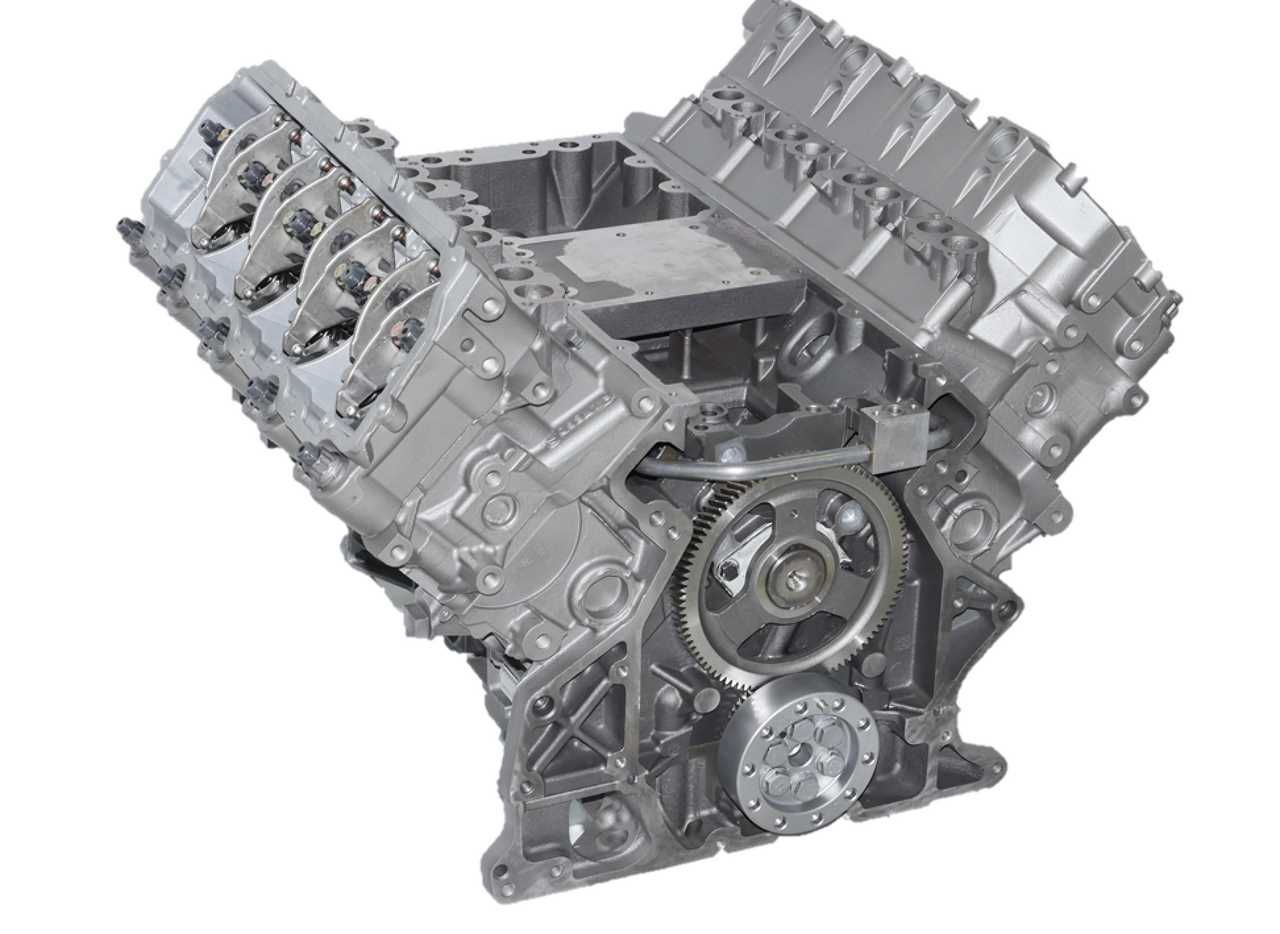

The efficient operation of modern diesel systems relies on a variety of critical elements working in harmony. Each element plays a significant role in ensuring peak performance, durability, and fuel economy. From key functional mechanisms to supporting devices, the overall design is a complex and intricate arrangement aimed at delivering high levels of output.

In this section, we’ll explore the various mechanical and electrical assemblies that make up these advanced systems. By breaking down each crucial component, we can gain a deeper appreciation of how they collectively contribute to optimal functionality. Whether focusing on energy distribution, fluid management,

The electrical system of a vehicle is crucial for its overall functionality and performance. This section will explore the various components that contribute to the effective operation of the electrical framework, ensuring that all systems work in harmony.

Key components of the electrical framework include:

- Battery: Supplies the necessary power for starting and running various systems.

- Alternator: Converts mechanical energy into electrical energy, recharging the battery and powering electrical systems while the vehicle is running.

- Starter Motor: Engages the engine’s flywheel to initiate the combustion process.

- Fuses: Protect electrical circuits from overloads and shorts, preventing damage to components.

- Wiring Harness: Connects all electrical components, facilitating the flow of electricity throughout the system.

- Sensors: Monitor various parameters, sending data to the control unit for optimal performance.

Each component plays a vital role in maintaining the efficiency and reliability of the vehicle. Regular inspection and maintenance of the electrical system can prevent potential issues and ensure smooth operation.

Understanding the electrical layout allows for better troubleshooting and repair, contributing to the longevity of the vehicle.

Transmission and Its Role

The transmission is a vital component within a vehicle’s drivetrain, responsible for transferring power from the propulsion system to the wheels. This intricate system enables the vehicle to change speeds and adapt to various driving conditions, ensuring optimal performance and efficiency.

Functionality of the Transmission

At its core, the transmission regulates the flow of power by selecting the appropriate gear ratios. This allows the vehicle to accelerate smoothly while maintaining engine efficiency. A well-functioning transmission also contributes to improved fuel economy and reduces wear on the mechanical components, enhancing the overall lifespan of the vehicle.

Types of Transmissions

There are several types of transmissions available, each designed for specific applications. Automatic transmissions offer convenience and ease of use, while manual transmissions provide a more engaged driving experience. Continuously variable transmissions (CVTs) offer seamless transitions between gear ratios, optimizing power delivery under various conditions. Understanding the differences between these systems can help in selecting the right transmission for a vehicle’s intended use.

Common Engine Issues and Solutions

Every motor may encounter a range of problems during its lifespan, leading to performance drops and potential failures. Understanding these common issues and their respective solutions is crucial for maintaining optimal functionality and longevity.

Frequent Problems

- Overheating: This can result from coolant leaks, a malfunctioning thermostat, or a blocked radiator.

- Starting Difficulties: Battery issues, faulty starters, or fuel delivery problems may hinder the ignition process.

- Unusual Noises: Knocking or tapping sounds can indicate worn bearings or insufficient lubrication.

- Decreased Power: A lack of acceleration can stem from clogged air filters or exhaust restrictions.

- Fuel Leaks: This may arise from deteriorated hoses or faulty injectors, posing a fire hazard.

Proposed Solutions

- Check and replace coolant levels, inspect hoses for leaks, and ensure the radiator is clear to combat overheating.

- Test the battery’s voltage, inspect connections, and consider replacing the starter to resolve starting difficulties.

- Examine the oil levels and change the oil regularly to prevent unusual noises caused by insufficient lubrication.

- Replace air filters and check the exhaust system for blockages to restore lost power.

- Inspect fuel lines and injectors, replacing any damaged components to eliminate fuel leaks.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle requires a proactive approach to care and upkeep. Regular maintenance plays a crucial role in enhancing performance and preventing potential issues that could lead to costly repairs. By following specific practices, you can significantly extend the lifespan of your machinery.

First and foremost, it is essential to adhere to the recommended service intervals outlined in your owner’s manual. This includes routine oil changes, filter replacements, and inspections of critical systems. Using high-quality lubricants and fluids tailored for your vehicle can also improve efficiency and reduce wear.

Another key aspect is monitoring fluid levels and conditions. Regularly check coolant, transmission fluid, and brake fluid to ensure they are at optimal levels and free from contamination. Addressing any leaks or discrepancies promptly can prevent more serious damage over time.

Additionally, keeping an eye on tire health is vital. Maintaining proper tire pressure and tread depth not only enhances safety but also contributes to better fuel efficiency. Rotating tires as recommended ensures even wear and prolongs their lifespan.

Lastly, don’t overlook the importance of cleanliness. Regularly washing the exterior and undercarriage of your vehicle helps prevent corrosion and damage from dirt and debris. A clean interior contributes to overall comfort and satisfaction.

Replacement Parts and Options

When it comes to maintaining the performance and reliability of your vehicle’s components, choosing the right replacements is crucial. There are various alternatives available on the market, catering to different needs and budgets. Understanding the options helps ensure that you select the best fit for your specific requirements.

Here are some common replacement alternatives that you might consider:

| Type | Description | Benefits |

|---|---|---|

| OEM | Original equipment manufacturer items, made to the same specifications as the original components. | Guaranteed compatibility and quality. |

| Aftermarket | Third-party products that can be less expensive and may offer enhanced performance features. | Cost-effective and often available in various configurations. |

| Rebuilt | Refurbished components that have been restored to a functional state. | Eco-friendly option that can save money. |

| Performance | High-performance alternatives designed to improve efficiency and output. | Enhanced power and reliability for those looking to upgrade. |

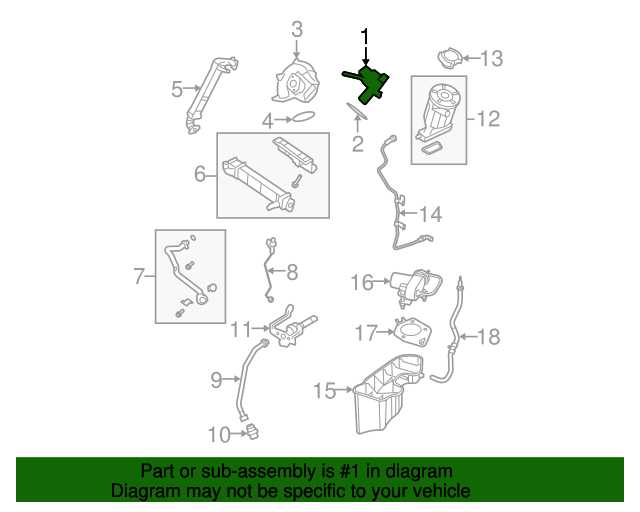

Wiring Diagram Overview

This section provides a comprehensive understanding of the electrical connections within the system. A clear representation of how various components interact is essential for effective troubleshooting and maintenance. By examining the layout of wires and connectors, users can better grasp the flow of electricity and the relationships between different elements.

Below is a simplified table illustrating the key components and their respective functions:

| Component | Description |

|---|---|

| Battery | Supplies electrical energy to start the system. |

| Fuses | Protects circuits from overload by breaking the connection if excessive current flows. |

| Starter Motor | Engages the engine’s flywheel to initiate the starting process. |

| Alternator | Charges the battery and powers electrical systems when the engine is running. |

| ECU (Electronic Control Unit) | Manages various functions by processing input from sensors and sending signals to actuators. |

Tools Needed for Repairs

When undertaking maintenance or repair work, having the right tools is essential for ensuring efficiency and effectiveness. This section will outline the various implements required to perform tasks properly, helping to streamline the repair process and achieve optimal results.

Essential Hand Tools

Basic hand tools form the foundation of any repair toolkit. Wrenches, screwdrivers, and pliers are vital for loosening or tightening components and making necessary adjustments. A ratchet set can also be particularly useful, allowing for quick changes between socket sizes without the need to switch tools frequently.

Power Tools and Equipment

In addition to hand tools, power tools can greatly enhance efficiency. A cordless drill is indispensable for quick fastening and unfastening tasks. A cutting tool, such as a reciprocating saw, may be required for more complex modifications or repairs. Having a reliable torque wrench is crucial for ensuring that components are tightened to the manufacturer’s specifications, preventing potential damage or failure.