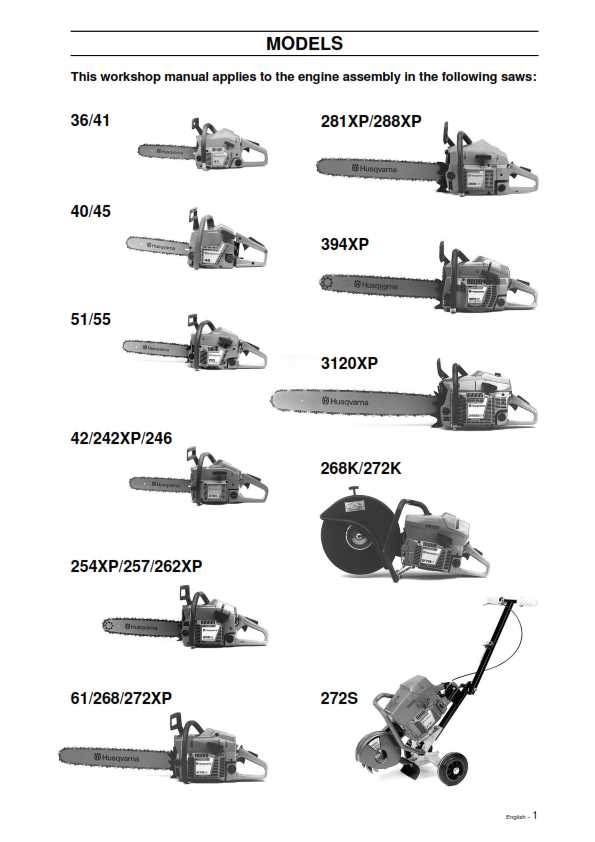

The effective operation of any chainsaw depends on the well-functioning interaction of numerous elements. Each piece, no matter how small, plays a crucial role in ensuring the tool performs efficiently. For those looking to maintain or repair their equipment, it is essential to have a clear understanding of the individual components and their arrangement within the system.

Recognizing the layout of key elements can greatly assist in troubleshooting and ensuring proper maintenance. A well-organized overview of these sections allows users to address issues and perform routine tasks with confidence. Whether it’s for replacing a specific piece or simply gaining insight into the machine’s workings, having access to this information is invaluable.

With detailed insights into the structural arrangement, both professionals and enthusiasts can ensure their tools remain reliable over time. Knowing how each piece fits together not only facilitates repairs but also helps in prolonging the tool’s overall lifespan.

Overview of Key Chainsaw Components

Chainsaws consist of several essential parts that work together to ensure efficient cutting and reliable performance. Each component plays a critical role in the machine’s operation, contributing to its overall functionality and durability. Understanding these key elements can help with maintenance and troubleshooting.

- Engine: The core of the machine, responsible for generating the power needed to drive the cutting chain.

- Guide Bar: A long metal bar that provides support and direction for the chain as it moves during operation.

- Cutting Chain: A loop of sharpened teeth that rotates around the guide bar to perform the actual cutting action.

- Clutch: A mechanism that controls when the chain is engaged, ensuring it only moves when needed.

- Throttle: A control mechanism that regulates the engine’s speed, allowing the operator to adjust cutting power.

- Chain Brake: A safety feature designed to stop the chain’s movement in case of kickback or other hazards.

- Oil Reservoir: A compartment that holds lubrication for the chain, keeping it running smoothly and reducing wear.

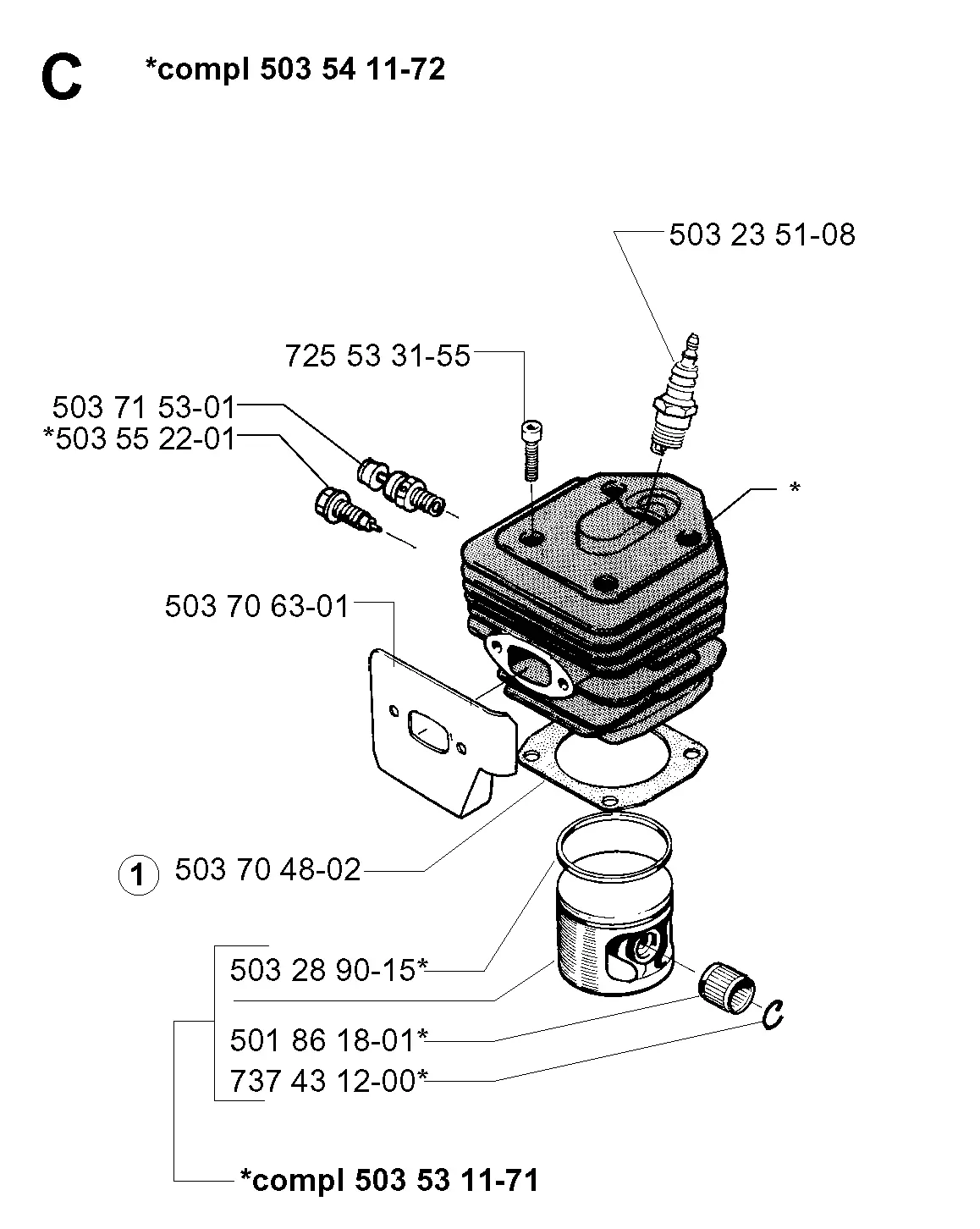

Exploring the Engine Assembly

The engine assembly is a complex yet essential part of the machine’s overall function. It includes a variety of components that work together to deliver the necessary power and efficiency. Understanding how these elements interact helps in maintaining and troubleshooting performance issues.

Below is an overview of the key elements found within the engine assembly:

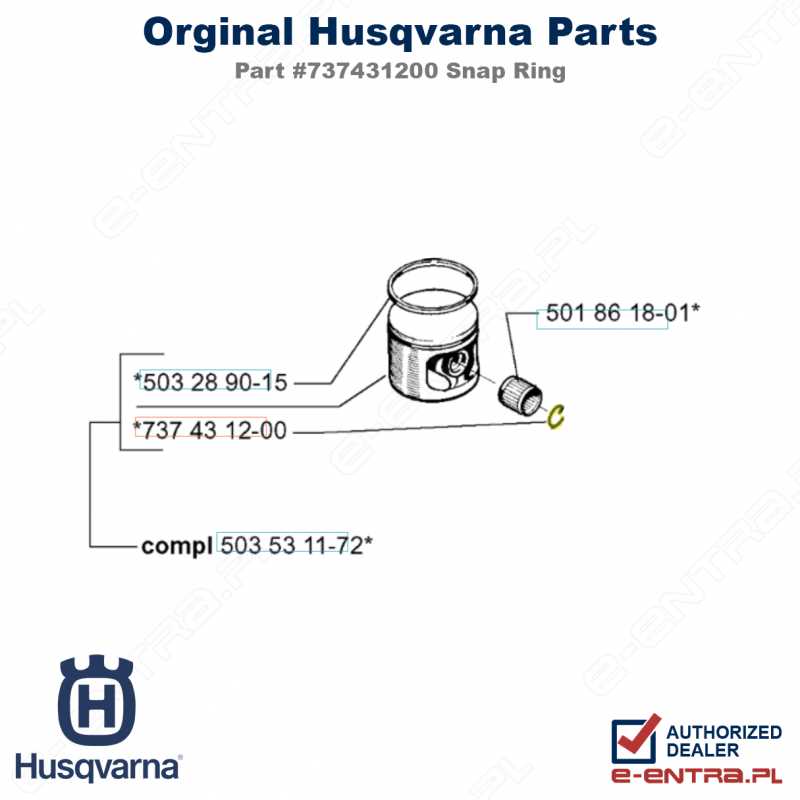

- Cylinder: The main chamber where combustion occurs, converting fuel into mechanical energy.

- Piston: A moving component that transfers force from expanding gas in the cylinder to the crankshaft.

- Crankshaft: Converts the linear motion of the piston into rotational motion, driving the rest of the system.

- Carburetor: Mixes air and fuel in the right proportions before combustion.

- Flywheel: Helps to maintain consistent engine speed by storing rotational energy.

Each of these elements plays a critical role

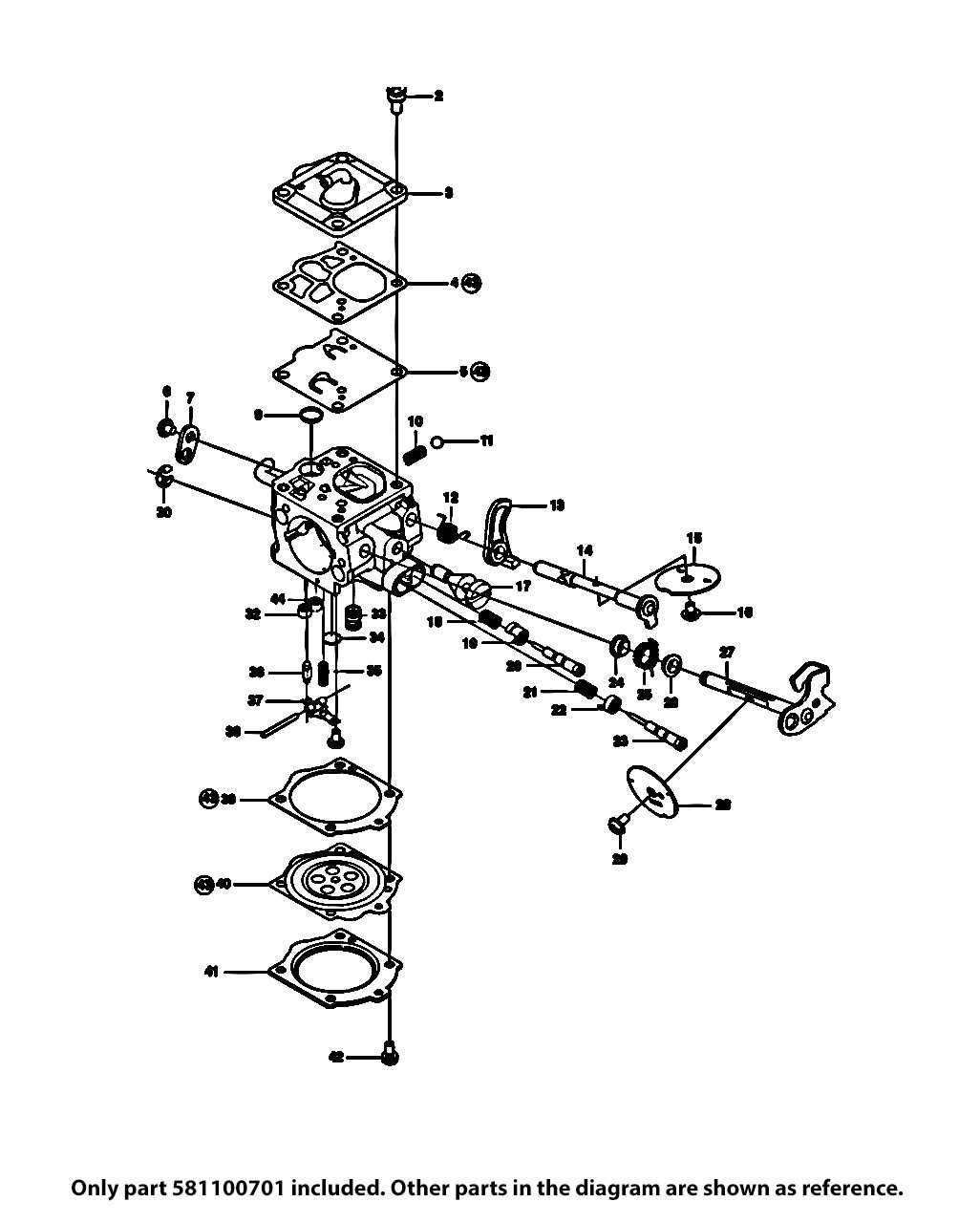

Understanding the Carburetor System

The carburetor system plays a crucial role in ensuring that the engine operates smoothly by blending fuel and air in precise amounts. This mixture is then delivered to the engine for combustion, impacting overall performance and efficiency. Understanding how this system works helps maintain optimal functionality and troubleshoot issues that might arise during use.

Below are the key components involved in the carburetor system:

- Air intake: Controls the amount of air entering the system, affecting the air-fuel ratio.

- Fuel inlet: Manages the flow of fuel into the carburetor, ensuring proper mixing with air.

- Venturi: A narrowed section that speeds up airflow, reducing pressure and pulling fuel into the stream.

- Throttle valve: Regulates the amount of the fuel-air mixture reaching the engine, controlling engine speed.

- Idle system: Ensures the engine runs smoothly when not under load by maintaining a steady low-speed mixture.

Guide to the Chain Mechanism

The chain mechanism is an essential component of any chainsaw, playing a crucial role in its overall functionality. This section will provide an overview of how the system works, focusing on the main elements involved in ensuring smooth operation. Proper understanding and maintenance of the chain mechanism can help prolong the tool’s lifespan and improve efficiency.

At the heart of the system is the chain itself, which must be tensioned and aligned correctly for optimal performance. The drive mechanism moves the chain along the bar, allowing for precise cutting action. Regular checks and adjustments are necessary to ensure that the chain runs smoothly without excess friction or wear.

Another vital part of the setup is the tensioning system, which allows the user to modify the tightness of the chain. Maintaining the correct tension is essential for preventing chain slippage and ensuring safe operation. Additionally, the lubrication system plays a critical role in reducing friction and minimizing wear on the chain and bar, keeping them in good working condition.

Identifying Key Ignition Parts

The ignition system is a vital component in ensuring that the engine starts and runs smoothly. Recognizing the essential elements within this system can help with both troubleshooting and maintenance. Understanding how these components work together can greatly assist in identifying any potential issues that may arise during operation.

Ignition Coil

The ignition coil plays a crucial role in generating the spark needed to ignite the fuel. It transforms the low voltage from the power source into the high voltage required to create a spark. Without this component, the engine would fail to start, as no ignition process could take place.

Spark Plug

The spark plug is responsible for delivering the electric current from the ignition system to the combustion chamber. It creates the spark that ignites the air-fuel mixture, powering the engine. A well-maintained spark plug ensures efficient combustion and smooth engine performance.

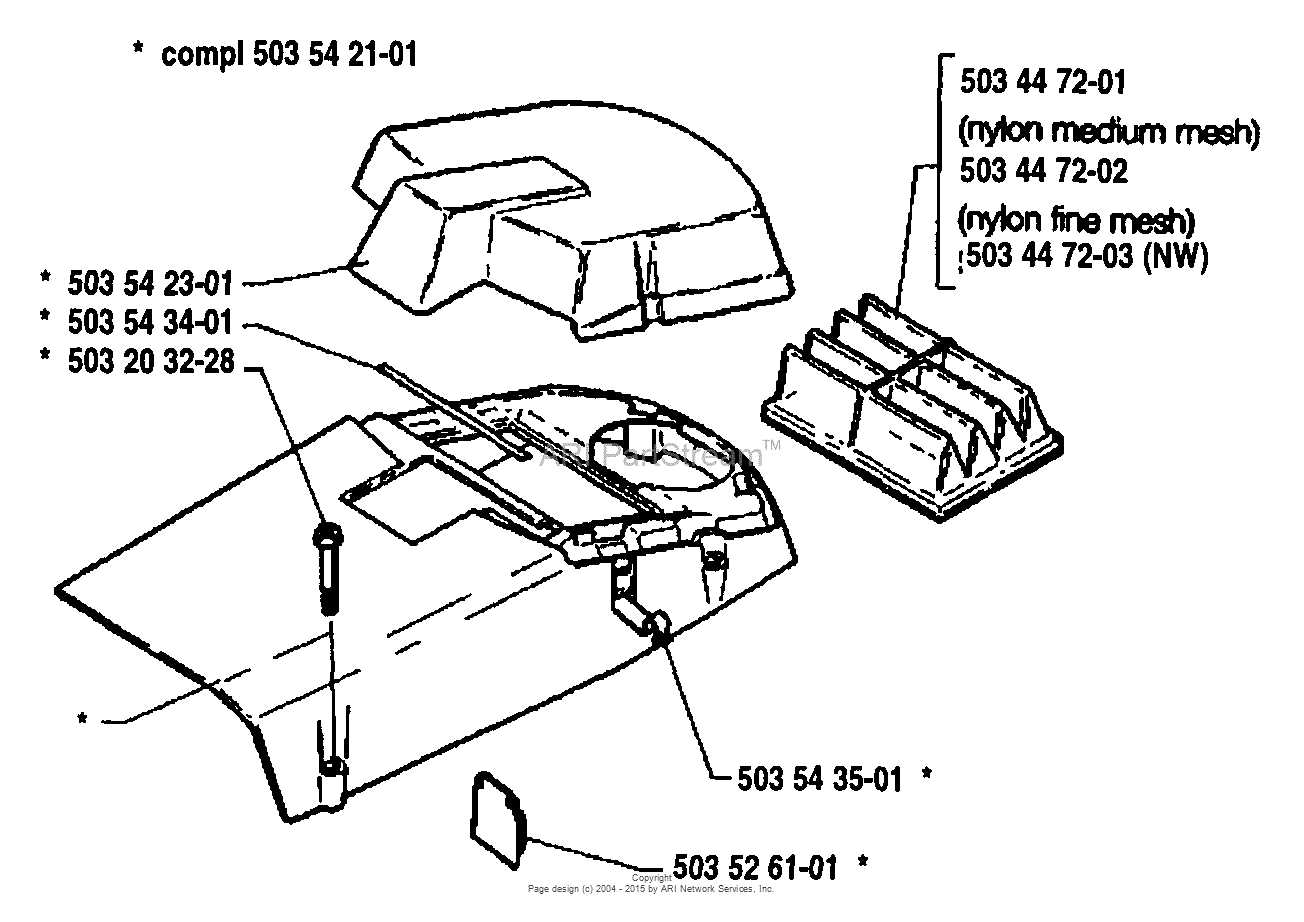

Air Filtration System Breakdown

The air filtration mechanism is a crucial component in ensuring optimal performance and longevity of outdoor power equipment. This system prevents dust, debris, and other contaminants from entering the engine, which can lead to wear and potential damage. Understanding its components and functionality can help users maintain their equipment effectively.

Components of the Air Filtration Mechanism

The air filtration system typically comprises several key elements that work together to provide clean air to the engine. These components include the air filter, pre-filter, and intake system, each playing a vital role in the filtration process.

| Component | Function |

|---|---|

| Air Filter | Catches particles and impurities from the air before they enter the engine. |

| Pre-filter | Provides an initial layer of filtration, trapping larger debris to extend the life of the main air filter. |

| Intake System | Directs filtered air into the engine for combustion. |

Maintenance Tips for Optimal Performance

Analyzing the Fuel System Setup

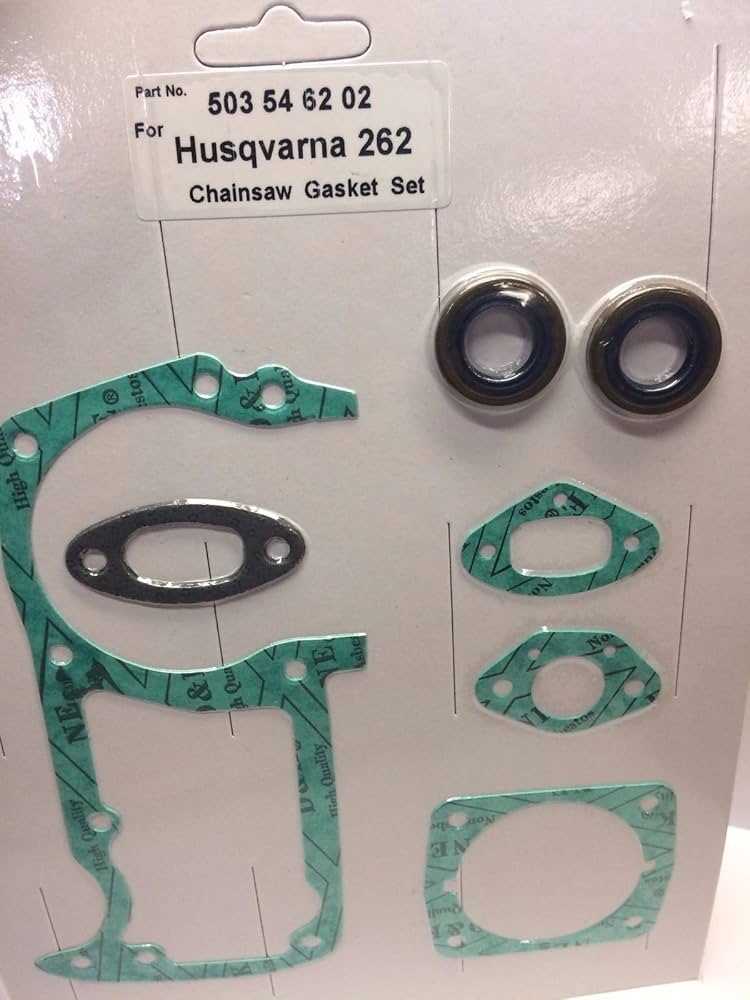

The fuel system plays a crucial role in the performance and efficiency of a two-stroke engine. Understanding its components and functionality can help users maintain optimal operation and troubleshoot potential issues.

Key elements of the fuel system include the fuel tank, lines, filters, and the carburetor. Each part contributes to the overall process of delivering the correct fuel-air mixture to the engine. Proper setup ensures that the engine runs smoothly and efficiently, minimizing the risk of performance problems.

Common issues within the fuel system can often lead to reduced power output or starting difficulties. Regular inspection and maintenance of these components are essential for sustaining performance and prolonging the engine’s lifespan. By familiarizing oneself with the layout and function of the fuel system, users can effectively address any concerns that may arise.

Overview of the Clutch Assembly

The clutch assembly is a crucial component in various mechanical systems, responsible for engaging and disengaging power transmission between the engine and the driven mechanism. Its efficient operation ensures smooth functionality and optimal performance of the equipment, preventing damage to both the engine and the drivetrain.

Key Components

This assembly typically consists of several essential parts, including the clutch drum, shoes, and springs. The clutch drum acts as a housing for the shoes, while the shoes are the friction elements that engage with the drum to transmit torque. The springs play a vital role in maintaining the tension required for proper engagement and disengagement of the assembly.

Functionality and Maintenance

Understanding the functionality of the clutch assembly is critical for maintenance and troubleshooting. Regular inspection of its components can help identify wear or damage, ensuring longevity and reliable operation. Proper care will prevent premature failure and maintain the efficiency of the entire system.

Examining the Starter Mechanism

The starter mechanism plays a crucial role in the overall functionality of any outdoor power equipment. Its design and operation significantly influence the ease with which the engine ignites and runs smoothly. Understanding how this component works can help in troubleshooting issues and ensuring optimal performance.

Components of the Starter System

The starter system consists of various elements that work in tandem to facilitate the ignition process. Each part contributes to the effective functioning of the mechanism, allowing for a seamless start-up of the engine.

| Component | Function |

|---|---|

| Starter Rope | Used to manually engage the starting mechanism. |

| Starter Pulley | Transmits force from the rope to the engine flywheel. |

| Return Spring | Rewinds the starter rope after pulling. |

| Ignition Switch | Activates the engine’s ignition system. |

Troubleshooting Common Issues

When faced with starting difficulties, it’s essential to inspect the starter mechanism thoroughly. Common issues may include a frayed starter rope, a malfunctioning pulley, or a faulty ignition switch. Regular maintenance can prevent these problems and enhance the longevity of the equipment.

Chassis and Frame Structure

The chassis and frame serve as the backbone of any machinery, providing essential support and stability. A well-designed structure ensures that various components are securely mounted while absorbing vibrations and impacts during operation. The integrity of the frame directly influences the overall performance and longevity of the equipment.

Materials used in the construction of the frame are crucial for durability and weight management. Typically, manufacturers opt for high-strength alloys or reinforced plastics that can withstand harsh environmental conditions. This choice of material plays a vital role in enhancing the machine’s resilience and efficiency.

Furthermore, the design of the chassis is meticulously engineered to optimize functionality. Features such as mounting points for accessories, access to maintenance areas, and integration of safety measures are all taken into account. This thoughtful layout ensures that users can operate and maintain the equipment with ease, contributing to a seamless experience.

Troubleshooting Common Chainsaw Issues

Chainsaws are essential tools for various cutting tasks, but they can encounter problems that hinder their performance. Understanding common issues and their solutions can significantly enhance efficiency and prolong the lifespan of your equipment.

One frequent challenge is difficulty starting the machine. This can stem from several factors, including fuel quality, spark plug condition, or issues with the carburetor. Ensure that you use fresh, high-quality fuel and check the spark plug for wear or damage. Cleaning or replacing the spark plug can often resolve starting problems.

Another common issue is poor cutting performance. If the chainsaw struggles to cut through wood, the chain may be dull or improperly tensioned. Regularly sharpen the chain and adjust its tension to ensure optimal cutting efficiency. Additionally, check for any debris or obstructions that might be affecting the chain’s movement.

Overheating can also occur during operation. This may be due to insufficient lubrication or a clogged air filter. Ensure that the bar and chain are adequately lubricated and clean the air filter to allow for proper airflow. Regular maintenance can prevent overheating and ensure smooth operation.

Finally, unusual noises or vibrations may indicate mechanical issues. Inspect the chainsaw for any loose components or damage to the housing. Addressing these concerns promptly can prevent further damage and ensure safe operation.