When it comes to maintaining a tidy and productive lawn, having an organized method for collecting debris is crucial. This system offers a streamlined solution for handling clippings and leaves, ensuring that the yard stays in optimal condition without the need for constant manual clean-up.

The system operates by utilizing a series of components designed to gather and transfer material effectively, allowing for seamless and efficient management of the collected waste. These elements work in harmony to reduce the effort required while enhancing the overall performance of your equipment.

Understanding how each element contributes to the process is key to ensuring longevity and functionality. Proper installation and maintenance of these components will help to keep your lawn care routine smooth and uninterrupted.

Overview of the Collection System

This section provides a broad understanding of a specialized grass and debris gathering system designed to enhance the efficiency of lawn maintenance. It ensures optimal collection of clippings, leaves, and other material during mowing, improving the overall tidiness and ease of disposal.

- Enhanced material capture for a cleaner yard

- Streamlined attachment for ease of use and operation

- Efficient design to reduce the frequency of emptying

- Compatible with various mower models for versatile functionality

The system is engineered to assist in maintaining a pristine landscape by effectively gathering debris while providing a convenient solution for handling larger loads without disrupting workflow.

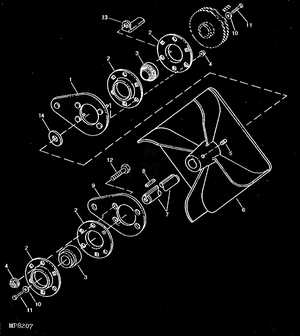

Main Components of the Power Flow Bagger System

The collection system relies on several interconnected elements designed to efficiently gather and direct materials during operation. These components work together to ensure that debris is channeled smoothly from the ground into the collection unit, minimizing blockages and maintaining continuous flow.

One of the critical elements is the intake mechanism, responsible for drawing in materials. It operates in tandem with the transfer chute, which guides the collected matter toward the holding compartment. The final stage involves the storage container, where the gathered material is securely deposited until emptied.

To maintain optimal performance, each of these parts must function cohesively, ensuring efficient material transfer from the collection point to the storage unit, without interruptions.

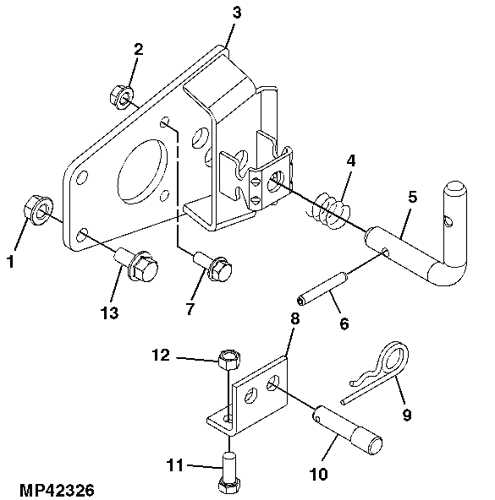

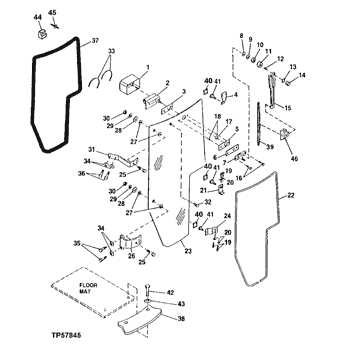

Diagram Layout for Bagger Parts Identification

The layout of components within a collection system is essential for clear understanding and maintenance. This section provides an organized view, helping users navigate and locate specific elements efficiently. By breaking down the structure into distinct areas, the process of identifying and replacing individual parts becomes more intuitive.

Main Sections of the Collection System

The collection system consists of several interconnected sections, each serving a unique purpose. The upper chamber typically houses the initial collection area, directing material flow to the appropriate outlets. Below it, the filtering unit ensures that larger debris is properly separated, preventing clogs and maintaining efficiency.

Detailed View of Critical Components

To streamline the identification process, the components are grouped based on their function. Each section, from the intake to the discharge area, plays a critical role in ensuring smooth operation. Understanding the placement of these elements allows for quicker troubleshooting and efficient system upkeep.

Key Features of Grass Collection System

The innovative grass collection system offers enhanced efficiency and convenience for maintaining large lawns. Designed to streamline the process of gathering clippings, this tool ensures a clean, tidy finish with minimal effort.

Efficient Clipping Collection: The system’s design ensures optimal airflow, helping to channel grass into the container without blockages or delays. This makes the mowing experience smoother and more productive.

High Capacity Container: Equipped with a spacious collection container, the system minimizes the need for frequent emptying, allowing users to cover larger areas without interruption.

Easy Attachment and Detachment: The system’s user-friendly setup allows for quick installation and removal, saving time during maintenance routines.

Durable Construction: Built with high-quality materials, the system is designed to withstand regular use and harsh conditions, ensuring long-term reliability.

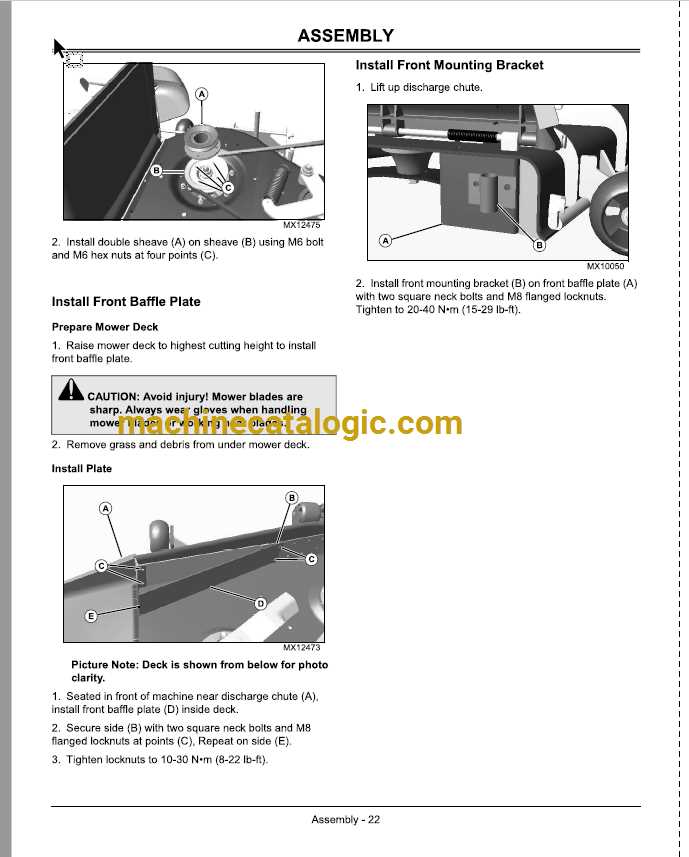

Installation Tips for Power Flow Bagger Parts

Ensuring a smooth setup process for your collection system can significantly improve its efficiency and longevity. Proper assembly not only enhances performance but also reduces the risk of future issues. By following a few essential guidelines, you can complete the installation without unnecessary complications.

Before beginning, gather all required components and tools. This preparation will streamline the task and help avoid interruptions. It’s also important to work on a clean, flat surface to ensure stability during assembly. Carefully review any provided instructions to ensure each part is placed in the correct position.

When attaching the various elements, make sure all fasteners are securely tightened. Loose connections can cause performance problems or even damage over time. If specific adjustments are necessary, be sure to use the recommended settings or measurements for optimal functionality.

Lastly, after installation is complete, inspect the entire setup to confirm that everything is properly aligned and secured. This final check will help you avoid potential operational issues and ensure the system works efficiently from the start.

Maintenance Guidelines for Bagger Attachments

Proper upkeep of collection accessories is essential for ensuring optimal performance and longevity. Regular attention to these components can enhance efficiency and prevent costly repairs. This section outlines key practices for maintaining your collection systems, ensuring they operate smoothly throughout their use.

Routine inspections should be conducted to identify any wear and tear. Checking for loose connections, damage to the housing, and blockages in the airflow are crucial steps. Addressing these issues promptly will minimize downtime and improve functionality.

| Maintenance Task | Frequency | Recommended Action |

|---|---|---|

| Inspect attachment connections | Before each use | Tighten any loose bolts and check for secure fittings |

| Clean collection chamber | After every use | Remove debris and residues to prevent clogs |

| Examine airflow components | Weekly | Ensure there are no blockages; clear any debris |

| Lubricate moving parts | Monthly | Apply appropriate lubricant to enhance performance |

| Replace worn or damaged components | As needed | Utilize original equipment for replacements to maintain quality |

Implementing these maintenance practices will significantly contribute to the efficiency and effectiveness of your collection equipment, leading to a more productive gardening or landscaping experience.

Troubleshooting Common Issues with the Bagger

When operating a grass collection device, various challenges can arise, impacting its efficiency and performance. Understanding the typical problems and their solutions can enhance the overall experience and prolong the lifespan of the equipment. This section aims to outline common complications users may face and offer practical advice for resolution.

Clogs and Blockages

One of the most frequent issues encountered is clogging within the collection system. This can happen due to excessive debris or wet grass accumulation. To resolve this, regularly inspect the chute and collection container for any obstructions. Cleaning these areas can restore proper airflow and ensure efficient operation. It’s advisable to perform this maintenance after each use, especially in humid conditions.

Reduced Collection Efficiency

If you notice a significant decrease in collection performance, it could be due to improper height settings on the mowing device. Ensure that the cutting height is adjusted according to the type of grass and terrain. Additionally, check the seals and connections to confirm they are intact. Regular maintenance of the blades and collection mechanisms will also contribute to optimal functioning.

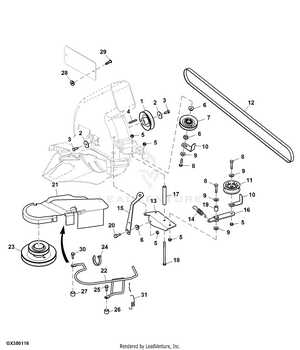

How to Replace Power Flow Bagger Belts

Replacing the belts in your lawn equipment is essential for maintaining optimal performance and ensuring efficiency during operation. This process can enhance the machine’s functionality and extend its lifespan. Below is a straightforward guide to assist you in performing this task effectively.

Gather Necessary Tools

Before starting the replacement, ensure you have all the required tools at hand. You will typically need a socket set, wrenches, and possibly a screwdriver. Having these tools ready will help streamline the process and minimize downtime.

Step-by-Step Replacement Process

Begin by disconnecting the power source to prevent any accidental starts. Next, locate the worn-out belts and remove any covers or guards that might obstruct access. Carefully detach the old belts, taking note of their routing for reinstallation. Install the new belts by following the original path, ensuring they are secure and properly aligned. Finally, reattach any covers or guards removed earlier, and reconnect the power source to complete the process.

By following these steps, you can efficiently replace the belts in your lawn care equipment, ensuring it runs smoothly for all your landscaping needs.

Cleaning and Care for Power Flow Bagger Components

Maintaining the efficiency and longevity of collection systems requires regular attention to cleaning and upkeep. Proper care ensures that all components function optimally and prevents the buildup of debris that can lead to operational issues. Regular maintenance not only enhances performance but also extends the lifespan of the equipment.

Essential Cleaning Steps

- Remove any residual material from the collection unit.

- Use a soft brush or cloth to clear dust and dirt from surfaces.

- Inspect all components for wear and tear, noting any areas needing replacement.

- Rinse with water if necessary, ensuring all parts are thoroughly dried afterward.

Care Recommendations

- Store components in a dry, sheltered location to prevent rust and damage.

- Regularly lubricate moving parts to reduce friction and wear.

- Check for any loose connections or fasteners and tighten them as needed.

- Conduct seasonal maintenance to prepare for changes in usage demands.

Upgrade Options for Power Flow Bagger System

Enhancing your grass collection system can significantly improve its efficiency and performance. There are various upgrade options available that can tailor the setup to better suit your specific needs, ensuring that the equipment operates at its optimal level while providing superior results.

Here are some popular upgrade choices to consider:

- High-Capacity Collection Bags: Investing in larger bags can reduce the frequency of emptying, allowing for longer uninterrupted operation.

- Improved Mulching Attachments: Adding high-performance mulching components can enhance the breakdown of clippings, providing better nutrient recycling for your lawn.

- Enhanced Blower Systems: Upgrading to a more powerful blower can increase suction and efficiency, helping to gather debris more effectively.

- Weather-Resistant Materials: Opting for durable, weatherproof components can prolong the lifespan of the collection system and improve its reliability under various conditions.

- Adjustable Mounting Brackets: Adjustable mounts can offer better compatibility with different models, ensuring a secure fit and easier installation.

By carefully selecting the right enhancements, you can ensure that your grass collection setup remains effective and meets the demands of your landscaping tasks.

Compatibility of Bagger Parts with John Deere Models

Understanding the interchangeability of components with various models is crucial for effective maintenance and operation. Different machinery versions may have specific requirements for attachments, making it essential to match the right accessories to the appropriate equipment.

When assessing compatibility, one must consider the specifications of each model, as well as the intended use of the accessories. This ensures optimal functionality and efficiency, preventing potential issues during operation.

| Model Series | Compatible Accessories |

|---|---|

| 100 Series | Compatible with various grass collection systems |

| 200 Series | Designed to work with specified collecting attachments |

| X300 Series | Includes options for additional debris management systems |

| X500 Series | Features compatibility with advanced collecting devices |

Where to Buy Genuine Power Flow Bagger Parts

Finding authentic components for your lawn care equipment is essential for maintaining its performance and longevity. Several options are available for those seeking reliable sources to purchase these necessary items. By ensuring you select the right outlets, you can guarantee that you receive high-quality and compatible elements for your machinery.

Authorized Retailers

One of the most dependable ways to acquire genuine components is through authorized dealers. These retailers are officially recognized and provide a range of original items tailored to your equipment’s specifications.

- Locate nearby dealers through the manufacturer’s official website.

- Visit local garden centers that offer equipment sales and services.

Online Marketplaces

In addition to physical stores, numerous online platforms specialize in outdoor machinery components. These websites often provide a vast selection, competitive pricing, and convenient delivery options.

- Check dedicated online retailers for a comprehensive inventory.

- Explore auction sites for potential bargains on new or used items.

Understanding Part Numbers in Bagger Diagrams

In the realm of lawn maintenance equipment, recognizing the significance of identification codes is crucial. These codes serve as a systematic approach to categorize various components, enabling users to pinpoint specific items needed for maintenance or replacement. A thorough comprehension of these identifiers enhances the ability to efficiently manage equipment and ensure optimal performance.

The Structure of Identification Codes

Typically, identification codes are designed with a specific format that includes alphanumeric characters. This structured approach allows for easy categorization and retrieval of items. The initial characters often denote the type of component, while subsequent characters may specify size, model, or other essential attributes. Familiarity with this structure empowers users to navigate maintenance catalogs effectively.

Utilizing Identification Codes for Maintenance

Accurate identification is vital when seeking replacements or performing upgrades. Users should reference these codes when consulting manuals or parts catalogs, as this guarantees compatibility with existing machinery. Additionally, understanding the nuances of these codes can prevent errors in ordering and installation, ultimately prolonging the life of the equipment.