Understanding the intricate workings of outdoor machinery is crucial for optimal performance and longevity. This section delves into the essential elements that make up these powerful tools, offering insights into their structure and functionality. By familiarizing yourself with these vital components, you can ensure your equipment operates smoothly and efficiently.

In the realm of outdoor machinery, having access to a comprehensive visual guide can significantly enhance your ability to identify and manage different components. Such a reference not only aids in maintenance tasks but also empowers users to make informed decisions when it comes to repairs and replacements. By breaking down the assembly into easily recognizable sections, you can navigate the complexities of these machines with confidence.

Whether you are a seasoned professional or a novice enthusiast, grasping the layout of these essential components is invaluable. A thorough understanding equips you with the knowledge necessary to troubleshoot issues and maintain the functionality of your equipment over time. Embrace the journey of discovery as you familiarize yourself with the core elements that drive your outdoor machinery.

tags: Overview of Husqvarna 162 SE”>

tags: Overview of Husqvarna 162 SE”>

This section aims to provide a comprehensive overview of a specific model of outdoor machinery, focusing on its key components and their functionalities. Understanding the different elements of this equipment is essential for proper maintenance and effective operation. The following headings will delve into various aspects of the machinery, ensuring a thorough exploration of its construction and utility.

| Heading | Description |

|---|---|

| General Specifications | A brief outline of the model’s key specifications and features. |

| Engine Components | An overview of the engine parts, including their roles and maintenance tips. |

| Transmission System | Insights into the transmission parts and their significance in operation. |

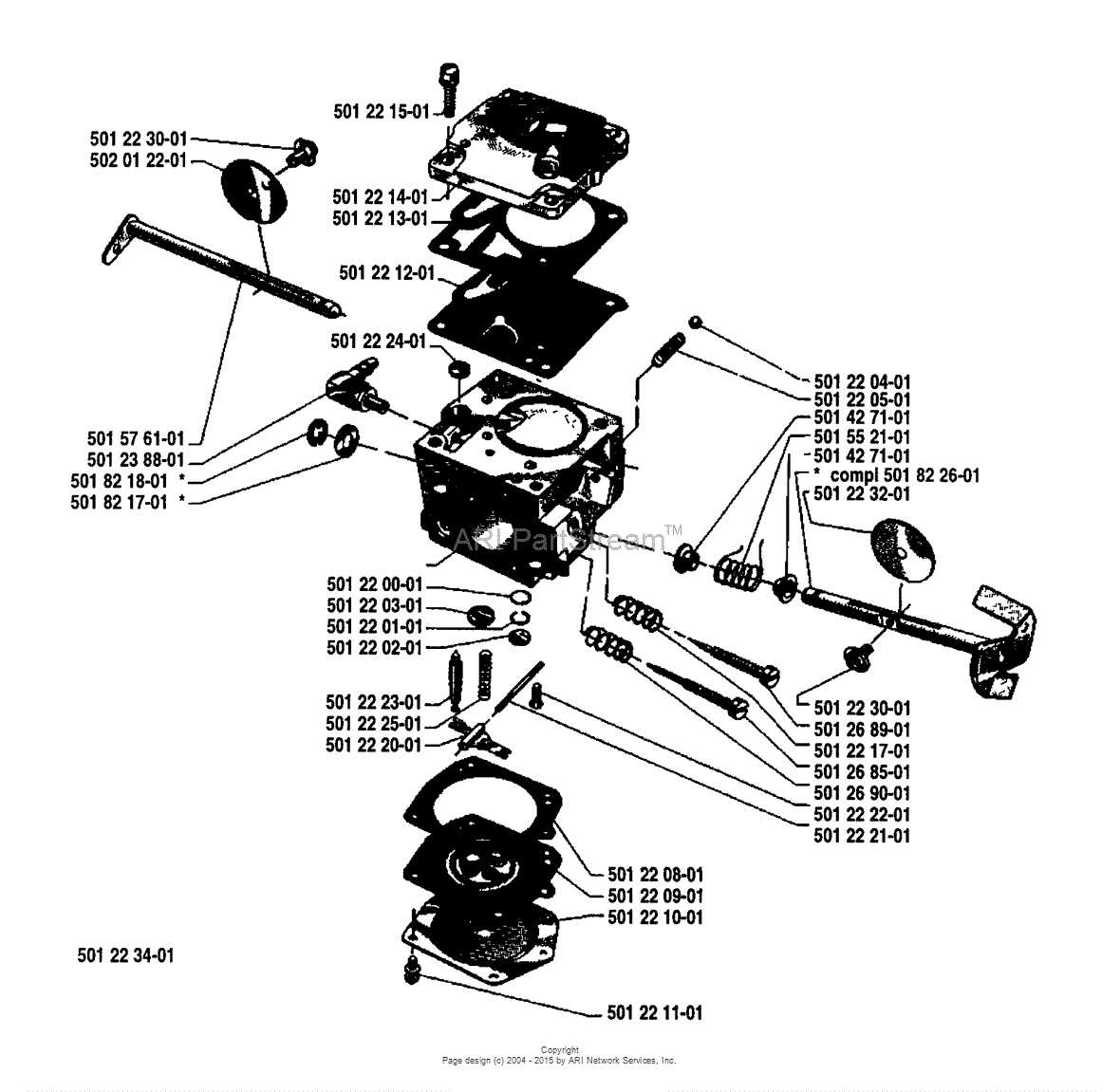

| Fuel System | Detailed discussion on the fuel components and their functionalities. |

| Electrical System | Exploration of the electrical components and their maintenance. |

| Chassis and Frame | Examination of the chassis structure and its importance. |

| Cutting Mechanism | Description of the cutting parts and their operation. |

| Safety Features | Overview of safety components that ensure user protection. |

| Common Issues | A look into frequent problems and troubleshooting methods. |

| Maintenance Tips | Guidelines for proper upkeep and servicing of the machinery. |

| Replacement Parts | Information on sourcing and replacing essential components. |

| Conclusion | A summary highlighting the importance of understanding the machinery. |

Key Features of the Model

This particular unit boasts a range of distinctive attributes that enhance its functionality and user experience. Designed for efficiency, it integrates advanced technology that ensures optimal performance across various applications.

One of the standout characteristics is its robust construction, which contributes to durability and reliability in demanding environments. The innovative engineering allows for seamless operation, making it suitable for both professional and personal use.

Additionally, the model features an ergonomic design that promotes user comfort during extended periods of operation. Its intuitive controls facilitate ease of use, ensuring that even novice users can navigate its functionalities with confidence.

Moreover, the versatility of this equipment is a significant advantage, allowing it to adapt to a variety of tasks with ease. With its enhanced capabilities, it is well-equipped to handle challenging conditions, making it a valuable asset for any operator.

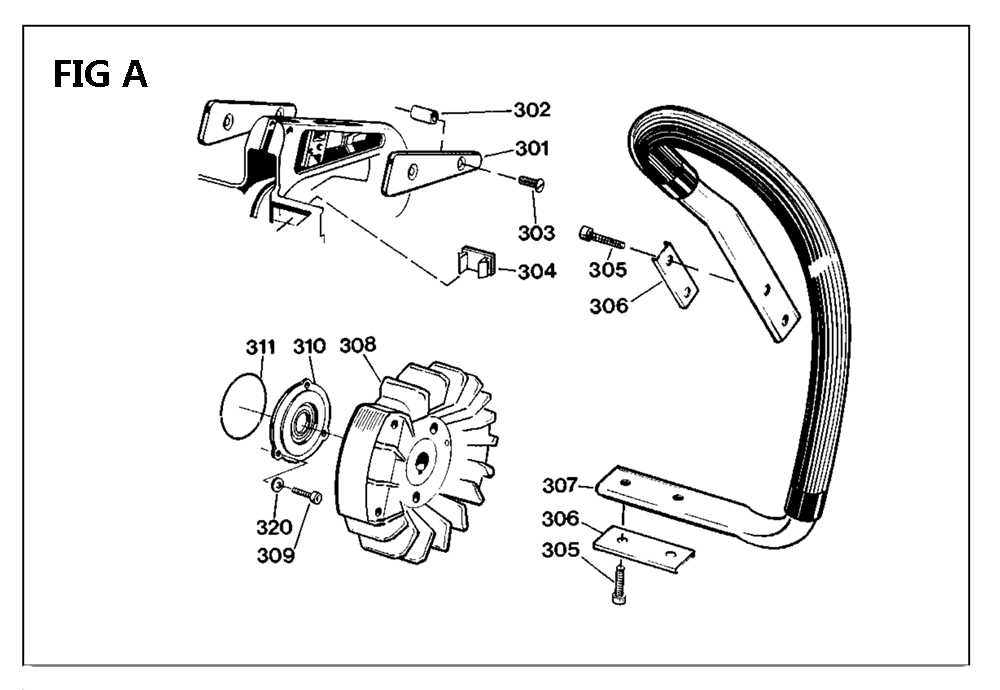

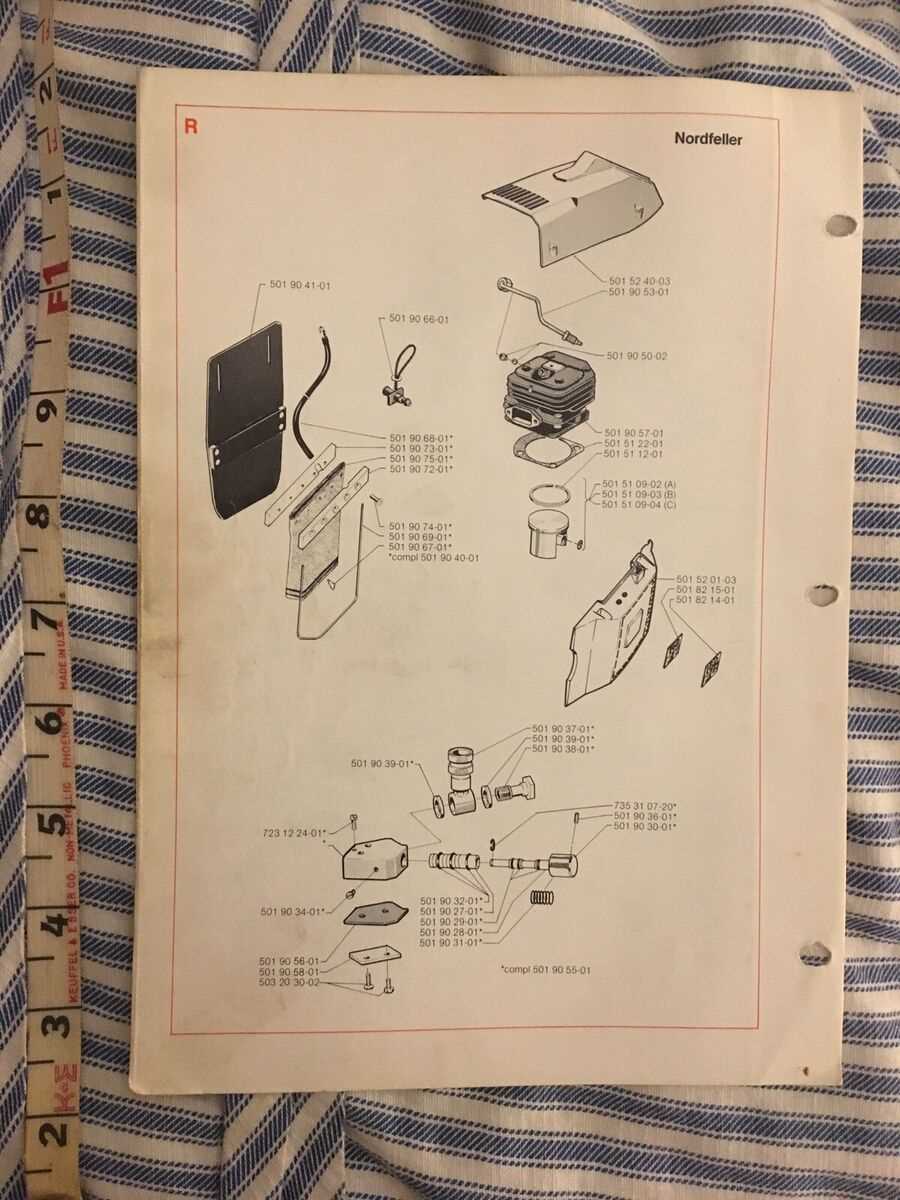

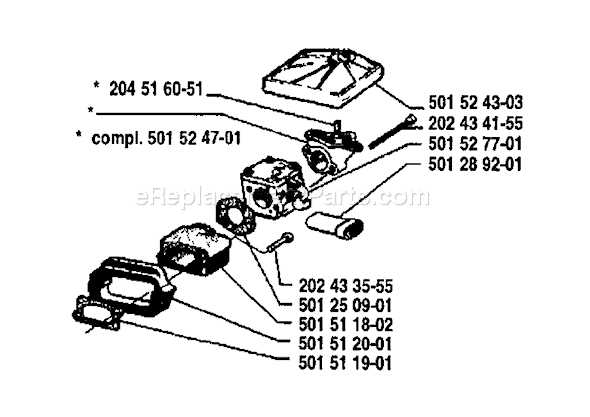

Importance of Parts Diagrams

Understanding the components of any machine is crucial for efficient maintenance and repairs. Visual representations serve as valuable tools for users, providing clarity on how various elements interact within the system. These illustrations facilitate a deeper comprehension of the equipment, enabling operators to identify and address issues effectively.

Having access to these visuals streamlines the repair process by allowing individuals to locate specific items quickly. This not only saves time but also reduces the risk of errors during assembly or disassembly. Additionally, such resources enhance communication between technicians and users, ensuring everyone is on the same page regarding repairs or replacements.

Moreover, these visuals are essential for educational purposes. They help new users familiarize themselves with the equipment, fostering a better understanding of its functionality. Overall, these aids play a vital role in promoting efficiency and effectiveness in maintenance practices.

Understanding Component Functions

In any machinery, comprehending the roles of various elements is essential for optimal performance and maintenance. Each part contributes uniquely to the overall functionality, ensuring smooth operation and efficiency. By analyzing these roles, users can make informed decisions regarding repairs and upgrades, ultimately prolonging the equipment’s lifespan.

Key Functional Areas

- Power System: This section includes components responsible for generating and supplying energy, critical for the machinery’s operation.

- Transmission Mechanism: Elements in this area facilitate the transfer of power from the engine to the working parts, enabling effective movement.

- Control Features: These parts allow users to manipulate the machine’s functions, ensuring precision in operations.

Maintenance and Troubleshooting

Regular inspection of each component is vital for identifying potential issues. Understanding how each part operates helps in diagnosing problems accurately. Here are some common areas to focus on:

- Inspecting connections for wear and tear.

- Ensuring fluid levels are maintained to prevent overheating.

- Cleaning filters and airways to promote efficient operation.

Common Issues and Solutions

When operating outdoor power equipment, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems and their corresponding solutions can help maintain optimal functionality and extend the lifespan of the machinery.

Frequent Problems

- Engine failure to start

- Uneven cutting or trimming

- Excessive vibration during operation

- Fuel leakage

- Inconsistent power output

Effective Solutions

- For engine startup issues, check the fuel level, ensure the spark plug is clean, and inspect the ignition system.

- To address uneven cutting, examine the blade for damage or dullness, and adjust the cutting height if necessary.

- Excessive vibrations may indicate loose components; tightening screws and checking for wear can resolve this problem.

- If fuel leakage occurs, inspect fuel lines and connections for cracks or loose fittings.

- Inconsistent power output can often be corrected by replacing the air filter and ensuring proper carburetor adjustment.

Parts Replacement Tips

When it comes to maintaining equipment, understanding the process of component substitution is essential for optimal functionality. Proper replacement not only ensures the longevity of the machinery but also enhances its overall performance. Below are some valuable insights to guide you through the replacement process effectively.

Identifying Components

Before initiating any substitution, it is crucial to accurately identify the components that require attention. Referencing a detailed visual guide can help you recognize specific elements that need to be replaced. This ensures that you obtain the correct items for your machinery.

Follow Manufacturer Guidelines

Always adhere to the manufacturer’s recommendations when it comes to replacement procedures. These guidelines provide crucial information regarding compatible items, installation techniques, and safety measures. Following these instructions will facilitate a smoother replacement process and mitigate potential issues.

How to Access the Diagram

To effectively view the schematic for your equipment, it is essential to follow a few straightforward steps. This visual representation provides valuable insights into the components and their arrangement, facilitating easier maintenance and repairs.

Here are some methods to retrieve the schematic:

- Check the user manual that came with your machine, as it often includes a detailed schematic.

- Visit the manufacturer’s official website to find downloadable resources and technical documentation.

- Utilize online forums or community groups where enthusiasts share resources and diagrams.

- Contact customer support for assistance in obtaining the necessary schematic.

By employing these approaches, you can ensure you have access to the information needed for efficient servicing and troubleshooting of your equipment.

Where to Find Authentic Parts

Locating genuine components for your equipment is essential to ensure optimal performance and longevity. Whether you’re looking to replace worn-out elements or upgrade existing features, sourcing quality replacements can significantly impact the overall functionality.

Here are some reliable sources to consider:

| Source Type | Description |

|---|---|

| Authorized Dealers | Official distributors often carry a wide range of genuine replacements and offer expert advice on compatibility and installation. |

| Online Retailers | Reputable websites specializing in outdoor equipment typically provide a selection of authentic components, often with customer reviews to guide your purchase. |

| Manufacturer’s Website | The official site often features a dedicated section for accessories and replacements, ensuring you find the right fit. |

| Local Repair Shops | Many repair facilities not only service equipment but also stock original components, allowing for immediate access to necessary items. |

Maintenance Best Practices

Ensuring optimal performance and longevity of outdoor equipment requires a strategic approach to upkeep. Regular maintenance not only enhances efficiency but also prevents potential breakdowns, saving time and resources in the long run. Adopting a systematic maintenance routine is crucial for achieving these goals.

Regular Inspection

Frequent examinations of the machinery are vital. Inspecting components for wear and tear allows for early detection of issues that could lead to more significant problems. Key areas to focus on include:

| Component | Inspection Frequency | Action Required |

|---|---|---|

| Blades | Before each use | Sharpen or replace as necessary |

| Filters | Every 25 hours of use | Clean or replace |

| Fuel System | Monthly | Check for leaks and clean |

Routine Cleaning

Keeping the equipment clean is essential for preventing dirt and debris buildup, which can hinder performance. Regularly washing the exterior and cleaning the air intake can significantly improve efficiency. Implement a cleaning schedule that aligns with your usage to maintain peak performance.

Tools for Effective Repairs

Having the right equipment is essential for ensuring successful maintenance and restoration tasks. Proper tools not only facilitate the repair process but also enhance the quality of work performed. This section highlights various implements that can significantly improve efficiency and outcomes during repair activities.

- Wrenches: Versatile and indispensable for loosening or tightening fasteners.

- Screwdrivers: Essential for adjusting and securing components in place.

- Pliers: Useful for gripping, twisting, and cutting various materials.

- Socket Sets: Ideal for accessing hard-to-reach nuts and bolts, providing increased leverage.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications, preventing damage.

- Multimeter: Vital for diagnosing electrical issues and ensuring components function properly.

Using appropriate tools can greatly reduce the time spent on repairs while ensuring that all tasks are performed safely and accurately. Investing in high-quality equipment will lead to more reliable outcomes and prolonged lifespan of the machinery.

Comparing with Other Models

This section aims to highlight the differences and similarities among various models in the same category, focusing on features, specifications, and usability. By examining these elements, users can make informed decisions based on their specific needs and preferences.

When evaluating different units, consider the following aspects:

- Performance: Analyze the engine capacity and efficiency to determine which models deliver the best power and fuel economy.

- Durability: Look into the materials used in construction, as well as user reviews regarding longevity and resistance to wear.

- Ease of Use: Assess the ergonomics and user-friendly features that enhance the overall experience, including controls and weight distribution.

Here are some key comparisons:

- Model A: Known for its robust design, it excels in heavy-duty tasks.

- Model B: Offers enhanced maneuverability, making it ideal for smaller spaces.

- Model C: Focuses on energy efficiency, attracting environmentally conscious users.

By considering these comparisons, potential buyers can better understand which model aligns with their expectations and requirements.

Specifications and Performance Review

This section provides an in-depth analysis of the key features and capabilities of the equipment, highlighting its efficiency and operational excellence. Understanding these elements is essential for users seeking to optimize their experience and achieve the best results during operation.

Key Features

The machinery boasts a robust design, engineered to handle various tasks with precision. Equipped with a powerful engine, it ensures reliability and exceptional performance even in demanding conditions. Its user-friendly interface allows for easy adjustments, making it suitable for both novice and experienced operators.

Operational Efficiency

Performance metrics indicate that this model excels in fuel efficiency, reducing operational costs while maintaining high output levels. The advanced cutting technology minimizes downtime, enabling users to complete projects in a timely manner. Additionally, the lightweight construction enhances maneuverability, providing ease of use across different terrains.