Every piece of machinery relies on intricate assemblies, where each element plays a key role in ensuring smooth performance. Understanding how these elements fit and function together is crucial for both routine maintenance and troubleshooting. In this section, we explore the layout and connectivity of various critical elements found in high-performance utility vehicles.

Accurate knowledge of these configurations helps users quickly identify problem areas and ensure proper upkeep. Whether you’re conducting minor repairs or planning a complete overhaul, having a detailed reference makes the task much easier. Organized layouts bring clarity, providing essential insights into which sections require attention.

Efficient servicing depends not only on tools but also on familiarity with how mechanical and electrical elements interact. Knowing which connections are vital can prevent costly errors and downtime, making it easier to keep your vehicle in top shape. This approach ensures that every

John Deere RSX 850i Parts Overview

This section provides a general look at essential components that play a crucial role in the performance and reliability of the vehicle. Each element, whether related to the engine, suspension, or electrical system, contributes to smooth operation and ensures durability in various conditions.

Key Mechanical Components

- Engine System: Responsible for delivering power efficiently, ensuring proper acceleration and handling under different loads.

- Suspension Setup: Absorbs shocks and maintains stability, improving ride quality across uneven surfaces.

- Brake Assembly: Provides reliable stopping power, enhancing control during both high-speed and low-speed maneuvers.

Electrical and Control Elements

- Battery and Wiring

Exploring Engine Components

The heart of any utility vehicle lies in the precision and functionality of its mechanical system. Understanding the key elements that drive performance helps in maintaining smooth operation and ensuring long-lasting reliability. This section provides a closer look at the essential internal mechanisms that contribute to an efficient powertrain.

Main Power Unit Structure

The primary unit consists of multiple integrated elements that convert fuel into kinetic energy. Each component within this structure, including cylinders, pistons, and valves, works in harmony to deliver optimal force. Careful synchronization among these elements ensures steady and balanced operation during varied conditions.

Auxiliary Systems for Engine Support

Beyond the core, various supporting systems contribute to peak efficiency. Cooling mechanisms manage temperature levels, while lubrication systems reduce friction and wear. These subsystems play a crucial role in preventing malfunctions and ensuring that all moving parts perform consistently under stress.

Suspension System Breakdown

The suspension system plays a crucial role in providing a smooth ride and ensuring vehicle stability on various terrains. It helps absorb shocks and vibrations, improving both comfort and control during operation. This section explores the key components responsible for maintaining optimal performance and their individual functions within the system.

- Shock Absorbers: These dampen the impact of uneven surfaces, minimizing bounce and improving ride quality.

- Springs: Vital for supporting the vehicle’s weight and absorbing road irregularities, ensuring consistent height and balance.

- Control Arms: These connect the wheels to the frame, allowing controlled motion while maintaining alignment.

- Stabilizer Bar: Helps reduce body roll when cornering, enhancing stability and steering responsiveness.

By maintaining these components, operators ensure smoother handling, better safety, and longevity of the entire system. Regular inspections and t

Electrical Parts and Wiring

Understanding the electrical system is essential for maintaining proper functionality in any utility vehicle. Wiring layouts and electrical elements form the core of the power distribution system, ensuring smooth communication between the control modules and essential components.

Wiring Structure and Connections

Wiring harnesses act as the backbone of the vehicle’s electrical system, linking various electronic units efficiently. These bundles of cables are organized to prevent signal interference and ensure stable power transmission. Proper routing helps to avoid wear and damage, extending the system’s longevity.

Key Electrical Components

Critical elements such as relays,

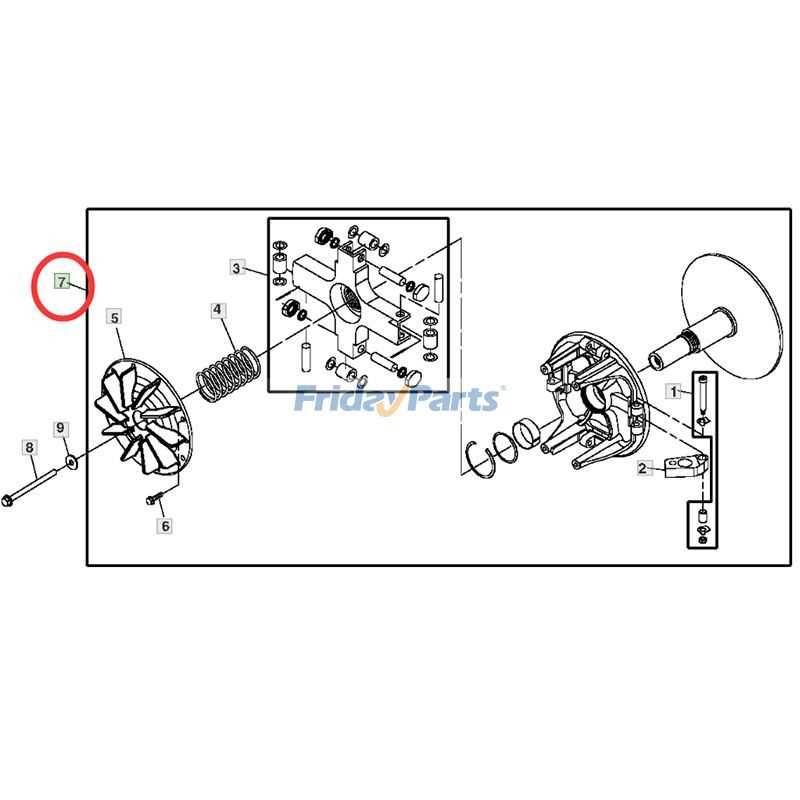

Transmission and Drive Train

The system responsible for delivering power from the engine to the wheels is essential for ensuring smooth movement and optimal performance. It plays a critical role in regulating how energy is transferred, allowing efficient handling across different terrains.

Transmission mechanisms govern the speed and torque output, adjusting the power flow according to driving conditions. This ensures the right balance between acceleration and control, especially when moving over uneven ground.

The drive train works in harmony with the transmission to distribute power evenly across the wheels. Its components reduce energy losses and ensure the vehicle maintains traction, whether on slopes, mud, or rough paths. Proper maintenance of these systems helps prolong performance and avoid unexpected failures.

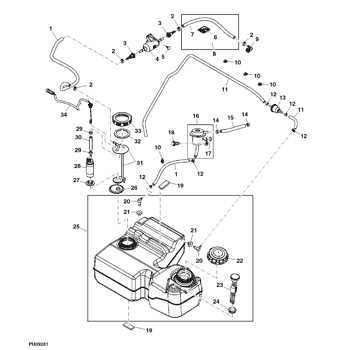

Understanding the Fuel System

The fuel system plays a crucial role in the overall performance and efficiency of any vehicle. It is designed to store, filter, and deliver fuel to the engine, ensuring optimal combustion and functionality. A thorough understanding of how this system operates can greatly enhance maintenance efforts and troubleshooting skills.

This system consists of several key components, each serving a distinct purpose. Fuel tanks are responsible for storing the fuel, while pumps facilitate its movement toward the engine. Filters are essential for removing impurities that could potentially damage engine components. Additionally, fuel injectors or carburetors ensure precise delivery of the correct amount of fuel to the engine’s combustion chamber.

Maintaining the integrity of the fuel system is vital for maximizing performance and longevity. Regular inspections, cleaning, and replacement of worn parts can prevent fuel contamination and ensure smooth operation. Understanding the various functions and interactions of these components empowers users to take proactive measures in preserving their vehicle’s efficiency.

Cooling System Essentials

The cooling system is a vital component that maintains optimal operating temperatures for various mechanical systems. It ensures that engines and other critical elements function efficiently by preventing overheating, which can lead to severe damage and performance issues.

Importance of Temperature Regulation

Effective temperature management is crucial for prolonging the lifespan of engines and enhancing performance. When temperatures exceed the recommended limits, it can cause components to warp, seize, or fail entirely. A well-designed cooling system utilizes fluids to dissipate heat and maintain a stable operating environment.

Key Components of the Cooling Mechanism

The primary elements of a cooling system typically include a radiator, coolant, hoses, and a thermostat. Radiators facilitate heat exchange by dispersing heat from the coolant into the air. Coolant plays a crucial role in absorbing heat from the engine and transporting it to the radiator. Hoses ensure the fluid flows smoothly, while the thermostat regulates the flow of coolant based on temperature, maintaining efficiency.

Brake Assembly Guide

This section provides a comprehensive overview of the assembly process for the braking system. Understanding the essential components and their arrangement is crucial for ensuring optimal performance and safety. Proper assembly enhances vehicle functionality and prolongs the lifespan of the braking system.

Essential Components

The following components are vital for the brake assembly:

- Brake pads

- Brake rotors

- Calipers

- Brake lines

- Master cylinder

Assembly Steps

Follow these steps to assemble the braking system effectively:

- Begin by positioning the brake rotor onto the wheel hub.

- Attach the caliper, ensuring it aligns with the rotor.

- Insert the brake pads into the caliper.

- Connect the brake lines to the caliper.

- Fill the master cylinder with the appropriate fluid.

- Bleed the brakes to eliminate any air in the system.

Steering Mechanism Details

The steering system plays a crucial role in ensuring smooth navigation and control of the vehicle. This assembly is designed to translate the driver’s inputs into precise movements, allowing for agile maneuvering and stability during operation. Understanding the components and their interactions within this system is essential for effective maintenance and troubleshooting.

Component Description Steering Wheel The primary control device used by the operator to guide the vehicle. Steering Column Connects the steering wheel to the rest of the steering apparatus, allowing for transmission of movement. Rack and Pinion A gear mechanism that converts rotational motion from the steering wheel into linear motion to turn the wheels. Steering Knuckles Connects the wheel to the steering system and allows for the pivoting movement necessary for turning. Power Assist Unit Enhances the driver’s steering effort, providing additional force for easier turning. Chassis and Frame Structure

The framework of a utility vehicle plays a crucial role in its overall performance and stability. It serves as the backbone, supporting various components and ensuring that the vehicle can endure the rigors of off-road environments. A well-designed chassis not only enhances durability but also optimizes weight distribution, which is essential for handling and control.

The construction of the chassis typically involves robust materials that provide strength without adding excessive weight. This balance is vital for achieving agility while maintaining structural integrity. The frame’s design is also tailored to accommodate attachments and modifications, allowing users to customize their vehicle according to specific needs.

In addition to supporting the engine and drivetrain, the chassis is engineered to absorb shocks and vibrations, improving ride comfort. It is essential for the frame to be resilient against harsh terrains, making its design a critical factor in performance and longevity.

Lighting and Instrument Panel

The illumination and control interface of a vehicle play a vital role in ensuring safe and efficient operation. This section explores the various components responsible for visual signals and dashboard displays, emphasizing their importance in enhancing the user experience.

Illumination Features

Effective lighting systems are essential for visibility during night-time driving and adverse weather conditions. These components include headlights, taillights, and turn signals, all designed to provide clear guidance to the operator and other road users. LED technology has become increasingly popular due to its energy efficiency and longevity, making it a preferred choice for modern vehicles.

Control Dashboard

The control dashboard serves as the primary interface for monitoring various vehicle functions. It features an array of gauges and indicators that provide real-time information on speed, fuel level, and engine status. Understanding these visual cues is crucial for maintaining optimal performance and addressing any issues that may arise during operation. Proper layout and design enhance usability, ensuring that operators can easily interpret the information presented.

Seats and Comfort Features

The design of seating and comfort attributes plays a vital role in enhancing the overall experience of the operator. Comfort-focused elements contribute to reducing fatigue during prolonged use, making the vehicle more enjoyable to operate. Attention to ergonomic design ensures that users can maintain an optimal posture while engaged in various tasks.

Ergonomic Seating

Seating arrangements are engineered to provide optimal support, ensuring that individuals can comfortably navigate different terrains. Features such as adjustable backrests and cushioned surfaces allow for personalized settings, accommodating a wide range of body types and preferences. This thoughtful design minimizes discomfort during extended periods of operation.

Convenient Controls

Incorporating user-friendly controls within easy reach enhances the overall functionality of the vehicle. This arrangement not only improves accessibility but also enables operators to focus on their tasks without unnecessary distractions. Additionally, strategically placed storage compartments contribute to an organized and clutter-free environment, further enhancing comfort.

Maintenance Tools and Accessories

Keeping your outdoor equipment in optimal condition requires a variety of essential implements and supplementary items. These tools facilitate efficient upkeep, ensuring that your machinery operates smoothly and lasts longer. A well-equipped toolkit not only simplifies routine checks but also enhances the overall performance of your machine.

Essential Implements

When it comes to maintenance, certain implements are indispensable. Here are some of the most common tools you should have on hand:

Tool Description Wrenches Used for tightening and loosening bolts and nuts. Screwdrivers Essential for adjusting and securing various components. Oil Filter Wrench Specialized tool for easy removal of oil filters during changes. Grease Gun Utilized for applying lubricant to moving parts to reduce friction. Multimeter Instrument for measuring voltage, current, and resistance in electrical systems. Helpful Accessories

In addition to tools, certain accessories can enhance your maintenance efforts. These items help in achieving precise and effective care:

Accessory Purpose Toolbox Organizes and stores all tools securely. Maintenance Manual Provides detailed instructions and specifications for upkeep tasks. Safety Gear Includes gloves, goggles, and masks to protect during maintenance activities. Cleaning Supplies Necessary for keeping surfaces clean and free of debris. Storage Containers Facilitates organized storage of small parts and accessories.