In the realm of outdoor machinery, understanding the intricate elements that comprise a lawn care vehicle is crucial for efficient maintenance and repair. This knowledge not only enhances performance but also extends the lifespan of the equipment. By examining these essential components, users can ensure their machines operate at peak efficiency.

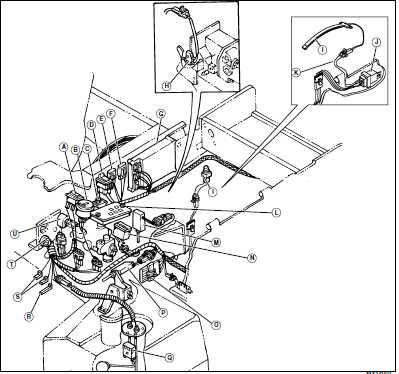

For enthusiasts and professionals alike, having a comprehensive visual representation of these critical elements allows for a deeper insight into assembly and functionality. Whether you’re troubleshooting an issue or performing routine checks, this information serves as a valuable resource.

Ultimately, gaining familiarity with the layout and interconnectivity of these parts empowers operators to make informed decisions, streamline repairs, and optimize the overall user experience. Embrace the opportunity to delve into the specifics, and enhance your understanding of this vital machinery.

Understanding John Deere LTR166 Parts

Grasping the components of a specific lawn maintenance machine is essential for effective upkeep and troubleshooting. Each element plays a vital role in ensuring optimal performance and longevity. Familiarity with the individual sections allows for informed decisions when it comes to repairs or upgrades.

Key Components and Their Functions

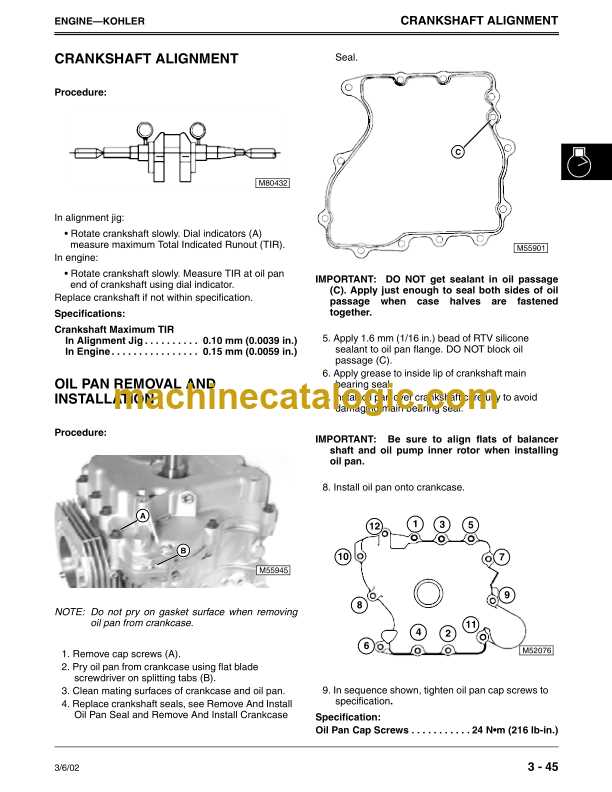

Every machine comprises several critical elements that contribute to its functionality. The engine, for instance, serves as the powerhouse, driving the entire system. Additionally, the cutting mechanism is crucial for achieving a precise finish on the lawn. Understanding the interrelationship between these parts enhances operational efficiency.

Maintenance Tips for Longevity

Regular inspection and maintenance of various components are paramount for preserving the machine’s health. This includes checking fluid levels, replacing worn-out pieces, and ensuring proper lubrication. By staying proactive, operators can prevent minor issues from escalating into significant problems, ultimately extending the lifespan of their equipment.

Overview of LTR166 Lawn Tractor

The lawn care machine discussed here is designed to offer efficient performance and ease of use for homeowners and landscapers alike. With its robust features and reliable build, it provides a seamless mowing experience while catering to various terrain types.

This model boasts a powerful engine that ensures optimal cutting power and longevity. Its ergonomic design allows for comfortable operation, reducing fatigue during extended use. Equipped with a user-friendly control panel, it enables quick adjustments and enhances overall maneuverability.

The cutting system features a versatile deck that can handle different grass types and lengths, making it suitable for a range of lawn conditions. Additionally, the machine’s compact size facilitates easy storage and transport, making it a practical choice for those with limited space.

Maintenance is simplified through accessible components, ensuring that routine care can be performed with minimal effort. Overall, this lawn care equipment stands out for its combination of durability, efficiency, and user convenience, making it a valuable asset for any lawn enthusiast.

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for maintenance and repair. Visual representations serve as essential tools, providing clarity and precision when dealing with complex systems. They allow users to identify each element, ensuring proper functionality and longevity.

Effective communication is enhanced through these visuals, facilitating collaboration between technicians and users. Detailed illustrations minimize misunderstandings, streamlining the repair process and reducing downtime.

Moreover, having a comprehensive visual guide aids in troubleshooting, allowing for quicker diagnosis of issues. This ultimately leads to more efficient repairs and improved performance of the equipment.

Key Components of LTR166

This section explores the essential elements that contribute to the overall functionality and efficiency of the machine. Each part plays a crucial role in ensuring smooth operation, enhancing performance, and maintaining longevity.

One of the primary features includes the engine, which serves as the powerhouse, delivering the necessary energy for various tasks. Coupled with the transmission system, it facilitates seamless power transfer to the wheels, allowing for agile movement.

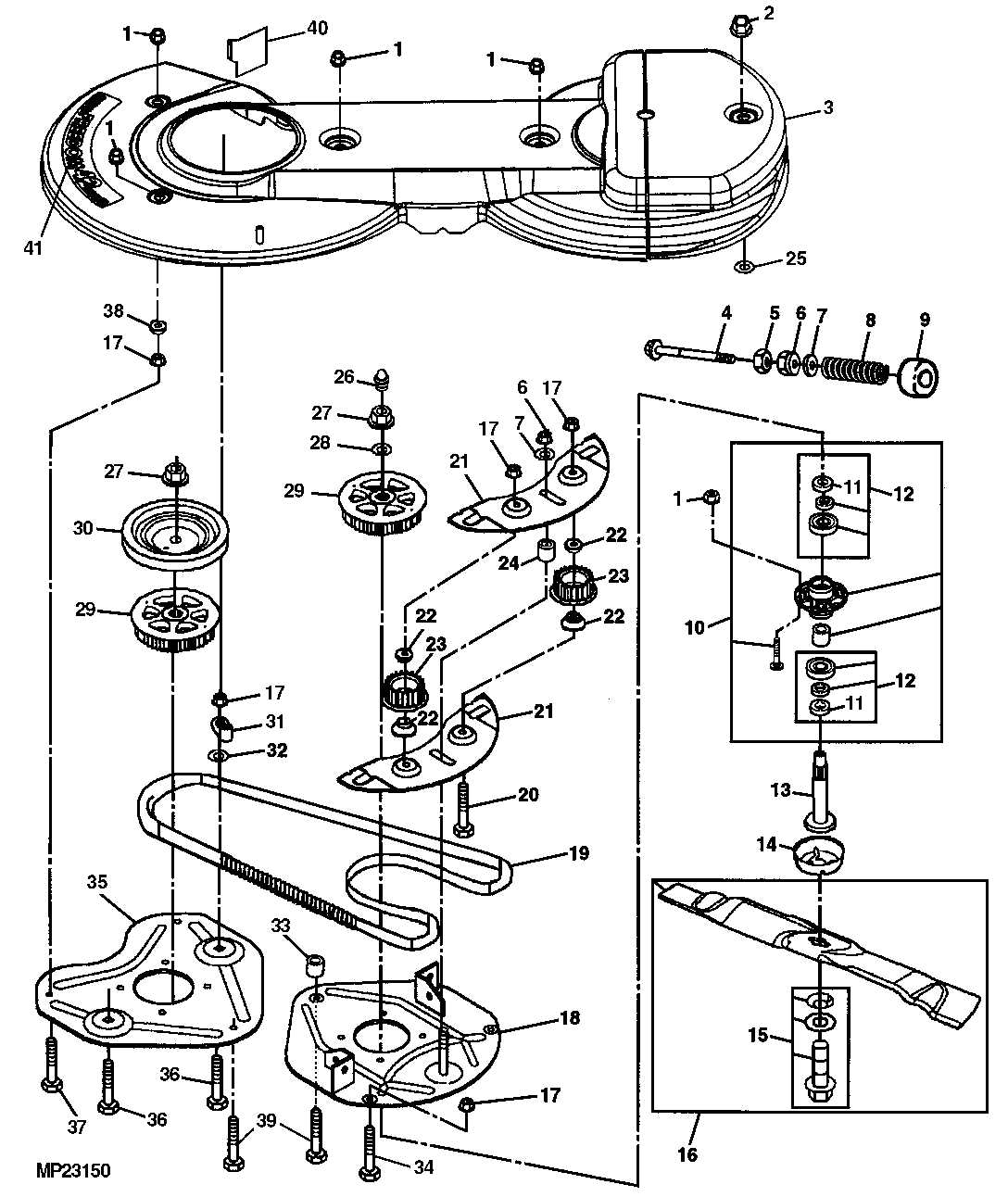

The cutting deck is another significant aspect, designed to provide a clean and precise cut. Its robust construction ensures durability while accommodating various terrains.

Additionally, the steering mechanism offers precision control, allowing the operator to navigate effortlessly. Complementing these components, the electrical system ensures reliable operation of lights and other features, enhancing overall user experience.

Where to Find Parts Diagrams

Locating detailed schematics for machinery components can significantly enhance maintenance and repair processes. Understanding where to source these valuable resources is essential for effective servicing.

- Manufacturer Websites: Official sites often provide downloadable resources, including breakdowns of various models.

- Online Retailers: Many specialized shops offer digital catalogs, allowing users to browse through detailed illustrations.

- Forums and Communities: Engaging with online groups can lead to shared resources and firsthand advice from experienced users.

- Repair Manuals: Purchasing or accessing service guides can yield comprehensive visuals and instructions for troubleshooting.

- Local Dealerships: Authorized dealers typically have access to original documentation and can assist in obtaining necessary visuals.

By exploring these avenues, individuals can efficiently acquire the information needed for repairs and maintenance tasks.

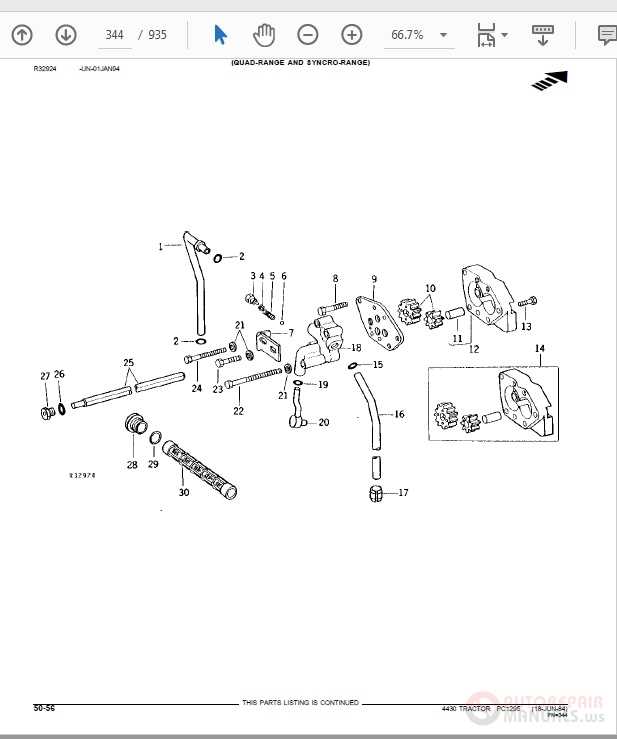

Interpreting the Diagram Symbols

Understanding the symbols used in mechanical schematics is essential for effective maintenance and repair. Each icon represents specific components or functions, enabling users to navigate complex layouts with ease. Familiarity with these symbols can significantly enhance your ability to troubleshoot and make informed decisions during servicing tasks.

Common Symbols and Their Meanings

- Circle: Indicates a junction or connection point.

- Arrow: Represents the direction of flow or movement.

- Square: Signifies a component housing or enclosure.

- Triangle: Used for indicating safety or warning elements.

Utilizing the Symbols Effectively

- Familiarize yourself with the legend provided in the schematic.

- Cross-reference symbols with corresponding components to understand their interactions.

- Pay attention to any additional notes that clarify specific functions.

- Regularly review the symbols as you perform maintenance to build your knowledge base.

Common Replacement Parts for LTR166

Maintenance and repair are essential for ensuring optimal performance of outdoor equipment. Understanding frequently needed components can help users keep their machinery running smoothly and efficiently. This section explores the typical items that often require attention and replacement over time.

Blades: Sharp and well-maintained cutting edges are crucial for achieving a clean cut. Regular inspection and replacement ensure the best results in lawn care.

Belts: Drive and deck belts experience wear due to friction and constant use. Replacing these components at the first sign of damage can prevent further issues.

Filters: Air and fuel filters play a vital role in maintaining engine performance. Regularly replacing these filters helps in keeping the machinery running smoothly.

Batteries: Reliable power sources are essential for starting and operating equipment. Replacing old batteries ensures dependable performance, especially in colder weather.

Wheels: Worn or damaged wheels can affect maneuverability and efficiency. Inspecting and replacing them as needed is key to maintaining optimal functionality.

Tips for Maintenance and Repair

Regular upkeep and timely fixes are essential for ensuring optimal performance and longevity of your machinery. By adhering to a few best practices, you can prevent minor issues from escalating into significant problems, thereby saving both time and money.

1. Schedule Routine Inspections: Establish a maintenance calendar to perform regular checks on all vital components. This proactive approach helps identify wear and tear early.

2. Keep It Clean: Regularly clean the exterior and interior parts to prevent dirt accumulation that can lead to malfunctions. A clean machine is less prone to issues.

3. Use Quality Lubricants: Always opt for high-quality lubricants to ensure smooth operation of moving parts. Proper lubrication reduces friction and extends the life of components.

4. Follow Manufacturer Guidelines: Adhere to the maintenance instructions provided by the manufacturer. These guidelines offer the ultimate insights into best practices for your specific model.

5. Document Repairs: Maintain a detailed log of all repairs and maintenance tasks. This record helps track the history of your equipment and can aid in diagnosing future issues.

6. Train Personnel: Ensure that anyone operating or maintaining the equipment is properly trained. Knowledgeable personnel can detect problems early and implement solutions effectively.

How to Order Genuine Parts

Acquiring authentic components for your machinery is essential for optimal performance and longevity. This section outlines the steps to ensure you receive high-quality items tailored to your equipment’s needs.

Step-by-Step Guide

- Identify the specific component required by referencing your equipment’s manual.

- Visit the manufacturer’s official website or authorized dealers.

- Use the search function to find the component by name or code.

- Confirm compatibility with your model before proceeding.

- Add the item to your cart and review your selection.

- Complete the order by providing necessary shipping and payment information.

Tips for Successful Ordering

- Double-check the part number for accuracy.

- Consult customer service if you have any doubts.

- Keep records of your orders for future reference.

Aftermarket vs. OEM Parts

The choice between replacement components can significantly impact performance, longevity, and maintenance costs. Understanding the differences between these options is crucial for making informed decisions that align with personal preferences and operational needs.

Quality and Performance

OEM items are typically produced by the original manufacturer, ensuring compatibility and adherence to specific standards. In contrast, aftermarket options can vary widely in quality; while some match or exceed OEM specifications, others may fall short.

Cost Considerations

Aftermarket solutions often present a more affordable alternative, appealing to budget-conscious consumers. However, it’s essential to evaluate the potential trade-offs in quality and warranty offerings compared to OEM components, which may come with higher price tags but often guarantee reliability.

Common Issues and Solutions

Maintenance of lawn care equipment can often present various challenges that affect performance and longevity. Identifying common problems and implementing effective solutions can significantly enhance efficiency and reduce downtime.

- Starting Difficulties:

If the machine struggles to start, check the following:

- Ensure the battery is charged and connections are secure.

- Inspect the fuel system for clogs or old fuel.

- Examine the spark plug for wear and replace if necessary.

- Unusual Noises:

Noises that seem out of the ordinary could indicate issues. Address them by:

- Checking for loose components or debris in the engine compartment.

- Inspecting belts and pulleys for signs of wear.

- Ensuring proper lubrication of moving parts.

- Poor Cutting Performance:

When cutting quality declines, consider the following:

- Sharpen or replace the blades as needed.

- Adjust the cutting height for optimal performance.

- Examine the deck for blockages or damage.

- Overheating:

Overheating can lead to serious damage. To prevent this:

- Check the cooling system for proper airflow.

- Ensure the oil level is adequate and oil is clean.

- Clean any debris from cooling fins and vents.

phpCopy code

By addressing these common issues with appropriate solutions, users can maintain their equipment effectively, ensuring reliability and optimal performance throughout the season.

Resources for DIY Repairs

Engaging in do-it-yourself maintenance can be rewarding and cost-effective. Utilizing a variety of available resources can significantly enhance your ability to tackle repairs effectively. Whether you’re a seasoned mechanic or a beginner, having the right tools and knowledge at your disposal is crucial for successful outcomes.

Online Forums: Connecting with communities online provides access to a wealth of shared experiences and advice. Many enthusiasts discuss troubleshooting techniques and share valuable tips.

Tutorial Videos: Platforms like YouTube host countless instructional videos that can guide you through specific repair processes, showcasing step-by-step methods to resolve common issues.

Manufacturer Manuals: Official documentation often includes detailed guidance on maintenance practices, specifications, and component layouts. These manuals are invaluable for understanding your equipment’s intricacies.

Local Workshops: Consider attending local repair workshops or classes. These sessions often cover practical skills and offer hands-on experience, making them perfect for learning new techniques.

With these resources, you can delve into repairs confidently and enhance your mechanical skills over time.

Warranty Considerations for Parts

When purchasing components for your equipment, understanding the warranty policies associated with them is crucial. Warranties serve as a safeguard for consumers, ensuring that they receive quality products and providing peace of mind in case of defects or performance issues.

Duration of the warranty is an important aspect to consider. Most manufacturers offer varying lengths of coverage, typically ranging from a few months to several years. It is essential to check the specific terms to understand what is included during the warranty period.

Coverage details are equally significant. Not all warranties cover the same issues; some may include defects in materials and workmanship, while others may exclude certain types of wear and tear. Familiarizing yourself with these details can help you make informed decisions when selecting components.

Claim process can vary among manufacturers. Knowing the steps required to file a warranty claim can save you time and frustration in the event of an issue. This often involves documentation, proof of purchase, and potentially returning the faulty item for assessment.

Lastly, it’s wise to consider aftermarket options. While they may offer competitive pricing, the warranty terms can differ significantly from original manufacturers. Always review and compare warranty provisions before making a purchase to ensure adequate protection for your investment.