In the realm of machinery designed for fluid management, a comprehensive grasp of its individual elements is crucial for optimal functionality. Each component plays a significant role in ensuring efficiency and reliability, making knowledge of their arrangement invaluable for users and technicians alike.

Illustrating the configuration of these vital components allows for easier maintenance and troubleshooting. Familiarity with how each part interacts within the system enhances overall performance and longevity.

By exploring these intricate relationships, users can delve into the mechanics behind the operation, gaining insights that facilitate informed decisions regarding repairs and upgrades. This understanding ultimately leads to improved outcomes in various applications.

Understanding Honda WT20X Trash Pumps

This section explores the essential components and functionalities of a specific type of liquid transfer device, designed for efficiency and reliability. Users will gain insights into how these machines operate and the significance of their various elements in effective fluid management.

Key Features

The device boasts a range of characteristics that enhance its performance. Key features include:

| Feature | Description |

|---|---|

| Portability | Lightweight design allows for easy transport. |

| Durability | Constructed with robust materials for long-lasting use. |

| High Efficiency | Optimized for effective liquid movement with minimal energy consumption. |

Maintenance Tips

Regular upkeep is crucial for maintaining optimal function. Key maintenance tips include checking fluid levels, cleaning filters, and inspecting hoses for wear and tear. These practices ensure longevity and reliable operation.

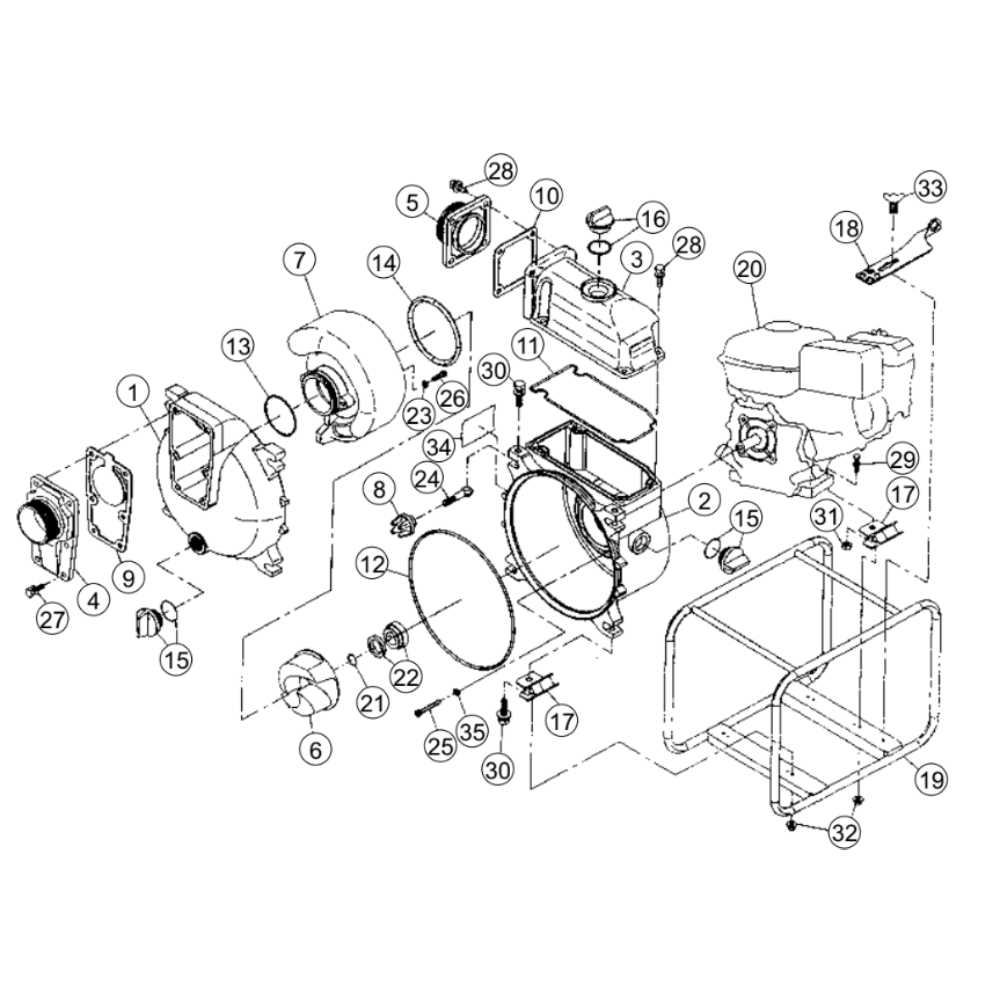

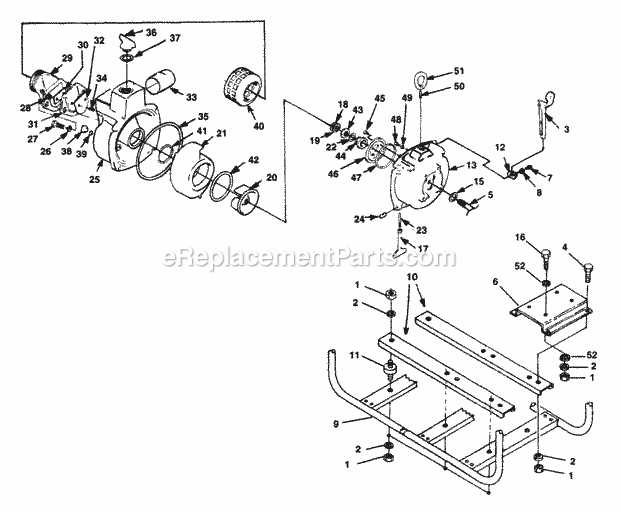

Key Components of the Pump

Understanding the essential elements of a fluid transfer device is crucial for optimal operation and maintenance. Each component plays a specific role, contributing to the overall functionality and efficiency of the machinery.

Impeller

The impeller is a vital element that generates flow by converting rotational energy into kinetic energy. Its design significantly influences the performance, enabling efficient movement of liquids through the system.

Housing

The housing encapsulates the internal components, providing structural integrity and protecting against external elements. It is designed to withstand pressure while allowing for easy access during maintenance or repairs.

Importance of Proper Maintenance

Benefits of Regular Upkeep

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Inspect components | Monthly | Identifies wear and tear early |

| Change filters | Every 3 months | Ensures clean operation |

| Lubricate moving parts | Every 6 months | Reduces friction and wear |

| Check fluid levels | Monthly | Prevents overheating |

Conclusion

Common Issues and Troubleshooting

When dealing with water transfer devices, users may encounter several frequent challenges that can impede performance. Understanding these issues and knowing how to address them is essential for maintaining optimal functionality.

- Low Flow Rate:

- Check for blockages in the intake or discharge lines.

- Inspect seals and gaskets for wear and tear.

- Strange Noises:

- Look for loose components that may need tightening.

- Examine the motor for any signs of damage.

- Starting Issues:

- Ensure there is adequate fuel and oil levels.

- Inspect the spark plug for wear or fouling.

By identifying these common problems, users can delve deeper into troubleshooting and achieve the ultimate efficiency from their equipment.

Benefits of Using Trash Pumps

Utilizing high-capacity fluid transfer systems offers numerous advantages in various applications. These machines are designed to efficiently move large volumes of liquids containing debris, making them essential for construction sites, agricultural needs, and emergency flood response.

Enhanced Efficiency: These systems can handle a variety of materials, including solids and sludge, which allows for quicker and more effective cleanup operations.

Durability: Constructed with robust materials, they are capable of withstanding harsh conditions, ensuring longevity and reliability in demanding environments.

Versatility: Their ability to tackle different types of liquids makes them suitable for multiple industries, from municipal projects to landscaping.

Cost-Effective: Investing in these systems can reduce labor costs and time spent on maintenance, ultimately leading to greater savings over time.

Overall, employing these powerful tools can significantly improve operational efficiency and address a wide range of fluid management challenges.

Comparing Different Pump Models

When evaluating various models in the market, it’s essential to consider their unique features, performance capabilities, and intended applications. Each design serves specific needs, which can influence efficiency and usability.

Key Features to Consider

- Flow Rate: Determines the volume of fluid moved per minute.

- Lift Height: Refers to the maximum vertical distance the liquid can be raised.

- Fuel Type: Electric vs. gas options can affect mobility and operational cost.

- Durability: Materials and build quality influence longevity and reliability.

Popular Models Overview

- Model A: Known for its high efficiency and lightweight design, making it ideal for residential use.

- Model B: Offers robust performance suitable for heavy-duty tasks and larger volumes.

- Model C: Features advanced technology for quiet operation and energy savings.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right instruments at hand is crucial for efficiency and precision. This section outlines essential tools that facilitate the repair process, ensuring that you can address any issues effectively.

Essential Hand Tools

Begin with a basic set of hand tools, including wrenches, screwdrivers, and pliers. These instruments are fundamental for loosening and tightening components, allowing for easy access to internal mechanisms. Additionally, a utility knife can be useful for cutting through various materials.

Power Tools and Accessories

For more extensive repairs, consider investing in power tools such as a drill or impact driver. These tools can significantly reduce time and effort, particularly when dealing with stubborn fasteners. Don’t forget to keep a selection of drill bits and sockets to accommodate various tasks.

Step-by-Step Assembly Guide

This section provides a detailed approach to assembling the equipment efficiently and correctly. Following these instructions will ensure optimal performance and longevity, minimizing potential issues during operation.

1. Gather Required Components: Before beginning, ensure all necessary components are available. Refer to your reference material for a complete list, including fasteners and seals.

2. Prepare the Workspace: Clear a designated area for assembly. A clean, well-lit space will facilitate better organization and prevent misplacing parts.

3. Assemble the Base: Start by attaching the foundation. Align the components carefully, ensuring that the mounting holes match. Secure with appropriate fasteners, tightening them evenly.

4. Install the Engine: Position the engine onto the assembled base. Ensure that all connections, including fuel and electrical lines, are properly aligned and secured. Check for any loose parts before proceeding.

5. Attach the Housing: Carefully place the housing over the engine assembly. Make sure all gaskets are in place to prevent leaks. Secure the housing with the designated screws, tightening them in a crisscross pattern for even pressure.

6. Connect the Inlet and Outlet: Attach the inlet and outlet fittings. Ensure all seals are intact and tighten the connections firmly, avoiding over-tightening which could damage components.

7. Perform a Final Inspection: Review the entire assembly to confirm that all parts are correctly positioned and secured. Double-check all connections and ensure no tools or loose parts are left behind.

8. Conduct a Test Run: After assembly, perform a test run to ensure everything operates smoothly. Monitor for any unusual sounds or leaks, and make adjustments as necessary.

By following these steps, you can achieve a successful assembly, ensuring that your equipment functions effectively and reliably.

Understanding Pump Diagrams

Grasping the intricacies of schematic representations is essential for anyone involved in fluid transfer systems. These illustrations serve as vital tools, offering clarity on the various components and their interconnections, thus enabling effective maintenance and troubleshooting.

By familiarizing oneself with these visual guides, operators can enhance their comprehension of the overall assembly and function of the equipment. A deeper understanding ultimately leads to improved performance and longevity of the machinery.

| Component | Description |

|---|---|

| Inlet | The entry point for fluid intake. |

| Impeller | The rotating part that moves the fluid. |

| Outlet | The exit point for fluid discharge. |

| Casing | The outer shell that houses the internal components. |

Replacement Parts Overview

This section provides an insightful look into the components that may require substitution over time due to wear and tear. Understanding the essential elements of the equipment helps ensure optimal functionality and longevity. Each component plays a crucial role in maintaining performance and reliability.

| Component | Description | Typical Issues | Recommended Action |

|---|---|---|---|

| Impeller | Moves fluid through the system. | Wear from prolonged use. | Replace if damaged or worn. |

| Seals | Prevent leakage and maintain pressure. | Cracking or deterioration over time. | Inspect regularly; replace as needed. |

| Filters | Traps debris and protects internal components. | Clogging can reduce efficiency. | Clean or replace to ensure proper flow. |

| Fuel Line | Delivers fuel to the engine. | Cracking can lead to leaks. | Check for wear; replace if necessary. |

Where to Buy Genuine Parts

Finding authentic components for your equipment is crucial for maintaining performance and longevity. Opting for genuine replacements ensures compatibility and reliability, helping you avoid issues that may arise from substandard alternatives. Below are some recommended sources where you can purchase these essential items.

- Authorized Dealers: Check with local authorized dealers who specialize in your brand. They typically have access to the complete range of genuine items and can provide expert advice.

- Official Online Stores: Visit the official online platforms of manufacturers. These websites often feature a dedicated section for replacement items, ensuring you receive certified components.

- Specialty Retailers: Look for specialty retailers that focus on your equipment type. Many of these stores maintain a robust inventory of original components.

- Repair Shops: Consult with local repair shops that work on your brand. They often have direct access to genuine components and can assist with installation as well.

In addition to these options, always verify the authenticity of the items before making a purchase to ensure you receive high-quality replacements that meet the standards of your equipment.

Tips for Efficient Operation

Maximizing performance during usage requires careful attention to several key factors. By implementing best practices and maintaining proper procedures, one can ensure that the equipment operates at its optimal capacity. Below are essential recommendations for effective functioning.

| Tip | Description |

|---|---|

| Regular Maintenance | Conduct routine checks and servicing to keep the machine in top shape, preventing unexpected failures. |

| Proper Setup | Ensure the unit is correctly positioned and leveled to facilitate smooth operation and avoid unnecessary strain. |

| Check Fluid Levels | Monitor and maintain appropriate fluid levels to prevent overheating and ensure efficiency. |

| Utilize Filters | Install high-quality filters to reduce debris intake, thereby prolonging the lifespan of the system. |

| Monitor Environment | Be aware of surrounding conditions; avoid operating in extreme weather or unsuitable terrains that can hinder performance. |

Safety Precautions While Using Pumps

When operating equipment designed for liquid transfer, ensuring safety is paramount. Understanding potential hazards and following necessary guidelines can prevent accidents and injuries during use.

Personal Protective Equipment

Always wear appropriate protective gear, such as gloves, goggles, and sturdy footwear. This equipment safeguards against splashes and mechanical injuries, enhancing overall safety while handling the machinery.

Proper Setup and Maintenance

Before initiating operations, check the setup for stability and secure connections. Regularly inspect the unit for wear or damage to prevent malfunction. Delving into maintenance protocols is the ultimate way to ensure reliable and safe performance.