In the realm of agricultural machinery, a particular model stands out for its efficiency and durability. Grasping the intricacies of its build can significantly enhance maintenance and operational effectiveness. This section aims to explore the essential elements that contribute to the performance and longevity of this equipment.

Identifying each component is crucial for both repair and optimization purposes. By analyzing how various parts interact and function together, users can better manage their machinery’s upkeep. This knowledge not only fosters a deeper connection with the equipment but also ensures that it operates at its ultimate potential.

Furthermore, having access to a visual representation of these elements aids in pinpointing specific issues quickly. Whether you’re a seasoned operator or a novice, delving into the details of the machinery’s structure will empower you to make informed decisions regarding maintenance and upgrades.

Understanding the John Deere SST16

This section explores a specific model in the world of outdoor machinery, focusing on its components and overall functionality. Recognizing the significance of each element can enhance both maintenance and performance.

Key Features: This model is known for its innovative design, which combines efficiency with durability. Users appreciate its ability to tackle various tasks seamlessly, making it a reliable choice for landscaping and gardening needs.

Maintenance Insights: Regular upkeep is essential to ensure optimal performance. Understanding how each component interacts allows for timely interventions and repairs, prolonging the life of the equipment.

Usage Applications: From residential yards to larger commercial landscapes, this machinery is versatile. Knowing how to leverage its features can yield the ultimate results in lawn care and ground management.

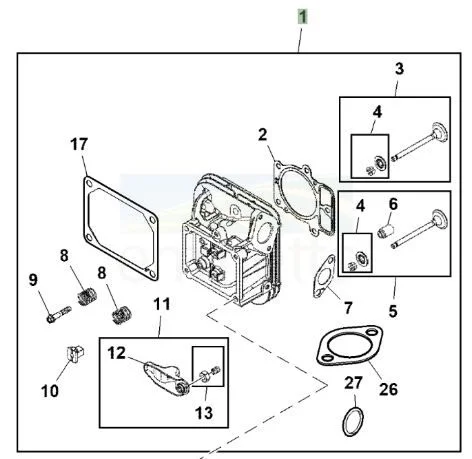

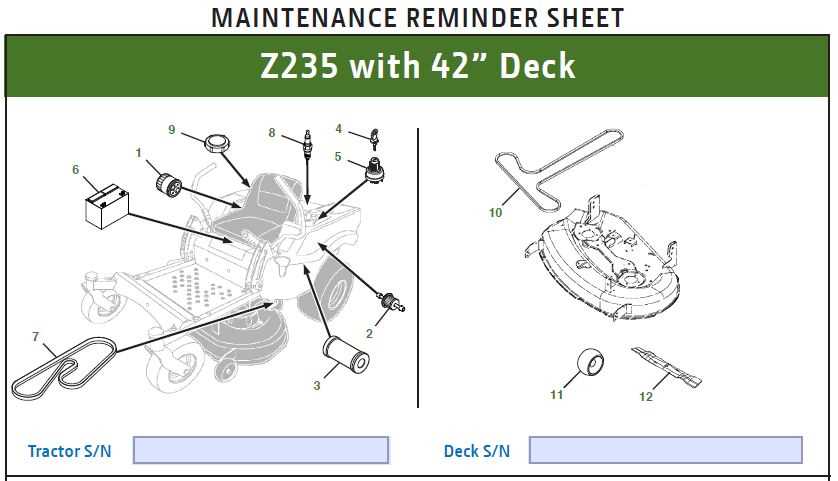

Key Components of SST16 Lawn Mower

Understanding the essential elements of a lawn maintenance machine is crucial for efficient operation and upkeep. Each component plays a vital role in ensuring the equipment functions smoothly, providing users with a reliable tool for yard care.

- Engine: The heart of the machine, providing the necessary power to drive the mower and its various functions.

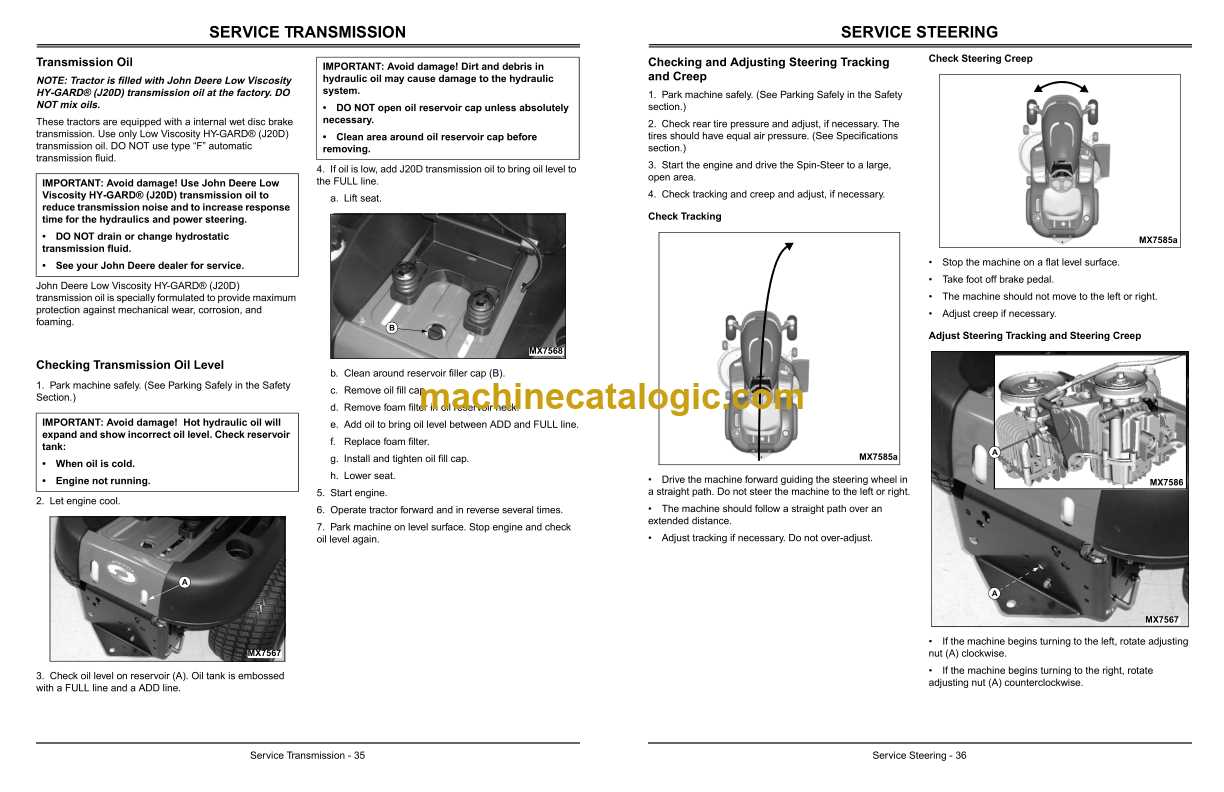

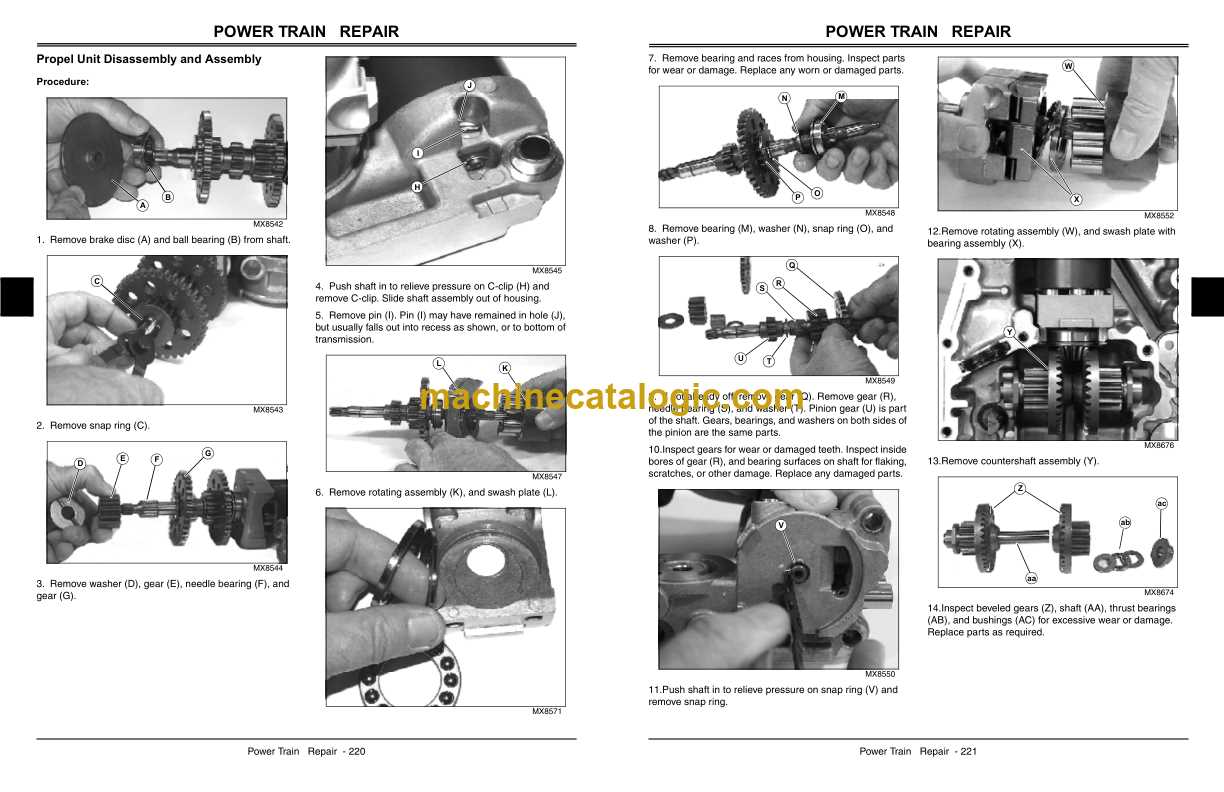

- Transmission: This mechanism transfers power from the engine to the wheels, allowing for smooth movement across different terrains.

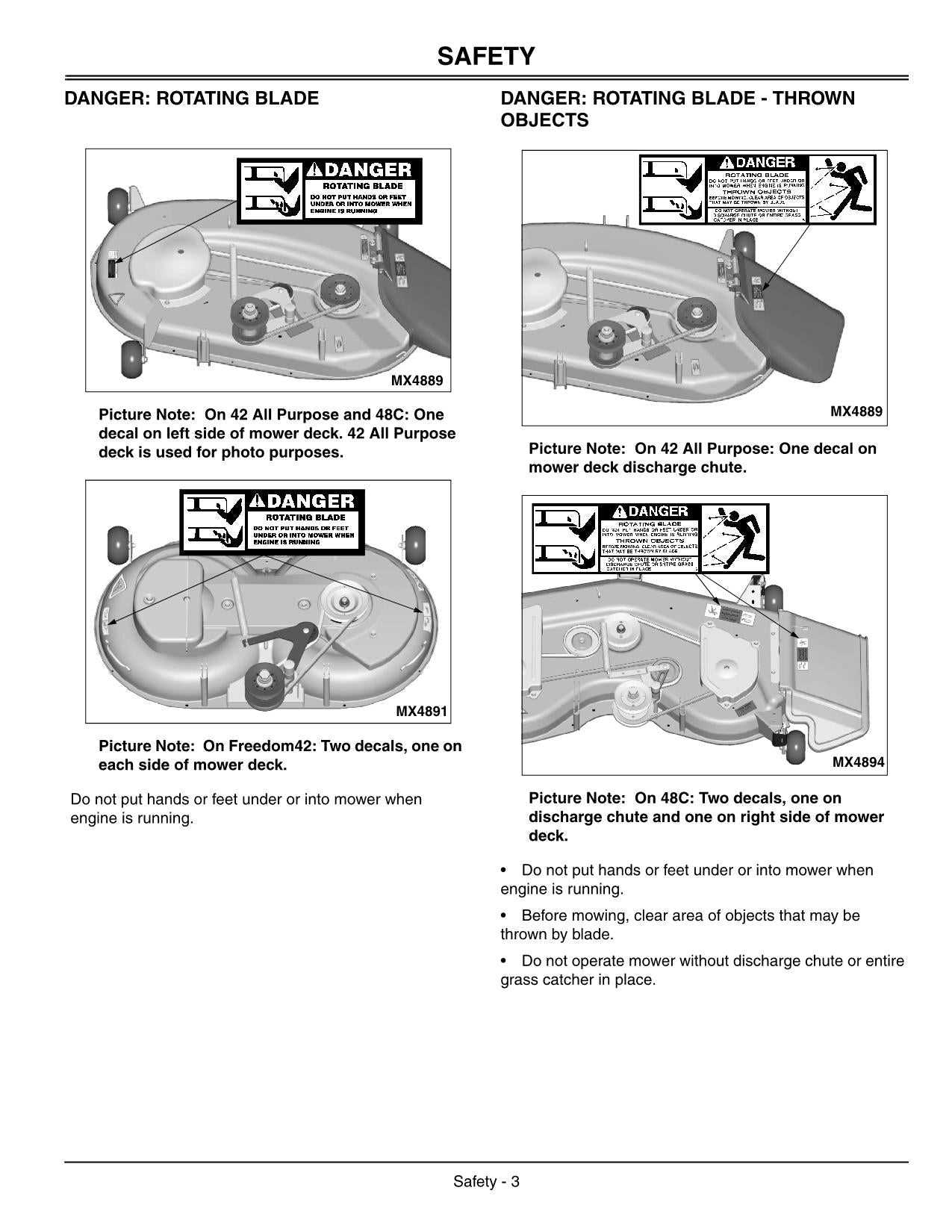

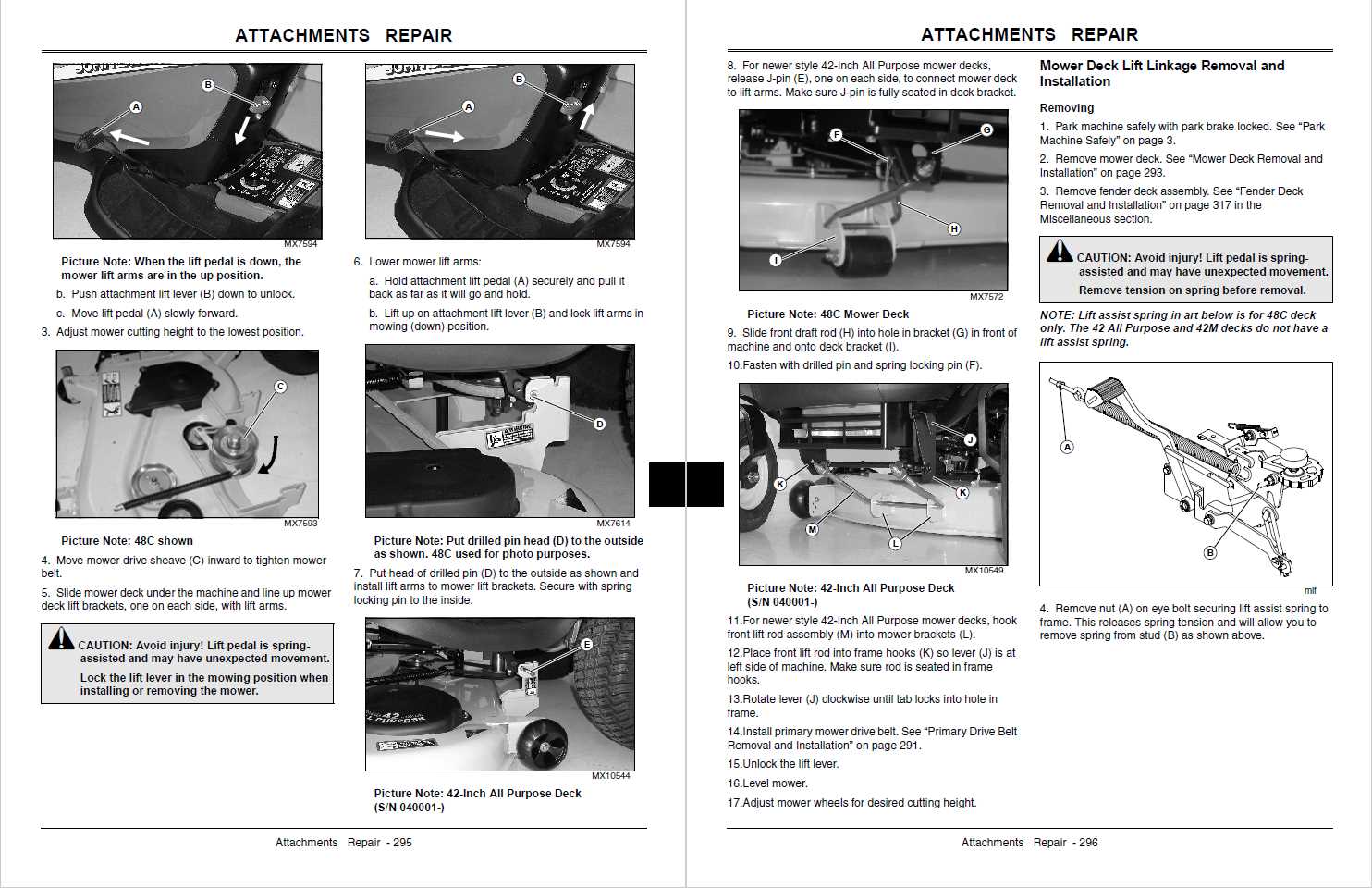

- Deck: The housing that contains the cutting blades, designed to provide an even cut while protecting the user from debris.

- Blades: Sharp tools responsible for trimming grass to the desired height, essential for achieving a well-manicured lawn.

- Wheels: These components support the machine’s mobility, ensuring stability and ease of navigation on various surfaces.

- Fuel System: This includes the tank and lines that store and deliver fuel to the engine, crucial for operation.

- Electrical System: Powers lights and the ignition system, playing a key role in starting the engine and ensuring safety during operation.

By familiarizing oneself with these components, users can better maintain their equipment, troubleshoot issues, and enhance their mowing experience.

How to Access Parts Diagram

Accessing visual schematics for machinery components is essential for maintenance and repairs. These illustrations provide detailed information about each piece, making it easier to identify and source necessary replacements.

Steps to Locate the Visual Schematics

- Visit the official website of the manufacturer.

- Navigate to the support or resources section.

- Search for your specific model or type in the search bar.

- Look for downloadable content or a dedicated section for schematics.

Utilizing Third-Party Resources

- Check online forums and communities dedicated to machinery enthusiasts.

- Explore repair manuals available on e-commerce platforms.

- Use websites that specialize in aftermarket parts and services.

By following these methods, you can easily find the illustrations needed for effective maintenance and repairs, ensuring your equipment runs smoothly.

Common Issues with SST16 Parts

Understanding the typical problems associated with components can enhance maintenance and prolong the lifespan of your equipment. Identifying these challenges early allows for timely interventions, ensuring optimal performance.

Frequent Component Failures

Certain elements may experience wear and tear due to constant usage. Recognizing these can aid in preventing breakdowns.

| Component | Common Issue | Signs of Failure |

|---|---|---|

| Battery | Weak charge | Slow starting |

| Engine | Overheating | Unusual noises |

| Transmission | Slipping | Difficulty shifting |

Preventative Measures

Regular inspections and maintenance can significantly reduce the likelihood of encountering these issues. Establishing a routine check-up schedule is advisable.

Replacement Parts: What to Consider

When it comes to maintaining and repairing machinery, selecting the right components is crucial for optimal performance and longevity. Understanding the various factors that influence the choice of these components can save time and resources while ensuring the equipment operates efficiently.

Quality and Compatibility

One of the primary considerations when sourcing components is their quality and compatibility with existing machinery. High-quality alternatives may provide better durability and reliability, which can lead to lower long-term costs. Always check if the components meet the manufacturer’s specifications and standards.

Cost vs. Value

While price is an important factor, it’s essential to evaluate the overall value of a component. Sometimes, opting for a less expensive option may result in frequent replacements or poor performance. Assess the long-term benefits versus the initial cost to make an informed decision.

| Factor | Consideration |

|---|---|

| Material Quality | Durability and lifespan of the component |

| Brand Reputation | Reliability based on customer feedback |

| Warranty | Protection against defects or failures |

| Availability | Ease of sourcing replacements when needed |

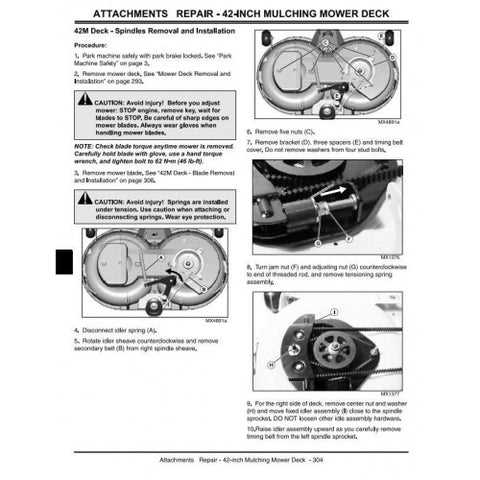

Maintenance Tips for SST16 Users

Proper upkeep is essential for ensuring longevity and optimal performance of your machinery. Regular attention can prevent costly repairs and enhance efficiency. This guide provides essential strategies for maintaining your equipment effectively.

Regular Inspection

Conduct frequent evaluations to identify wear and tear. Focus on key components such as the engine, belts, and tires. Early detection of issues can save time and resources.

Cleaning and Lubrication

Keep the machinery clean to prevent dirt buildup. Regularly lubricate moving parts to reduce friction and extend their lifespan. This simple practice can lead to significant improvements in performance.

| Maintenance Task | Frequency |

|---|---|

| Check Oil Levels | Every 10 hours |

| Inspect Belts | Weekly |

| Clean Air Filter | Monthly |

| Sharpen Blades | Every season |

Tools Needed for Part Replacement

Replacing components in machinery requires specific instruments to ensure efficiency and safety. Having the right tools not only facilitates the process but also minimizes the risk of damage to the equipment. Below is a comprehensive list of essential tools that can assist in the replacement procedure.

- Wrenches: A variety of sizes is crucial for loosening and tightening fasteners.

- Screwdrivers: Both flathead and Phillips types are necessary for different screw types.

- Socket Set: Ideal for reaching nuts and bolts in tight spaces.

- Pliers: Useful for gripping and twisting components during removal and installation.

- Torque Wrench: Ensures fasteners are tightened to the manufacturer’s specifications.

- Hammer: Can assist in loosening stuck parts when used carefully.

Before starting any replacement task, it is advisable to gather these tools and familiarize oneself with their use. Proper preparation leads to a smoother process and better outcomes.

- Safety Gear: Always wear gloves and safety glasses to protect against injuries.

- Work Light: Adequate lighting helps in spotting small components and ensuring visibility in dim areas.

- Parts Organizer: Keeps small components sorted and prevents loss during the replacement process.

By equipping yourself with the necessary tools, you can effectively navigate the challenges of component replacement and maintain the machinery in optimal condition.

Comparing SST16 with Similar Models

This section explores the distinctions and similarities between a specific model and its counterparts in the same category. By analyzing features, performance, and user feedback, we aim to provide a comprehensive overview for potential buyers.

Key Features

- Engine power and efficiency

- Cutting capabilities and deck size

- Durability and build quality

User Experience

- Ease of operation

- Maintenance requirements

- Warranty and customer support options

Understanding these aspects allows users to make informed decisions based on their specific needs and preferences, ultimately enhancing their ownership experience.

Where to Buy SST16 Parts

Finding components for your machinery can be a straightforward task if you know where to look. Numerous options exist to source quality replacements, ensuring your equipment remains operational and efficient.

Online Retailers

Many online platforms specialize in selling various machine components. Websites like Amazon and specialized retailers offer a wide range of options, often with user reviews to help you make informed choices.

Local Suppliers

Your local equipment dealer or repair shop may stock necessary components or can order them for you. Establishing a relationship with these suppliers can also lead to valuable advice on maintenance and compatibility.

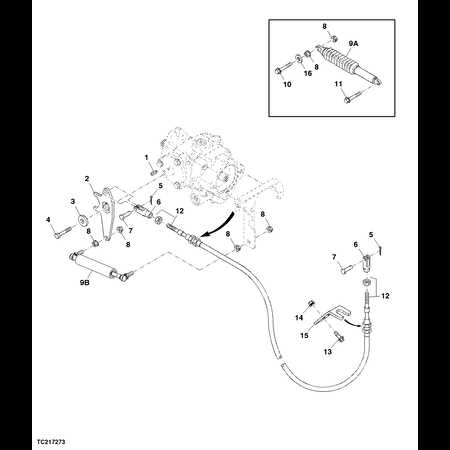

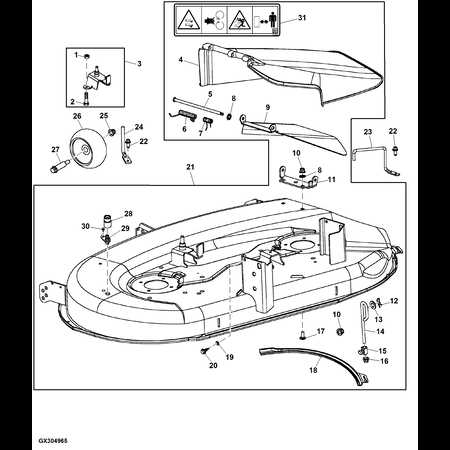

How to Read Parts Diagrams

Understanding technical illustrations is essential for efficient maintenance and repair of machinery. These visual representations serve as a guide, enabling users to identify components and their relationships within a system. Familiarity with these images enhances comprehension and aids in locating specific items when needed.

To effectively interpret these illustrations, one should follow a few key steps:

| Step | Description |

|---|---|

| 1 | Familiarize yourself with the overall layout. Note the orientation and arrangement of various elements. |

| 2 | Identify the legend or key. This section provides crucial information regarding symbols and annotations. |

| 3 | Examine each section closely. Focus on the individual components and how they connect to one another. |

| 4 | Look for reference numbers or codes associated with each item. These help in cross-referencing with catalogs for procurement. |

| 5 | Consider any notes or instructions that accompany the visuals. They often provide important context or assembly guidance. |

By following these steps, one can gain a clearer understanding of technical illustrations, leading to more effective maintenance and repair efforts.

Ultimate Guide to SST16 Repair

This comprehensive guide aims to provide you with essential insights and techniques for effectively restoring and maintaining your equipment. Understanding the intricacies of repair will enhance performance and prolong lifespan, ensuring your machine operates at its best.

| Component | Common Issues | Repair Tips |

|---|---|---|

| Engine | Overheating, noise | Check oil levels, clean filters |

| Transmission | Slipping, grinding | Inspect fluid levels, replace seals |

| Electrical System | Flickering lights, dead battery | Test connections, clean terminals |

| Blades | Dull, uneven cuts | Sharpen regularly, check alignment |

By following these guidelines, you can delve deeper into each area, ensuring your machinery remains reliable and efficient for all your tasks.