Comprehending the intricate components that constitute a modern automobile is essential for any enthusiast or mechanic. This exploration not only enhances maintenance skills but also deepens one’s appreciation for automotive engineering. By dissecting the various elements, individuals can identify issues and optimize performance.

In this section, we will delve into the layout of crucial components within a specific model, providing insights into their functions and relationships. Recognizing how these elements interact can lead to more effective troubleshooting and repairs, ensuring longevity and reliability.

Ultimately, gaining a visual representation of these mechanical structures empowers individuals to tackle challenges with confidence. This knowledge serves as a foundation for more advanced automotive concepts, paving the way for future exploration and expertise.

Understanding the 2005 Honda CR-V Engine

This section delves into the intricate workings of a popular compact SUV’s power unit, exploring its components and functionalities. Understanding the core elements can enhance your appreciation of how this vehicle operates and performs on the road.

Key Components of the Power Unit

The heart of this vehicle consists of various critical components that work in harmony. These include the cylinder block, crankshaft, and camshaft, which are essential for converting fuel into mechanical energy. Additionally, the intake and exhaust systems play vital roles in maintaining optimal airflow, contributing to efficiency and performance.

Maintenance and Troubleshooting

Regular maintenance is crucial for longevity and reliability. Common practices include checking fluid levels, replacing filters, and inspecting belts and hoses. Understanding potential issues, such as overheating or unusual noises, can help in early detection and prevent more serious problems down the line.

In summary, a thorough comprehension of the essential elements and maintenance of the power unit can significantly enhance vehicle performance and reliability, ensuring a smooth driving experience.

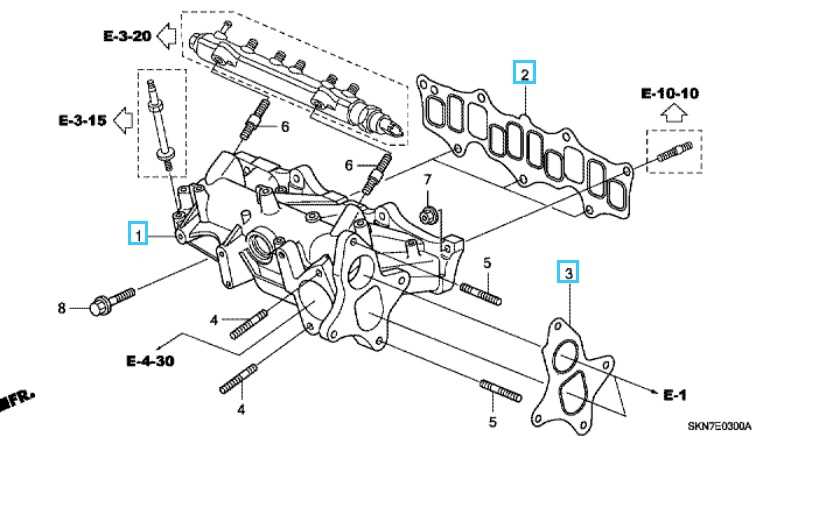

Key Components of the Engine System

The heart of any vehicle’s performance lies within its core assembly, where various elements work in harmony to convert fuel into motion. Understanding these critical components is essential for anyone looking to grasp the mechanics behind a vehicle’s operation. Each piece plays a pivotal role, ensuring efficiency, power delivery, and overall functionality.

Core Elements of the Powertrain

At the forefront of this assembly is the combustion chamber, where fuel and air mix to create explosive energy. This reaction propels the pistons, which are vital for transforming that energy into rotational force. Alongside this, the crankshaft serves as a central axis, translating linear motion into the circular motion necessary for driving the wheels.

Supporting Components

Equally important are the valvetrain components, which regulate the intake and exhaust of gases. This system includes valves, springs, and timing mechanisms that synchronize the opening and closing actions with the movement of the pistons. Additionally, the cooling system ensures that the assembly operates within optimal temperature ranges, preventing overheating and maintaining performance integrity.

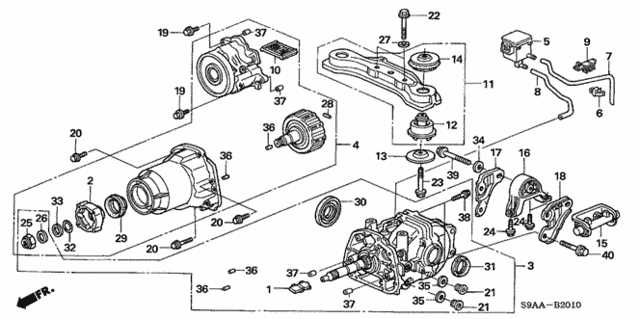

How the Engine Diagram Helps Mechanics

Understanding the layout and components of a vehicle’s propulsion system is crucial for technicians. Visual representations serve as essential tools, allowing for quicker identification of elements and their relationships. This clarity facilitates efficient troubleshooting and maintenance, ultimately enhancing performance.

Diagrams provide a comprehensive overview, enabling mechanics to delve into specific areas with confidence. They can pinpoint issues without unnecessary guesswork, leading to faster repairs and improved accuracy. Such resources are invaluable, especially when addressing complex systems.

Moreover, these illustrations foster a deeper understanding of how various components interact, aiding in preventive maintenance and optimizing overall functionality. Mechanics who utilize these visuals often achieve superior results, making them indispensable in the automotive field.

Common Issues with the 2005 CR-V Engine

The reliability of any vehicle can be compromised by various mechanical challenges. Understanding these potential pitfalls is crucial for maintaining optimal performance and ensuring longevity. Many drivers have encountered recurring problems that can affect both efficiency and safety.

Overheating is a frequent concern, often stemming from coolant leaks or malfunctioning thermostats. This can lead to serious damage if not addressed promptly. Keeping an eye on temperature gauges and fluid levels can help prevent severe issues.

Oil leaks are another common dilemma. Seals and gaskets can wear down over time, resulting in loss of vital lubricants. Regular inspections and timely replacements are essential to avoid engine wear and maintain proper functioning.

Fuel system problems may arise as well, often due to clogged injectors or a failing pump. These issues can lead to poor acceleration and decreased fuel efficiency. Routine maintenance can help identify these problems before they escalate.

Electrical faults can also affect performance, particularly with sensors and ignition systems. These components are critical for smooth operation, and malfunctions can trigger warning lights and erratic behavior.

Being aware of these typical issues allows for proactive care, helping drivers to keep their vehicles running smoothly and efficiently.

Visual Breakdown of Engine Parts

This section provides an insightful overview of the various components found within a vehicle’s power unit, focusing on their roles and interactions. Understanding these elements is crucial for anyone interested in automotive mechanics and performance enhancement.

Key Components Overview

- Cylinders

- Pistons

- Crankshaft

- Camshaft

- Timing belt

Functional Importance

- Cylinders: Where combustion occurs, generating power.

- Pistons: Transfer energy from combustion to mechanical movement.

- Crankshaft: Converts linear motion to rotational motion.

- Camshaft: Controls the timing of valve openings and closings.

- Timing belt: Synchronizes the movement of critical components.

Maintenance Tips for CR-V Owners

Keeping your vehicle in top shape requires regular attention and care. Adopting a proactive approach to maintenance can enhance performance, extend lifespan, and ensure safety. Here are some essential practices every owner should follow.

Regular Fluid Checks

Monitoring and replacing fluids is crucial for optimal functioning. Check the oil, coolant, brake fluid, and transmission fluid levels regularly. Clean, fresh fluids help prevent mechanical failures and improve overall performance.

Tire Care

Maintaining proper tire pressure and tread depth is vital for safety and efficiency. Inspect your tires frequently for signs of wear and rotate them as recommended. This not only extends tire life but also contributes to better fuel economy and handling.

Importance of Regular Engine Inspections

Conducting routine assessments of your vehicle’s mechanical components is crucial for maintaining optimal performance and longevity. These evaluations help identify potential issues before they escalate, ensuring that all systems operate smoothly and efficiently.

Regular check-ups not only enhance the reliability of your automobile but also contribute to safety on the road. Neglecting these inspections can lead to unforeseen breakdowns and costly repairs, ultimately affecting your driving experience.

| Benefit | Description |

|---|---|

| Early Detection | Spotting minor problems before they become major issues. |

| Improved Performance | Ensuring all components function at their best. |

| Safety | Reducing the risk of accidents caused by mechanical failures. |

| Cost Savings | Preventing expensive repairs through proactive maintenance. |

| Longevity | Extending the life of your vehicle through regular care. |

Investing time in periodic evaluations can save both money and hassle in the long run, making it a wise choice for any vehicle owner. Regular attention to your automobile’s vital systems is key to a dependable and enjoyable driving experience.

Aftermarket Parts for Enhanced Performance

Upgrading components can significantly boost vehicle functionality and driving experience. Enthusiasts often seek alternatives that provide superior performance, durability, and efficiency. By exploring various enhancements, owners can tailor their rides to meet specific needs and preferences.

| Component | Benefits |

|---|---|

| High-Performance Air Filter | Improves airflow, enhances throttle response, and increases horsepower. |

| Upgraded Exhaust System | Reduces back pressure, optimizes sound, and boosts engine efficiency. |

| Performance Chips | Tweaks fuel maps for better acceleration and fuel economy. |

| Sport Suspension Kits | Enhances handling, lowers ride height, and improves stability. |

OEM vs. Aftermarket: What to Choose?

When it comes to selecting components for your vehicle, the decision between original equipment manufacturer options and alternative replacements can significantly impact performance and reliability. Each choice carries its own set of advantages and drawbacks that cater to different preferences and budgets.

Understanding the Differences

Original parts are crafted by the same manufacturers that produce the vehicle’s components, ensuring compatibility and often a higher standard of quality. In contrast, alternative parts may be produced by various companies, offering a wide range of prices and specifications, which can be appealing to those seeking cost-effective solutions.

Making the Right Choice

Ultimately, the decision should be guided by your specific needs, whether you prioritize warranty coverage and guaranteed fit or are inclined to explore more economical options. Consider factors such as longevity, performance, and your budget to delve into the best path forward for your automotive maintenance.

Step-by-Step Guide to Engine Repairs

Repairing the heart of a vehicle requires a systematic approach to ensure everything functions smoothly. This guide provides essential steps to navigate through the complexities of fixing various components, emphasizing safety and efficiency.

Preparation and Tools

Before beginning, gather necessary tools such as wrenches, screwdrivers, and a diagnostic device. Ensure you have ample workspace and protective gear. Familiarize yourself with the vehicle’s layout to streamline the repair process.

Troubleshooting Techniques

Start by identifying issues through visual inspection and listening for unusual sounds. Document any findings to create a clear path for repairs. Delve into specific components if necessary, utilizing manuals for guidance on the ultimate solutions.

Resources for Honda CR-V Enthusiasts

For those passionate about their vehicles, a wealth of information and tools is available to enhance understanding and maintenance. From forums to manuals, these resources can elevate your experience and knowledge.

- Online Forums: Engaging with fellow enthusiasts can provide insights and tips.

- Repair Manuals: Detailed guides are essential for DIY maintenance and repairs.

- Parts Suppliers: Reliable vendors offer quality components for upgrades and replacements.

- Video Tutorials: Visual guides can simplify complex procedures.

Exploring these options allows owners to delve into every aspect of their vehicle, ensuring they achieve the ultimate performance and longevity.