When maintaining any outdoor machinery, a clear visualization of its structure is essential. This not only aids in effective repairs but also enhances overall performance and longevity. Knowing how each element fits together allows for a more thorough understanding of its function.

Visual references play a crucial role in ensuring that all components are recognized and properly managed during maintenance. By having a comprehensive overview of the assembly, operators can easily identify the necessary items for replacement or enhancement.

Additionally, a detailed schematic provides clarity on how various elements interact within the system. This knowledge empowers users to troubleshoot issues more effectively, ensuring that the equipment operates at its best. Familiarity with these parts can ultimately lead to improved efficiency and satisfaction.

Understanding the Husqvarna 125R

This section aims to provide insight into a popular model known for its efficiency and versatility in the world of outdoor power equipment. Its design caters to both casual users and professionals, making it a reliable choice for various gardening tasks.

Key Features

- Lightweight construction for easy maneuverability

- Powerful engine that balances performance and fuel efficiency

- User-friendly controls for enhanced convenience

- Durable components designed to withstand heavy use

Applications

- Perfect for trimming grass and weeds

- Ideal for maintaining garden edges

- Useful for clearing brush in larger areas

- Can assist in landscaping projects

Key Components of the 125R

The functionality of a cutting tool relies heavily on its essential elements, each playing a crucial role in its overall performance. Understanding these components can enhance both efficiency and maintenance practices.

Motor Assembly

The heart of any machine, the motor assembly generates the necessary power for operation. It is designed to provide optimal torque and speed, ensuring effective cutting and trimming capabilities.

Cutter Head

The cutter head is responsible for the actual cutting action. Equipped with durable blades or trimmer lines, it is engineered to handle various tasks, from precision edging to heavy-duty clearing.

Importance of Maintenance and Parts

Regular upkeep of equipment plays a crucial role in ensuring optimal performance and longevity. Understanding the components involved allows users to effectively manage and replace necessary elements, contributing to the overall functionality of the machine.

Preventive care not only enhances efficiency but also reduces the likelihood of unexpected breakdowns. By routinely checking and maintaining essential elements, operators can avoid costly repairs and extend the lifespan of their machinery.

Moreover, familiarity with component replacements ensures that users can quickly identify when a part requires attention. This knowledge fosters a proactive approach to maintenance, ultimately leading to improved reliability and effectiveness in operations.

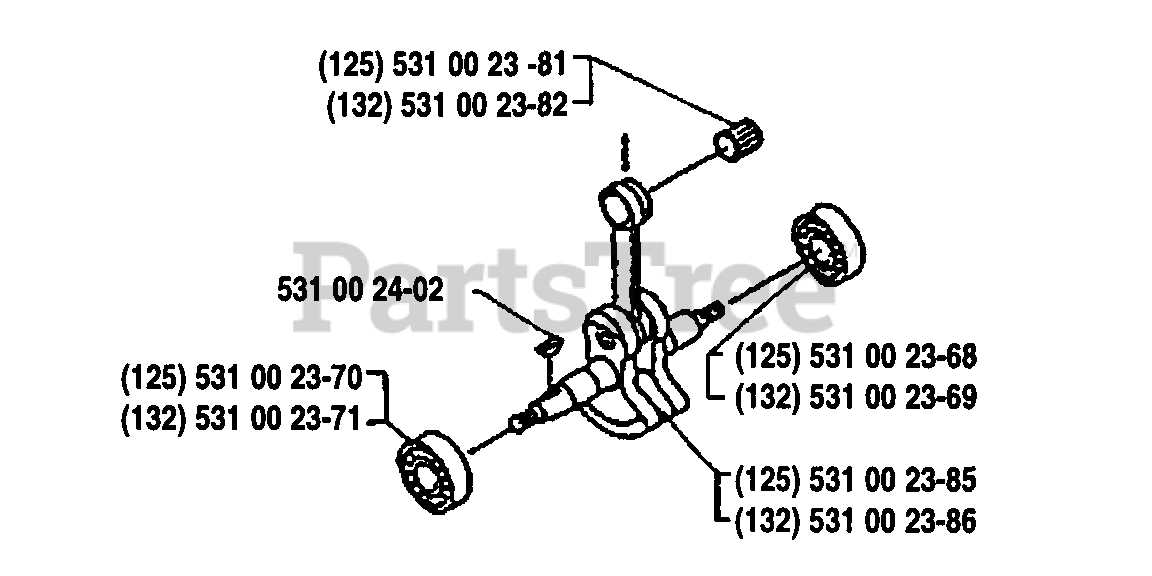

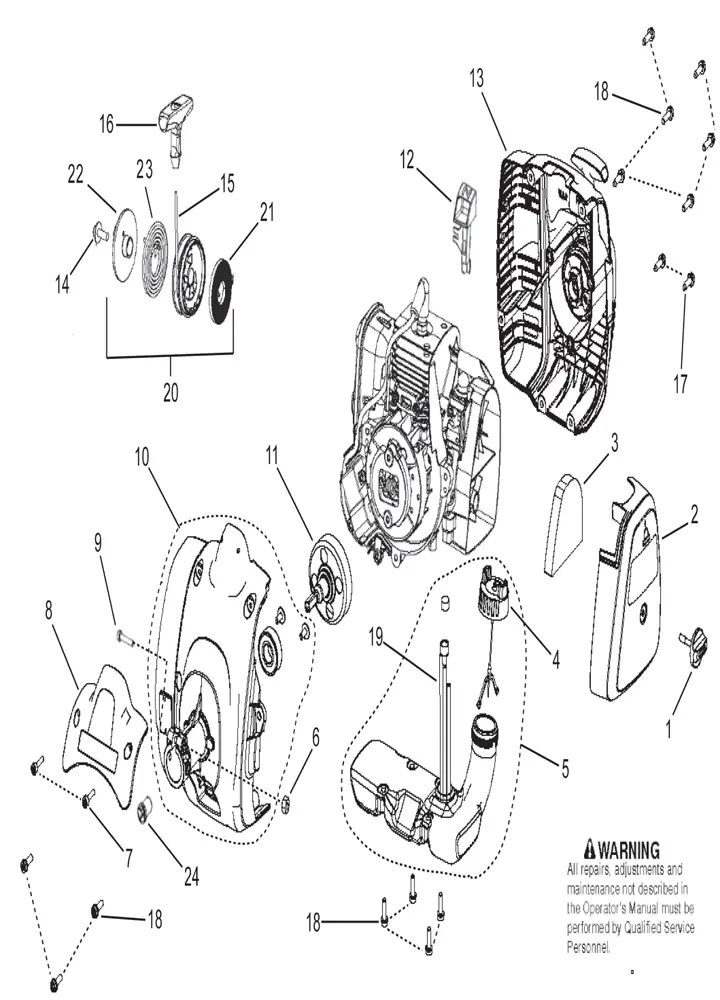

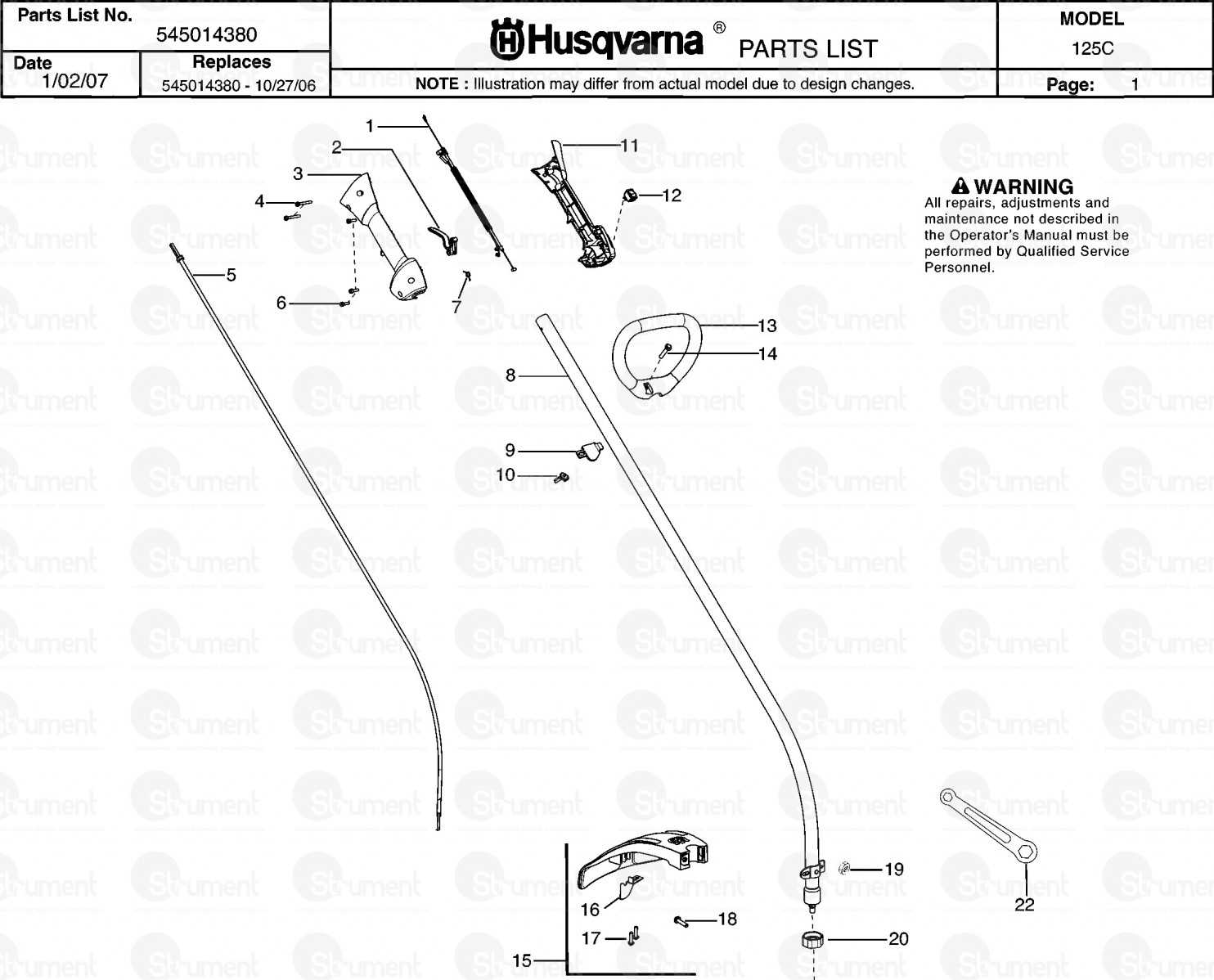

Visual Breakdown of Parts Diagram

This section provides a detailed exploration of the components within a specific model’s assembly. Understanding the arrangement and functionality of each element is essential for effective maintenance and repairs. By visualizing these components, users can gain insights into how they interact and contribute to the overall operation.

Key Elements Overview

- Engine Assembly: The heart of the machine, responsible for power generation.

- Fuel System: Includes the tank and lines that supply energy to the engine.

- Cutting Mechanism: Features blades or wires that execute the primary task.

- Handle and Control Unit: Ensures operator comfort and equipment maneuverability.

- Chassis: The structural framework that supports all other components.

Importance of Understanding Components

Familiarity with each part enables users to identify potential issues quickly. Regular inspection and knowledge of how these components work together can lead to enhanced performance and longevity of the equipment. Proper maintenance can prevent costly repairs and extend the service life of the machine.

Common Issues and Solutions

This section addresses typical challenges faced by users of various outdoor power equipment and offers practical solutions. Understanding these common problems can enhance maintenance and prolong the lifespan of the machinery.

- Starting Difficulties:

If the engine fails to start, check the fuel level, spark plug condition, and air filter cleanliness. Often, ensuring proper fuel mix and replacing a worn spark plug can resolve this issue.

- Power Loss:

Experiencing reduced power can indicate air filter blockage or fuel supply issues. Regularly clean or replace the air filter and inspect the fuel lines for obstructions.

- Vibrations:

Excessive vibrations during operation may stem from loose components or unbalanced parts. Tighten screws and bolts and ensure that all attachments are properly fitted.

- Overheating:

If the engine overheats, check the cooling fins for debris and ensure that the fuel is not contaminated. Regular cleaning can help maintain optimal engine temperature.

By regularly monitoring these aspects, users can effectively prevent many common issues, ensuring reliable performance and efficiency.

Ordering Replacement Parts Online

Acquiring new components for your equipment has never been easier with the rise of online shopping. Many websites specialize in providing a wide array of items that cater to various machinery needs. This convenience allows users to quickly find the necessary elements without the hassle of visiting multiple physical stores.

When selecting an online vendor, ensure they offer detailed descriptions and images of the products to guarantee compatibility. Reading customer reviews can also provide insights into the reliability and quality of the items available. By taking these steps, you can confidently make informed purchasing decisions, ensuring your machinery remains in optimal condition.

Tools Needed for Repairs

When undertaking maintenance or repairs on outdoor equipment, having the right tools is essential for efficiency and effectiveness. This section outlines the necessary instruments to ensure successful work.

Essential Tools

- Wrenches: Various sizes for tightening and loosening bolts.

- Screwdrivers: Flathead and Phillips for different screw types.

- Pliers: For gripping and bending tasks.

- Socket set: Provides versatility for nut and bolt sizes.

Safety Equipment

- Gloves: Protect your hands from injuries.

- Safety goggles: Shield your eyes from debris.

- Hearing protection: Essential when working with loud machinery.

Step-by-Step Repair Guide

This section provides a detailed process for conducting maintenance and repairs on your outdoor power equipment. Understanding the components and their arrangement is essential for effective troubleshooting and restoring functionality.

Preparation Steps

Before starting any repair, ensure you have the necessary tools and replacement components at hand. A clean workspace will also facilitate the process.

Repair Process

Follow these systematic steps to perform the repair:

| Step | Description |

|---|---|

| 1 | Disconnect the power source for safety. |

| 2 | Carefully disassemble the relevant sections, taking note of the arrangement. |

| 3 | Inspect components for wear and tear, replacing any that are damaged. |

| 4 | Reassemble the unit, ensuring all parts are securely fitted. |

| 5 | Reconnect the power source and test the equipment. |

Identifying Genuine vs. Aftermarket Parts

When it comes to equipment maintenance, distinguishing between authentic and alternative components is crucial for optimal performance and longevity. Understanding the differences can help ensure that your machinery operates smoothly and efficiently.

Here are some key aspects to consider:

- Quality: Authentic components are typically manufactured to higher standards, ensuring better fit and durability.

- Price: While alternative options may be less expensive, they often compromise on quality, leading to potential issues in the long run.

- Warranty: Genuine items usually come with a warranty, providing assurance of reliability and support.

- Packaging: Authentic parts often feature specific branding and packaging that signify their legitimacy.

By carefully assessing these factors, users can make informed decisions, enhancing the overall performance of their equipment.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and components of outdoor equipment. Understanding these aspects can significantly enhance the user experience and ensure optimal functionality.

| Question | Answer |

|---|---|

| What should I check regularly for maintenance? | Regular inspections of the fuel system, air filter, and cutting mechanism are essential for performance. |

| How do I know if a component needs replacement? | Signs of wear, unusual noises, or decreased efficiency typically indicate the need for replacement. |

| Where can I find replacement components? | Replacement items can be sourced from authorized dealers, online retailers, or local repair shops. |

| What tools are necessary for assembly? | A basic toolset, including screwdrivers and wrenches, is generally sufficient for most assembly tasks. |

Tips for Prolonging Equipment Life

Maintaining the longevity of your machinery is essential for optimal performance and cost efficiency. By implementing a few strategic practices, you can significantly extend the lifespan of your equipment.

Regular Maintenance: Conducting routine inspections and servicing is crucial. Ensure that all components are clean, lubricated, and functioning properly. This helps identify potential issues before they escalate into costly repairs.

Proper Usage: Adhering to the manufacturer’s guidelines on usage can prevent unnecessary strain on the machine. Avoid overloading and ensure that you operate the equipment within its designed capabilities.

Storage Conditions: When not in use, store the equipment in a dry and sheltered area. Exposure to harsh weather conditions can lead to rust and other forms of deterioration. Additionally, cover the machinery to protect it from dust and debris.

Quality Parts: When replacements are needed, opt for high-quality components that meet or exceed the original specifications. Using subpar parts can compromise the overall performance and longevity of the machine.

Training and Awareness: Ensure that all operators are trained and aware of best practices for handling the equipment. A knowledgeable user can make informed decisions that contribute to the machine’s efficiency and lifespan.

Connecting with Husqvarna Community

Engaging with a vibrant network of enthusiasts offers valuable insights and support for anyone passionate about outdoor equipment. By connecting with fellow users, one can share experiences, tips, and even troubleshooting advice, enhancing the overall ownership experience.

Online forums and social media groups serve as excellent platforms for interaction. Participants can exchange ideas, post queries, and showcase their projects, fostering a sense of camaraderie.

| Platform | Description |

|---|---|

| Forums | Dedicated spaces for in-depth discussions and advice sharing. |

| Social Media | Groups and pages for quick updates and community events. |

| Events | Local meetups and workshops to connect in person. |