The mechanical design of a pickup vehicle plays a crucial role in its performance and longevity. A well-structured assembly enhances driving stability and contributes to overall safety. This section aims to explore the various elements that constitute the front section of a classic pickup, providing insights into their functions and interconnections.

Each component in this assembly serves a distinct purpose, from supporting the vehicle’s weight to enabling smooth steering and handling. Understanding these elements not only aids in maintenance but also empowers enthusiasts and owners to make informed decisions regarding repairs and upgrades. With a focus on functionality and durability, this overview will highlight the essential features that make up this integral part of the vehicle.

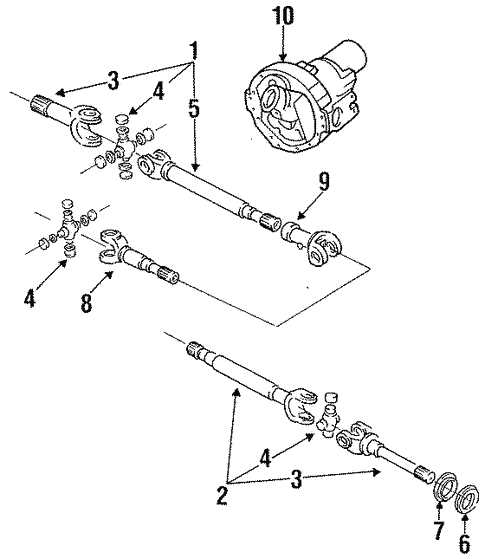

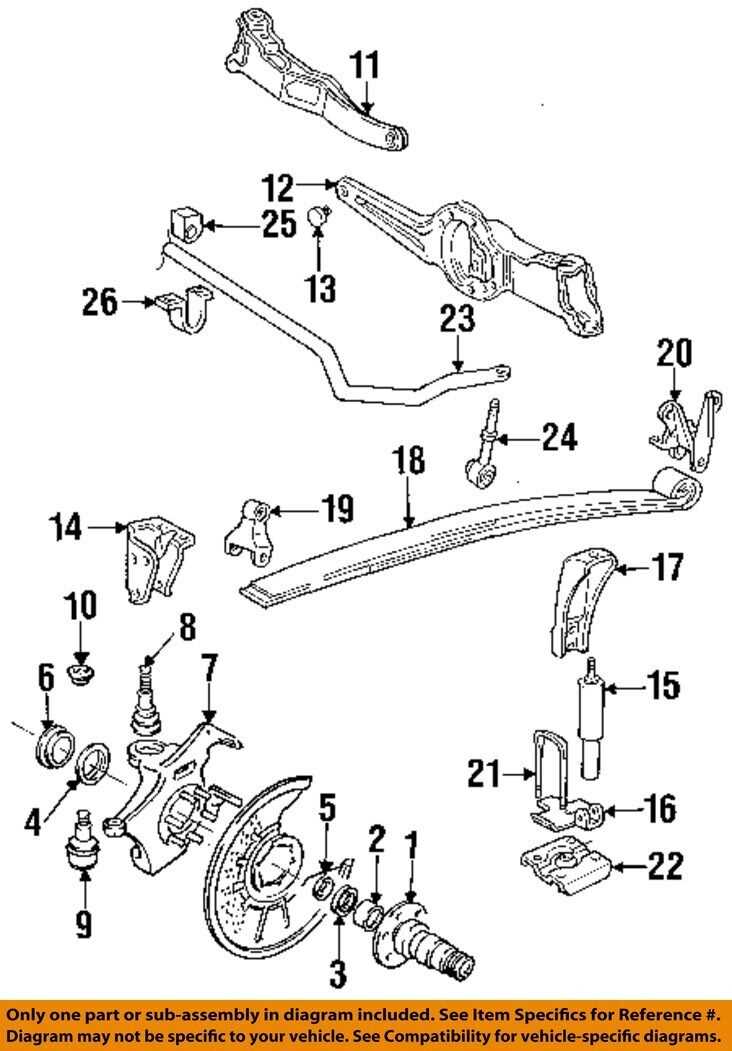

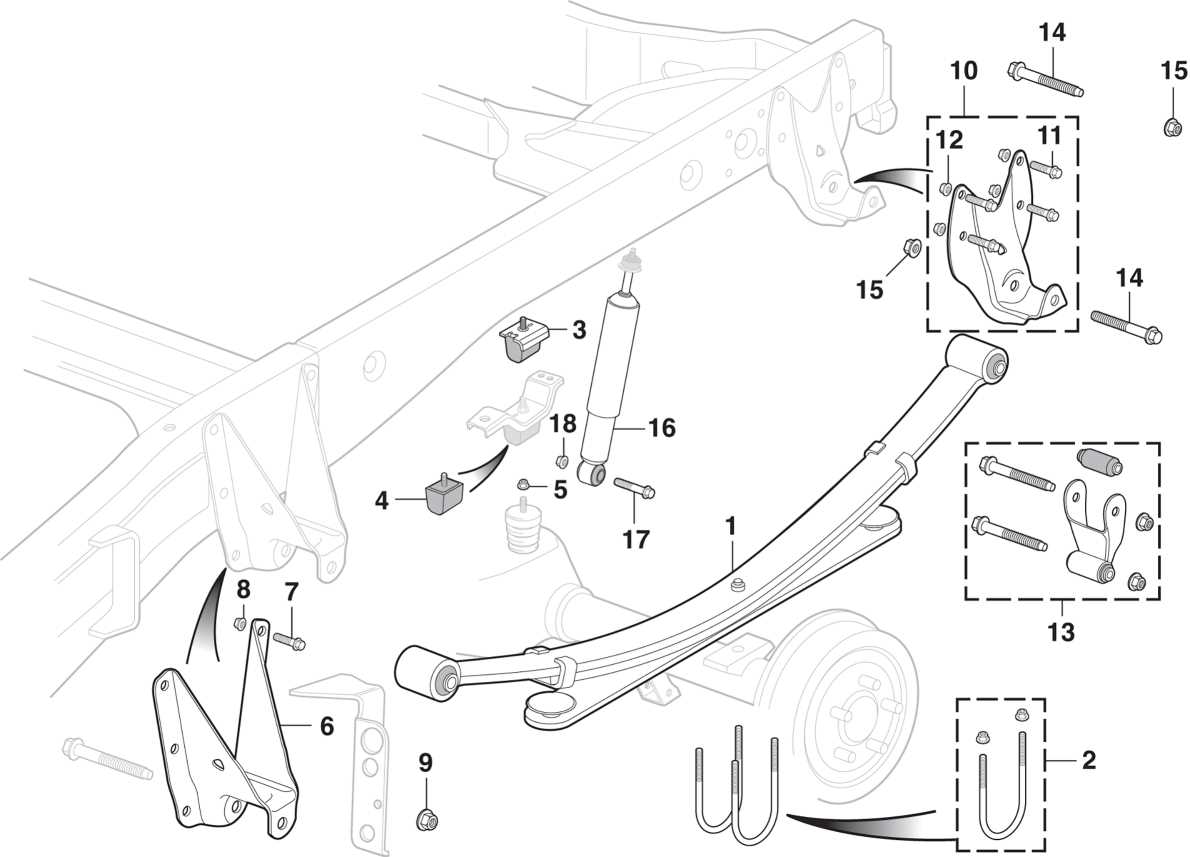

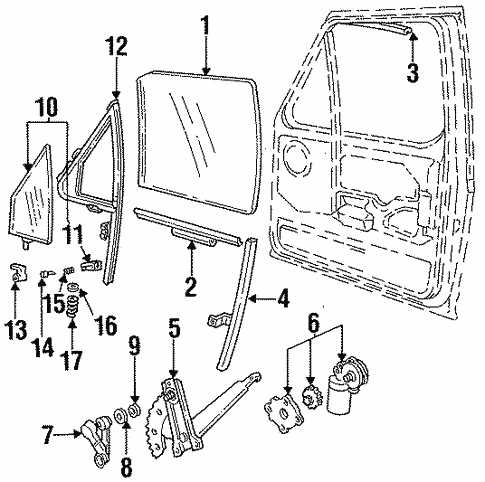

Additionally, visual representations can be invaluable tools in comprehending how each component fits together. Diagrams can simplify complex relationships, making it easier to identify individual elements and their roles within the entire assembly. By delving into the specifics, one can appreciate the engineering that underpins the functionality of these vehicles.

tags without repeating phrases or words. Overview of Front End Components”>

tags without repeating phrases or words. Overview of Front End Components”>

The front assembly of a vehicle plays a crucial role in its overall performance and safety. Understanding the various components that comprise this section is essential for maintenance and repair. This segment will explore the primary elements that contribute to the functionality of the front structure, emphasizing their significance and interrelations.

Key Components of the Vehicle’s Front Assembly

This section will outline the essential elements, including suspension, steering mechanisms, and other vital parts. Each component’s function and importance will be highlighted to provide a comprehensive understanding of the assembly.

Maintenance Tips for Optimal Performance

Regular upkeep of the front assembly is crucial for ensuring vehicle stability and safety. This section will offer practical advice on how to inspect and maintain these components effectively, enhancing their longevity and performance.

Common Issues and Troubleshooting Techniques

Identifying potential problems within the front assembly can save time and costs. This part will discuss frequent challenges faced by vehicle owners and provide guidance on troubleshooting methods to address these issues promptly.

Common Issues with F150 Front End

Various challenges can arise in the assembly of the vehicle’s front section, impacting overall performance and safety. Understanding these common problems is essential for effective maintenance and repair.

- Worn Bearings: Over time, bearings may deteriorate, leading to increased play in the steering system.

- Misalignment: Improper alignment can cause uneven tire wear and affect handling.

- Damaged Bushings: Rubber bushings can crack or degrade, resulting in poor suspension response.

- Leaking Seals: Seals may fail, leading to fluid leaks that compromise hydraulic systems.

- Corroded Components: Exposure to harsh conditions can lead to rust and corrosion, weakening structural integrity.

Regular inspections and timely interventions can help mitigate these issues, ensuring better performance and longevity of the vehicle.

Detailed Parts Diagram Explanation

This section provides an in-depth overview of the various components and their interrelations within the vehicle’s structure. Understanding these elements is crucial for effective maintenance and repair procedures.

The schematic representation showcases several key components, each serving specific functions. Familiarizing oneself with these elements can greatly enhance the efficiency of any restoration or repair project.

- Chassis: The foundational structure that supports the entire assembly.

- Suspension: Includes springs and shock absorbers, which ensure a smooth ride.

- Steering System: Comprises the wheel assembly and linkage mechanisms, providing control and maneuverability.

- Braking Components: Encompasses calipers, pads, and rotors, crucial for safety and stopping power.

- Alignment Features: Essential for maintaining tire wear and vehicle handling.

Each component works in unison to ensure optimal performance. Regular inspection and understanding of these elements can prevent potential issues and prolong the vehicle’s lifespan.

Replacement Parts for Front Suspension

When maintaining the suspension system of your vehicle, it is essential to consider various components that contribute to its overall performance and safety. Replacing worn-out elements can enhance handling, comfort, and stability on the road. This section outlines key replacement options for the suspension system, ensuring that you can make informed decisions when servicing your automobile.

Essential Components

Several critical components comprise the suspension system. Understanding their roles and knowing when to replace them is crucial for optimal vehicle performance. Here are the main elements that may require replacement:

| Component | Description | Signs of Wear |

|---|---|---|

| Shock Absorbers | Dampen the impact of bumps and uneven surfaces, providing a smooth ride. | Excessive bouncing, leaking fluid. |

| Control Arms | Connect the vehicle frame to the wheels, allowing for controlled movement. | Clunking noises, uneven tire wear. |

| Ball Joints | Act as pivot points between the suspension and wheels, enabling movement. | Loose steering, grinding noises. |

| Struts | Combine shock absorption and structural support, crucial for stability. | Fluid leaks, bouncing, and instability during turns. |

Choosing Quality Replacements

Opting for high-quality replacements is vital for ensuring longevity and performance. Always consider parts that meet or exceed original equipment specifications to maintain the integrity of your suspension system. Consulting with professionals and using reputable suppliers can also enhance your vehicle’s overall reliability.

Step-by-Step Installation Guide

This section outlines the essential steps for properly installing components in the vehicle’s front structure. By following this guide, you will ensure a successful setup, enhancing both performance and safety.

Preparation for Installation

Before beginning the installation process, gather all necessary tools and materials. A well-organized workspace will facilitate a smoother workflow.

- Required tools: wrenches, sockets, pliers, and a jack.

- Replacement components: ensure all parts are compatible with your specific model.

- Safety gear: gloves and goggles for protection.

Installation Process

Follow these steps to install the components correctly:

- Raise the vehicle using a jack and secure it on jack stands.

- Remove the old components by unscrewing bolts and disconnecting any attached elements.

- Clean the mounting areas to remove dirt and debris.

- Position the new components in place and align them properly.

- Tighten all bolts securely, following the manufacturer’s torque specifications.

- Reattach any necessary connections and perform a final check of the installation.

After completing these steps, lower the vehicle and conduct a test to ensure everything is functioning as expected.

Tools Required for Front End Repair

Effective maintenance and restoration of vehicle components demand specific instruments. Having the right tools ensures that tasks can be completed efficiently and safely.

Below is a list of essential tools that are commonly used during the repair process:

- Wrench Set: A comprehensive set of wrenches in various sizes helps to tighten or loosen bolts and nuts.

- Sockets and Ratchet: These are necessary for accessing fasteners in tight spaces.

- Jack and Jack Stands: Elevating the vehicle safely is crucial for performing repairs underneath.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications.

- Ball Joint Separator: Essential for removing and installing ball joints without damage.

- Hammer: Useful for tapping components into place or loosening rusted parts.

- Pry Bar: Helps in dislodging stuck components with leverage.

- Impact Wrench: Speeds up the process of removing stubborn fasteners.

Having these tools at hand can significantly streamline the repair process, allowing for a more effective approach to vehicle maintenance.

Understanding Steering Mechanism Functions

The steering mechanism is a crucial component of any vehicle, enabling drivers to navigate safely and accurately. It translates the driver’s input into controlled movement, allowing the wheels to pivot in response to directional changes. This system encompasses various elements that work harmoniously to enhance maneuverability and stability.

Components of the Steering System

Different components contribute to the effective functioning of the steering mechanism. Each part has a specific role, ensuring the entire system operates smoothly and reliably. Below is a table outlining key components and their functions:

| Component | Function |

|---|---|

| Steering Wheel | Allows the driver to initiate directional changes. |

| Steering Column | Connects the steering wheel to the mechanism and provides support. |

| Rack and Pinion | Converts rotational motion into linear motion for wheel movement. |

| Power Steering Pump | Assists in reducing the effort needed to steer by providing hydraulic pressure. |

| Steering Linkage | Transfers the movement from the steering wheel to the wheels. |

Importance of Proper Maintenance

Regular maintenance of the steering system is essential for optimal performance and safety. Neglecting this aspect can lead to decreased responsiveness and potential handling issues. Routine checks can help identify wear and tear, ensuring the mechanism remains in good working condition.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended lifespan of your vehicle’s components. By implementing effective strategies, you can minimize wear and enhance performance, resulting in a more reliable driving experience.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Checks | Every 3,000 miles | Regularly inspect and replace essential fluids such as oil, coolant, and brake fluid to maintain optimal operation. |

| Tire Rotation | Every 6,000 miles | Rotate tires to ensure even wear, enhancing handling and prolonging tire life. |

| Brake Inspection | Every 12,000 miles | Examine brake pads and rotors for wear and replace as necessary to ensure safe stopping power. |

| Suspension Check | Every 15,000 miles | Inspect suspension components for damage or wear, ensuring a smooth ride and proper alignment. |

| Belt and Hose Inspection | Every 30,000 miles | Check for cracks or wear in belts and hoses, replacing them as needed to prevent breakdowns. |

Identifying Signs of Wear

Recognizing indications of deterioration in vehicle components is crucial for maintaining optimal performance and safety. Various symptoms can suggest that specific elements require attention or replacement. Regular inspections can help detect these signs early, potentially preventing more significant issues in the future.

Visual Inspection

Conducting a thorough visual examination of the vehicle’s components is essential. Look for any unusual discoloration, cracks, or fraying materials. Corrosion or rust on metal surfaces can also indicate potential failure points. Identifying these physical changes can help pinpoint parts that may need servicing.

Unusual Noises and Vibrations

Pay attention to any abnormal sounds or vibrations during operation. Clunking, grinding, or excessive noise when turning or navigating bumps may signify wear in suspension elements or steering mechanisms. These auditory cues can be vital in assessing the overall health of the vehicle.

Comparison of Aftermarket Parts Options

When considering enhancements or replacements for essential components in a vehicle, it’s crucial to explore the diverse choices available in the aftermarket sector. These alternatives often provide a blend of performance, durability, and cost-effectiveness, appealing to a wide range of preferences and budgets.

Quality and Performance Variability

The quality of aftermarket alternatives can vary significantly. Some manufacturers prioritize high-performance materials and advanced technology, resulting in superior functionality. Others may focus on affordability, potentially sacrificing longevity or efficiency. It’s essential to research and select options that align with your specific requirements.

Installation and Compatibility Considerations

Another critical aspect is the ease of installation and compatibility with existing systems. Certain aftermarket solutions offer direct fitment, simplifying the installation process. Others may require modifications or specialized tools, impacting overall convenience. Evaluating these factors can aid in making an informed choice that minimizes complications during setup.