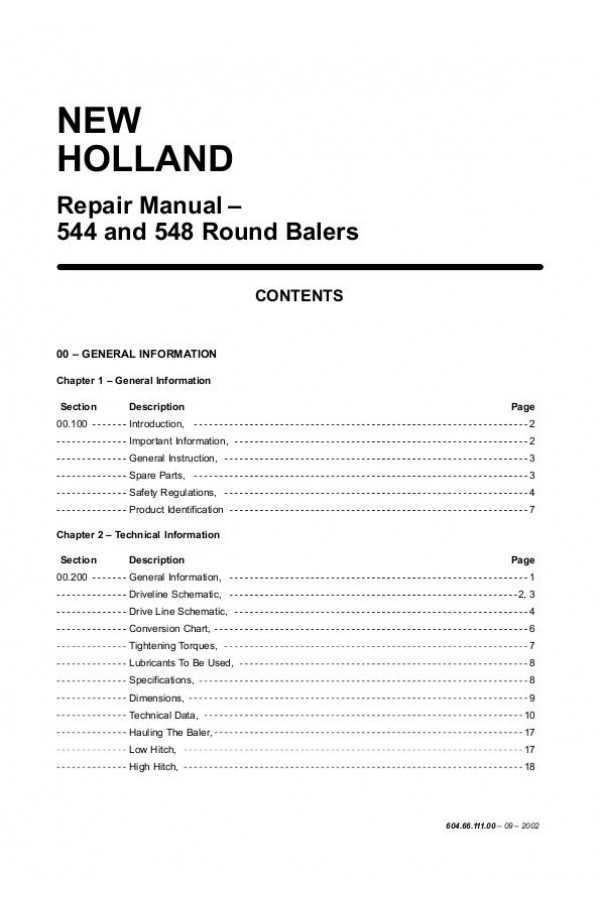

Understanding the structure and organization of machinery is essential for proper maintenance and smooth operation. This guide provides a detailed look into the essential elements and how they fit together to ensure optimal performance.

In this section, we will explore the arrangement and interaction of various mechanical elements, highlighting their importance in the overall functionality. Each part plays a vital role in ensuring efficiency and durability.

By gaining insights into the connections and functionality, you’ll be better equipped to manage upkeep and address any potential issues before they escalate. This knowledge will be valuable for anyone looking to maintain their equipment in the best possible condition.

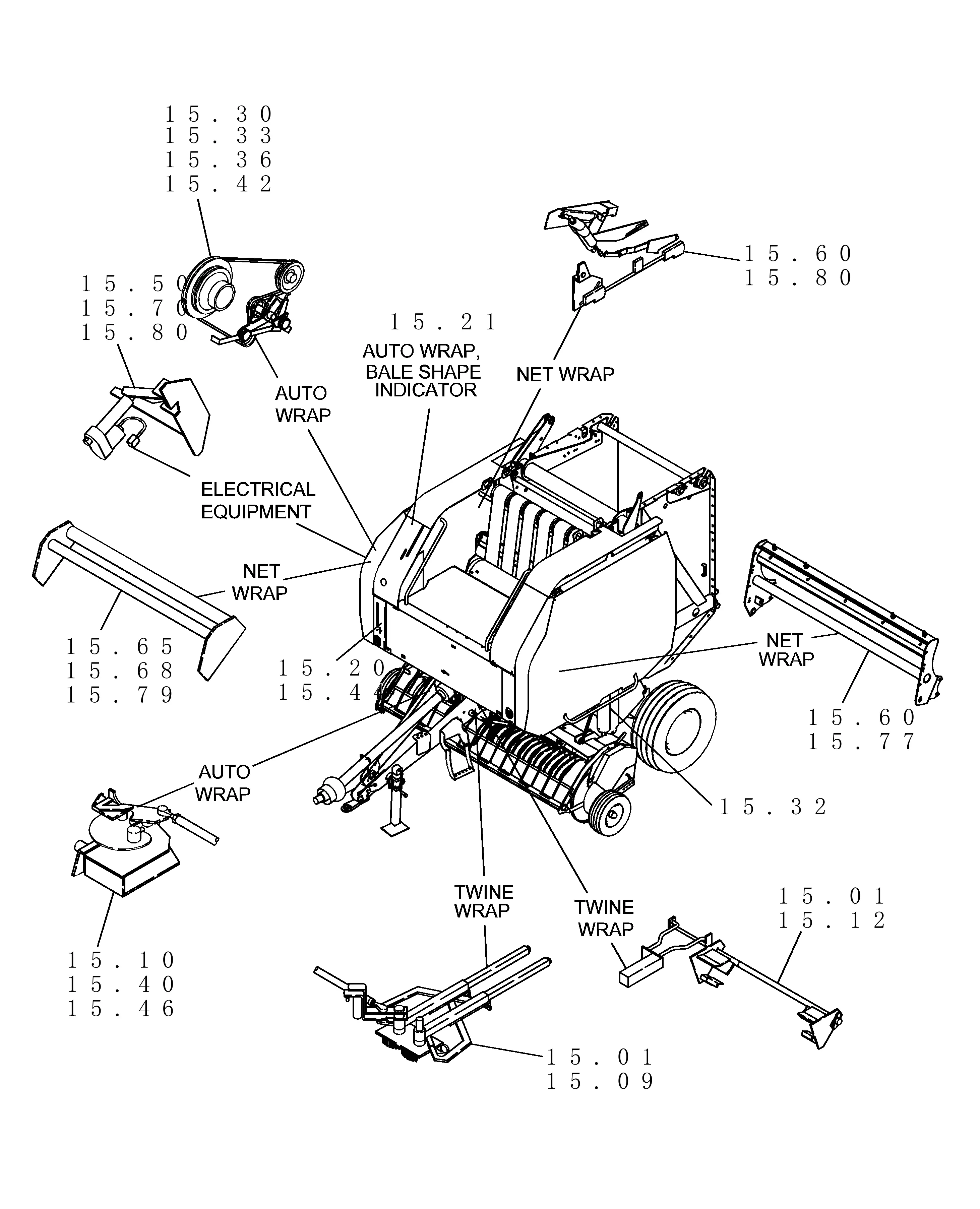

Overview of the BR740 Components

This section provides a detailed look at the main elements that make up the machinery, ensuring smooth operation and reliability. Understanding these components is essential for efficient maintenance and performance optimization.

Key Structural Elements

- Frame: The foundation supporting all major parts, designed to handle significant workloads.

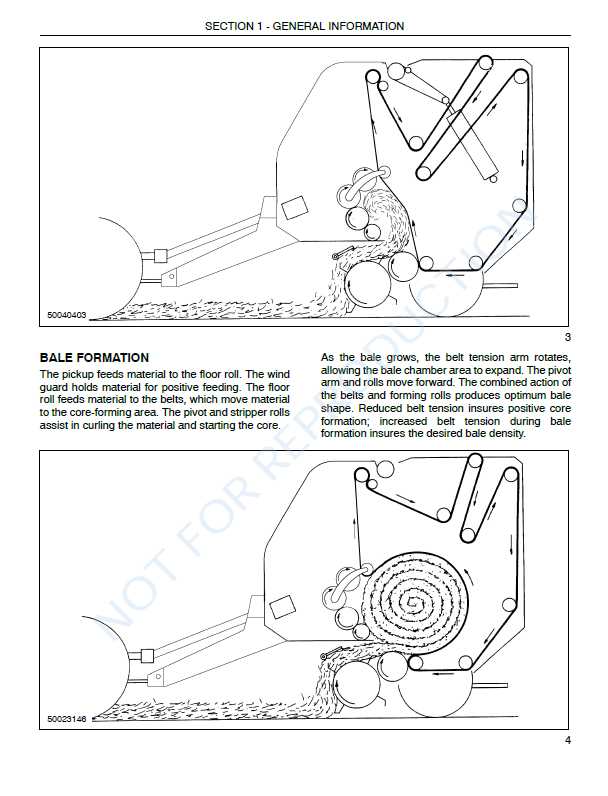

- Feeding system: Responsible for guiding the material through the system efficiently and evenly.

- Compression chamber: Ensures proper shaping and compacting of the processed material.

Mechanical and Functional Components

- Drive system: Powers the various mechanisms involved in the operation.

- Control unit: Allows precise adjustments and management of different functions.

- Safety features: Ensures protection during operation by preventing malfunction and damage.

Key Features of the New Holland BR740

The machinery stands out for its advanced capabilities and durable construction, making it a reliable choice for various agricultural tasks. Its design ensures efficient operation in diverse environments, providing farmers with the tools they need for optimal performance. Below are some of the standout characteristics that enhance its overall functionality and usability.

| Feature | Description |

|---|---|

| Automatic Bale Formation | Ensures consistent results by automatically adjusting to create uniform, tightly-packed bales. |

| Efficient Pickup System | Designed to gather materials quickly and efficiently, reducing time spent in the field. |

| Heavy-Duty Frame | Built to withstand challenging conditions and extended use, offering long-lasting durability. |

| Easy Maintenance Access | Components are arranged for convenient access, allowing for quicker routine checks and repairs. |

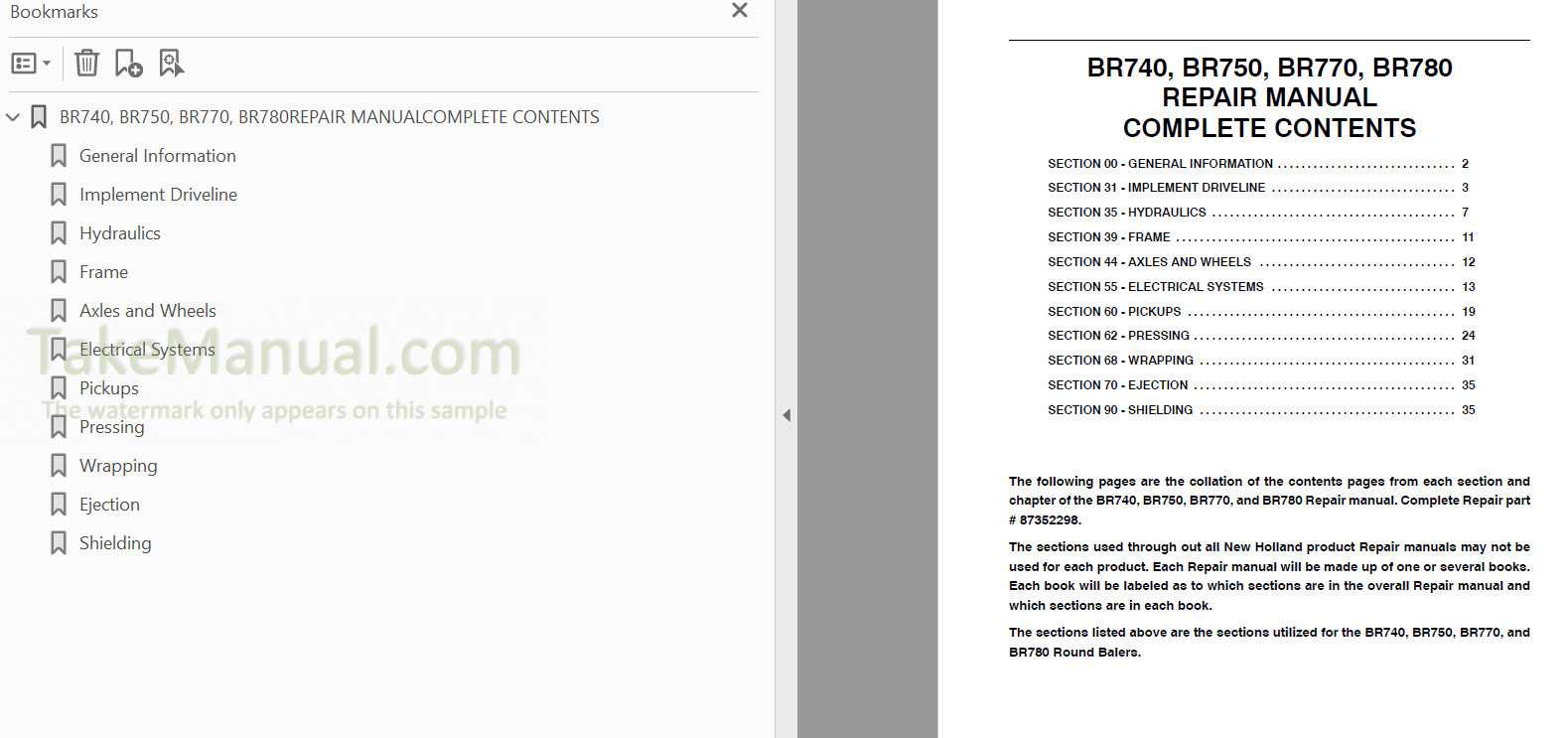

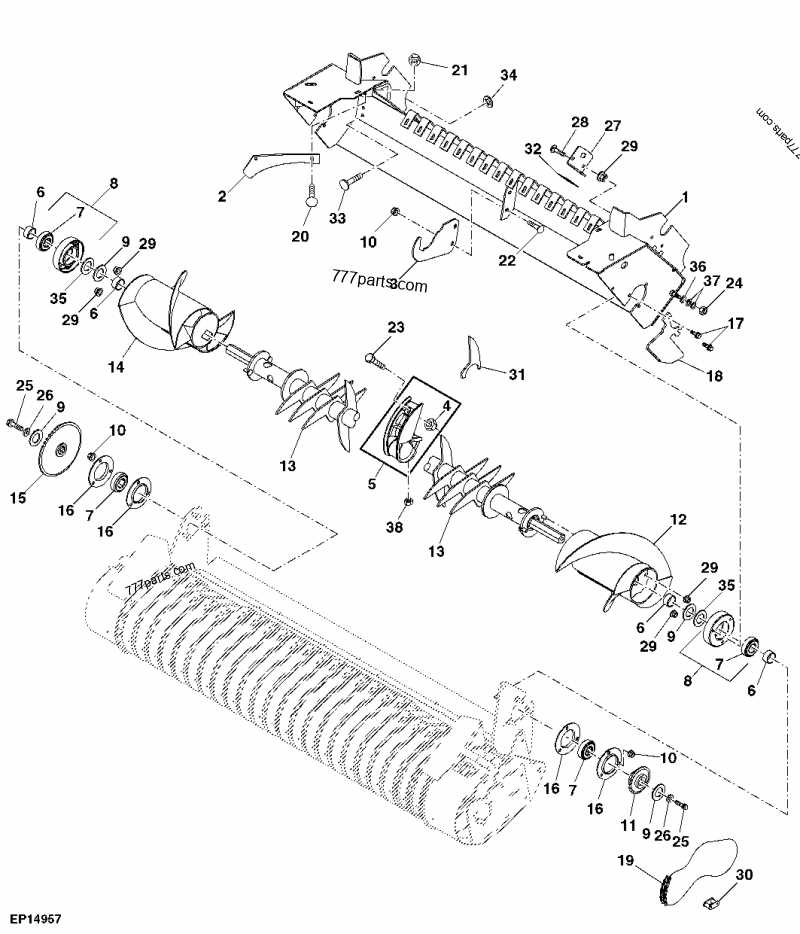

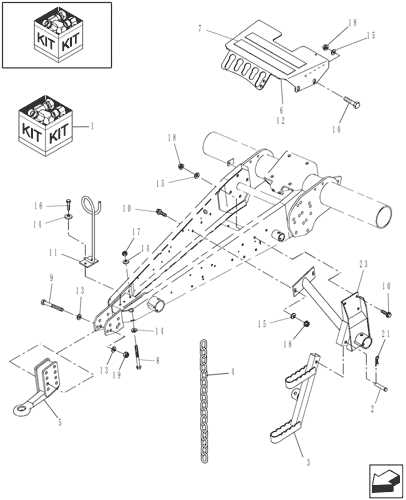

Understanding the Diagram Structure

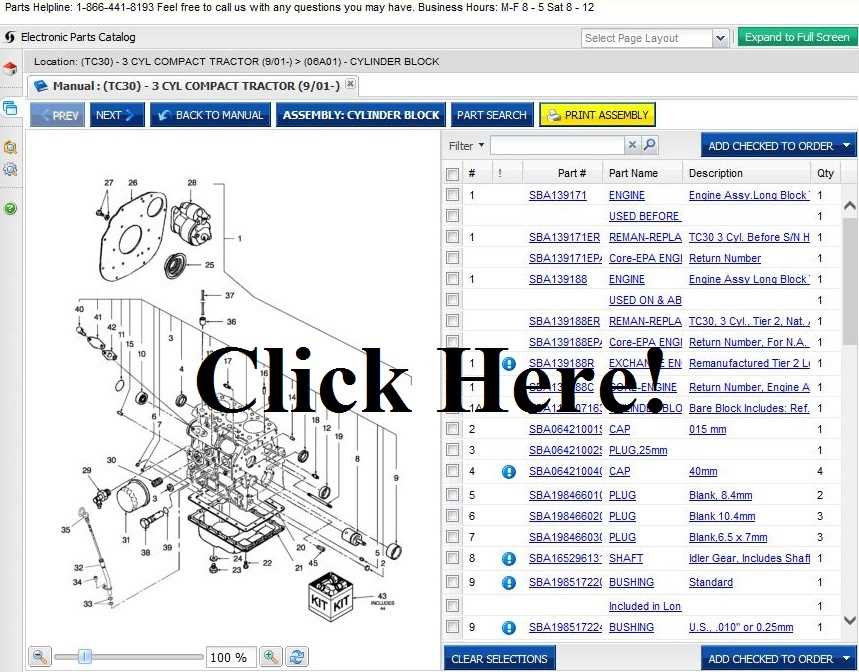

Exploring the layout and connections within mechanical blueprints can help in grasping the functionality and organization of various elements. By carefully examining the schematic, users can better understand how individual components interact and are positioned, ensuring a more comprehensive approach to maintenance and assembly.

To simplify this process, the illustration is often divided into sections, allowing the user to focus on specific areas. This segmentation helps in pinpointing particular functions and relationships between various parts of the machine, making troubleshooting and repairs more efficient.

| Section | Description |

|---|---|

| Top View | Provides an overview of the upper elements and their connections. |

| Side View | Shows the positioning of components from a lateral perspective. |

| Detailed Zoom | Highlights smaller, intricate components for closer inspection. |

Common Parts and Their Functions

Understanding the key components of this type of equipment helps ensure smooth operation and efficient maintenance. Each element plays a crucial role in the overall functionality, and recognizing these will aid in timely upkeep and troubleshooting.

Main Structural Components

The primary frame supports the overall machine, providing stability and alignment. It holds various mechanical elements together, allowing them to work in harmony. Moving mechanisms within this framework are responsible for transferring power and motion to essential systems, ensuring that the machine operates effectively.

Operational Systems

Key systems include those responsible for gathering, processing, and ejecting materials. These systems rely on precise coordination between driving forces, transmission systems, and other mechanical parts. Regular inspection of these systems helps prevent wear and tear, keeping the equipment running efficiently over time.

Identifying the Essential BR740 Elements

Understanding the key components of this specific machinery is vital for effective maintenance and operation. Each element plays a crucial role in ensuring optimal functionality and performance, which directly impacts productivity. Familiarity with these fundamental features can assist operators and technicians in troubleshooting and enhancing the efficiency of the equipment.

Core Components Overview

The primary elements include the drive mechanism, which facilitates movement, and the hydraulic system that powers various functions. Additionally, the cutting apparatus is essential for achieving the desired results in the field. Recognizing these core components can greatly improve the operator’s ability to manage and optimize the machine’s capabilities.

Importance of Regular Inspection

Routine checks on these essential features are necessary to prevent potential breakdowns and ensure longevity. By systematically inspecting each key element, operators can identify wear and tear early on, allowing for timely repairs or replacements. This proactive approach contributes significantly to maintaining peak operational efficiency.

Maintaining the Bale System Effectively

Ensuring optimal performance of the baling mechanism is crucial for efficient operations in the field. Regular upkeep not only extends the lifespan of the equipment but also enhances its productivity. By following a systematic approach to maintenance, users can prevent common issues and ensure seamless functionality.

Routine Inspections: Conducting frequent checks is vital to identify any wear and tear. Look for signs of damage on moving parts and ensure that all components are functioning correctly. This proactive measure can help catch problems early before they escalate.

Lubrication: Proper lubrication of moving parts reduces friction and wear. Use high-quality lubricants as recommended in the equipment manual, and apply them consistently to maintain smooth operation.

Cleaning: Dirt and debris can hinder performance. Regularly clean the baling system, paying special attention to areas where materials can accumulate. This practice not only improves efficiency but also prevents potential blockages.

Adjustments: Ensure that all settings are properly calibrated according to the manufacturer’s specifications. Regular adjustments can optimize the bale formation process, leading to better quality and consistency.

By adhering to these essential maintenance practices, operators can significantly enhance the functionality of their baling systems, resulting in more efficient and productive operations.

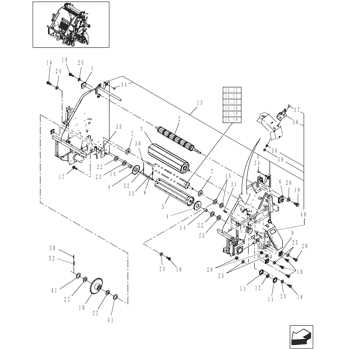

Breakdown of Mechanical and Hydraulic Components

This section provides an overview of the various mechanical and hydraulic components commonly found in agricultural machinery. Understanding these elements is crucial for effective maintenance and troubleshooting. The interplay between mechanical systems and hydraulic mechanisms is vital for ensuring optimal performance and efficiency.

Mechanical Elements

Mechanical components play a significant role in the functionality of equipment. These parts work together to facilitate movement and support various operations. Key elements include the frame, gear systems, and drive shafts, each contributing to the overall performance of the machinery.

Hydraulic Systems

Hydraulic systems are essential for powering several functions within agricultural machines. These systems utilize fluid power to operate various tools and attachments. Important components include pumps, valves, and cylinders, which collectively enhance the equipment’s capabilities.

| Component Type | Description |

|---|---|

| Frame | Provides structural support and stability to the machine. |

| Gear System | Transmits power from the engine to various moving parts. |

| Hydraulic Pump | Generates fluid pressure needed for hydraulic operations. |

| Valves | Control the flow and direction of hydraulic fluid. |

| Cylinders | Convert hydraulic energy into mechanical movement. |

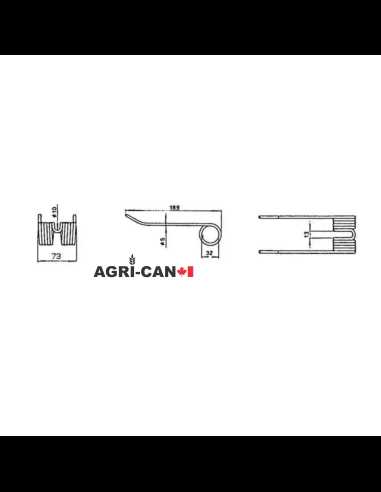

Replacement Guide for Key Components

Maintaining essential machinery involves understanding how to effectively replace crucial elements to ensure optimal performance. This guide offers insights into the most important components, providing information on their functions and suggestions for selecting appropriate substitutes. By familiarizing yourself with these elements, you can enhance the longevity and efficiency of your equipment.

1. Drive Belts: These are vital for the proper operation of various mechanisms within the machinery. When replacing drive belts, ensure that you choose high-quality options that match the original specifications for durability and performance.

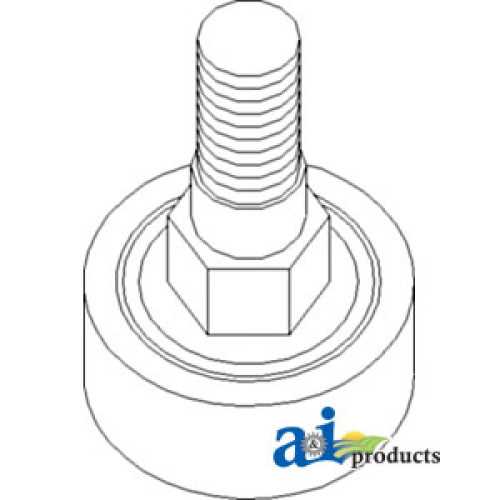

2. Bearings: Bearings facilitate smooth movement and reduce friction between moving parts. It’s important to select replacements that offer the same load rating and size as the original to maintain functionality.

3. Hydraulic Hoses: These components are crucial for fluid transfer and proper hydraulic function. Regular inspection is recommended, and when replacements are needed, ensure compatibility with existing fittings and pressure ratings.

4. Filters: Maintaining clean filters is essential for the efficiency of the machinery. Choose replacements that meet or exceed the specifications of the original to ensure effective filtration and performance.

5. Gaskets: These components prevent leaks and ensure a tight seal between different parts. When selecting new gaskets, ensure they are made from materials that can withstand the specific conditions of your equipment.

Troubleshooting Using the Parts Diagram

Effective diagnostics of machinery can be greatly enhanced by utilizing a detailed visual representation of its components. This resource serves as a valuable tool for identifying issues, facilitating repairs, and ensuring optimal performance. By closely examining this illustration, users can pinpoint specific areas of concern and streamline their troubleshooting efforts.

Identifying Common Issues

When faced with malfunctions, it’s essential to recognize frequent problems that may arise. Understanding the layout of the machinery can help in isolating the source of a malfunction. Below are some typical issues to look for:

| Issue | Symptoms | Potential Solution |

|---|---|---|

| Poor Performance | Insufficient output or power loss | Inspect for clogged filters or faulty components |

| Excessive Noise | Unusual sounds during operation | Check for loose parts or misalignments |

| Fluid Leaks | Visible drips or stains | Examine seals and connections for wear |

Utilizing the Visual Reference

By referencing this visual guide, users can enhance their understanding of the machinery’s assembly and functionality. It is advisable to compare the illustrated components with the actual machine to identify discrepancies and prioritize repairs effectively.

How to Source Genuine BR740 Parts

Finding authentic components for agricultural machinery is crucial for ensuring optimal performance and longevity. When seeking quality replacements, it is essential to consider various avenues that guarantee reliability and durability. This section provides insights into effective strategies for obtaining these necessary elements.

Research Authorized Dealers

One of the most reliable methods to acquire authentic components is through authorized distributors. These vendors often offer:

- Comprehensive product catalogs

- Expert guidance on compatibility

- Warranty options for peace of mind

Engaging with these professionals can provide access to original equipment, ensuring the integrity of your machinery is maintained.

Utilize Online Resources

In today’s digital age, many platforms specialize in machinery components. When using online resources, keep the following in mind:

- Verify the credibility of the website.

- Check customer reviews and ratings.

- Look for return policies to safeguard your purchase.

By leveraging these digital tools, you can expand your options and locate the required items efficiently.