The intricate mechanics behind compact propulsion systems play a crucial role in their performance and efficiency. Gaining insight into these elements not only enhances one’s knowledge but also facilitates effective maintenance and optimization of these machines.

In this exploration, we will delve into the various components that contribute to the overall functionality of a small-capacity motor. Each element serves a specific purpose, and understanding these roles is essential for both enthusiasts and professionals alike.

By examining a detailed representation of these components, readers can appreciate the ultimate synergy that exists within the system. This comprehensive overview aims to empower users with the information necessary to troubleshoot and enhance their machinery effectively.

Understanding the Lifan 125cc Engine

This section delves into the intricacies of a specific type of small combustion mechanism commonly used in various applications. By examining its components and their functions, we can appreciate the engineering that contributes to its performance and efficiency.

Key Components

- Fuel Delivery System

- Ignition Mechanism

- Cooling Arrangement

- Lubrication System

- Exhaust Configuration

Each of these elements plays a crucial role in the overall functionality. Understanding how they interact is essential for maintenance and optimization.

Functionality Overview

- The fuel delivery system ensures an appropriate mixture of air and fuel reaches the combustion chamber.

- The ignition mechanism is responsible for initiating combustion at the right moment.

- Cooling arrangements prevent overheating, enhancing longevity and reliability.

- The lubrication system reduces friction, ensuring smooth operation.

- The exhaust configuration directs waste gases away efficiently.

By gaining insights into these components, users can make informed decisions regarding upkeep and potential modifications to enhance performance.

Overview of Lifan Engine Design

This section explores the fundamental architecture and functionality of a specific power unit, emphasizing its efficiency and performance characteristics. Understanding the construction and operation of these units provides insight into their reliability and suitability for various applications.

Core Components

The assembly consists of several critical elements that work together seamlessly. Each part is meticulously crafted to ensure optimal performance, durability, and maintenance ease, contributing to the overall effectiveness of the system.

Operational Efficiency

The design prioritizes fuel efficiency and power output, resulting in a balanced performance. With innovative features, this setup enhances responsiveness and reduces emissions, making it a commendable choice for environmentally conscious users.

Key Components of the Engine

Understanding the essential elements of a power unit is crucial for anyone interested in maintenance or performance enhancements. Each component plays a vital role in ensuring the smooth operation and efficiency of the system. From fuel delivery to ignition, every part works in harmony to create the desired output.

Fuel Delivery System

The fuel delivery mechanism is responsible for transporting the necessary mixture of air and fuel to the combustion chamber. This process is critical for achieving optimal performance and efficiency. Key elements include the carburetor or fuel injector, which precisely regulates the flow of fuel, and the fuel pump, which maintains the required pressure for delivery.

Ignition Assembly

The ignition system initiates the combustion process, transforming the fuel-air mixture into energy. This assembly typically consists of the spark plug, ignition coil, and associated wiring. Each component must function effectively to ensure reliable starts and smooth operation throughout the unit’s lifespan.

Fuel System Essentials Explained

The fuel system is a crucial component that ensures optimal performance and efficiency of any motorized vehicle. It plays a vital role in delivering the right amount of fuel to the combustion chamber, where it mixes with air and ignites to produce power. Understanding the various elements of this system can help in maintaining and troubleshooting issues effectively.

At its core, the fuel system consists of several key components, including the fuel tank, fuel pump, fuel lines, and the carburetor or fuel injector. Each part works in harmony to transport fuel from the tank to the engine, ensuring a consistent flow that matches the engine’s demands under different operating conditions.

The fuel tank stores the fuel and is designed to prevent leaks while providing easy access for refueling. The fuel pump, either mechanical or electric, is responsible for drawing fuel from the tank and pushing it through the fuel lines. These lines are crucial for directing the fuel to the next stage without any interruptions or pressure drops.

Finally, the carburetor or fuel injector atomizes the fuel, mixing it with air before it enters the combustion chamber. This process is essential for achieving the correct fuel-to-air ratio, which directly influences performance, emissions, and fuel economy. Understanding these essentials allows for better care and enhancement of the vehicle’s overall functionality.

Cooling Mechanisms in Lifan Engines

The efficiency of a motor relies heavily on effective thermal management. Various strategies are employed to maintain optimal temperatures, ensuring reliable performance and longevity. This section explores the crucial systems that prevent overheating and promote smooth operation.

Liquid cooling is a prevalent approach, utilizing a coolant to absorb heat from critical components. This method circulates the fluid through passages, dissipating heat through a radiator, thereby maintaining a stable operating temperature.

Another common strategy is air cooling, which relies on the natural flow of air to cool the system. This technique often incorporates fins and ducts to enhance airflow, maximizing heat dissipation without the complexity of liquid systems.

Ultimately, the choice of cooling method impacts the overall efficiency and performance of the machinery, making it essential to delve into the specific requirements of each design.

Understanding these mechanisms is vital for proper maintenance and optimal performance, as they play a significant role in the longevity and reliability of any motorized device.

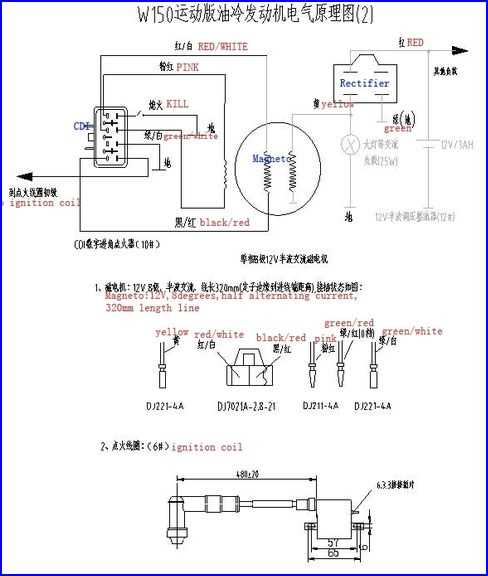

Electrical System Breakdown

The electrical framework of a motorbike plays a crucial role in ensuring optimal performance and reliability. It encompasses various components that work together to provide power, control, and safety. Understanding each element of this system is essential for effective maintenance and troubleshooting.

Key Components

At the heart of the electrical setup are the battery and the alternator, which supply the necessary energy. The battery stores electricity and powers the ignition system, lights, and other electrical accessories. Meanwhile, the alternator generates electricity while the vehicle is in motion, recharging the battery and powering systems directly.

Control Mechanisms

Another vital aspect involves the wiring harness and fuse box. The wiring harness connects all electrical components, ensuring efficient transmission of power. The fuse box protects these circuits from overloads by interrupting the flow of electricity when necessary, thus preventing potential damage to sensitive parts.

Transmission Features and Functionality

The transmission system plays a crucial role in delivering power from the power source to the wheels, ensuring smooth and efficient operation. Its design allows for the effective transfer of energy while adapting to varying speed and torque requirements.

Key Features

- Gear Ratios: Multiple gear settings enable adjustments for different driving conditions.

- Clutch Mechanism: Allows for seamless shifting, enhancing rider control.

- Durability: Constructed from robust materials to withstand high-stress conditions.

Functionality Overview

- Power Transfer: Converts rotational energy into usable motion.

- Speed Regulation: Adjusts vehicle speed based on rider input.

- Torque Management: Optimizes performance for acceleration and hill climbing.

Maintenance Tips for Longevity

Proper upkeep is essential for maximizing the lifespan of any mechanical device. By following a few simple guidelines, users can ensure optimal performance and minimize the risk of unexpected failures. Regular care not only enhances efficiency but also helps maintain the overall value of the unit.

- Regular Oil Changes: Consistently replacing the lubricant prevents wear and tear on internal components.

- Check Fluid Levels: Ensure that all necessary fluids are topped up and free of contaminants.

- Inspect Filters: Clean or replace air and fuel filters to guarantee proper airflow and fuel delivery.

- Tighten Bolts and Screws: Regularly check all fasteners to avoid any loose parts that could lead to larger issues.

- Clean the Unit: Remove dirt and debris to prevent buildup that could affect performance.

By implementing these practices, individuals can significantly enhance the reliability and durability of their equipment, ultimately leading to a smoother and more enjoyable experience.

Troubleshooting Common Issues

When operating a small motorized vehicle, encountering various challenges is not uncommon. Understanding how to identify and resolve these issues can significantly enhance performance and longevity. This section outlines some frequent problems and their potential solutions, aiding in maintaining optimal functionality.

Starting Difficulties

One prevalent challenge is the inability to start the machine. This can stem from several factors, including fuel supply problems, electrical malfunctions, or issues with the ignition system. Checking the fuel level and ensuring that it is fresh is a crucial first step. If the fuel is adequate, inspecting the battery and connections can reveal potential electrical faults. Additionally, examining the spark plug for wear or damage may also provide insights into ignition-related issues.

Overheating

Another frequent concern is overheating, which can lead to severe damage if not addressed promptly. Common causes include low coolant levels, a malfunctioning radiator, or obstructions in the cooling system. To troubleshoot, start by checking the coolant level and ensuring that there are no leaks. Additionally, inspecting the radiator for blockages and ensuring that airflow is not restricted can help mitigate overheating risks. Regular maintenance of the cooling components is vital for preventing this issue in the future.

Replacement Parts and Their Importance

Ensuring optimal performance and longevity of a mechanical unit often hinges on the quality and condition of its components. When original elements wear out or malfunction, replacing them with suitable alternatives becomes crucial. This practice not only enhances functionality but also safeguards against potential failures that could arise from neglected issues.

High-quality replacements play a vital role in maintaining efficiency and reliability. Utilizing inferior substitutes may lead to further complications, resulting in more significant repairs and increased costs. Therefore, selecting reputable brands or OEM options is essential for preserving the integrity of the entire system.

Moreover, regular assessments and timely replacements of essential components contribute to smoother operation and improved safety. By staying proactive, users can prevent unexpected breakdowns and ensure that their machinery performs at its best. In essence, understanding the significance of appropriate replacements is key to maximizing both performance and durability.

Assembly and Disassembly Guidelines

Understanding the processes involved in assembling and disassembling mechanical components is essential for effective maintenance and repairs. Following systematic instructions can ensure proper functioning and longevity of the unit while minimizing the risk of damage during the procedure. This section provides key principles to help streamline these operations.

Preparation Steps

Before starting, gather all necessary tools and materials. Ensure the workspace is clean and well-lit, allowing for easy access to components. Reviewing the assembly sequence and disassembly order is crucial, as it helps in identifying the specific elements involved. Additionally, taking notes or photographs during disassembly can aid in reassembly.

Safe Practices

Always prioritize safety by wearing appropriate protective gear. When disassembling, handle components with care to avoid damaging fragile parts. If applicable, refer to the manufacturer’s guidelines for torque specifications and other critical information. After completing the tasks, conduct a thorough inspection to confirm that everything is securely in place and functioning correctly.

Performance Upgrades for the Engine

Enhancing the capabilities of your power unit can lead to significant improvements in speed and efficiency. By focusing on specific modifications, enthusiasts can unlock the true potential of their machines, achieving a more thrilling riding experience.

One of the most effective upgrades is the installation of a high-performance exhaust system. This modification improves airflow, allowing for better combustion and increased horsepower. Additionally, upgrading the air intake can further enhance engine performance by providing a more significant amount of air, which is essential for optimal fuel combustion.

Another popular choice is tuning the ignition system. A more advanced ignition setup can lead to more precise timing, resulting in improved throttle response and overall power delivery. Consider using a performance CDI (Capacitor Discharge Ignition) to maximize ignition efficiency and boost acceleration.

Finally, re-gearing the transmission can make a noticeable difference in how power is delivered to the wheels. Adjusting gear ratios can optimize your ride for either acceleration or top speed, depending on your personal preferences and riding style. These upgrades collectively contribute to a more exhilarating experience on the road or track.