When it comes to maintaining outdoor machinery, a clear comprehension of its elements is essential for optimal performance and longevity. Identifying how each part fits together can greatly enhance your ability to troubleshoot issues and execute repairs effectively.

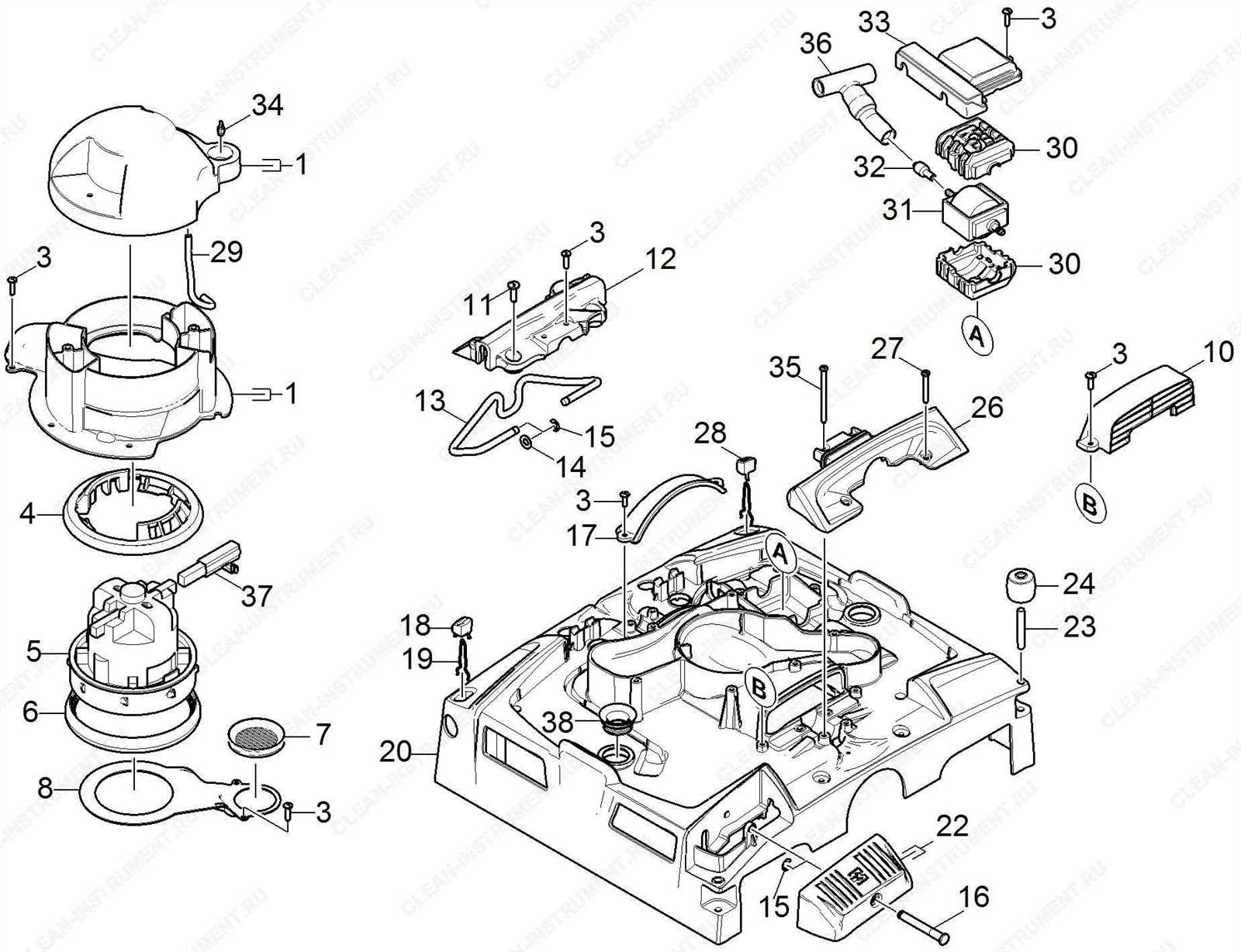

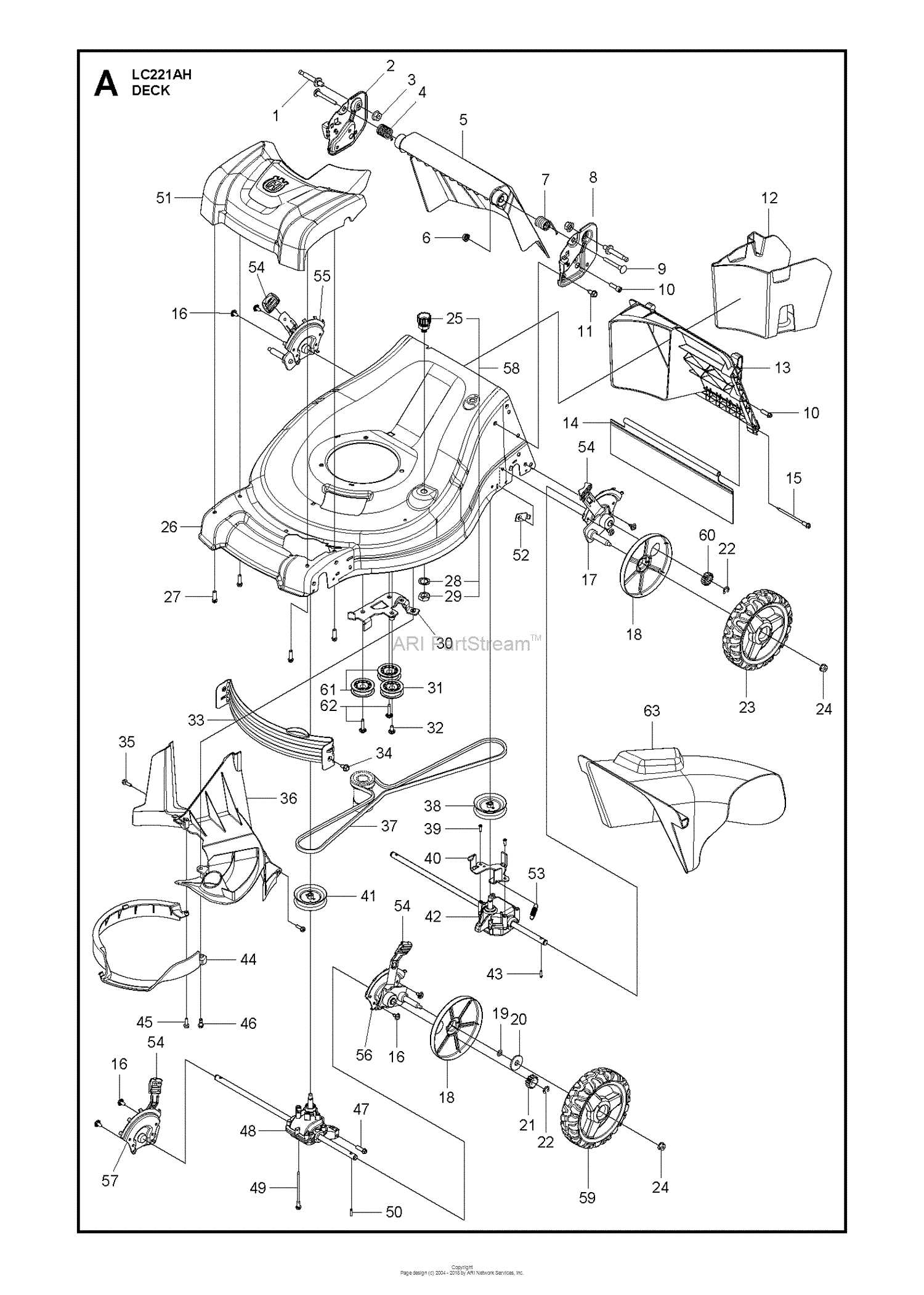

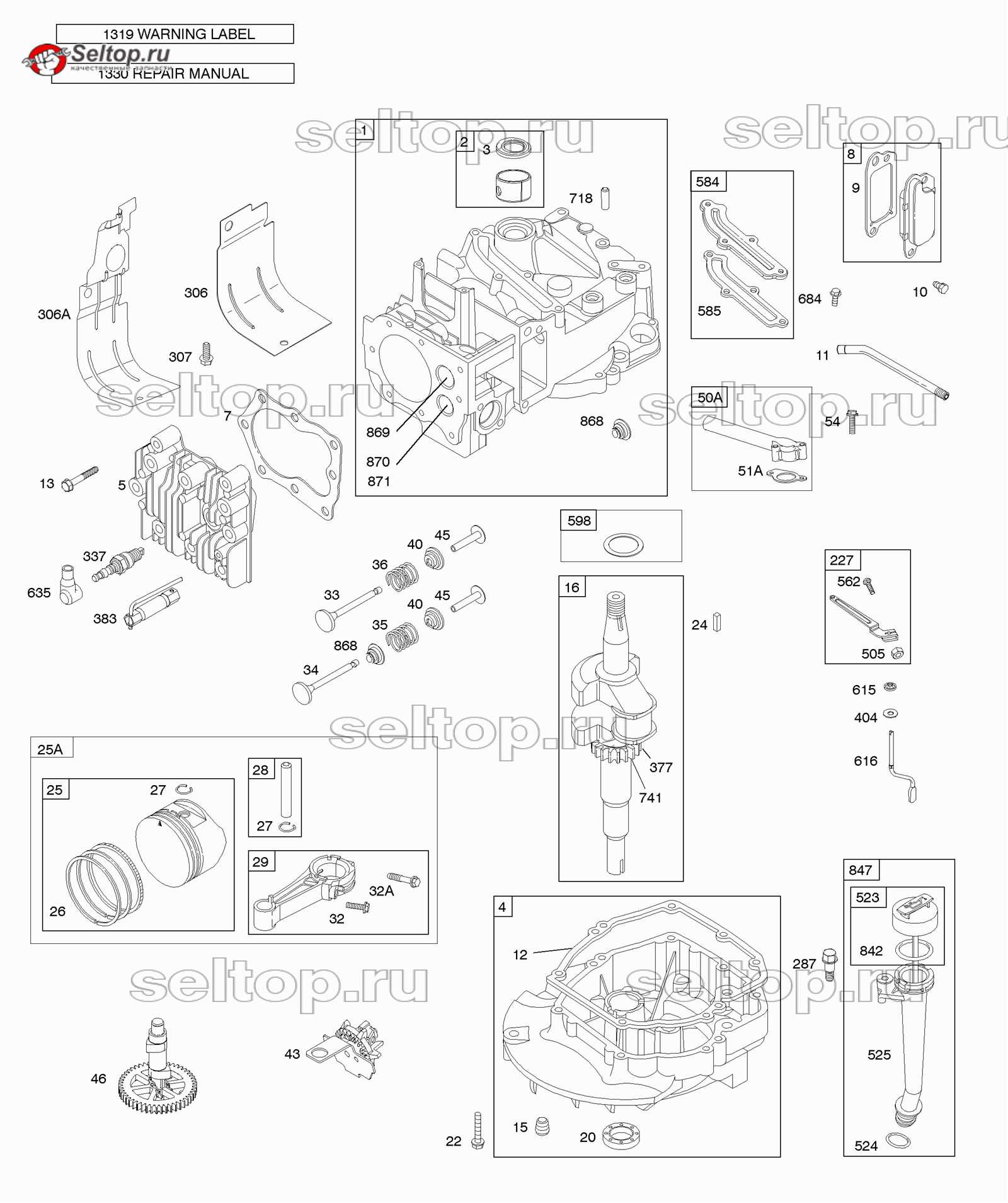

In this section, we will explore a visual representation that outlines the various components of a specific model. By examining this illustration, users can easily reference individual parts, facilitating a deeper understanding of their functions and interconnections.

Grasping the layout of these mechanical features is the ultimate key to successful maintenance. With the right knowledge at hand, you can delve into repairs with confidence, ensuring your equipment runs smoothly for years to come.

Understanding Husqvarna 725ex Parts

Gaining insight into the components of your outdoor power equipment is essential for optimal performance and maintenance. Each element plays a crucial role in the overall functionality, and knowing how they interact can significantly enhance your experience. By familiarizing yourself with these essential pieces, you can ensure that your machine operates smoothly and efficiently.

Key Components Overview

The machinery is composed of various integral parts that contribute to its efficiency. The engine serves as the powerhouse, while the ignition system ignites the fuel for operation. Additionally, the carburetor regulates the air-fuel mixture, ensuring optimal combustion. Understanding these fundamental components can help you troubleshoot issues and perform necessary repairs.

Maintenance and Replacement

Regular upkeep is vital for extending the lifespan of your equipment. Keeping an eye on wear and tear is essential; components such as filters, spark plugs, and belts should be checked and replaced as needed. Utilizing quality replacements enhances performance and reduces the risk of malfunction. By being proactive about maintenance, you can avoid costly repairs and enjoy uninterrupted use.

Overview of Husqvarna 725ex Model

This section provides an insight into a specific model known for its efficiency and reliability in various outdoor tasks. It highlights the key features, performance aspects, and essential components that contribute to its overall functionality.

- Engine Power: Offers robust performance suitable for demanding conditions.

- Design: Engineered for user comfort and ease of use, ensuring a pleasant experience during operation.

- Durability: Built with high-quality materials that withstand wear and tear, ensuring longevity.

Understanding the essential attributes of this model allows users to appreciate its capabilities and maintenance needs, ensuring optimal performance over time.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repairs. Visual representations serve as essential tools, offering clarity and guidance when dealing with various elements. These resources enhance the efficiency of troubleshooting and assembling units, allowing users to quickly identify necessary components and their functions.

Furthermore, such visual aids can significantly reduce the time spent on repairs, minimizing the potential for errors. When technicians or enthusiasts have access to detailed illustrations, they can more easily locate specific items and ensure they are using the correct replacements. This not only streamlines the repair process but also extends the lifespan of the equipment by promoting proper handling.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual aids simplify complex information, making it accessible. |

| Time Efficiency | Reduces the duration of repairs by providing quick reference points. |

| Minimized Errors | Helps in avoiding mistakes during assembly or replacement. |

| Improved Longevity | Encourages correct usage and maintenance, prolonging equipment life. |

In summary, utilizing visual references is indispensable for anyone involved in machinery upkeep. They not only facilitate a deeper understanding of components but also enhance overall operational efficiency.

Common Issues with Husqvarna 725ex

Every piece of equipment can face challenges that affect its performance and longevity. Understanding these potential problems is crucial for maintaining efficiency and ensuring smooth operation. This section highlights the frequent issues encountered with this model, providing insights into symptoms and potential solutions.

Engine Performance Problems

One of the most common challenges is related to engine performance. Users often report difficulty starting or inconsistent operation. Symptoms may include stalling, reduced power, or unusual noises. Fuel quality can significantly impact performance; ensuring the use of fresh, high-grade fuel is essential. Additionally, checking the air filter and spark plug can help identify potential blockages or wear that may hinder functionality.

Mechanical Failures

Mechanical failures can arise from wear and tear or improper maintenance. Belts and cables are particularly susceptible to fraying or snapping, leading to decreased efficiency or total breakdown. Regular inspections and timely replacements can mitigate these issues. Moreover, paying attention to any vibrations or unusual sounds during operation may signal the need for immediate attention to avoid further damage.

Identifying Key Components

Understanding the essential elements of a machine is crucial for effective maintenance and operation. Recognizing each part and its function can enhance performance and prolong longevity. This section will guide you through the primary components that are vital to the unit’s functionality.

Engine Assembly

The engine assembly serves as the heart of the machinery, providing the necessary power for operation. It consists of several parts, including the cylinder, piston, and spark plug, each playing a significant role in generating energy.

Drive System

The drive system is responsible for transferring power from the engine to the wheels. Key components here include the transmission, belts, and gears. Understanding how these parts interact will help in troubleshooting and ensuring optimal performance.

Where to Find Parts Diagrams

Finding detailed visual representations of components is essential for effective maintenance and repair of machinery. These resources provide clear guidance on assembly and disassembly, helping users identify the necessary elements for their projects.

Online Resources

- Manufacturer’s Official Website

- Authorized Dealers and Service Centers

- Online Retailers Specializing in Equipment

- Dedicated Forums and Community Websites

Physical Locations

- Local Repair Shops

- Parts Distributors

- Trade Shows and Expos

Interpreting the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repairs. This illustration serves as a valuable reference, showcasing the various elements and their relationships within the assembly. By familiarizing oneself with this guide, users can identify each part’s function and locate any specific item needed for service.

First and foremost, it is important to recognize how each section is labeled. Typically, the diagram includes numbers or letters corresponding to a list, which details the specific components. This system allows for quick identification and enhances the efficiency of the repair process.

Additionally, pay attention to the arrangement of parts. The layout often reflects the actual assembly order, aiding in both disassembly and reassembly. Understanding how components fit together can prevent mistakes and ensure a smoother workflow.

Lastly, it is beneficial to consult supplementary resources or manuals that provide further context or troubleshooting tips related to the depicted elements. By combining visual aids with detailed descriptions, users can gain a comprehensive understanding of the machinery they are working with.

Replacement Parts for Husqvarna 725ex

When it comes to maintaining outdoor power equipment, ensuring that all components are functioning optimally is crucial. Over time, certain elements may wear out or require replacement to keep the machinery operating smoothly. Identifying the right substitutes can enhance performance and extend the lifespan of your equipment.

Common Components for Replacement

Regular maintenance often necessitates the replacement of specific elements. Below is a list of frequently needed substitutes along with their descriptions:

| Component | Description |

|---|---|

| Air Filter | Essential for keeping the engine clean, preventing debris from entering. |

| Spark Plug | Critical for ignition; should be checked and replaced regularly. |

| Fuel Filter | Helps maintain fuel quality by filtering impurities before they reach the engine. |

| Blade | Key for cutting efficiency; should be sharpened or replaced when dull. |

Where to Find Quality Substitutes

Quality replacements can be sourced from authorized dealers or reputable online retailers. It’s essential to verify compatibility with your specific model to ensure optimal performance. Additionally, consulting the user manual can provide guidance on selecting the correct components for your needs.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also prevents costly repairs. Here are some essential practices to keep in mind:

- Regular Cleaning: Keep the exterior and interior clean from debris and dirt. Use a soft brush or cloth to wipe surfaces.

- Check Fluid Levels: Regularly inspect and replenish necessary fluids, including oil and fuel, to maintain optimal operation.

- Inspect Filters: Clean or replace air and fuel filters periodically to ensure proper airflow and efficiency.

- Sharpen Blades: Maintain sharp blades for effective cutting. Dull blades can strain the engine and lead to uneven results.

- Store Properly: After use, store equipment in a dry and sheltered place to protect it from weather elements.

By implementing these maintenance strategies, you can significantly enhance the durability of your equipment and ensure it operates efficiently for years to come.

Tools Needed for Repairs

Performing maintenance and repairs on your equipment requires a specific set of tools to ensure efficiency and accuracy. Having the right instruments not only simplifies the process but also enhances safety and extends the lifespan of your machinery.

Essential Hand Tools

Basic hand tools are indispensable for any repair task. These tools allow for detailed work and adjustments, making them crucial for both minor fixes and major overhauls.

| Tool | Description |

|---|---|

| Wrenches | Used for loosening and tightening bolts and nuts. |

| Screwdrivers | Essential for driving screws into various components. |

| Pliers | Useful for gripping, twisting, and cutting wires or other materials. |

| Socket Set | Provides a range of sizes for more efficient fastening. |

Power Tools for Efficiency

In addition to hand tools, power tools can greatly expedite the repair process. These devices are designed to handle more substantial tasks with ease, making them valuable in a repair setting.

| Tool | Description |

|---|---|

| Drill | Ideal for creating holes or driving screws with speed and precision. |

| Impact Wrench | Provides high torque output, making it easier to loosen or tighten large fasteners. |

| Angle Grinder | Useful for cutting and grinding metal parts during repairs. |

| Reciprocating Saw | Great for making quick cuts in various materials. |

Frequently Asked Questions

This section addresses common inquiries related to maintenance and components of outdoor equipment. Here, you will find answers to typical concerns that users may have, ensuring you have the information needed for efficient upkeep.

What are the signs that my equipment needs maintenance?

Indicators such as unusual noises, decreased performance, or difficulty starting often suggest that your device requires attention. Regular inspection can help identify issues early.

How can I find suitable replacements for worn-out components?

Consulting your user manual or trusted retailers will provide you with information on compatible replacements. Online resources can also offer diagrams and part numbers to simplify your search.

Is it possible to perform repairs myself?

Many users successfully conduct their own repairs, especially for minor issues. However, for complex problems, seeking professional assistance may be advisable to avoid further complications.

How often should I perform maintenance checks?

Routine checks are recommended before each use, with more comprehensive evaluations every season. This ensures optimal performance and longevity of your device.

Cost of Replacement Parts

When maintaining outdoor equipment, understanding the expenses associated with acquiring new components is essential. These costs can vary widely based on the specific part, brand, and where it is purchased. It’s important for users to consider both the quality and the longevity of the components when making purchasing decisions.

Typically, prices can range from a few dollars for smaller items like filters and spark plugs to significant amounts for larger assemblies or specialized elements. Additionally, many retailers offer warranties or guarantees that can add value to the investment. Exploring different suppliers can help in finding competitive pricing and ensuring that the right components are obtained for optimal performance.

Furthermore, budgeting for these replacements should include not only the parts themselves but also any tools or services required for installation. By planning ahead, owners can ensure their equipment remains in top condition without incurring unexpected expenses.

Warranty Information and Support

Understanding the coverage and support options available for your equipment is crucial for maintaining its performance and longevity. This section provides essential details regarding the guarantees offered, along with the avenues for assistance should any issues arise during usage.

Warranty Coverage

The warranty for your machinery includes protection against defects in materials and workmanship for a specified period. This assurance allows users to operate with confidence, knowing that repairs or replacements will be managed under the warranty terms. It is advisable to keep your purchase receipt, as it may be required for warranty validation.

Customer Support Services

If you encounter any problems or have questions about your equipment, dedicated customer service representatives are available to assist you. You can reach out via phone or email for troubleshooting advice, service options, or to learn more about the warranty conditions. Timely support can help ensure your machinery remains in optimal condition.