Understanding the internal makeup of a reliable tool can be essential for both maintenance and repairs. Every device is made up of various elements that work together, ensuring smooth operation and longevity. To effectively service or upgrade such tools, it’s important to become familiar with their key features and how they function as a unit.

When delving into the inner workings of a power device, it becomes clear that each component plays a specific role in ensuring the tool operates efficiently. Whether you’re focusing on the electrical system, mechanical parts, or other essential elements, having a clear idea of their arrangement and functionality can make troubleshooting and maintenance much easier.

In this guide, we will take a closer look at the main elements of one popular tool model, providing insights into its construction. This knowledge will not only help you perform repairs but also give you a deeper appreciation of how these tools are engineered for durability and performance.

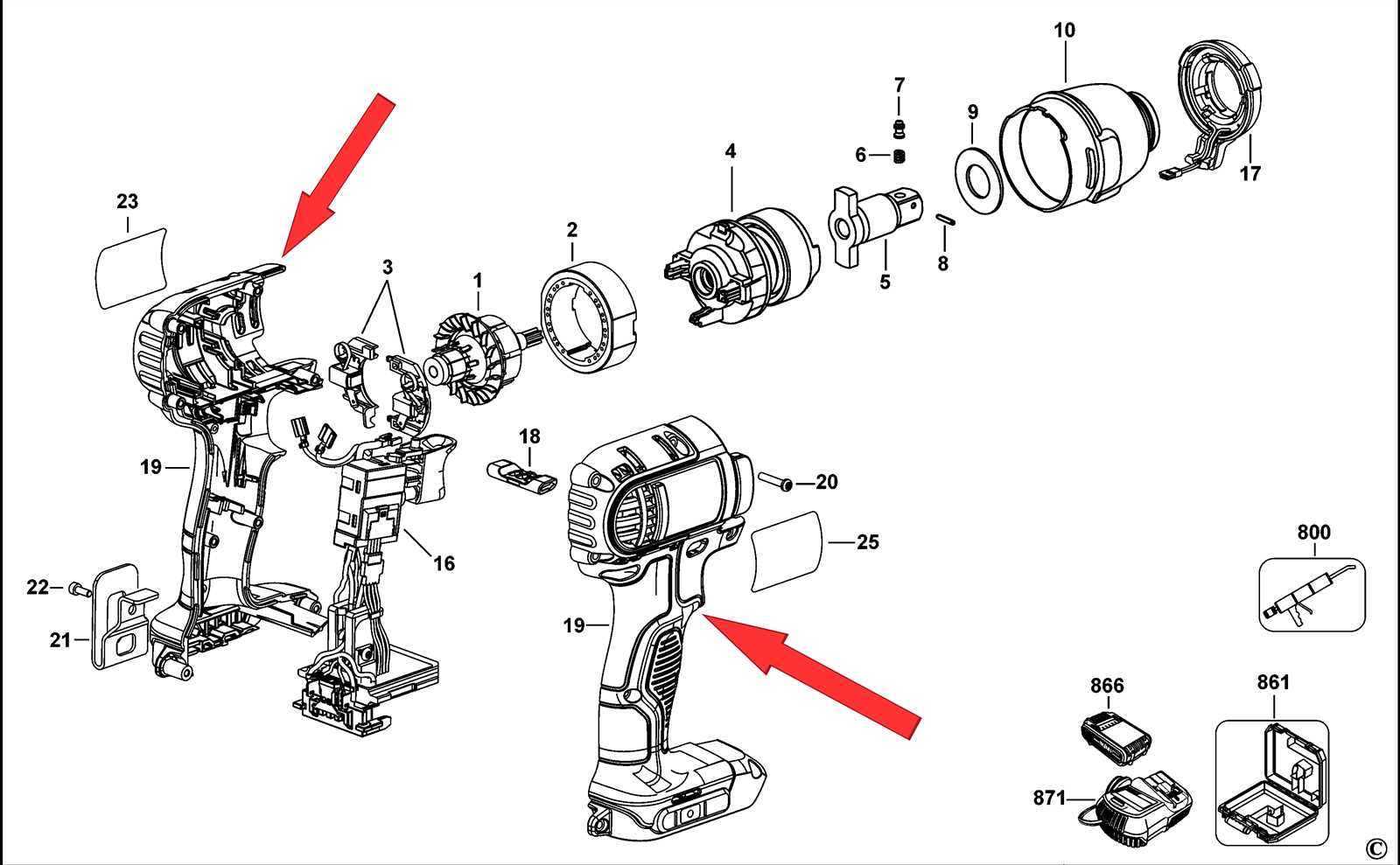

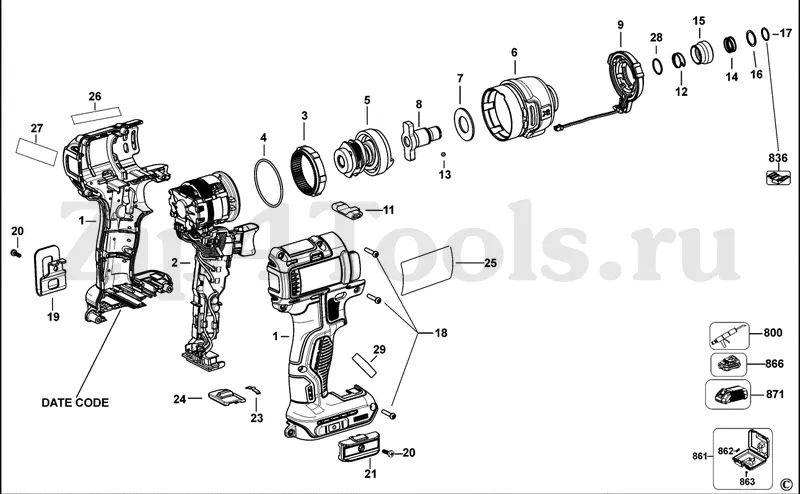

Key Components of the DCD791 Drill

This powerful tool consists of several essential elements that work together to ensure efficient performance. Each component plays a specific role in enhancing the durability, functionality, and overall user experience. By understanding these key features, you can better appreciate how this equipment delivers reliable results in various tasks.

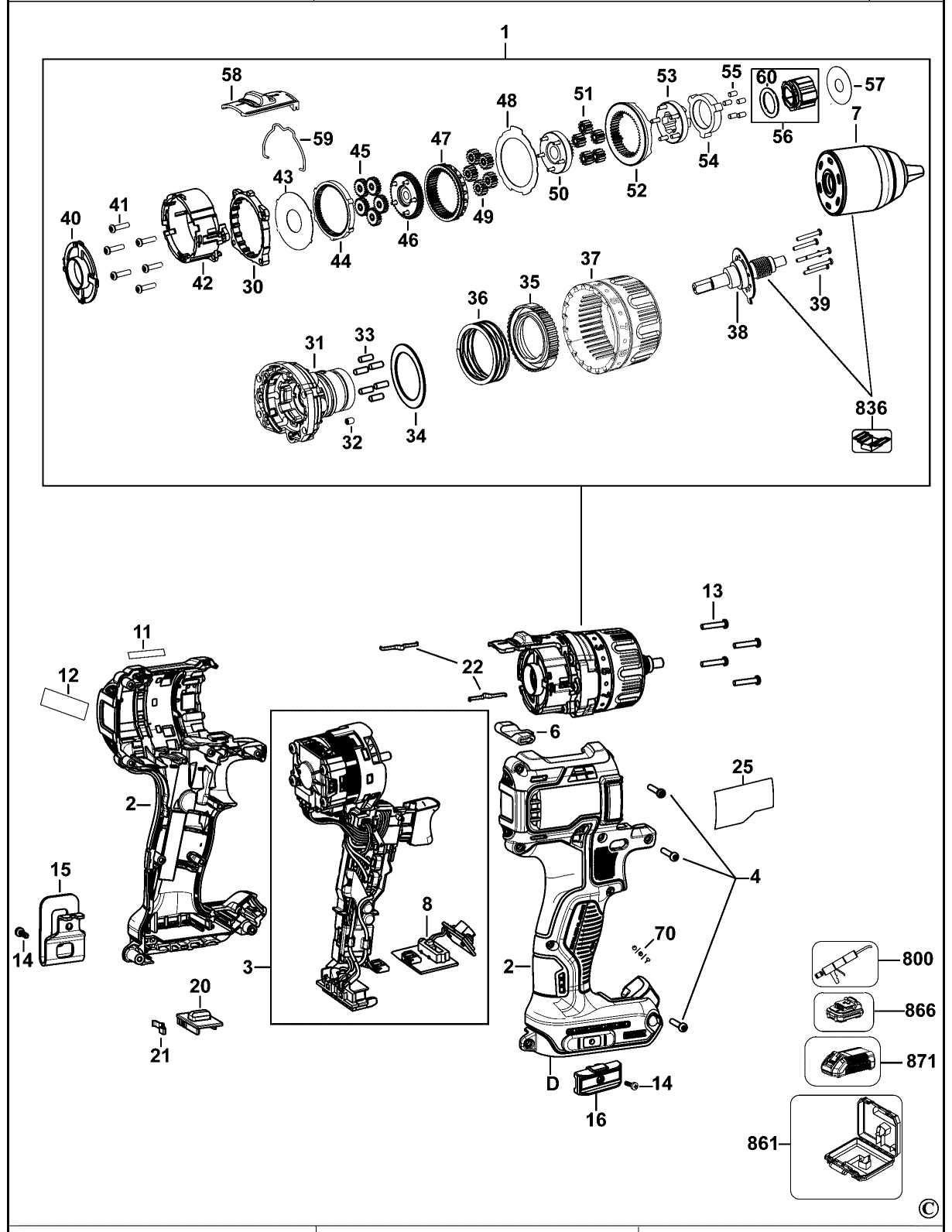

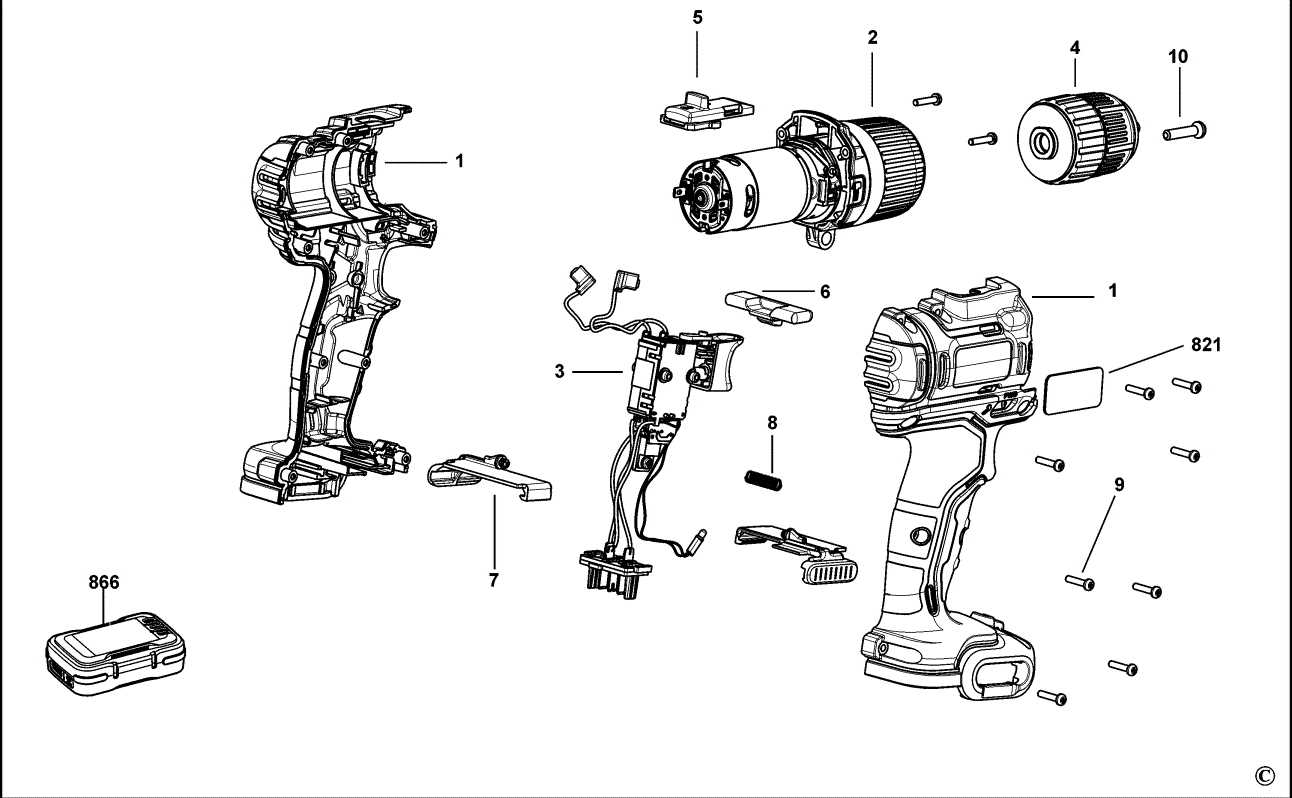

Motor and Transmission System

The core of the drill is its motor, which provides the necessary power for drilling and fastening. The transmission system optimizes speed and torque, allowing the user to adjust to different materials and applications. This balance between strength and precision is crucial for achieving professional-grade outcomes.

Ergonomic Design and Grip

Another important aspect is the ergonomic design, which enhances comfort during prolonged use. The textured grip ensures a secure hold, reducing fatigue and improving control. Combined with its lightweight structure, this feature makes the tool easy to maneuver, even in tight or awkward spaces.

Understanding the Motor and Its Role

The driving force behind any cordless tool is its motor. This key component is responsible for converting electrical energy into mechanical power, allowing the tool to function efficiently and handle demanding tasks.

Core Functionality of the Motor

At its heart, the motor takes energy from the battery and translates it into rotational motion, which is essential for drilling and fastening operations. The speed and torque are managed through internal mechanisms that optimize performance based on the task at hand.

- Speed Control: The motor adjusts to different levels of speed depending on user input, ensuring precision during various stages of work.

- Torque Management: By regulating torque, the motor provides enough force to handle tough materials while preventing damage to the tool.

Advantages of an Efficient Motor

An effective motor not only enhances performance but also contributes to the lon

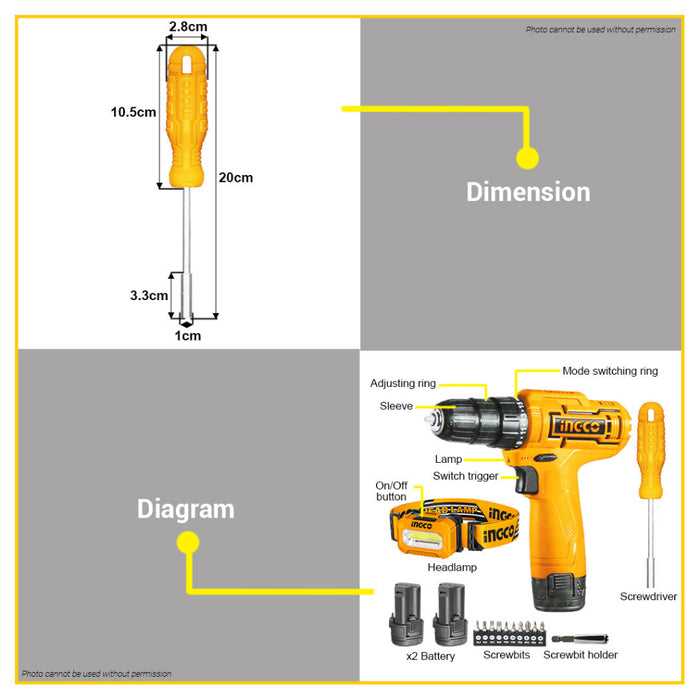

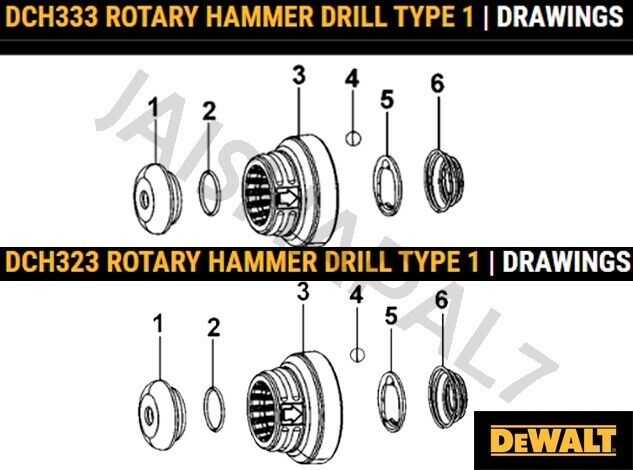

How the Chuck Mechanism Operates

The chuck is an essential component that allows for the secure attachment of various tools. Its main function is to hold and release bits or other attachments, providing a stable grip during operation. The design ensures quick changes while maintaining a firm hold on the accessory in use.

Inside, the chuck uses a series of jaws that contract and expand, gripping the bit with precision. This is achieved through a simple yet effective rotation mechanism. As the outer ring is turned, the internal jaws either tighten or loosen, depending on the direction of the rotation.

Durability and ease of use are key features of this mechanism. The materials used in its construction allow it to endure significant stress without compromising performance. Additionally, the simplicity of its operation makes it highly reliable, even in demanding tasks.

Battery Compatibility and Maintenance Tips

Ensuring the right power source for your equipment is essential for maintaining its performance and longevity. By selecting compatible power units and following key care guidelines, you can enhance both efficiency and durability. Keeping your tool powered with the appropriate energy source while adopting proper upkeep practices will prevent wear and extend its usability.

When choosing a power unit, always confirm that it fits the specific requirements of your tool model. Mismatched energy sources can lead to reduced performance or even potential damage. For optimal results, refer to the manufacturer’s guidelines on compatible power units.

Proper maintenance of power units is crucial for their longevity. Regularly check for dirt and debris on the connectors, as these can interfere with proper function. Store your power sources in a cool, dry place and avoid exposure to extreme temperatures, which can significantly reduce their lifespan. Periodically cycle the charge by fully draining and recharging, which helps maintain optimal capacity.

By following these simple steps, you can ensure that your tool remains efficient and reliable, ready to handle any task with consistent power and performance.

Examining the Gearbox Functionality

The inner workings of any mechanical tool rely heavily on the efficient performance of its transmission mechanism. Understanding how this component operates is crucial for ensuring smooth power transfer and durability in various tasks. In this section, we will explore the role of the gearbox, focusing on its ability to modulate speed and torque for different applications.

Speed and Torque Regulation

The gearbox is responsible for adjusting rotational speed and torque, allowing users to choose between high-speed, low-torque settings or slower speeds with enhanced power. This versatility is critical for adapting to different tasks, ensuring that the tool can handle both delicate operations and more demanding workloads.

Durability and Maintenance

Proper maintenance of the gearbox is essential to extend its lifespan and maintain optimal performance. Regular lubrication and inspection can prevent wear and tear, ensuring that the gears mesh smoothly and efficiently. Failure to address these needs can result in reduced performance, leading to costly repairs or even replacement of the entire mechanism.

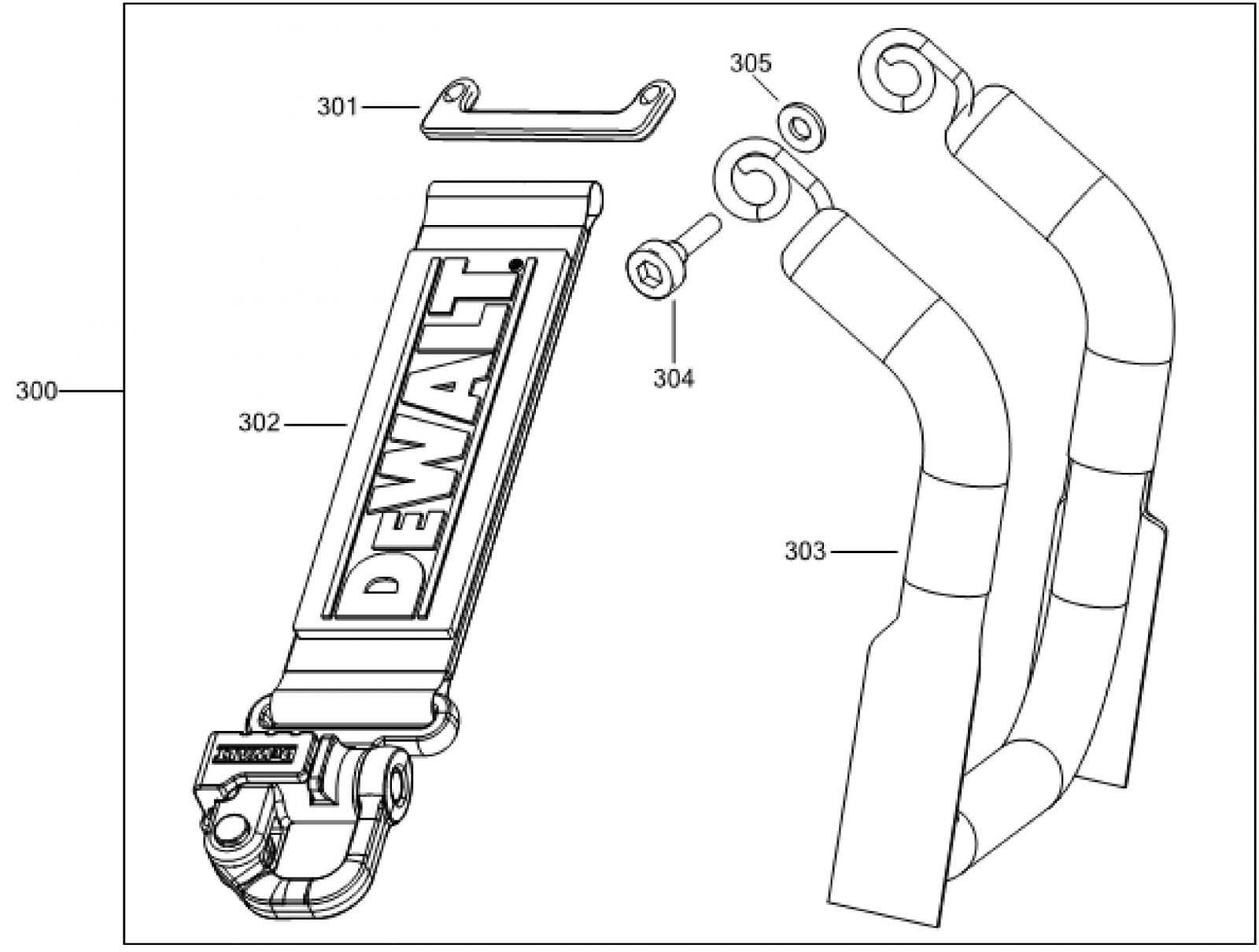

Trigger Assembly: Usage and Replacement

The trigger assembly serves as a vital component in power tools, facilitating user control over the device’s operation. Understanding its functionality and the process for replacement is essential for maintaining optimal performance and safety. This section delves into the purpose of the trigger assembly and provides insights on how to effectively replace it when necessary.

Functionality of the Trigger Mechanism

The trigger mechanism allows the operator to engage and disengage the tool effortlessly. Its design ensures that power delivery is smooth and responsive, enabling precise handling during various applications. Key aspects include:

- Control: Enables variable speed and torque adjustments.

- Safety: Prevents accidental activation when not in use.

- Durability: Built to withstand repeated use and pressure.

Steps for Replacement

Replacing the trigger assembly is straightforward, provided you follow these steps carefully:

- Gather Necessary Tools: Ensure you have the right tools, such as a screwdriver, pliers, and replacement components.

- Disassemble the Housing: Remove screws and carefully open the tool’s casing to access the trigger assembly.

- Disconnect the Trigger: Carefully detach the existing trigger from its connections.

- Install the New Trigger: Align the new component correctly and connect it securely.

- Reassemble the Tool: Close the housing, ensuring all screws are tightened properly.

- Test Functionality: Before full use, test the tool to confirm that the trigger operates smoothly.

By understanding the role of the trigger assembly and following proper replacement procedures, users can ensure their tools remain efficient and reliable over time.

Understanding the LED Light System

The illumination feature in power tools plays a crucial role in enhancing visibility during operation. This technology is designed to provide adequate lighting in dimly lit environments, ensuring users can work safely and effectively. The integration of LED lights allows for improved focus on tasks, reducing the chances of errors and enhancing overall efficiency.

Typically, the LED lighting system is strategically positioned to illuminate the working area directly in front of the tool. This positioning minimizes shadows and highlights specific areas, allowing users to maintain precision while performing various tasks. Furthermore, the LED technology is energy-efficient, contributing to the longevity of the tool’s battery life while providing bright and consistent lighting.

Many modern tools also feature adjustable lighting options, allowing users to select different brightness levels based on their needs. This versatility ensures that whether working in tight spaces or larger areas, users can customize the lighting to suit their specific requirements. Overall, understanding the functionality and advantages of the LED illumination system enhances the user experience, making tasks easier and more enjoyable.

Housing Design and Structural Integrity

The design of the outer casing of power tools plays a pivotal role in their overall performance and durability. A well-constructed housing not only protects internal components but also enhances user comfort and operational efficiency. This section explores the critical aspects of housing design, focusing on materials, structural integrity, and the influence of ergonomic factors.

Material Selection

Choosing the right materials is essential for ensuring the robustness and longevity of the outer shell. Commonly utilized materials include high-grade plastics and metals, each offering unique advantages:

| Material Type | Advantages | Disadvantages |

|---|---|---|

| High-Grade Plastic | Lightweight, corrosion-resistant | Less heat resistance |

| Aluminum | Durable, excellent heat dissipation | Heavier than plastic |

Structural Considerations

Effective housing design incorporates structural elements that enhance strength and reduce the risk of failure. Features such as reinforced corners and strategic ribbing can significantly improve rigidity. Additionally, a thoughtful design ensures proper weight distribution, which contributes to overall tool balance and user control.

Clutch System: Features and Benefits

The clutch mechanism is a pivotal component in power tools, ensuring optimal control over torque and preventing potential damage during operation. This system allows users to tailor the tool’s performance according to the material being worked on, enhancing precision and efficiency. By engaging and disengaging power transmission, it facilitates seamless transitions between tasks, providing a versatile solution for various applications.

Enhanced Control

One of the primary advantages of the clutch system is its ability to offer enhanced control. Users can adjust the torque settings to match specific requirements, which minimizes the risk of stripping screws or damaging workpieces. This feature is particularly beneficial when working with delicate materials or when precision is paramount.

Durability and Longevity

Moreover, the inclusion of a clutch system contributes to the overall durability and longevity of the tool. By reducing unnecessary strain on internal components, it helps to prevent wear and tear, ensuring that the equipment remains reliable over extended periods. This characteristic not only enhances performance but also provides peace of mind to users, knowing that their investment is protected.

Control Board: Ensuring Precision

The control board serves as the brain of a power tool, orchestrating its functions with remarkable accuracy. This crucial component is responsible for regulating various operational parameters, ensuring that the device performs optimally under different conditions. A well-designed control board is essential for achieving the desired performance, providing both efficiency and reliability.

At the heart of the control board lies a sophisticated network of circuits that monitor and manage power delivery to the tool’s motor. This enables the user to maintain precise control over speed and torque, facilitating a variety of tasks with ease. Regular maintenance and timely replacement of this component can significantly enhance the lifespan and functionality of the equipment.

Moreover, the control board plays a vital role in safety features, preventing overheating and other potential hazards. By integrating advanced technology, it contributes to a seamless user experience, allowing for smooth operation and consistent results. Investing in a high-quality control board ensures that the tool operates efficiently, making it an indispensable element in the overall performance of any power device.

Durability of External Materials

When assessing the longevity and resilience of tools, the choice of external materials plays a crucial role. High-quality components contribute significantly to the overall performance and reliability of equipment. Understanding the factors influencing material strength helps users select tools that can withstand demanding conditions.

Several key aspects define the durability of external materials:

- Material Composition: The type of materials used, such as reinforced plastics or metals, affects resistance to wear and impact.

- Coating and Finish: Protective coatings enhance resistance to corrosion and scratches, extending the lifespan of the outer surfaces.

- Structural Design: Innovative design elements improve shock absorption and stress distribution, minimizing the risk of damage during use.

Ultimately, selecting equipment with robust external materials ensures reliability and performance even in the most challenging environments.