix.

- Carefully follow any guidelines for disassembly, noting how components fit together.

- Replace or repair the identified part as needed, using the reference for guidance.

- Reassemble the machinery, ensuring all components are correctly positioned.

- Test the machinery to confirm that the repair was successful.

By utilizing a comprehensive visual reference, anyone can tackle repairs with greater assurance, leading to enhanced performance and longevity of their equipment.

Comparing F911 Parts with Other Models

This section explores the similarities and differences between components of one specific model and various alternatives within the same category. Understanding these distinctions is crucial for users looking to optimize performance, maintenance, and compatibility across their equipment.

Component Similarities

Many machines share foundational elements, which can simplify repairs and upgrades. Key components like engines, transmissions, and chassis design often reflect industry standards, leading to interchangeable options that enhance versatility. Users may find that certain parts fit multiple models, allowing for easier sourcing and potentially reduced costs.

Unique Features and Enhancements

Despite some commonality, each model can also present unique characteristics tailored for specific tasks. Innovations in design, material quality, and technology integration can significantly impact efficiency and durability. Analyzing these specialized features is essential for making informed decisions about replacements or enhancements, ensuring that users select the best components for their operational needs.

Resources for F911 Owners

For enthusiasts and operators of specialized machinery, having access to quality resources is essential for maintenance and repairs. This section provides valuable information and links that can enhance your ownership experience and ensure optimal performance.

- Online Forums: Engage with a community of users who share tips and experiences.

- Manufacturer Websites: Access official documentation, user manuals, and support resources.

- Local Dealerships: Connect with authorized sellers for genuine replacements and expert advice.

- Social Media Groups: Join dedicated groups to exchange knowledge and seek assistance.

- YouTube Channels: Watch tutorials and maintenance guides to learn best practices.

Utilizing these resources can help owners delve deeper into their machinery’s functionality and achieve the ultimate in reliability and efficiency.