When it comes to maintaining a vehicle’s performance, having a clear view of how everything is organized beneath the surface is crucial. The intricate mechanisms responsible for movement and overall efficiency are crafted to work together seamlessly, ensuring smooth rides and longevity.

Exploring the various elements under the hood gives you a better understanding of how these systems interact. This knowledge can be especially useful for troubleshooting or when it’s time for routine maintenance, as each component plays a significant role in the vehicle’s operation.

Having a well-structured overview of these elements is essential for both seasoned mechanics and those new to the world of automotive care. With this guide, you’ll gain insights into the individual elements that make everything work as intended.

2011 Kia Sorento Engine Overview

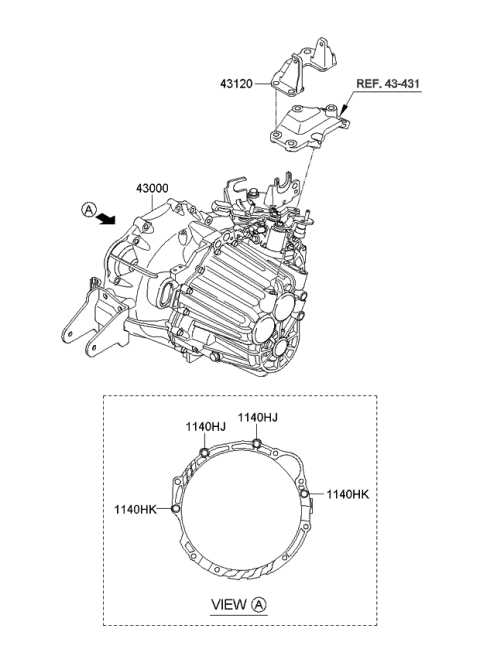

The power system in this vehicle model is designed to provide reliable performance and adaptability for various driving conditions. Its core focus is efficiency, ensuring that drivers experience a balance between power output and fuel consumption. The layout of key components contributes to seamless operation, promoting longevity and durability in everyday use.

Performance and Efficiency

The system is engineered to offer a smooth driving experience, with attention given to the distribution of power throughout different driving modes. This allows the vehicle to handle both city commutes and longer highway journeys with ease, while maintaining an emphasis on conserving energy.

- Optimized for fuel savings

- Responsive under varying loads

- Designed to minimize emissions

Key Functional Components

The central mechanism is supported by a network of essential elements, all working in harmony to ensure peak functionality. Each component plays a vital role in maintaining overall system health and supporting the vehicle’s performance under diverse conditions.

- Fuel Pump Operation: This component is responsible for transporting fuel from the tank to the engine. It must maintain adequate pressure to facilitate the flow of fuel.

- Fuel Filtration: Impurities in fuel can cause significant damage. Filtration systems work to remove contaminants before the fuel reaches the combustion area.

- Fuel Injection: Precise timing and atomization of the fuel are crucial for optimal combustion. Injection systems ensure a fine mist of fuel is delivered at the right moment.

- Pressure Regulation: Maintaining the correct pressure within the fuel system is essential for efficient engine operation. Regulators adjust pressure based on engine demands.

- Return Lines: Excess fuel needs to be returned to the tank to prevent flooding. Return lines help maintain the necessary fuel levels in the system.

- Ignition Coils: These devices amplify the electrical signal, enabling a strong discharge that generates a spark.

- Spark Plugs: Positioned in the combustion chamber, they provide the spark necessary for igniting the air-fuel mixture.

- Timing: The precise timing of the spark is essential for maximizing power output and fuel efficiency.

Main Components of the Engine System

The core of any vehicle’s powertrain consists of several essential elements working together to convert energy into motion. These components are meticulously designed to ensure efficient performance, durability, and reliability throughout the system’s operation. Understanding these parts is crucial for maintaining the overall health and longevity of the vehicle.

The combustion chamber is a vital area where fuel and air mix to generate power. Its role is to control the combustion process and manage the resulting force. Pistons operate within this chamber, moving up and down to create the necessary pressure that powers the drive system.

The crankshaft serves as the connecting link between the combustion process and mechanical motion. It converts the linear force from the pistons into rotational energy, which is transmitted to the drivetrain. This mechanism ensures that power flows seamlessly to other systems.

The valves play an essential part in regulating airflow and exhaust gases. They open and close in precise timing, controlling the intake of fresh air and the release of burnt gases, ensuring optimal performance and emission standards are met.

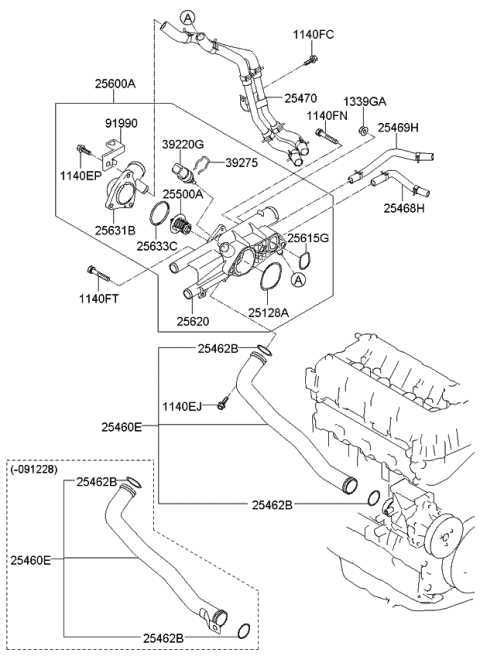

Understanding the Sorento’s Cooling System

The cooling mechanism in vehicles plays a crucial role in regulating temperature and preventing overheating. It ensures that the motor operates within a safe range, improving efficiency and extending its lifespan. An efficient thermal management system helps in dispersing heat generated by various components during operation, maintaining optimal functionality even in challenging conditions.

Key Components of the Cooling System

This system is composed of several vital elements that work together to control the temperature. Each part is essential to maintaining balance, from the liquid coolant to the radiator and thermostat. Together, these components ensure that excess heat is dissipated and the core temperature remains stable.

| Component | Function |

|---|---|

| Radiator | Dissipates heat from the coolant to the air. |

| Thermostat | Regulates coolant flow to maintain optimal temperature. |

| Water Pump | Circulates coolant through the system. |

Maintaining the Cooling System

Proper maintenance is essential to ensure the longevity of the cooling system. Regular checks on fluid levels

Key Elements of the Radiator and Hoses

The cooling system relies heavily on several critical components that work together to manage temperature and prevent overheating. Among these, the radiator and hoses form the backbone of the system, ensuring the proper flow of coolant and efficient heat dissipation. Understanding their role is essential for maintaining optimal vehicle performance, as these parts play a crucial role in regulating engine temperature.

Radiator Structure

The radiator is designed to allow coolant to pass through thin tubes, where heat is transferred from the liquid to the surrounding air. This process ensures the coolant is cooled before being recirculated. Fins are attached to these tubes to increase surface area and enhance heat dissipation. The overall efficiency of the system depends on the cleanliness and condition of the radiator, making regular maintenance vital.

Function of Hoses

Hoses serve as the conduits for transporting coolant between the radiator and other parts of the system. They are typically made from durable, heat-resistant materials that can withstand both the temperature fluctuations and the pressure within the system. Properly fitted and undamaged hoses are crucial to avoid leaks and ensure continuous coolant circulation.

| Component | Function | |||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Radiator | Dissipates heat from

Examining the Fuel Injection MechanismThe fuel injection system plays a crucial role in ensuring that the proper mix of air and fuel reaches the combustion chambers for efficient operation. Its primary function is to deliver fuel with precision, adapting to various driving conditions. This allows for optimal performance and smooth running while minimizing unnecessary waste. Efficiency in this process is achieved through carefully timed injection cycles that ensure just the right amount of fuel enters at the correct moment. These cycles are regulated by a complex network of sensors and actuators that respond to the vehicle’s speed, load, and throttle position. Modern systems typically employ advanced techniques to maintain accuracy and consistency. By precisely controlling pressure and delivery, they reduce emissions and increase fuel economy. Any disruptions or malfunctions in this mechanism can lead to reduced performance or increased fuel consumption, underscoring its importance in the overall operation of the vehicle. Core Functions of Fuel DeliveryThe process of supplying fuel to a vehicle’s combustion chamber is vital for optimal performance. This system is designed to ensure that the right amount of fuel reaches the engine at the appropriate time, enabling efficient operation and power generation. Several key functions contribute to the overall effectiveness of fuel delivery systems: Understanding these core functions is essential for diagnosing performance issues and ensuring the longevity of the vehicle’s operation. Kia Sorento Timing Belt StructureThe timing belt plays a crucial role in the synchronization of various components within a vehicle’s internal mechanism. This flexible loop, made from a durable material, connects critical elements, ensuring they operate in harmony for optimal performance. Understanding its design and functionality is essential for maintaining the longevity and efficiency of the overall system. Key Components of the Timing Belt AssemblyThis assembly consists of several integral parts that contribute to its functionality. The belt itself, featuring grooves on its inner surface, meshes with sprockets to maintain the correct timing between the crankshaft and camshaft. Additionally, tensioners are employed to keep the belt securely in place, preventing slippage and wear. Idlers also play a significant role in guiding the belt, enhancing its overall performance. Maintenance and Replacement Considerations

Regular inspection of the timing belt and its associated components is vital for preventing potential failures. Over time, wear and tear can lead to cracking or fraying of the belt material, which can result in severe damage if not addressed promptly. It is advisable to consult the manufacturer’s recommendations regarding replacement intervals to ensure that the system remains in optimal condition. Proactive maintenance can save both time and expenses in the long run. Role of the Timing Belt and ChainsThe timing belt and chains are essential components in the operation of a vehicle’s internal mechanics, ensuring that various parts work in harmony. They play a critical role in maintaining the precise timing of the engine’s operations, allowing for optimal performance and efficiency. These elements serve to synchronize the rotation of the crankshaft and camshaft, ensuring that the valves open and close at the correct intervals during the combustion cycle. A well-functioning timing belt or chain can prevent serious mechanical issues and enhance the longevity of the entire system.

Exhaust System Elements in DetailThe exhaust system plays a crucial role in the overall performance and efficiency of a vehicle. Its primary function is to direct harmful gases produced during combustion away from the engine and cabin, ensuring optimal operation and passenger comfort. This complex assembly consists of various components, each designed to facilitate the safe and efficient expulsion of exhaust gases while minimizing noise and emissions. Key Components of the Exhaust SystemOne of the main elements is the manifold, which collects gases from the cylinders and channels them into the exhaust pipes. Following the manifold, the catalytic converter plays a vital role in reducing harmful emissions by facilitating chemical reactions that convert toxic substances into less harmful gases. This is essential for meeting environmental regulations and improving air quality. Importance of Mufflers and ResonatorsMufflers and resonators are also critical to the exhaust system’s function. The muffler serves to dampen the sound produced by the escaping gases, providing a quieter driving experience. Meanwhile, the resonator fine-tunes the sound further, ensuring that the vehicle operates within desired acoustic parameters. Together, these components help balance noise reduction with performance, enhancing the overall driving experience. Understanding the Function of Key PartsEvery vehicle comprises a multitude of components that play vital roles in ensuring optimal performance and reliability. Grasping the significance of these crucial elements allows for better maintenance and troubleshooting, ultimately enhancing the driving experience. The core assembly includes various segments, each designed to perform specific tasks that contribute to the overall operation of the vehicle. Below is a table outlining some of the fundamental components and their respective functions:

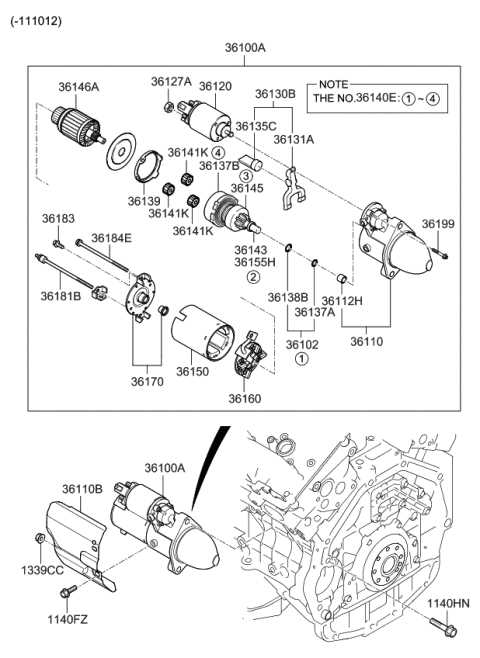

Understanding these components and their functions can greatly assist in diagnosing issues and making informed decisions regarding maintenance and repairs. Ignition System Components ExplainedThe ignition system is a vital aspect of any vehicle, responsible for initiating the combustion process within the internal combustion chamber. Understanding its various components can significantly enhance one’s knowledge of how this system operates efficiently and effectively. Ignition Coil: This device transforms low voltage from the battery into the high voltage needed to create a spark. It plays a crucial role in providing the necessary energy to ignite the air-fuel mixture. Spark Plug: Situated within the combustion chamber, the spark plug generates the electric spark that ignites the fuel-air mixture. Its performance directly affects the engine’s efficiency and overall functionality. Distributor: This component is responsible for directing the high voltage from the ignition coil to the appropriate cylinder at the right moment. Its precise timing is essential for optimal engine performance. Ignition Timing: Refers to the precise moment when the spark plug fires to ignite the fuel-air mixture. Proper ignition timing is critical for maximizing power and reducing emissions. Wiring and Connectors: These elements facilitate the connection between various components within the ignition system. They must be in good condition to ensure reliable performance and prevent misfires. Each element of the ignition system works in harmony to ensure that the combustion process occurs smoothly, enabling the vehicle to operate at its best. Regular maintenance and understanding of these components can lead to improved performance and longevity. How Spark Plugs and Coils Work TogetherThe interaction between ignition components is crucial for optimal combustion within a vehicle’s internal combustion system. Spark plugs and ignition coils play significant roles in this process, ensuring that the fuel-air mixture is ignited at the right moment for efficient performance. Ignition coils are responsible for transforming low voltage from the battery into high voltage, which is essential for creating a spark. This spark is then delivered to the spark plugs, which ignite the compressed fuel-air mixture in the combustion chamber. The coordination between these components is vital for proper engine function. When the ignition coil sends a high-voltage pulse to the spark plug, a spark is produced that initiates combustion. This process is repeated thousands of times per minute, highlighting the importance of having well-functioning ignition components. Regular maintenance of these parts ensures reliability and performance, preventing misfires and inefficiencies. Ultimately, the seamless collaboration between ignition coils and spark plugs is fundamental for achieving smooth operation, enhancing both power and fuel efficiency in the vehicle. Analyzing the Oil Circulation PathThe pathway through which lubrication fluid travels within a vehicle’s propulsion system is crucial for its optimal performance. Understanding this route helps in diagnosing potential issues and ensuring that all components receive adequate lubrication, reducing wear and tear. A well-maintained circulation system plays a vital role in maintaining the longevity of mechanical elements and promoting efficiency. Key Components of the Circulation SystemSeveral essential elements contribute to the effective flow of lubrication fluid. Each component has a specific role, ensuring that the fluid reaches every necessary part without obstruction. This section will examine these integral components.

Importance of a Proper Circulation Path

Maintaining a clear and efficient pathway for lubrication fluid is essential for preventing potential mechanical failures. Blockages or leaks can lead to inadequate lubrication, which in turn can cause increased friction and heat generation. Regular inspections and maintenance of the circulation components are vital for ensuring that the entire system operates smoothly, ultimately enhancing the overall performance of the vehicle. |