Mechanical components are essential in the operation of any all-terrain vehicle, and understanding how these elements interact is crucial for maintaining peak performance. By examining detailed schematics, one can gain valuable insights into how different parts work together to ensure a smooth ride and efficient operation. This knowledge is particularly useful for those who want to enhance their vehicle’s durability and functionality.

In this guide, we will explore the intricacies of various systems and their interrelated mechanisms. These visual representations help users identify specific elements, offering a clear path to diagnosing potential issues or planning modifications. Whether you’re a seasoned mechanic or a hobbyist, having a thorough understanding of these blueprints is key to successful upkeep and repairs.

Overview of 2008 Honda Foreman 500 Components

The core framework of this robust utility vehicle consists of various interconnected elements designed to ensure both performance and durability. Each section of the machine plays a vital role in providing the necessary support for smooth operation across different terrains, ensuring stability, power, and reliability. Understanding the relationship between these individual components can help in maintaining and optimizing the vehicle’s efficiency.

Engine and Powertrain

The heart of this vehicle lies in its powerful engine, which is responsible for generating the force required for movement. Alongside the engine, the transmission system distributes the power efficiently to the wheels, allowing for effective handling and control. Together, they ensure a balance between speed and torque, adapting to varying driving conditions.

Chassis and Suspension

The chassis forms the structural backbone, supporting the overall framework and ensuring the machine can handle weight and stress. The suspension system complements this by absorbing shocks from uneven terrain, providing a smoother ride while protecting other critical components from excessive wear. Both these elements are designed to enhance comfort and longevity.

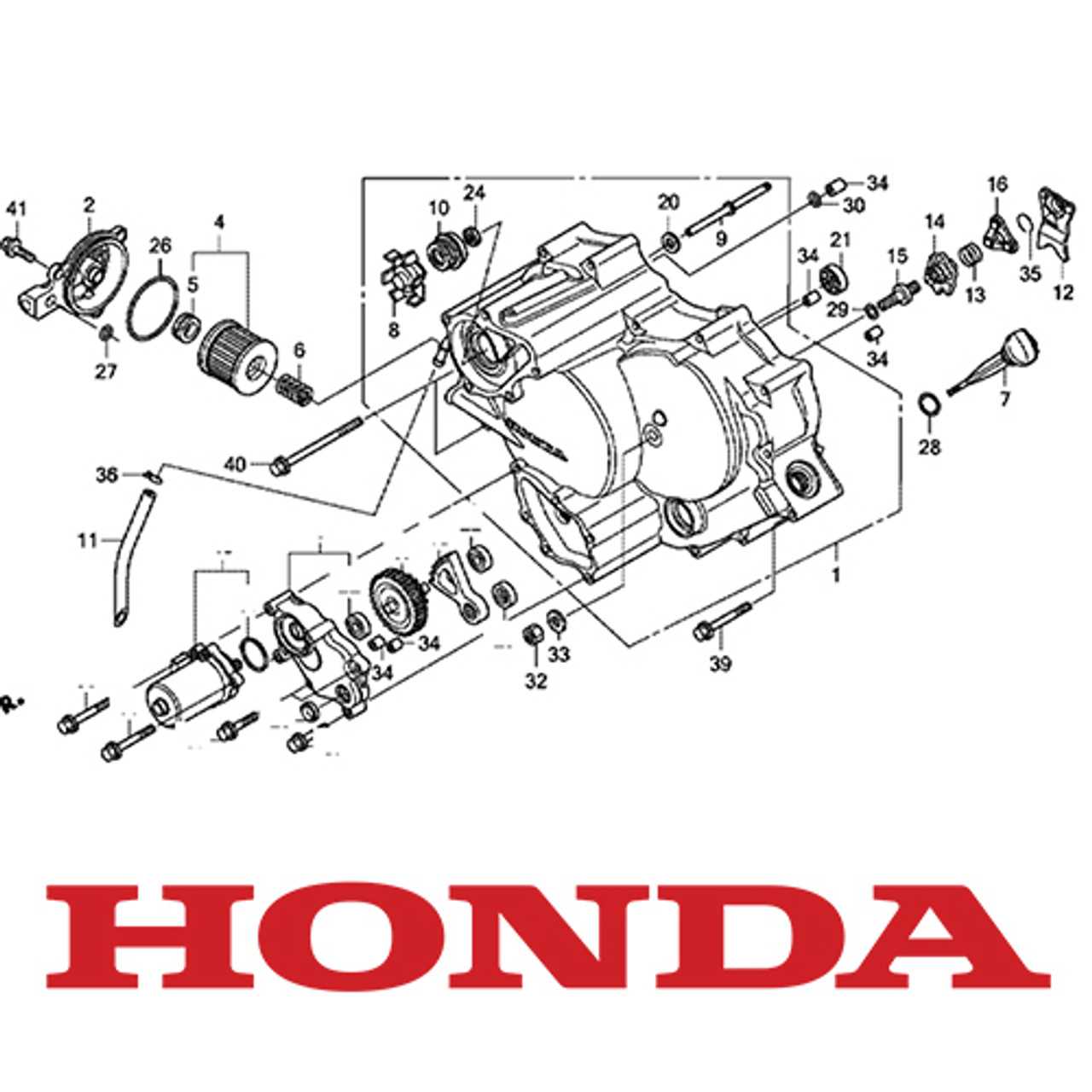

Engine Structure and Key Elements

The engine’s structure is built to deliver power efficiently, combining a variety of components that work together to ensure smooth operation. Its core function revolves around the transformation of fuel into mechanical energy, which is then harnessed to move the vehicle. Each part plays a specific role in this process, contributing to the engine’s overall performance and reliability.

Main Engine Components

Key elements of the engine include the cylinder, which houses the combustion process, and the crankshaft, responsible for converting linear motion into rotational force. Other essential parts, such as the piston, camshaft, and valves, work in harmony to regulate the intake and exhaust of gases, maintaining a balanced operation.

Supporting Systems

In addition to the primary components, various supporting systems like the lubrication and cooling mechanisms ensure the engine operates within optimal conditions. These systems prevent overheating and reduce friction between

Suspension and Frame Layout

The suspension and frame are critical components that ensure both stability and comfort while riding. These systems work together to absorb shocks from uneven terrain and maintain the structural integrity of the vehicle, providing a smooth and controlled ride. Understanding their arrangement can help in maintaining performance and longevity.

Suspension System Overview

The suspension setup plays a pivotal role in handling rough surfaces and reducing vibrations. With a balanced combination of front and rear mechanisms, it enhances rider comfort while ensuring the vehicle maintains traction.

- Front suspension typically consists of independent components, allowing flexibility on rugged terrain.

- Rear suspension focuses on stability, supporting the overall structure during heavy loads or high-speed travel.

Frame Structure

The frame provides the skeleton of the vehicle, supporting all major parts and distributing weight evenly. Built for durability, it must withstand various environmental stresses while maintaining its form.

- The frame supports key systems like the engine and drivetrain, ensuring proper alignment and function.

- It also plays a role in protecting internal components from impact and wear during extended use.

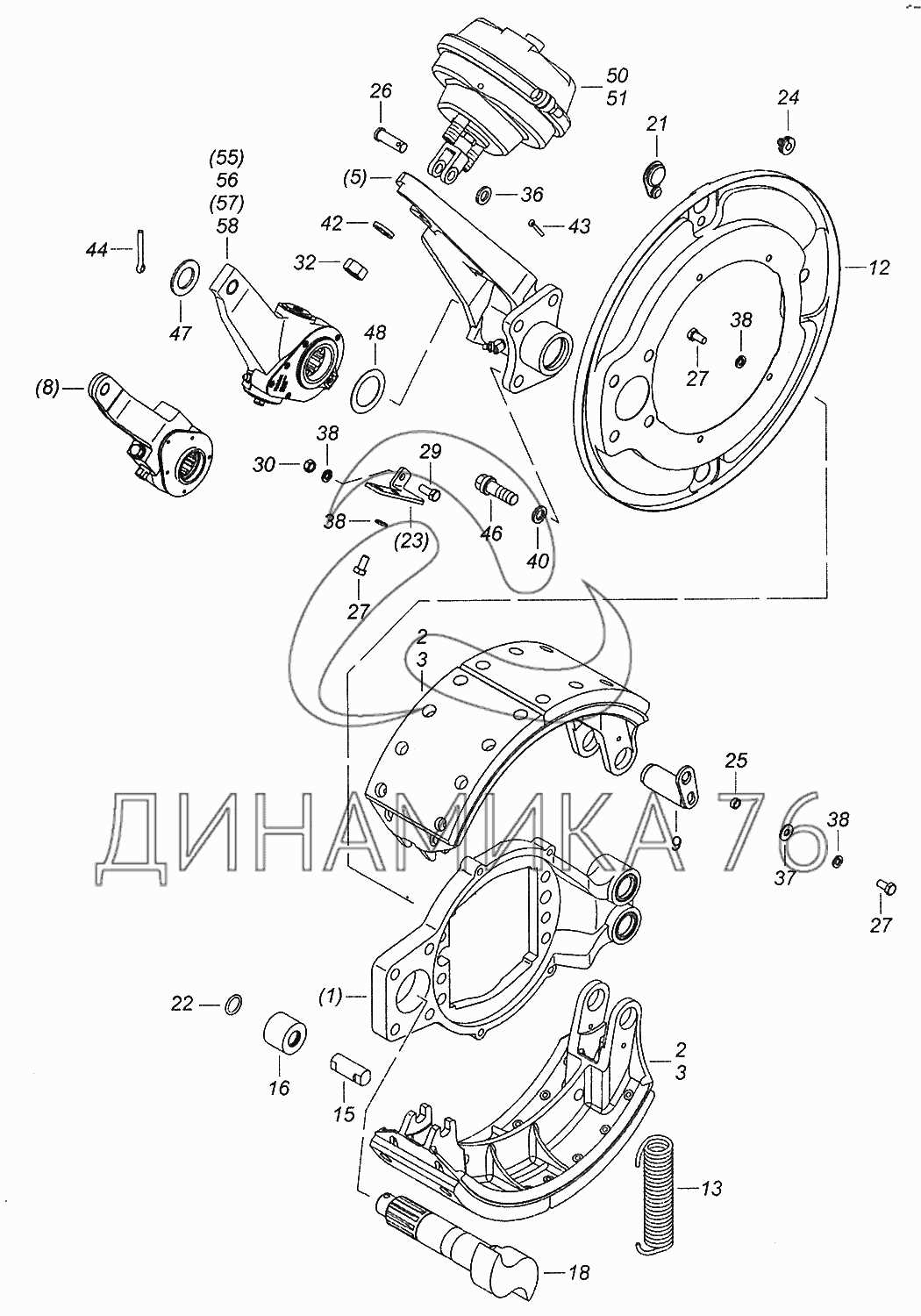

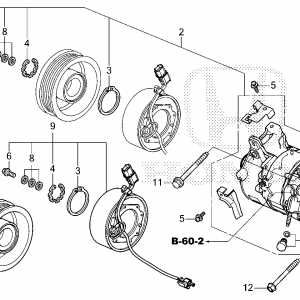

Brake System Parts and Function

The brake system is essential for ensuring a vehicle’s safety by allowing the operator to control and reduce speed effectively. This system is composed of various interconnected components that work together to apply friction, bringing the machine to a stop or slowing it down. Understanding the role of each element within the system is key to maintaining optimal performance and safety.

Main Components of the Brake System

The braking mechanism consists of several crucial elements that cooperate to provide reliable performance. These include the levers, hydraulic lines, brake pads, and calipers. Each part plays a specific role in generating the necessary friction and converting motion into heat, thereby stopping the machine.

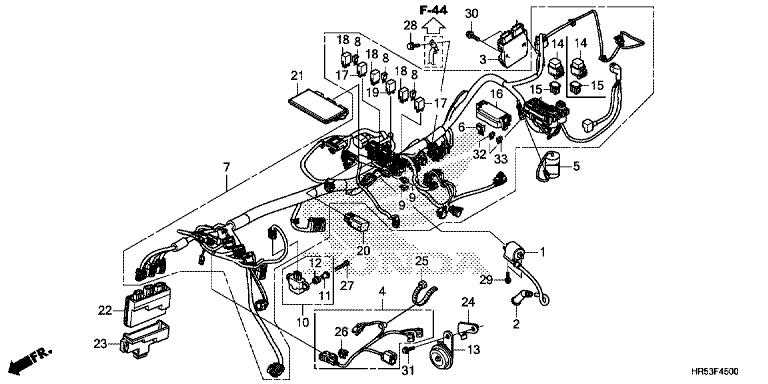

Electrical Components and Wiring Diagram

The electrical system plays a crucial role in ensuring that the vehicle operates efficiently, from powering the engine to maintaining the functionality of key features. Understanding the various elements involved in the system is essential for proper maintenance and troubleshooting.

Main Components Overview

The electrical setup includes several vital components such as the battery, ignition system, and various sensors. These components work together to provide the necessary power and control throughout the vehicle. Identifying their roles within the system helps ensure smoother diagnostics and repair processes.

Wiring and Connectivity

The wiring network connects all electrical components, ensuring that power is distributed effectively. A well-maintained and organized wiring system is key to avoiding electrical issues. Reviewing the layout and ensuring all connections are secure can prevent common malfunctions, and a proper understanding of the connections is essential for addressing electrical concerns.

Fuel System and Carburetor Design

The fuel system plays a critical role in the overall performance of any motorized vehicle. Its primary function is to ensure that the engine receives an adequate supply of fuel mixed with air, which is essential for combustion. A well-designed system not only enhances efficiency but also contributes to smoother operation and reduced emissions.

Components and Functionality

The core of the fuel system typically includes a fuel tank, fuel lines, a fuel pump, and a carburetor. The tank stores the fuel, which is then transported through lines to the pump. The pump ensures a consistent flow of fuel, delivering it to the carburetor, where it is mixed with air in the correct ratio before entering the engine. The design of the carburetor is crucial as it regulates this mixture, significantly affecting engine performance and responsiveness.

Importance of Maintenance

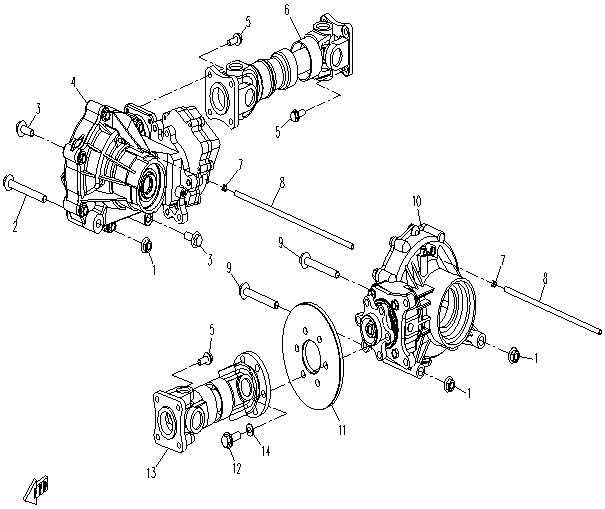

Transmission and Gear Mechanisms

The transmission system plays a crucial role in the overall performance of any vehicle, facilitating the transfer of power from the engine to the wheels. Understanding the various components involved in this system is essential for maintaining optimal functionality and performance. This section explores the intricacies of the transmission and gear mechanisms, emphasizing their importance in enhancing driving experience and efficiency.

Key Components

- Gears: These are critical for changing speed and torque. Different gear ratios allow for effective acceleration and deceleration.

- Transmission Housing: This component encases the transmission, protecting it from external elements and ensuring proper operation.

- Shifter Mechanism: This enables the driver to select the desired gear, influencing the vehicle’s responsiveness.

- Drive Shafts: These components transfer power from the transmission to the wheels, allowing for movement.

Maintenance Considerations

- Regularly check and change transmission fluid to ensure smooth operation.

- Inspect the gears for wear and tear to prevent unexpected failures.

- Maintain the shifter mechanism for precise gear selection.

- Keep the transmission housing clean to avoid contamination of the internal components.

Exhaust System Configuration

The exhaust system is a crucial component of any engine, responsible for directing combustion gases away from the engine and reducing harmful emissions. Its configuration significantly impacts overall performance, efficiency, and sound output. Understanding the layout and functioning of the exhaust system is essential for maintenance and potential upgrades.

Components of the Exhaust System

The exhaust system typically consists of several key elements that work together to facilitate the expulsion of gases. These components include the exhaust manifold, catalytic converter, muffler, and various pipes. Each part plays a specific role in ensuring the system operates effectively.

| Component | Function |

|---|---|

| Exhaust Manifold | Collects gases from the engine’s cylinders and directs them to the exhaust system. |

| Catalytic Converter | Reduces harmful emissions by converting toxic gases into less harmful substances. |

| Muffler | Reduces engine noise by dissipating sound waves produced during combustion. |

| Pipes | Transport exhaust gases from the engine to the rear of the vehicle. |

Performance Considerations

The configuration of the exhaust system can influence engine performance significantly. Modifications, such as installing high-performance components, can enhance airflow, reduce back pressure, and improve overall power output. Regular inspection and maintenance of these parts are essential to ensure optimal functioning.

Cooling System Components Breakdown

The efficiency of a vehicle’s cooling mechanism is vital for maintaining optimal operating temperatures. This section delves into the essential elements that constitute the cooling system, highlighting their functions and interconnections.

Radiator: This component serves as the primary heat exchanger, dissipating heat from the engine coolant into the surrounding air. Its design facilitates efficient cooling, ensuring that the engine does not overheat during operation.

Water Pump: The water pump is responsible for circulating coolant throughout the engine and radiator. By maintaining a consistent flow, it plays a crucial role in regulating temperature and preventing localized overheating.

Thermostat: This device regulates coolant flow based on the engine’s temperature. It opens and closes to maintain the optimal operating range, ensuring efficient engine performance and fuel economy.

Coolant Hoses: These flexible conduits transport coolant between the engine, radiator, and other components. Their integrity is essential to prevent leaks and ensure a continuous flow of coolant.

Cooling Fans: These fans assist in drawing air through the radiator, enhancing the cooling process, especially during low-speed operation or when idling. They ensure that the system can maintain a steady temperature even under heavy load.

Steering System and Handlebar Assembly

The steering system is a crucial component that enables precise control and maneuverability of the vehicle. This assembly consists of various elements that work together to ensure smooth navigation and stability during operation. Understanding the layout and function of these components is essential for maintenance and repair tasks.

Key Components

Within the steering system, several key parts play significant roles. These include the handlebars, steering column, and associated linkages. Each element contributes to the overall effectiveness of steering, allowing the operator to easily adjust direction and maintain control.

Assembly Overview

The assembly of the steering system requires careful alignment and secure connections between all parts. Proper installation is vital for safety and performance. Below is a table outlining the primary components involved in the assembly:

| Component | Description |

|---|---|

| Handlebars | Provide grip for the operator and facilitate steering adjustments. |

| Steering Column | Connects the handlebars to the steering mechanism, transmitting movements. |

| Linkages | Transfer motion from the handlebars to the wheels, enabling directional changes. |

| Bearings | Support smooth rotation of the steering column within the assembly. |

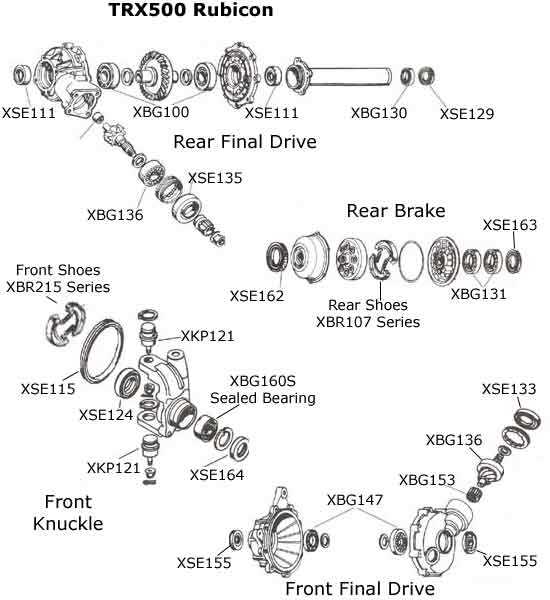

Wheels, Tires, and Axles Overview

This section provides a comprehensive look at the crucial components responsible for mobility and stability in off-road vehicles. Understanding these elements is essential for maintaining optimal performance and safety during operation. Each component plays a significant role in the overall functionality, contributing to traction, handling, and durability.

Wheels

The wheels serve as the primary connection between the vehicle and the terrain, influencing handling and comfort. Proper selection and maintenance of wheels can enhance driving experience, especially in challenging environments. Choosing the right wheel size and material is vital for achieving the desired performance characteristics.

Tires and Axles

Tires are designed to provide traction, absorb shocks, and offer stability. Selecting tires suitable for specific conditions ensures better grip and control. Meanwhile, axles play a key role in transferring power from the engine to the wheels, supporting the vehicle’s weight while allowing for smooth movement. Regular inspection and maintenance of these components are crucial to ensure reliability and longevity.