The proper understanding of equipment structure is key for maintaining efficiency and ensuring longevity. Various elements work together seamlessly, contributing to the overall functionality. Regular checks and timely replacements are important for keeping everything in optimal condition.

Comprehensive breakdowns are useful when determining which elements need attention. By following a detailed layout, one can easily identify the specific areas requiring maintenance or upgrades. Ensuring that each component is in working order can significantly extend the equipment’s lifespan.

Understanding the John Deere XT120

This model is known for its reliability and durability in handling various tasks. Its design is optimized for efficiency, allowing for smooth operation and long-term use. The system integrates various components, each playing a crucial role in maintaining functionality and performance. By understanding how these elements work together, users can better maintain and troubleshoot the equipment.

Main Components

The machine consists of several critical systems that contribute to its overall efficiency. Below is a summary of these systems:

| Component | Function |

|---|---|

| Engine | Provides the necessary power for operation |

| Transmission | Ensures smooth control and movement |

| Hydraulic System | Assists in lifting and maneuvering attachments |

| Electrical System | Controls and powers various functions |

Maintenance Tips

To ensure longevity, it is essential to regularly check fluid levels, inspect for wear and tear, and perform necessary adjustments. Timely maintenance will prevent breakdowns and extend the lifespan of the machine.

Key Components of XT120 Machinery

This machinery is known for its reliable construction and well-thought-out structure, designed to ensure durability and efficient operation in various conditions. The following elements play a crucial role in the overall performance, contributing to the seamless functionality of the equipment.

Core Mechanical Elements

- Engine block for powerful and steady operation

- Transmission system that ensures smooth movement and control

- Hydraulic system for efficient power distribution

Essential Supporting Components

- Cooling unit for optimal temperature regulation

- Fuel system that maximizes energy usage

- Steering mechanism providing precise navigation

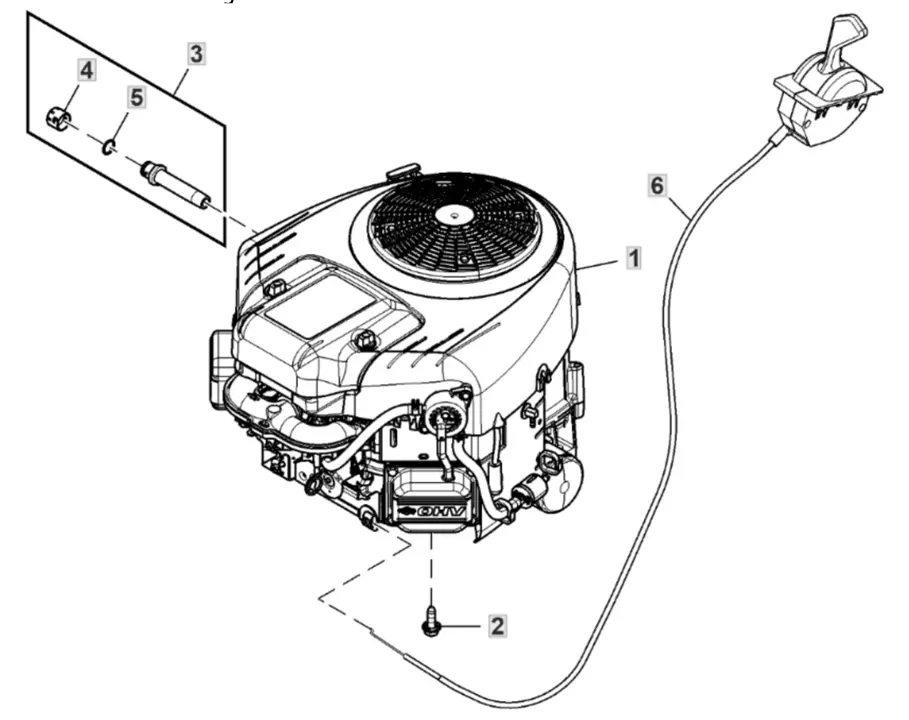

Diagrams for Engine Assembly

Understanding the layout and arrangement of components within an engine is essential for maintenance and repair. Visual representations provide a clear overview of how individual parts are positioned and how they interact with each other during operation. This section offers detailed visual guides to help in identifying and assembling the necessary elements for a functional engine.

Main Components Overview

The engine consists of various interconnected sections that work together to generate power. Below is a structured representation of key areas, including the combustion chamber, pistons, crankshaft, and valve mechanisms, allowing for easier identification of their locations and functions.

| Component | Function | Position |

|---|---|---|

| Combustion Chamber | Where fuel and air mix and ignite | Upper engine block |

| Pistons | Transfer energy from combustion | Within cylinder walls |

| Crankshaft | Converts piston movement into rotational motion | Lower engine block |

| Valves | Control the intake of air and fuel | Above pistons |

Hydraulic System Breakdown

The hydraulic system is an essential component in the operation of various machinery. It enables the smooth transfer of power, allowing the equipment to perform tasks efficiently and reliably. Understanding the layout and functionality of this system is crucial for maintenance and troubleshooting.

Pumps play a vital role in generating the necessary pressure within the system. These components ensure that the hydraulic fluid circulates effectively, supplying the required force to the operational elements.

The valves are responsible for directing the flow of the fluid, ensuring that the right amount of pressure reaches each component. They help maintain control over the equipment’s movements and functions.

Cylinders are the parts that convert hydraulic energy into mechanical force. They extend and retract based on the pressure applied by the fluid, driving various mechanical actions within the machine.

Wiring and Electrical Parts Overview

The electrical system plays a critical role in ensuring the smooth functioning of various components. Proper connections and reliable wiring are key to maintaining the performance and longevity of the system. A well-maintained electrical setup can prevent failures and ensure efficient operation across different conditions.

| Component | Description |

|---|---|

| Wiring Harness | Connects various electrical elements, ensuring stable transmission of power. |

| Fuses | Protect circuits by preventing excessive current flow and potential damage. |

| Switches | Enable the control of electrical flow to specific areas or systems. |

| Relays | Control higher p

Transmission Parts and FunctionsThe components involved in the transfer of power play a crucial role in the efficiency and functionality of machinery. Understanding their individual functions can greatly enhance performance and maintenance strategies.

Each of these elements contributes to the overall performance and efficiency of the machinery, making knowledge of their roles vital for effective operation and maintenance. Steering Mechanism Layout

The steering mechanism is a crucial component that ensures effective maneuverability and control of the vehicle. Understanding its configuration is essential for maintaining optimal performance and safety. This section outlines the arrangement and functionality of the steering elements, highlighting their interconnections and roles within the system. Components of the Steering SystemAt the core of the steering layout, various parts work together to facilitate directional changes. Key elements include the steering wheel, linkages, and the pivot point. Each component plays a significant role in transmitting the driver’s input to the wheels, enabling precise navigation. Functionality and InteractionThe interaction between the components is vital for achieving smooth operation. When the steering wheel is turned, it activates the linkages that adjust the angle of the wheels. This seamless communication allows for responsive handling, essential for a safe driving experience. Fuel System Components ExplainedThe fuel system is crucial for the efficient operation of any engine. It consists of various elements that work together to ensure that the right amount of fuel is delivered to the engine for optimal performance. Understanding these components can help in maintaining and troubleshooting fuel-related issues. One of the key parts is the fuel tank, which stores the fuel before it is sent to the engine. Fuel lines are responsible for transporting the fuel from the tank to the engine, while the fuel pump ensures a steady flow. Additionally, the fuel filter plays a vital role in removing impurities, safeguarding the engine from potential damage. Another important component is the fuel injector, which atomizes the fuel for efficient combustion. In some systems, a carburetor may be present, mixing air and fuel to create the right mixture for combustion. Each of these elements must function properly to maintain the overall efficiency of the fuel system. Cooling System Diagram and PartsThe cooling mechanism of machinery is essential for maintaining optimal performance and preventing overheating. Understanding the components involved in this system is crucial for effective maintenance and troubleshooting. This section provides an overview of the various elements that make up the cooling arrangement and how they function together. Key Components of the Cooling Arrangement

Maintenance Tips

Chassis and Frame StructureThe framework and chassis of a vehicle play a crucial role in its overall performance and stability. This section explores the essential components and configurations that contribute to the structural integrity and functionality of the machine. Key Components

Structural ConsiderationsUnderstanding the arrangement of the framework is vital for maintenance and repairs. Proper alignment and reinforcement can prevent premature wear and enhance longevity.

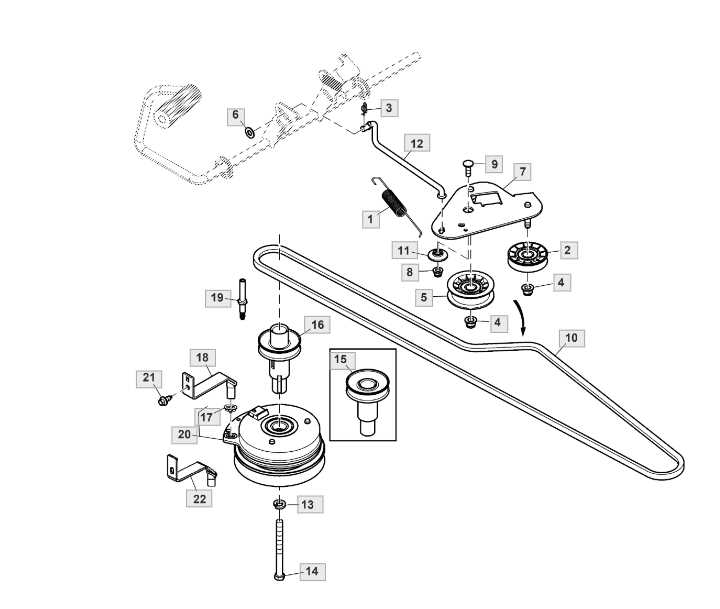

Maintenance and Replacement GuidelinesProper upkeep and timely substitutions are essential for the longevity and efficiency of any machinery. Regular attention to the components ensures optimal performance and helps avoid unforeseen breakdowns. Establishing a consistent maintenance routine can significantly extend the life of your equipment. Routine Checks and ServicingConduct frequent inspections of the system to identify wear and tear. Focus on key elements such as belts, filters, and fluids. Keeping a checklist can help ensure that no aspect is overlooked during the servicing process. Replacement ProceduresWhen it comes to replacing worn-out components, follow the manufacturer’s guidelines closely. Ensure that the replacements match the specifications required for seamless integration. Proper installation is crucial to maintaining the overall functionality of the machinery. Frequently Replaced XT120 PartsWhen maintaining outdoor machinery, certain components often require replacement due to wear and tear. Understanding which elements commonly need attention can help ensure optimal performance and longevity. Regular checks and timely updates of these critical elements can prevent larger issues down the line. Common ComponentsAmong the various elements, some of the most frequently replaced include filters, belts, and blades. Filters play a vital role in keeping the engine clean, while belts are essential for efficient operation. Blades, on the other hand, are crucial for achieving a precise cut, making their condition particularly important. Maintenance TipsTo maintain functionality, it is advisable to inspect these components regularly. Replacing them as needed not only improves efficiency but also extends the life of the machinery. Keeping an eye on wear indicators and adhering to the manufacturer’s recommendations can make a significant difference in overall performance. |