When it comes to maintaining your outdoor power tools, having a clear understanding of their components is essential. Proper knowledge of how each part interacts can significantly enhance the performance and longevity of your machinery. This section will delve into the intricacies of these tools, offering insights into their various elements and how they function together.

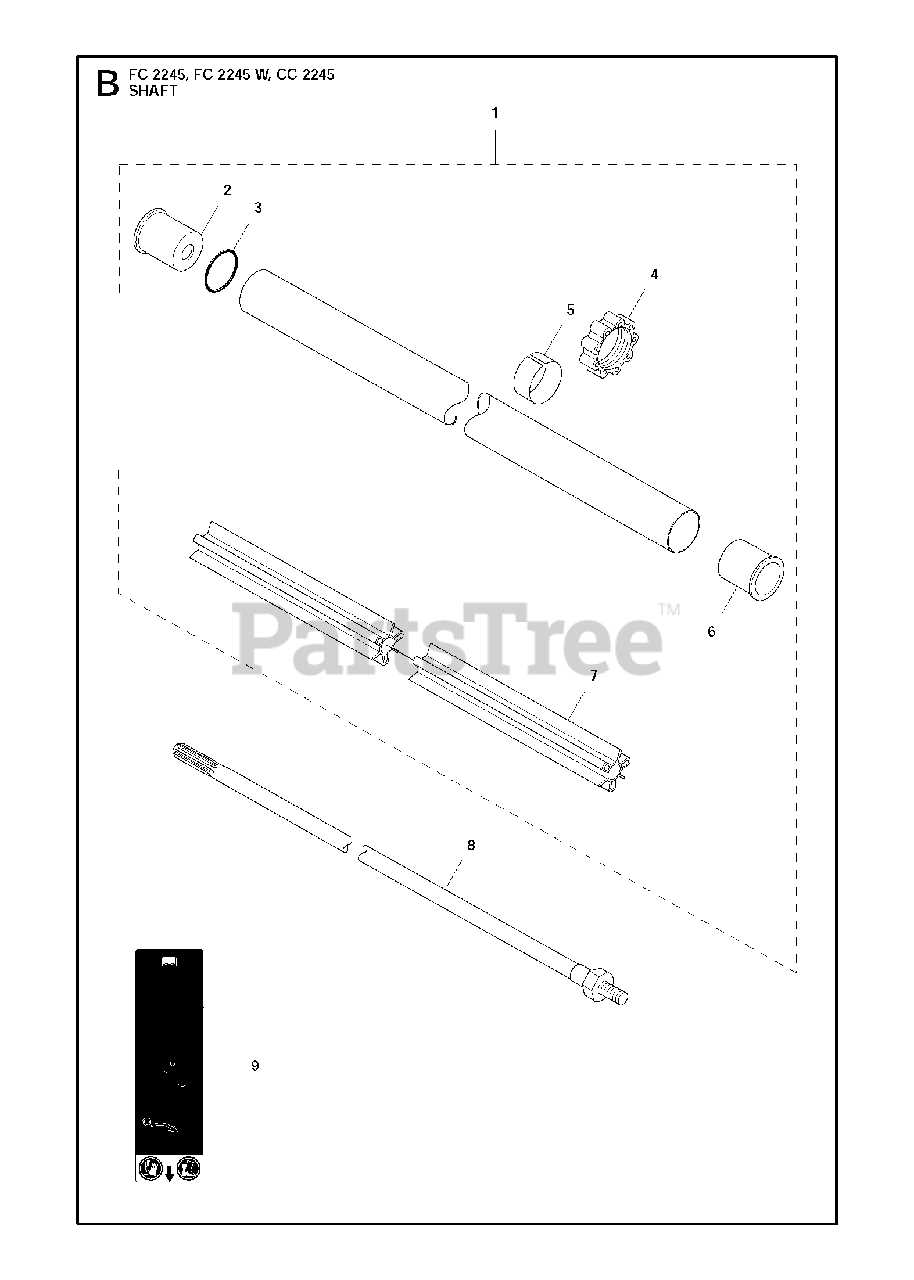

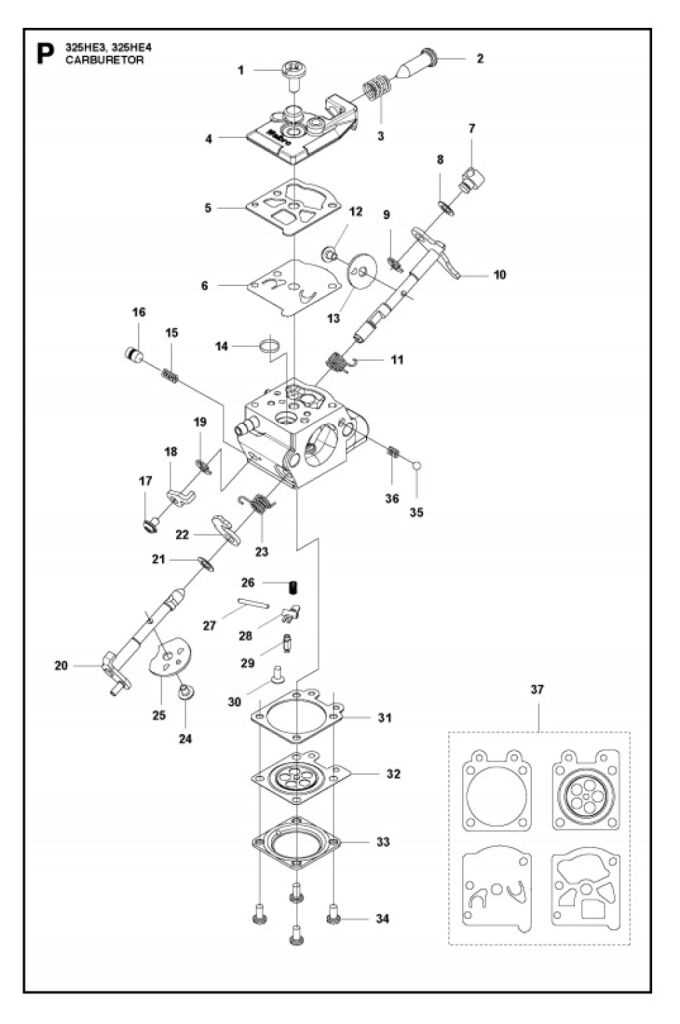

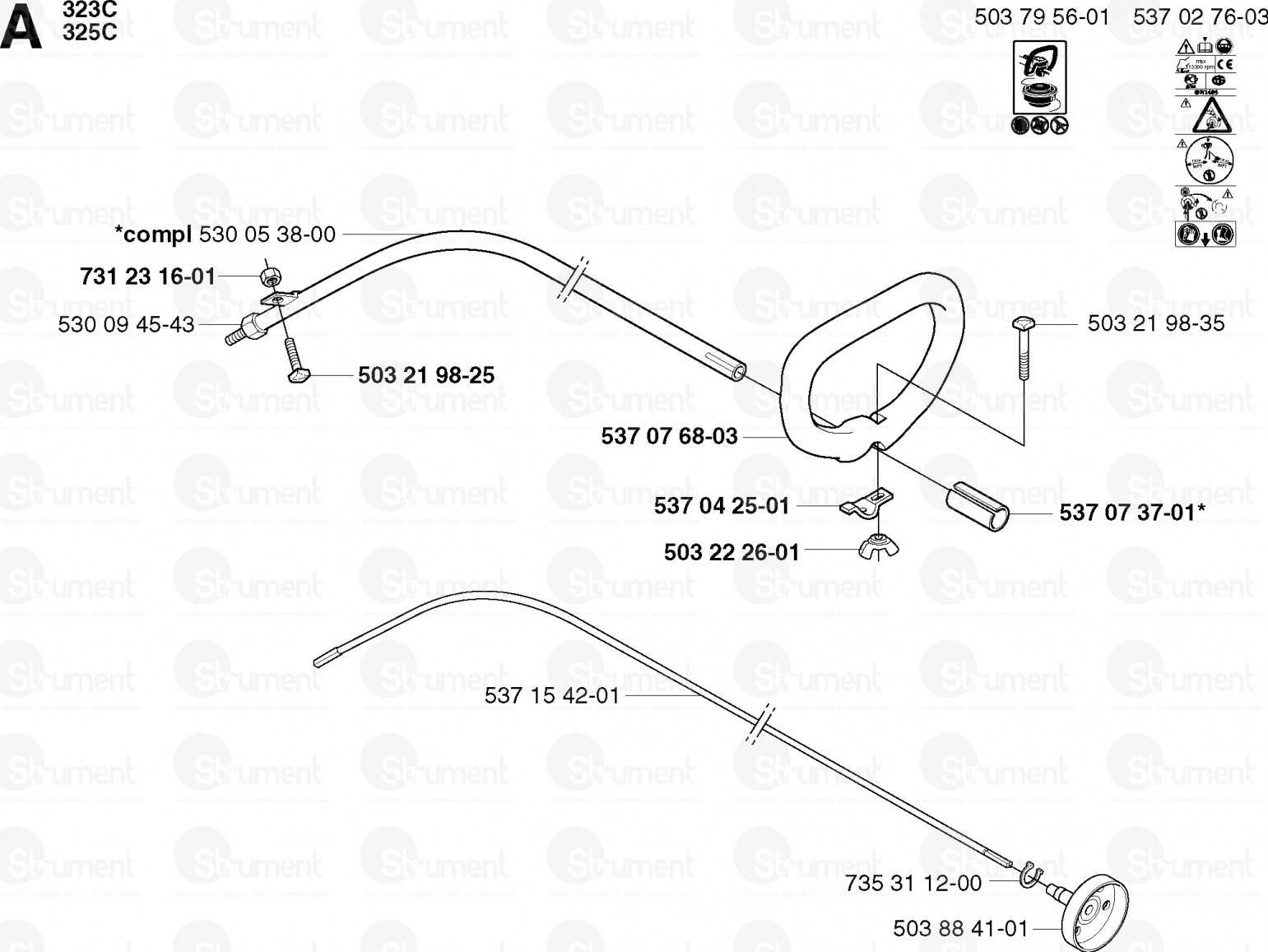

Visual aids can be invaluable for anyone looking to grasp the assembly of their equipment. By referencing a comprehensive illustration, users can easily identify each component and understand its role within the overall system. This understanding not only aids in troubleshooting but also empowers users to perform necessary maintenance tasks with confidence.

In this exploration, we will highlight key elements that contribute to optimal operation. Recognizing the specific functions and interrelations of these pieces can lead to informed decisions when it comes to repairs or upgrades. This knowledge is crucial for any enthusiast or professional seeking to enhance their experience with outdoor machinery.

Understanding Husqvarna 129LK Components

This section explores the essential elements that comprise a popular outdoor tool, focusing on their functions and interrelations. By understanding these components, users can enhance maintenance and troubleshooting, ensuring optimal performance.

Main Elements

The core structure includes the engine, which powers the device, and the cutting mechanism, designed for efficiency. Additionally, the fuel system plays a crucial role in ensuring smooth operation, while the handle and housing provide user comfort and safety.

Regular checks of each component are vital for longevity. Familiarity with the function of each part allows users to quickly identify issues, facilitating effective repairs and enhancing overall reliability.

Overview of Parts Diagram Importance

Understanding the components of a machine is crucial for effective maintenance and repair. A visual representation of these elements serves as an essential tool for both professionals and enthusiasts. It enhances comprehension of how each part interacts, facilitating smoother troubleshooting and assembly processes.

Moreover, such illustrations help identify specific pieces that may require replacement, ensuring that repairs are conducted efficiently. By having a clear overview, users can avoid confusion and make informed decisions regarding service needs. This organized approach not only saves time but also minimizes the risk of errors during maintenance tasks.

In addition, a detailed representation can enhance safety practices. Familiarity with the layout and functions of various components allows operators to work more confidently and safely. Overall, having access to a comprehensive visual guide significantly contributes to the longevity and performance of the equipment.

Key Features of the 129LK Model

This versatile tool is designed to meet the demands of various gardening tasks, combining power with ease of use. Its robust construction ensures durability, while its lightweight design allows for extended operation without fatigue. Users will appreciate the balance between efficiency and user-friendliness, making it an ideal choice for both novices and seasoned gardeners alike.

Powerful Engine

The engine provides reliable performance, enabling users to tackle a wide range of outdoor tasks effortlessly. With a focus on fuel efficiency, it minimizes environmental impact while maintaining high output, allowing for longer working sessions without frequent refueling.

Interchangeable Attachments

This model features a range of compatible attachments, enhancing its versatility. Users can easily switch between functions, from trimming to edging, ensuring that one tool can handle multiple applications. This adaptability not only saves time but also reduces the need for additional equipment.

Identifying Essential Replacement Parts

Understanding which components require replacement is crucial for maintaining the efficiency and longevity of outdoor equipment. Regular inspection and timely identification of worn or damaged elements can prevent further issues and enhance overall performance. Knowing the essential components helps in ensuring that your machinery runs smoothly and effectively.

Common Components to Monitor

When assessing the condition of your equipment, certain parts should be prioritized for regular checks. These include elements that are subject to wear and tear due to regular use. Identifying these components early can save time and resources in the long run.

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Blades | Dullness, chipping | Sharpen or replace |

| Filters | Clogging, discoloration | Clean or replace |

| Lines | Fraying, breakage | Replace immediately |

| Fuel System | Leaks, discoloration | Inspect and replace components |

Maintaining Optimal Performance

Regular maintenance and proactive identification of critical components not only improve functionality but also extend the lifespan of your machinery. By staying ahead of potential issues, you can ensure that your equipment operates at its best, ultimately enhancing productivity and reducing downtime.

Common Issues with Husqvarna 129LK

This section addresses frequent challenges encountered with a specific outdoor power tool. Users often face a range of operational difficulties that can affect performance and longevity. Understanding these issues can facilitate better maintenance and effective solutions.

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Problems | The machine may struggle to start or fail to ignite altogether. | Check the fuel mixture and spark plug; ensure the choke is in the correct position. |

| Power Loss | Loss of power during operation can hinder tasks. | Inspect the air filter and fuel lines; clean or replace as necessary. |

| Vibration Issues | Excessive vibration can lead to operator discomfort and wear on components. | Check for loose screws and ensure all parts are securely attached. |

| Overheating | The equipment may overheat during prolonged use. | Allow for adequate cooling breaks; monitor fuel levels and air intake. |

How to Use the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repair. This guide will help you navigate the schematic to identify various elements, ensuring you can easily locate what you need for replacements or upgrades.

Begin by familiarizing yourself with the layout. Each section is typically organized to represent different assemblies, which allows you to pinpoint specific items quickly. Take note of the labels that accompany each part, as they often include reference numbers and descriptions.

When you identify a component, cross-reference it with the manufacturer’s catalog for compatibility and ordering information. This will ensure that you acquire the correct replacement for your machine.

Additionally, keep track of your findings as you delve deeper into the representation. Noting down part numbers can streamline the purchasing process and enhance your repair efficiency.

Exploring the Engine Assembly Details

Understanding the intricacies of the power unit is essential for effective maintenance and operation. This section focuses on the various components that constitute the engine assembly, their functions, and how they interact to deliver optimal performance.

Key Components of the Power Unit

- Piston: Converts fuel energy into mechanical motion.

- Cylinder: Houses the piston and facilitates combustion.

- Cylinder Head: Contains valves and spark plugs for ignition.

- Crankshaft: Transforms linear motion of the piston into rotational motion.

- Fuel System: Supplies the necessary fuel mixture for efficient combustion.

Assembly Insights

When delving into assembly, each part must be precisely aligned and secured to ensure functionality. Regular checks and proper lubrication are crucial to maintain the longevity of the components. Familiarizing oneself with the layout can lead to improved troubleshooting and repair processes.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of your outdoor equipment. By following a few key practices, you can enhance performance and minimize the need for repairs. Regular attention to your tools not only promotes efficiency but also contributes to a safer working environment.

1. Regular Cleaning: After each use, clean the machine thoroughly to remove dirt and debris. This helps prevent corrosion and wear on vital components.

2. Inspect and Replace Worn Parts: Periodically check for signs of wear and tear. Replacing damaged or worn parts promptly can prevent further issues and ensure smooth operation.

3. Proper Storage: Store your equipment in a dry, sheltered place. Using protective covers can shield it from moisture and dust, prolonging its lifespan.

4. Follow Manufacturer’s Guidelines: Adhering to the recommended maintenance schedule outlined in the user manual can help keep your tools in peak condition.

5. Fuel Quality: Always use high-quality fuel and store it properly. Contaminated fuel can lead to engine issues, reducing overall performance.

By incorporating these maintenance tips, you can delve deeper into the care of your machinery, ensuring it remains reliable and effective for years to come.

Finding Authentic Replacement Parts

When seeking components for your outdoor equipment, ensuring their authenticity is crucial for optimal performance and longevity. Genuine pieces not only enhance the machine’s efficiency but also contribute to its safety and reliability. By sourcing original items, users can avoid the pitfalls of counterfeit products that may compromise functionality.

Where to Look for Genuine Components

Start by visiting authorized dealers and certified retailers who specialize in outdoor tools. These outlets typically offer a comprehensive selection of original items, backed by manufacturer warranties. Additionally, online platforms dedicated to authentic equipment can be a valuable resource.

Benefits of Using Original Items

Utilizing genuine components ensures compatibility and enhances the overall performance of your machinery. Quality materials used in authentic items lead to greater durability and reduced maintenance costs. Investing in original parts ultimately saves time and effort, delivering peace of mind in your outdoor tasks.

Tools Needed for Repairs

When it comes to performing maintenance on outdoor equipment, having the right tools is essential for achieving optimal results. The following list highlights the key instruments that can make the repair process smoother and more efficient.

Essential Tools

- Screwdrivers (flat and Phillips)

- Wrenches (adjustable and socket)

- Pliers (needle-nose and standard)

- Torque wrench

- Utility knife

Additional Supplies

- Safety goggles

- Work gloves

- Lubricants and cleaners

- Replacement parts as needed

- Storage containers for small items

With these tools at your disposal, you can confidently delve into repairs, ensuring that your equipment operates at its ultimate performance level.

Step-by-Step Repair Guide

This guide provides a systematic approach to restoring your outdoor equipment to optimal working condition. By following these steps, you can identify issues, replace necessary components, and enhance the overall performance of your machine.

Preparation

Before starting any repairs, ensure you have the right tools and a clean workspace. Gather the necessary equipment and a manual to assist with the specific details of your model.

Disassembly Process

Begin by carefully disassembling the unit. Take note of each step, and keep all parts organized to facilitate reassembly. Documenting the process can be incredibly helpful.

| Step | Description |

|---|---|

| 1 | Disconnect the power source. |

| 2 | Remove any protective covers. |

| 3 | Identify and take out worn components. |

| 4 | Clean all accessible areas. |

| 5 | Replace damaged parts with new ones. |

| 6 | Reassemble the unit in reverse order. |

DIY vs. Professional Services

When it comes to maintenance and repairs, individuals often face the choice between tackling the task themselves or hiring experts. Each option presents its own set of advantages and challenges that can influence the ultimate decision.

- DIY Approach:

- Cost savings by avoiding labor fees.

- Opportunity to learn and develop new skills.

- Flexibility to work at your own pace.

- Professional Services:

- Expertise and experience ensure quality results.

- Time-efficient, especially for complex tasks.

- Access to specialized tools and equipment.

Ultimately, the decision depends on the individual’s comfort level with the task, the complexity involved, and the resources available. Balancing these factors can lead to a satisfying outcome, whether through personal effort or professional assistance.

Resources for Husqvarna Owners

Maintaining outdoor equipment effectively requires access to a variety of helpful materials. Owners can benefit from detailed guides, instructional videos, and forums where enthusiasts share their experiences and solutions. These resources not only enhance understanding but also ensure optimal performance and longevity of machinery.

Online manuals and official websites serve as excellent starting points, providing essential information on operation and care. Additionally, user communities on social media platforms allow for valuable exchanges and tips. Engaging with these resources can ultimately improve the overall experience of managing and enjoying your tools.

For those seeking specific components or accessories, numerous retailers and marketplaces offer comprehensive catalogs. These platforms often feature customer reviews, making it easier to make informed purchasing decisions. Always consider exploring multiple options to find the best fit for your needs.