The intricate design of a powerful propulsion system showcases a harmonious interplay of various elements, each playing a crucial role in performance and efficiency. Understanding this assembly not only enhances appreciation for automotive engineering but also sheds light on the mechanics that drive high-performance vehicles.

As we delve into the specific components, it becomes evident that every piece contributes to the ultimate functionality. From the fundamental structures to the advanced mechanisms, each element is meticulously crafted to ensure seamless operation under demanding conditions.

Exploring these components reveals insights into their relationships and the way they enhance overall performance. By comprehending the interactions among these crucial structures, enthusiasts and engineers alike can gain a deeper understanding of what fuels the passion for automotive excellence.

Understanding the V8 Engine Layout

The V8 configuration is a popular choice in the automotive world, known for its balance of power and efficiency. This arrangement provides a robust framework that enhances performance and creates a distinct auditory experience. Grasping the layout of this setup is essential for anyone interested in the mechanics behind powerful vehicles.

At its core, this configuration features eight cylinders arranged in a specific manner. This layout contributes to the unique characteristics that define the performance and handling of various models. Here are some key aspects to consider:

- Configuration: The cylinders are positioned in two banks, forming a “V” shape. This design allows for a compact and efficient structure.

- Firing Order: The sequence in which the cylinders fire affects the smoothness and balance of the operation, influencing both power delivery and vibration.

- Displacement: The total volume of all cylinders plays a crucial role in determining the overall power output and efficiency.

Understanding these elements is vital for appreciating how the V8 setup delivers power and enhances performance in various applications. Each component works in harmony, creating a symphony of engineering that drives the fascination behind high-performance vehicles.

In summary, exploring this arrangement reveals the intricacies and advantages that come with the V8 layout, offering insights into the dynamic world of automotive engineering.

Key Components of a V8 Engine

Understanding the essential elements of a V8 configuration reveals the intricate mechanics behind its powerful performance. Each component plays a vital role in the overall function and efficiency of this powerhouse.

- Cylinders: The heart of the assembly, where fuel and air mix for combustion.

- Pistons: These move up and down within the cylinders, converting combustion energy into motion.

- Crankshaft: This crucial element transforms the linear motion of the pistons into rotational energy.

- Camshaft: Responsible for opening and closing the valves at the right moments during the cycle.

- Valves: These control the flow of air and fuel into the cylinders and exhaust out.

- Intake Manifold: Distributes the air-fuel mixture to the cylinders evenly.

- Exhaust Manifold: Channels exhaust gases away from the cylinders.

Each of these components interacts harmoniously, culminating in a sophisticated mechanism that defines the V8’s legendary performance.

How V8 Engines Work Mechanically

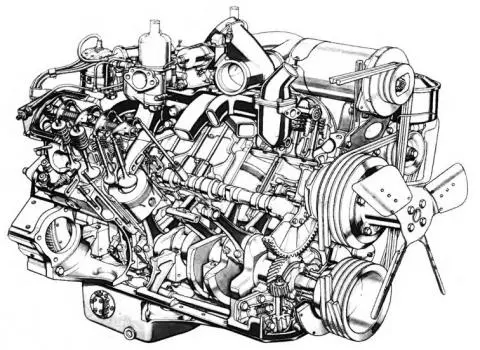

The intricate mechanics behind the V8 configuration involve a series of coordinated movements that transform fuel into kinetic energy. This process is driven by the precise interplay of various components, working in harmony to create powerful motion. Each cycle of combustion generates force, which is then harnessed to propel a vehicle forward.

At the heart of this system lies the arrangement of cylinders, where fuel and air mix before ignition. The explosion pushes pistons down, converting thermal energy into mechanical motion. This motion is then transmitted through connecting rods to a central crankshaft, which translates the linear movement into rotational energy.

Timing is crucial; the synchronization of valves opening and closing ensures that air enters and exhaust gases exit at the correct intervals. The role of the camshaft is vital, as it dictates the precise timing of these operations. Additionally, the lubrication system maintains smooth operation, reducing friction and wear on the moving components.

In essence, the V8 configuration exemplifies a finely tuned mechanical orchestra, where each element contributes to the overall performance. The result is a powerful and efficient machine, capable of delivering impressive power and torque for various applications.

V8 Engine Parts and Their Functions

This section explores the various components that come together to create the powerful performance characteristic of a V8 configuration. Each element plays a critical role in the overall operation, contributing to efficiency and output.

- Cylinders: Houses the combustion process, where fuel ignites to create power.

- Pistons: Moves up and down within the cylinders, converting energy from combustion into mechanical motion.

- Crankshaft: Transforms the linear motion of pistons into rotational force to drive the vehicle.

- Camshaft: Controls the timing of valve openings and closings, essential for airflow management.

- Valves: Regulates the intake of air and fuel and the expulsion of exhaust gases.

Understanding these elements provides insight into how this powerful configuration operates effectively and efficiently.

Common Variations of V8 Designs

The diversity within V8 configurations showcases the adaptability and engineering ingenuity behind this popular powertrain layout. Each variation presents unique characteristics tailored to specific performance requirements, driving experiences, and applications.

One notable distinction lies in the configuration of the cylinders. While traditional designs feature a 90-degree angle between cylinder banks, some manufacturers opt for a narrower angle, leading to a more compact layout. This approach can enhance handling dynamics and reduce overall weight, making it advantageous for sports applications.

Another variation is the choice between naturally aspirated and forced induction systems. Naturally aspirated configurations rely solely on atmospheric pressure for air intake, providing a linear power delivery. In contrast, forced induction systems, such as superchargers or turbochargers, significantly increase power output by compressing incoming air, allowing for a more aggressive driving experience.

Fuel types also contribute to the variety of V8 designs. While gasoline remains the most common, some models utilize alternative fuels, such as ethanol or diesel. These alternatives can improve efficiency and reduce emissions, appealing to environmentally conscious consumers.

Furthermore, advancements in technology have led to the rise of hybrid V8 configurations. By integrating electric components, these systems aim to provide a balance of power and efficiency, catering to a new generation of performance enthusiasts.

In summary, the common variations of V8 layouts reflect a rich tapestry of innovation, each tailored to meet specific needs and preferences in the automotive landscape.

Importance of the Cylinder Head

The cylinder head plays a crucial role in the overall functionality of an internal combustion mechanism. It serves as a vital component that contributes to the efficiency and performance of the system. Understanding its significance is essential for anyone interested in the mechanics of these machines.

One of the primary functions of the cylinder head is to provide a seal for the combustion chamber. This seal ensures that the air-fuel mixture remains contained during the combustion process, maximizing energy output. Additionally, the cylinder head facilitates the following:

- Thermal management, helping to dissipate heat generated during operation.

- Air and fuel distribution, ensuring optimal mixing for effective combustion.

- Exhaust gas evacuation, allowing for a smooth exit of gases after combustion.

Moreover, the design and construction of the cylinder head can significantly influence overall performance characteristics:

- Higher compression ratios can be achieved with an efficient design, leading to better power output.

- Improved airflow dynamics enhance responsiveness and throttle performance.

- Material choices impact durability and weight, affecting the balance of the entire system.

In summary, the cylinder head is not just a structural element; it is a key player in the mechanics of internal combustion. Its design, function, and materials directly affect the overall efficiency, performance, and reliability of the machinery.

Role of the Crankshaft in V8

The crankshaft serves a vital function in the V8 configuration, acting as the central component that translates linear motion into rotational force. This transformation is crucial for the overall performance and efficiency of the system, impacting power delivery and smooth operation.

Its design allows for the connection of multiple pistons, coordinating their movement to optimize energy output. The arrangement of the crankpins is key to maintaining balance and reducing vibrations, ultimately enhancing the driving experience.

| Function | Description |

|---|---|

| Power Conversion | Transforms linear motion from pistons into rotational energy. |

| Balance | Ensures even distribution of forces to minimize vibrations. |

| Durability | Constructed to withstand high stress and wear over time. |

Fuel Injection Systems in V8 Engines

The efficiency and performance of a V8 configuration heavily depend on its fuel delivery mechanism. This crucial system is designed to optimize combustion by precisely managing the amount of fuel entering each cylinder, ensuring that the air-fuel mixture is ideal for various operating conditions. Understanding the different types of fuel delivery systems can enhance maintenance and improve overall performance.

Fuel injection systems can be broadly classified into several categories, each with its unique characteristics and benefits. Here is a brief overview of the most common types:

| Type | Description | Advantages |

|---|---|---|

| Single-Point Injection | Utilizes one injector for multiple cylinders, often located in the throttle body. | Simplified design, cost-effective for lower horsepower applications. |

| Multi-Point Injection | Features one injector per cylinder, providing a more precise fuel delivery. | Improved fuel atomization, enhanced throttle response, and better fuel efficiency. |

| Direct Injection | Injects fuel directly into the combustion chamber under high pressure. | Greater power output, reduced emissions, and increased efficiency. |

| Sequential Injection | Injectors operate in a sequence, timed to the engine’s cycle for optimal performance. | Enhanced fuel efficiency and smoother operation across various speeds. |

Incorporating advanced technologies into fuel delivery systems allows for improved performance and reduced environmental impact. As automotive engineering evolves, these systems continue to play a pivotal role in enhancing the capabilities of V8 configurations.

Cooling Systems and Their Significance

The efficient management of temperature is crucial for the optimal performance and longevity of high-performance machinery. Effective cooling mechanisms prevent overheating, ensuring that components operate within safe limits. This section explores the importance of cooling systems and their role in maintaining overall functionality.

Preventing Overheating

One of the primary functions of cooling systems is to prevent excessive heat buildup. When temperatures rise beyond acceptable thresholds, the risk of damage increases significantly. Maintaining a stable temperature allows for consistent operation and minimizes wear on critical components.

Enhancing Performance

Another key aspect is the enhancement of overall performance. Efficient cooling not only safeguards individual components but also contributes to improved power output and responsiveness. By ensuring optimal thermal conditions, these systems allow machinery to perform at its best, delivering the reliability that users expect.

Maintenance Tips for V8 Components

Proper upkeep of a powerful unit’s elements ensures optimal performance and longevity. Regular attention to various components can prevent potential issues and enhance overall efficiency.

Regular Inspections

Conduct frequent checks of all critical components to identify wear or damage early. Pay special attention to seals and gaskets, as these are vital for maintaining pressure and preventing leaks. A proactive approach will help in addressing minor concerns before they escalate into major problems.

Fluid Management

Ensure that all necessary fluids, including lubricants and coolants, are at recommended levels and are changed at regular intervals. Using high-quality lubricants not only enhances performance but also extends the life of various elements. A well-maintained fluid system plays a crucial role in the efficiency of the entire setup.

Aftermarket Upgrades for V8 Engines

Enhancing the performance of your V8 can significantly elevate your driving experience. Various aftermarket modifications are available, designed to boost power, improve efficiency, and enhance overall responsiveness. These enhancements cater to both enthusiasts seeking speed and those looking for improved reliability in daily driving conditions.

Performance Enhancements

One of the most popular modifications involves upgrading the intake system. High-flow air filters and larger intake manifolds can facilitate better airflow, resulting in improved combustion. Coupled with a performance exhaust system, these upgrades work together to reduce back pressure, allowing for a more efficient release of gases and enhancing acceleration.

Tuning Options

Tuning the vehicle’s control unit is essential for optimizing the performance of any modifications. Custom tunes can adjust fuel maps, ignition timing, and more, ensuring that the vehicle runs efficiently with the new components. Additionally, incorporating a performance chip can provide instant improvements in throttle response and overall power delivery.

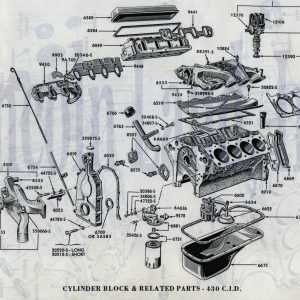

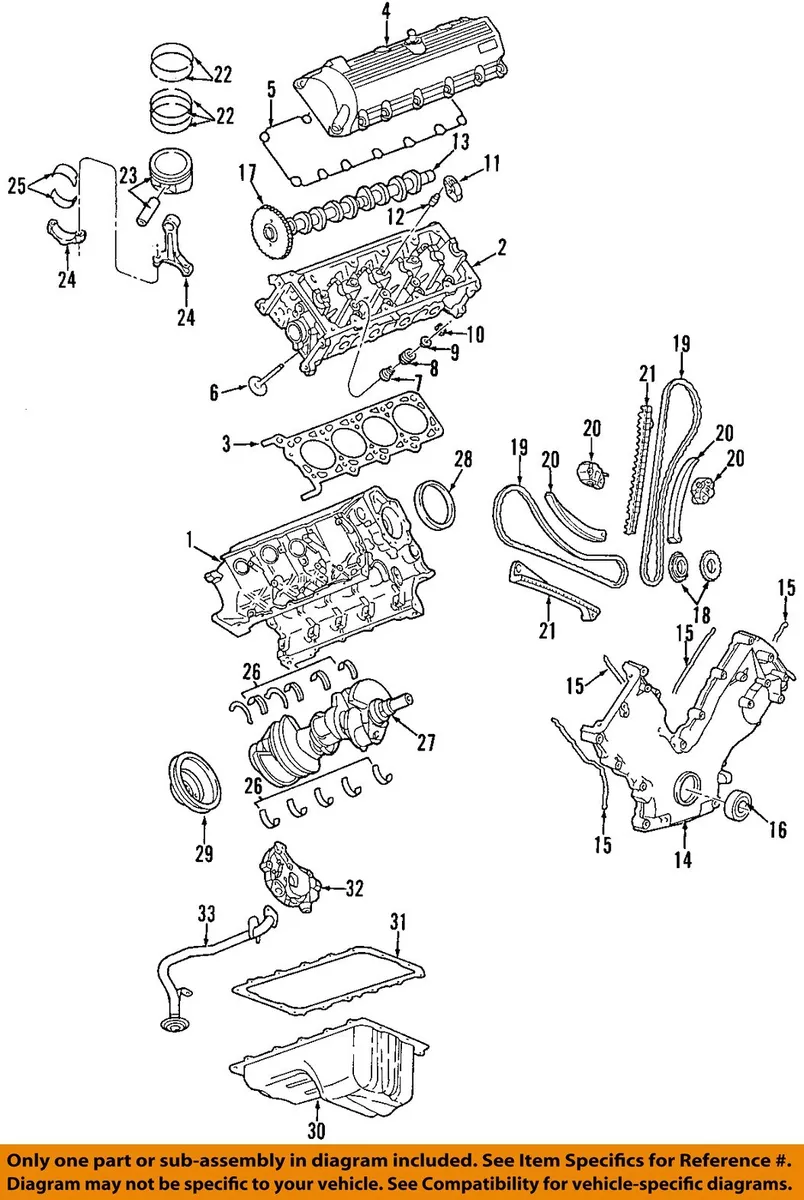

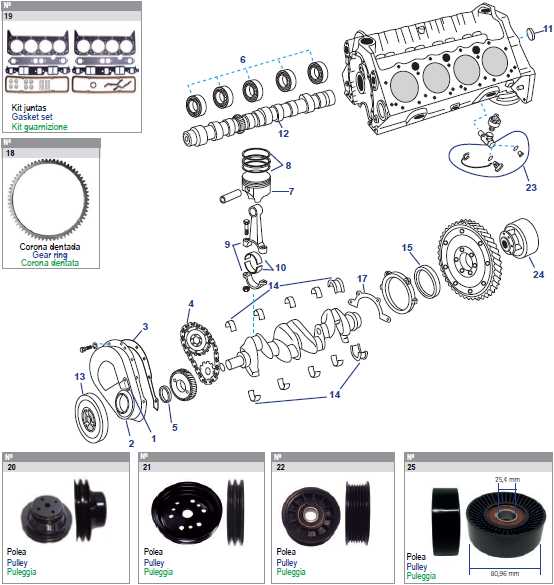

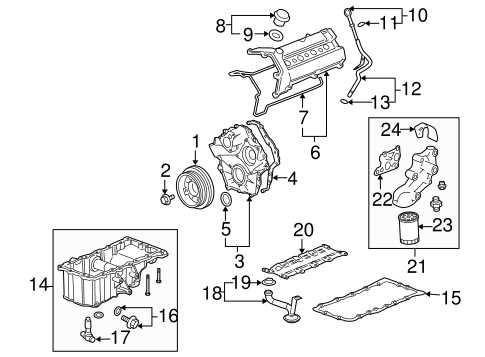

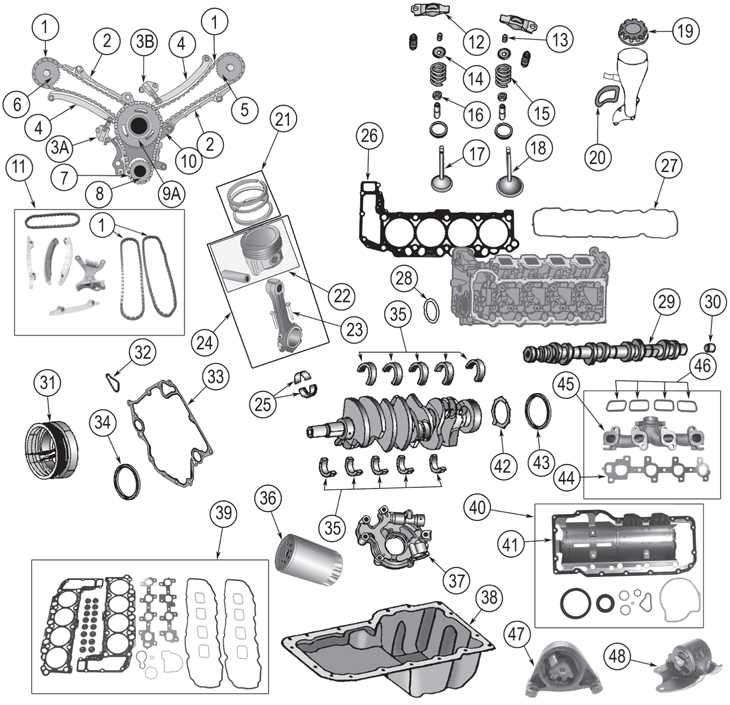

Visualizing V8 Engine Schematics

This section explores the intricacies of a V8 configuration, focusing on how its components interact and contribute to overall performance. By examining visual representations, we can gain insights into the structure and functionality of this powerful setup.

Understanding the Configuration

Grasping the arrangement of various elements helps enthusiasts appreciate the mechanical harmony within the V8 framework. Each segment plays a crucial role, and understanding their positions aids in troubleshooting and enhancements.

Key Components Overview

| Component | Function |

|---|---|

| Block | Houses cylinders and provides structural integrity. |

| Pistons | Convert combustion pressure into mechanical energy. |

| Crankshaft | Transforms linear motion into rotational force. |

| Camshaft | Controls valve timing for optimal airflow. |

| Intake Manifold | Distributes air and fuel mixture to cylinders. |