The intricacies of watercraft propulsion mechanisms are crucial for optimal performance and maintenance. A comprehensive overview of these systems can enhance both safety and efficiency on the water. Proper familiarity with various components can lead to a smoother experience and prolong the lifespan of your vessel.

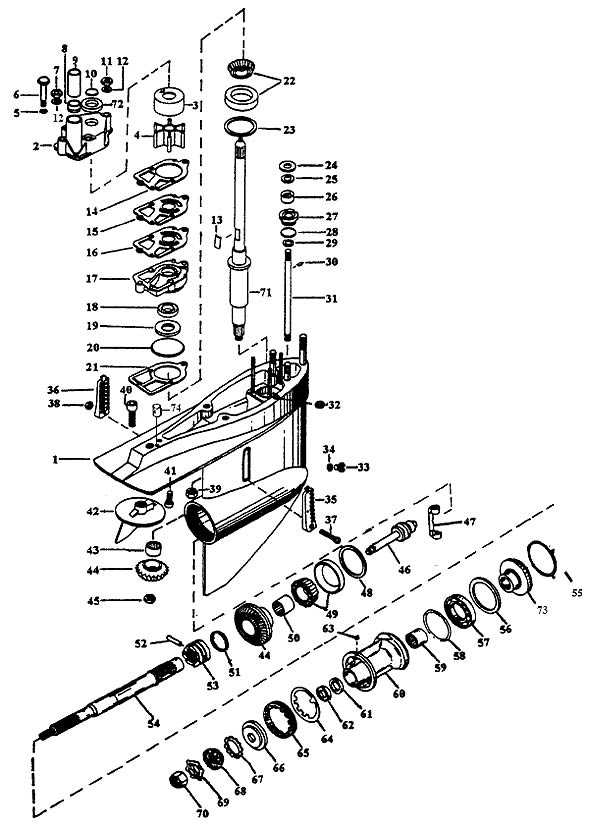

For enthusiasts and professionals alike, a detailed visual representation serves as an invaluable tool. This guide will illuminate essential elements, offering insights into their arrangement and function. Recognizing the ultimate role each component plays is key to troubleshooting and enhancing performance.

Diving deeper into these mechanical systems allows users to make informed decisions regarding repairs and upgrades. Understanding the layout fosters confidence, ensuring that every outing is not only enjoyable but also reliable. Explore the essential components that power your maritime adventures with clarity and purpose.

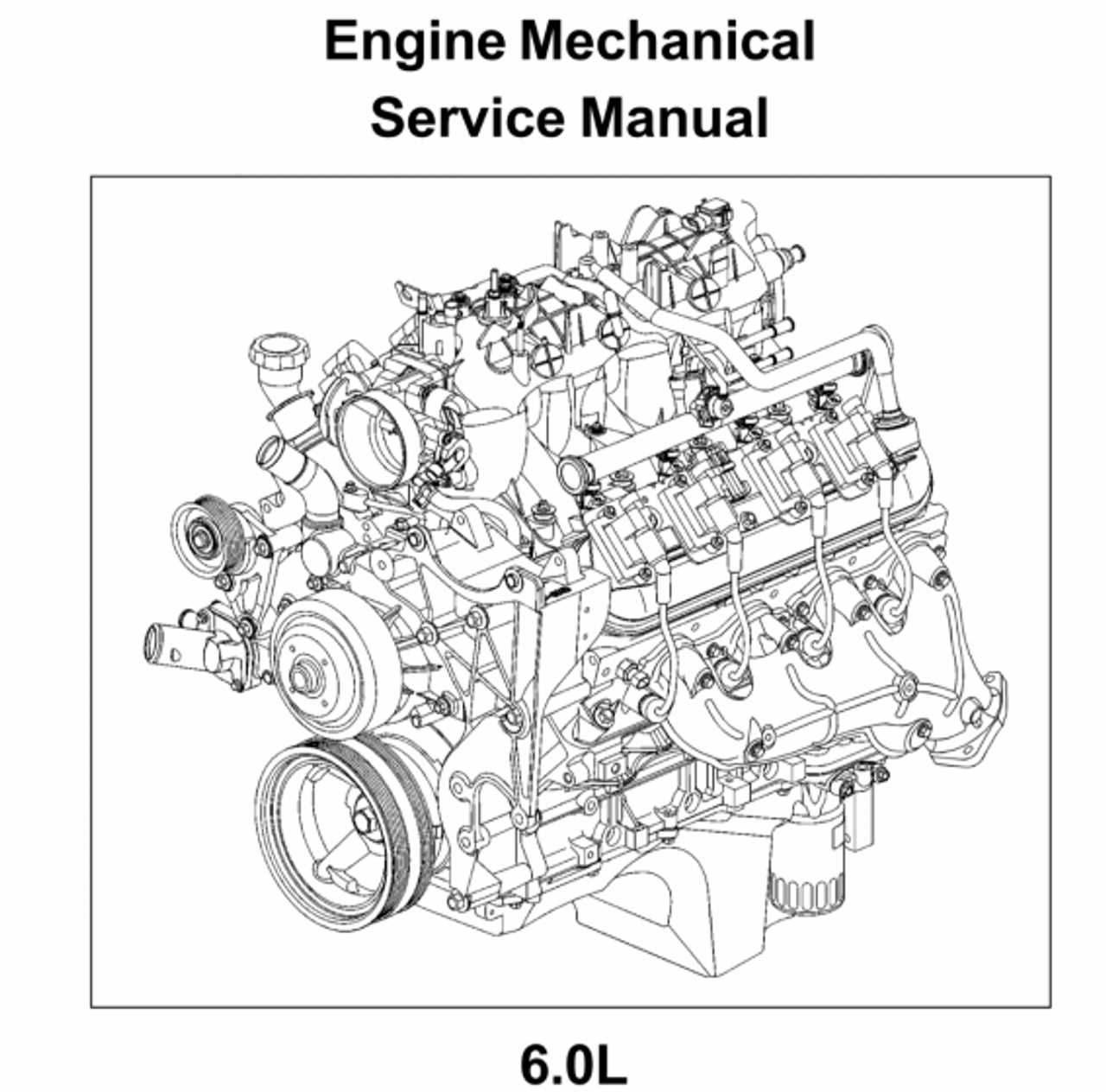

Understanding Indmar Engine Components

Grasping the intricacies of a marine propulsion system is essential for anyone involved in maintenance or operation. Each element plays a crucial role in ensuring optimal performance and reliability. Familiarity with these individual components allows for better troubleshooting and more effective care of the entire system.

Core Components: At the heart of this system are the critical mechanisms that generate power. These include elements responsible for combustion, airflow, and fuel delivery. Understanding how these parts interact can enhance performance and efficiency.

Supporting Structures: In addition to the primary mechanisms, various auxiliary structures help manage heat, lubrication, and exhaust. Each of these components contributes to the smooth functioning of the entire system, ensuring longevity and resilience.

Maintenance Considerations: Regular inspection of these elements is vital for preventing failures. Recognizing wear patterns and understanding the function of each component can guide effective maintenance strategies, ultimately extending the lifespan of the whole assembly.

By deepening your knowledge of these individual features, you empower yourself to make informed decisions that can significantly improve the performance and safety of your marine vessel.

Key Parts of Indmar Engines

This section focuses on the essential components that contribute to the functionality and performance of marine power units. Understanding these elements is crucial for maintenance and optimization of performance in watercraft.

Among the vital components, the following play significant roles:

- Block: The core structure that houses the main assemblies.

- Piston: A cylindrical part that moves up and down to create power through combustion.

- Crankshaft: Converts linear motion from the piston into rotational motion.

- Camshaft: Regulates the timing of valve openings and closings.

- Valves: Control the intake of air and the expulsion of exhaust gases.

- Fuel System: Delivers the necessary fuel for combustion efficiently.

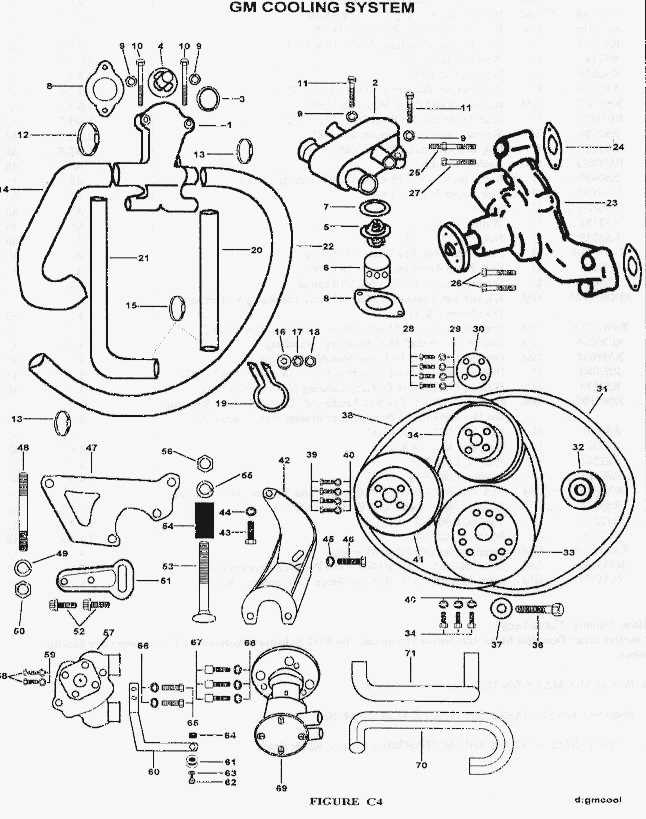

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

In addition to these primary elements, other auxiliary systems enhance the overall efficiency and reliability:

- Ignition System: Ensures timely spark generation for combustion.

- Lubrication System: Reduces friction between moving parts, promoting longevity.

- Exhaust System: Directs harmful gases away from the power unit.

- Intake Manifold: Distributes air and fuel mixture evenly to the cylinders.

Each of these components is crucial for the seamless operation and reliability of marine power units, making their understanding essential for any enthusiast or professional involved in watercraft maintenance.

Importance of Accurate Diagrams

Precise visual representations play a crucial role in understanding complex systems. They serve as essential tools for troubleshooting, maintenance, and assembly, ensuring that individuals can navigate intricate components with ease. Clarity in these illustrations significantly reduces the risk of errors and enhances overall efficiency in various tasks.

Enhancing Understanding

Clear visuals allow users to comprehend intricate details that might be overlooked in textual descriptions. This clarity fosters a better grasp of functionality and interrelations, making it easier to execute repairs or upgrades effectively.

Reducing Errors

When the visuals are accurate, the likelihood of mistakes decreases dramatically. Users can follow steps confidently, leading to successful outcomes and minimizing the chances of costly mishaps during operations.

How to Read Engine Diagrams

Understanding technical illustrations is essential for anyone looking to maintain or repair machinery. These visual representations provide a roadmap, allowing users to identify components and their interrelations effectively. By familiarizing yourself with the symbols and layouts, you can navigate complex systems with confidence.

Begin with the Legend: Most diagrams include a legend or key that explains the symbols used. Take a moment to review this section, as it is crucial for accurate interpretation.

Follow the Flow: Look for arrows or lines that indicate movement or connections. These will guide you through the relationships between different elements, helping you grasp how they work together.

Identify Key Components: Focus on major parts first. Once you recognize these elements, it becomes easier to understand their function and how they interact within the whole system.

Practice Makes Perfect: Like any skill, reading these visuals improves with practice. The more diagrams you study, the better you’ll become at quickly deciphering them and understanding the underlying mechanics.

Common Issues with Engine Parts

Understanding the frequent challenges encountered with mechanical components is crucial for maintaining optimal performance. These difficulties can lead to reduced efficiency, increased wear, and potential failures if not addressed promptly.

Wear and Tear

Over time, various components can experience degradation due to constant friction and stress. Regular inspections and timely replacements can mitigate this issue, ensuring longevity and functionality.

Leakage Problems

Fluid leaks are a common concern, often stemming from damaged seals or gaskets. Identifying and rectifying these leaks early can prevent more severe damage and costly repairs in the future.

Maintenance Tips for Indmar Engines

Proper upkeep of your motor is essential for optimal performance and longevity. Regular attention to specific areas can prevent potential issues and enhance the overall experience on the water. Adhering to these maintenance guidelines will ensure your vessel remains in peak condition.

Regular Inspections

Conduct frequent checks on essential components such as the cooling system, fuel lines, and electrical connections. Look for signs of wear or corrosion that may affect functionality. Early detection of issues can save time and costs in the long run.

Fluid Changes

Ensure timely replacement of fluids, including oil and coolant. Following the manufacturer’s recommendations on intervals will help maintain efficiency and prevent overheating. Clean, fresh fluids contribute significantly to the reliability of your machinery.

Finding Replacement Parts Easily

Locating suitable components for machinery can often feel overwhelming, but it doesn’t have to be. With the right approach, you can streamline the search process and ensure you get the quality you need. Understanding the essentials of your system will significantly simplify the journey toward obtaining the necessary replacements.

Start with Research: Familiarizing yourself with the specifications and requirements of your system is crucial. Utilize reliable online resources, manuals, and user forums to gather accurate information about what you need. This groundwork will provide a solid foundation for your search.

Utilize Reliable Suppliers: Partnering with reputable vendors can save you time and frustration. Look for suppliers that specialize in your specific type of machinery, as they are more likely to have the correct offerings. Consider customer reviews and ratings to gauge their reliability.

Explore Online Marketplaces: E-commerce platforms can be a treasure trove for finding what you need. Use targeted searches, and don’t hesitate to filter results to pinpoint the exact components you’re looking for. Pay attention to product descriptions and compatibility information.

Join Community Groups: Engaging with communities of enthusiasts or professionals can provide invaluable insights. Many members share tips on where to find components, and some may even offer their spare parts for sale. Building these connections can lead to quicker and more effective solutions.

Stay Organized: Keeping track of your findings is essential. Create a list of potential suppliers, contact details, and notes about each component you require. This will make it easier to compare options and make informed decisions.

By employing these strategies, you can navigate the process of acquiring necessary replacements with confidence and efficiency, ensuring your machinery continues to operate smoothly.

Benefits of OEM vs. Aftermarket Parts

When it comes to replacing components, the choice between original manufacturers and alternative suppliers can significantly impact performance and longevity. Each option offers distinct advantages that can cater to different needs and preferences.

Quality Assurance

Original equipment manufacturers provide a guarantee of quality and reliability, ensuring that every piece meets rigorous standards. In contrast, aftermarket alternatives can vary widely in quality, with some products potentially lacking the same level of durability.

Cost Considerations

While OEM products often come with a higher price tag, they may save money in the long run due to reduced maintenance and replacement frequency. Conversely, aftermarket options can be more affordable initially but may lead to higher costs over time if they fail or underperform.

Using Diagrams for Troubleshooting

Visual representations serve as invaluable tools when diagnosing issues within complex machinery. They allow users to pinpoint problems efficiently, guiding them through intricate systems with clarity. By understanding the layout and relationships of various components, technicians can more effectively identify and resolve malfunctions.

Benefits of Visual Aids

Employing visual aids enhances comprehension and speeds up the troubleshooting process. They provide a clear roadmap, minimizing guesswork and reducing the likelihood of errors. Additionally, these aids foster better communication among team members, ensuring everyone is aligned on the problem-solving approach.

Common Elements in Visual Representations

| Element | Description |

|---|---|

| Labels | Identifying each part for easy reference. |

| Connections | Illustrating how components interact with one another. |

| Color Coding | Highlighting critical areas to focus on during diagnostics. |

| Flow Direction | Indicating the movement of fluids or electricity through the system. |

Comparing Indmar Engine Models

This section explores various models from a prominent manufacturer, highlighting their unique features and specifications. Understanding the distinctions among these models can aid in making informed decisions for different applications and preferences.

Each model caters to specific needs, whether for performance, efficiency, or adaptability. Below are some key aspects to consider:

- Power Output: Different models offer varying horsepower, suitable for diverse activities such as water sports or leisure cruising.

- Fuel Efficiency: Some variants are designed for optimal fuel consumption, making them ideal for extended use.

- Maintenance Requirements: Consider the upkeep needs, as some models may require more frequent servicing than others.

- Cooling Systems: Explore the cooling mechanisms employed, which can significantly impact performance and reliability.

When selecting the right option, it is essential to evaluate:

- Intended usage and performance expectations.

- Compatibility with existing equipment or systems.

- Long-term reliability and support from the manufacturer.

By assessing these factors, users can determine which model aligns best with their specific requirements and preferences.

Resources for Engine Diagrams Online

Finding detailed visuals and documentation for mechanical systems can significantly enhance understanding and maintenance efforts. Various platforms offer valuable resources that help enthusiasts and professionals alike in navigating complex machinery layouts. Below are some excellent options for accessing such materials online.

Online Databases and Repositories

- Example Database 1: A comprehensive archive featuring a wide range of technical drawings and schematics.

- Example Database 2: A user-friendly platform offering high-resolution images and interactive tools for analysis.

- Example Database 3: A community-driven site where users can share and discuss technical illustrations.

Forums and Community Groups

- Forum 1: A space where experts share tips and visuals, making it easier to find specific layouts.

- Forum 2: An active community that frequently posts and updates various schematics, with insights from experienced members.

- Forum 3: A platform dedicated to technical discussions, often featuring shared illustrations and repair guides.

Upgrades and Modifications for Performance

Enhancing the capabilities of your watercraft can significantly improve its overall performance. Whether for speed, efficiency, or responsiveness, various upgrades can make a substantial difference. Below are some popular options to consider.

- High-Performance Exhaust Systems: These can improve airflow, resulting in better power output.

- Optimized Fuel Injectors: Upgrading to more efficient injectors can enhance fuel delivery and combustion.

- Aftermarket Superchargers: Adding a supercharger can provide a boost in horsepower and torque.

- Performance Tuners: These devices allow for custom tuning, maximizing the potential of your setup.

Each modification has its advantages, and combining them can lead to the ultimate enhancement of your vessel’s performance. Evaluate your needs and consider professional installation for the best results.