The inner workings of a compact automobile are essential for its performance and reliability. Recognizing the various elements that contribute to its functionality can greatly enhance your understanding of how these machines operate. A detailed examination of these components reveals the intricate design and engineering that goes into creating a high-performing vehicle.

By exploring the layout and interactions of the different assemblies, enthusiasts and mechanics alike can appreciate the complexity involved in automotive engineering. This knowledge not only aids in troubleshooting issues but also assists in routine maintenance and upgrades, ensuring optimal performance over time.

As we delve deeper into the specifics of these assemblies, it becomes clear how each section plays a pivotal role in the overall system. Understanding the configuration and purpose of each part allows for informed decisions regarding repairs and enhancements, ultimately leading to a more satisfying driving experience.

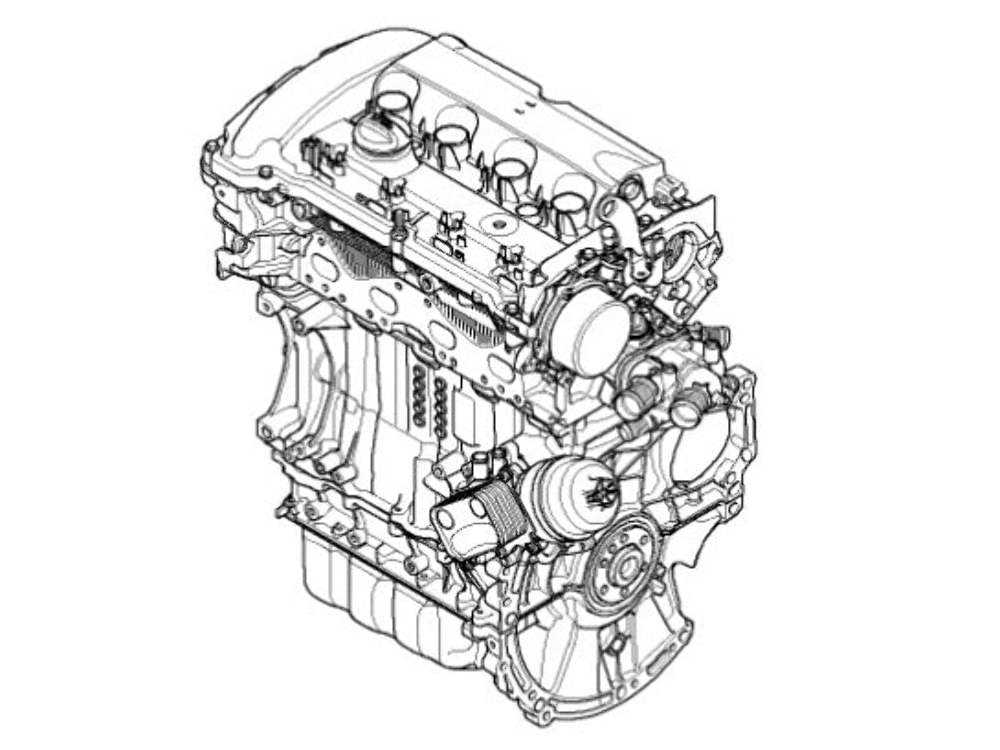

This section aims to provide a comprehensive understanding of the various elements that constitute a specific vehicle’s power unit. By examining the arrangement and functions of these components, readers can gain insights into how they work together to ensure optimal performance.

Key Elements of the Power Unit

- Crankshaft: This crucial component converts linear motion into rotational motion, playing a vital role in the overall functionality.

- Pistons: These cylindrical pieces move up and down within the cylinders, creating the necessary pressure for combustion.

- Camshaft: Responsible for opening and closing the intake and exhaust valves, this part is essential for the timing of air-fuel mixtures entering the combustion chamber.

- Oil Pan: This component holds the lubricant necessary for reducing friction and ensuring smooth operation of moving parts.

Functions of Major Components

- Fuel Delivery: A system that ensures an adequate supply of fuel to the combustion chamber, optimizing efficiency and performance.

- Ignition System: This element initiates the combustion process, critical for the engine’s operation.

- Cooling System: This system prevents overheating by regulating the temperature of the power unit.

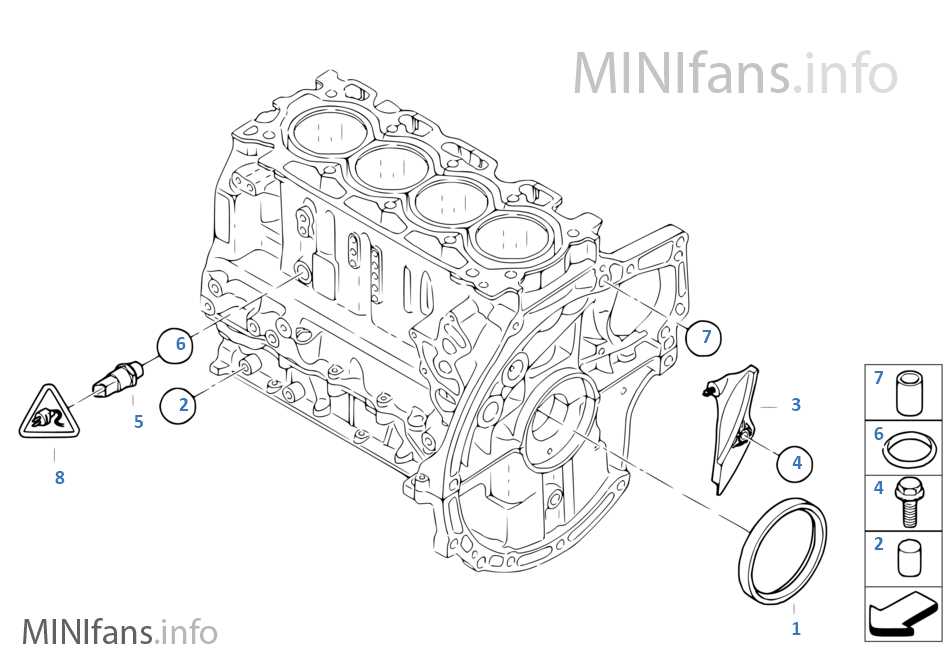

Function of Each Engine Part

Understanding the role of various components in a vehicle’s power unit is essential for effective maintenance and performance optimization. Each segment serves a unique purpose, contributing to the overall functionality and efficiency of the system.

- Block: The main structure that houses the cylinders and other critical elements.

- Cylinders: Spaces where the combustion of fuel occurs, generating power.

- Pistons: Move up and down within the cylinders, converting fuel energy into mechanical motion.

- Crankshaft: Transforms the linear motion of pistons into rotational motion to drive the vehicle.

- Camshaft: Regulates the timing of valve openings and closings, ensuring optimal airflow into the combustion chambers.

- Valves: Control the intake of air and the exhaust of gases, playing a critical role in the combustion cycle.

- Timing Belt: Synchronizes the rotation of the crankshaft and camshaft for accurate timing.

- Fuel Injector: Delivers fuel into the combustion chamber in precise amounts for efficient combustion.

- Exhaust Manifold: Collects exhaust gases from multiple cylinders and directs them to the exhaust system.

- Oil Pump: Circulates lubricating oil to reduce friction between moving parts and prevent wear.

Each element is intricately designed to work in harmony, ensuring that the power unit operates smoothly and efficiently.

Common Issues with Engine Parts

Understanding frequent problems associated with various components of a vehicle’s power unit can significantly enhance maintenance efforts. Identifying these issues early on allows for timely interventions, potentially saving time and resources while ensuring optimal performance.

Wear and Tear

Degradation of certain components is a common occurrence due to prolonged use. Factors such as heat, friction, and exposure to contaminants can lead to deterioration, affecting overall functionality. Regular inspections can help in pinpointing wear patterns and replacing affected elements before they cause more extensive damage.

Leaking Fluids

Fluid leaks are a prevalent concern, often stemming from faulty seals or gaskets. Monitoring fluid levels and inspecting for signs of leaks can prevent serious complications. Addressing these leaks promptly ensures that the system operates efficiently and minimizes the risk of more significant issues arising.

How to Identify Engine Parts

Understanding the components of a motor is crucial for effective maintenance and troubleshooting. Each element plays a significant role in the overall functionality, and recognizing these parts can aid in diagnosing issues and ensuring optimal performance.

Key Components Overview

Familiarity with major components enhances comprehension of how they interact. Below is a list of essential elements commonly found in many motors, along with their primary functions:

| Component | Function |

|---|---|

| Cylinder Head | Houses valves and spark plugs, facilitating air-fuel mixture intake and exhaust. |

| Crankshaft | Transforms linear motion from pistons into rotational force, driving the vehicle. |

| Piston | Moves within the cylinder, compressing the air-fuel mixture for combustion. |

| Timing Belt | Synchronizes the rotation of the crankshaft and camshaft for proper valve timing. |

| Fuel Injector | Delivers the precise amount of fuel into the combustion chamber for ignition. |

Visual Identification Tips

When examining a motor, look for distinguishing features and labels on components. Many parts have specific shapes, sizes, or colors that can aid in identification. Additionally, referring to manuals or online resources can provide visual references for better accuracy.

Maintenance Tips for Engine Longevity

Proper upkeep of a vehicle’s power source is crucial for ensuring its durability and optimal performance. Regular care not only enhances efficiency but also extends the lifespan of the vital components involved. By following a few essential guidelines, you can help maintain the integrity of these crucial systems and avoid costly repairs down the road.

Regular Fluid Checks

One of the most important aspects of maintaining a vehicle’s functionality is to routinely inspect and replace fluids. This includes oil, coolant, and transmission fluid, which play significant roles in keeping the internal mechanisms running smoothly.

Scheduled Maintenance Intervals

Adhering to a maintenance schedule is key to preventing unforeseen issues. Regular servicing can help identify potential problems early on, allowing for timely repairs and adjustments. This proactive approach minimizes the risk of major failures.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 5,000 miles |

| Coolant Flush | Every 30,000 miles |

| Transmission Fluid Change | Every 50,000 miles |

| Air Filter Replacement | Every 15,000 miles |

Replacing Engine Parts: A Guide

When it comes to maintaining the performance of your vehicle, understanding how to replace various components is essential. This section will provide you with insights into the process of swapping out critical elements within the power unit. Knowing when and how to make these changes can lead to enhanced functionality and longevity of your machine.

Preparation Steps

Before beginning the replacement process, ensure you have the necessary tools and components on hand. Familiarize yourself with the specific requirements of your vehicle to avoid any complications. It is also wise to consult a detailed reference to understand the layout and connection of the components involved.

Replacement Procedure

Start by carefully disconnecting the existing component, taking care to note any connections or brackets. Follow the removal instructions closely to prevent damage. Once the old part is out, install the new piece, ensuring all connections are secure. After the installation, conduct a thorough inspection to confirm everything is in place before starting the engine.

Tools Required for Engine Repair

Undertaking maintenance or repairs on a vehicle’s power unit necessitates specific instruments to ensure the task is performed efficiently and safely. The right tools not only facilitate the repair process but also help prevent potential damage to components during servicing. Having a well-equipped toolkit is essential for both novice and experienced mechanics.

Essential Instruments

Among the primary tools required are wrenches and sockets, which are vital for loosening and tightening various fasteners. Additionally, a torque wrench is crucial for applying the correct amount of force to prevent over-tightening. A good selection of screwdrivers, including both flathead and Phillips, will also prove beneficial for accessing different parts of the assembly.

Specialized Equipment

For more intricate repairs, specialized devices like an oil filter wrench and a timing belt tool can significantly ease the process. Furthermore, a diagnostic scanner may be necessary to troubleshoot and read error codes from the vehicle’s computer system, ensuring a comprehensive understanding of any issues at hand.

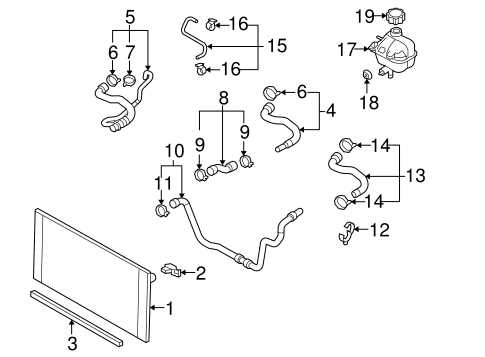

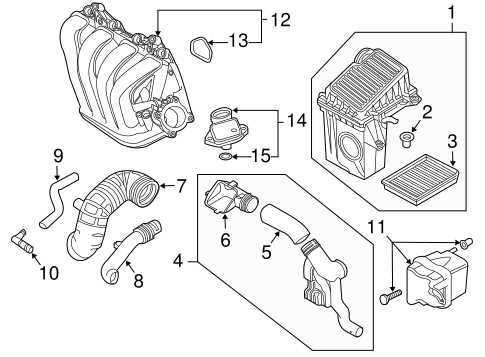

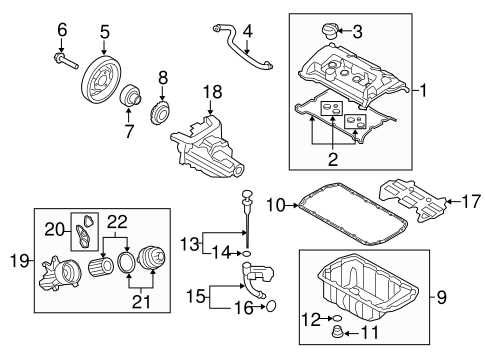

Engine Diagram: Understanding Layout

The layout of a motor is essential for comprehending its overall functionality. A well-structured representation can help identify various components and their interrelations. Understanding how each element interacts within the assembly enhances maintenance and troubleshooting efforts.

Typically, a schematic illustrates the arrangement of crucial elements such as the combustion chamber, valves, and crankshaft. By studying these configurations, one can gain insights into the operational principles of the unit. Recognizing the placement of individual components assists in diagnosing issues and planning repairs effectively.

Moreover, this visual guide serves as a valuable reference for both novice and experienced individuals alike. It enables a deeper appreciation of the complexities involved in automotive design. A thorough understanding of the layout can lead to improved performance and longevity of the system.

Aftermarket vs. OEM Parts

When it comes to replacing components in vehicles, enthusiasts and owners often face a critical choice between original manufacturer offerings and alternative solutions. Each option has its own set of benefits and drawbacks, influencing performance, longevity, and overall satisfaction.

Original manufacturer products are typically designed to meet specific standards set by the automaker. This often ensures compatibility and reliability. However, these offerings may come with a higher price tag.

- Benefits of OEM:

- Guaranteed fit and function

- High quality and durability

- Warranty protection

- Drawbacks of OEM:

- Higher costs

- Limited availability

On the other hand, alternative solutions can provide cost savings and potentially enhanced performance. However, buyers must be cautious, as quality can vary significantly.

- Benefits of aftermarket:

- Cost-effective options

- Variety of choices

- Potential for improved performance

- Drawbacks of aftermarket:

- Variable quality

- Risk of compatibility issues

- Limited or no warranty

Ultimately, the decision hinges on the owner’s priorities, whether they value guaranteed performance or seek cost-effective alternatives. Understanding the pros and cons of each choice is essential for making an informed decision.

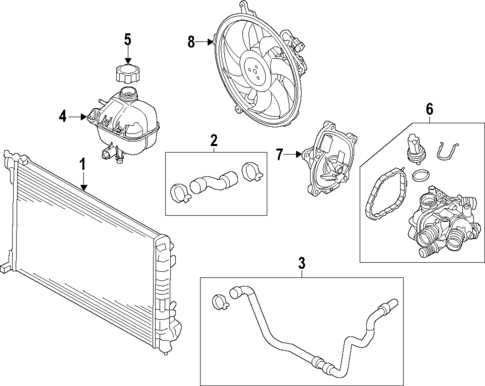

Importance of Proper Engine Cooling

Effective thermal regulation is crucial for the longevity and performance of any motorized vehicle. The cooling system plays a vital role in maintaining optimal operating temperatures, preventing overheating, and ensuring that the powertrain components function efficiently. When heat levels are managed correctly, it enhances reliability and minimizes the risk of catastrophic failures.

Consequences of Inadequate Cooling

Insufficient temperature management can lead to several detrimental outcomes. Overheating can result in warped components, reduced lubricating effectiveness, and increased wear on moving parts. This not only affects performance but also leads to costly repairs and downtime.

Components of a Cooling System

A well-functioning cooling system comprises various elements that work together to dissipate excess heat. The following table outlines the primary components and their functions:

| Component | Function |

|---|---|

| Radiator | Dissipates heat from the coolant. |

| Water Pump | Circulates coolant throughout the system. |

| Thermostat | Regulates coolant flow based on temperature. |

| Cooling Fans | Enhance airflow through the radiator. |

Wiring and Electrical Components Explained

The electrical system of a vehicle is a complex network that plays a crucial role in its overall functionality. This system comprises various components that work together to ensure smooth operation, from starting the vehicle to powering essential accessories. Understanding these elements is vital for effective troubleshooting and maintenance.

At the heart of the electrical system are the wiring harnesses, which serve as the main conduits for electrical flow. These harnesses connect different parts of the vehicle, allowing signals and power to travel efficiently. Additionally, connectors and terminals are essential for establishing secure links between components, ensuring reliable communication within the system.

| Component | Function |

|---|---|

| Battery | Stores electrical energy to start the vehicle and power electrical components. |

| Alternator | Generates electricity while the vehicle is running, recharging the battery. |

| Fuses | Protect circuits by breaking the connection in case of overload or short circuit. |

| Relays | Control high-current circuits using a low-current signal. |

| Sensors | Monitor various vehicle parameters and send data to the control unit for optimal performance. |

By understanding the role of each component and their interconnections, individuals can better appreciate the functionality of the vehicle’s electrical system and address potential issues effectively.

Upgrading Your Mini Cooper Engine

Enhancing the performance of your vehicle can significantly improve your driving experience. This process involves several modifications that can elevate efficiency and power. By focusing on various components, enthusiasts can achieve impressive results, making their rides more enjoyable and responsive.

When considering upgrades, it is essential to analyze the specific areas that can benefit from improvement. This includes aspects such as airflow, fuel delivery, and overall tuning. Each modification can contribute to a better balance of power and efficiency, leading to an exhilarating driving experience.

| Modification Type | Description | Benefits |

|---|---|---|

| Intake System | Upgrading the air intake allows for better airflow to the combustion chamber. | Increased horsepower and torque. |

| Exhaust System | A high-performance exhaust system enhances the flow of exhaust gases. | Improved efficiency and a more aggressive sound. |

| ECU Tuning | Reprogramming the engine control unit can optimize fuel and timing settings. | Better throttle response and fuel economy. |

| Turbocharger Upgrade | Installing a larger turbocharger can significantly boost power output. | Enhanced acceleration and overall performance. |

Each of these enhancements requires careful consideration and proper installation. Engaging with experienced professionals can ensure that upgrades are executed effectively, resulting in a well-balanced and powerful driving machine.

Resources for Mini Cooper Owners

Owning a compact vehicle comes with its unique set of challenges and opportunities. Access to reliable information and resources is essential for maintaining optimal performance and addressing potential issues. Below are some valuable sources to assist enthusiasts in their journey.

- Online Forums: Engaging with other owners through dedicated online communities can provide insights and tips for troubleshooting and maintenance.

- Official Manuals: Accessing the manufacturer’s official documentation ensures that owners have accurate and detailed information about their vehicle’s specifications and maintenance procedures.

- Parts Suppliers: Reliable suppliers offer a range of components and accessories, making it easier to find what is needed for repairs or upgrades.

- DIY Guides: Numerous websites and platforms provide step-by-step guides for various maintenance tasks, empowering owners to tackle repairs themselves.

- Local Clubs: Joining regional clubs can connect owners with like-minded individuals and facilitate events and gatherings that enhance the ownership experience.

Utilizing these resources can significantly enhance the ownership experience, making it more enjoyable and manageable.