The intricate world of machinery often relies on a clear visualization of its elements for optimal functionality. Grasping the arrangement of various components is essential for both maintenance and repairs, ensuring that every part serves its intended purpose. A well-structured overview can greatly enhance one’s ability to troubleshoot and replace essential items.

When it comes to complex devices, having a detailed representation of their makeup allows users to navigate through potential issues with confidence. This understanding not only streamlines the repair process but also fosters a deeper appreciation for the engineering behind these machines. By dissecting the structure of key components, one can quickly identify necessary actions to keep the equipment running smoothly.

In this exploration, we will delve into the significance of visual guides that depict the arrangement and interaction of various elements within machinery. These illustrations serve as invaluable tools for both novices and seasoned professionals, bridging the gap between theoretical knowledge and practical application. Whether you’re performing routine checks or addressing specific concerns, a clear representation can be a game-changer.

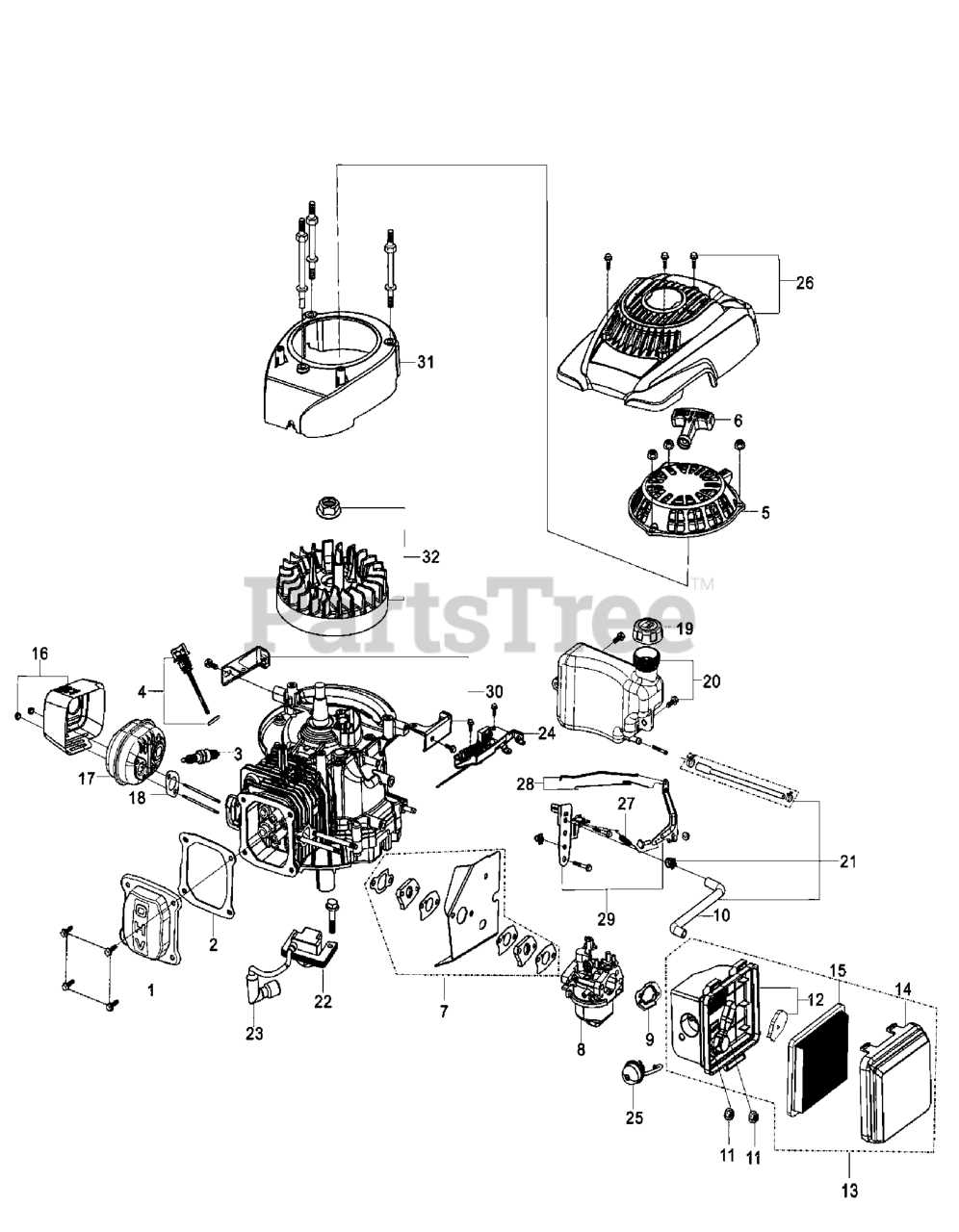

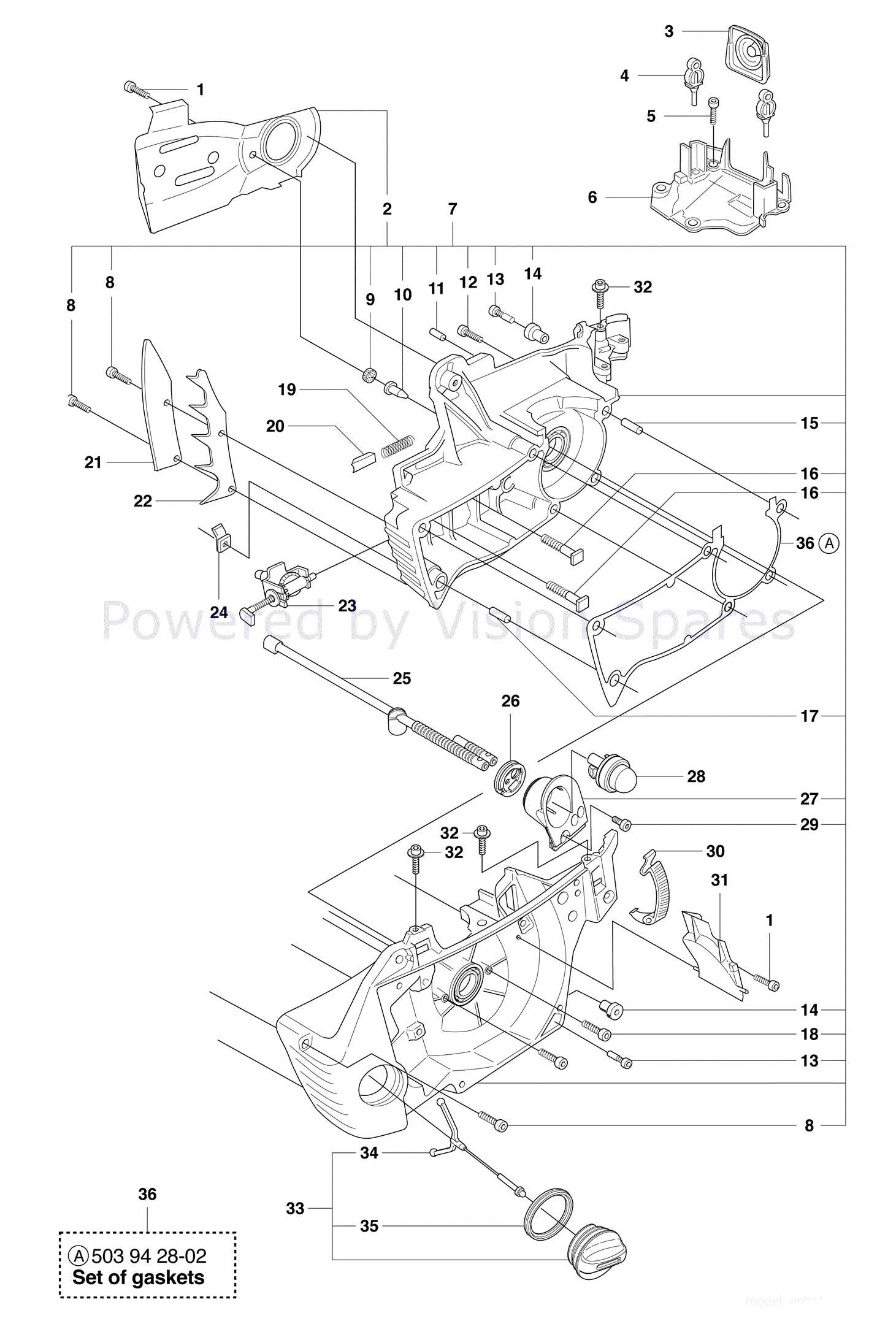

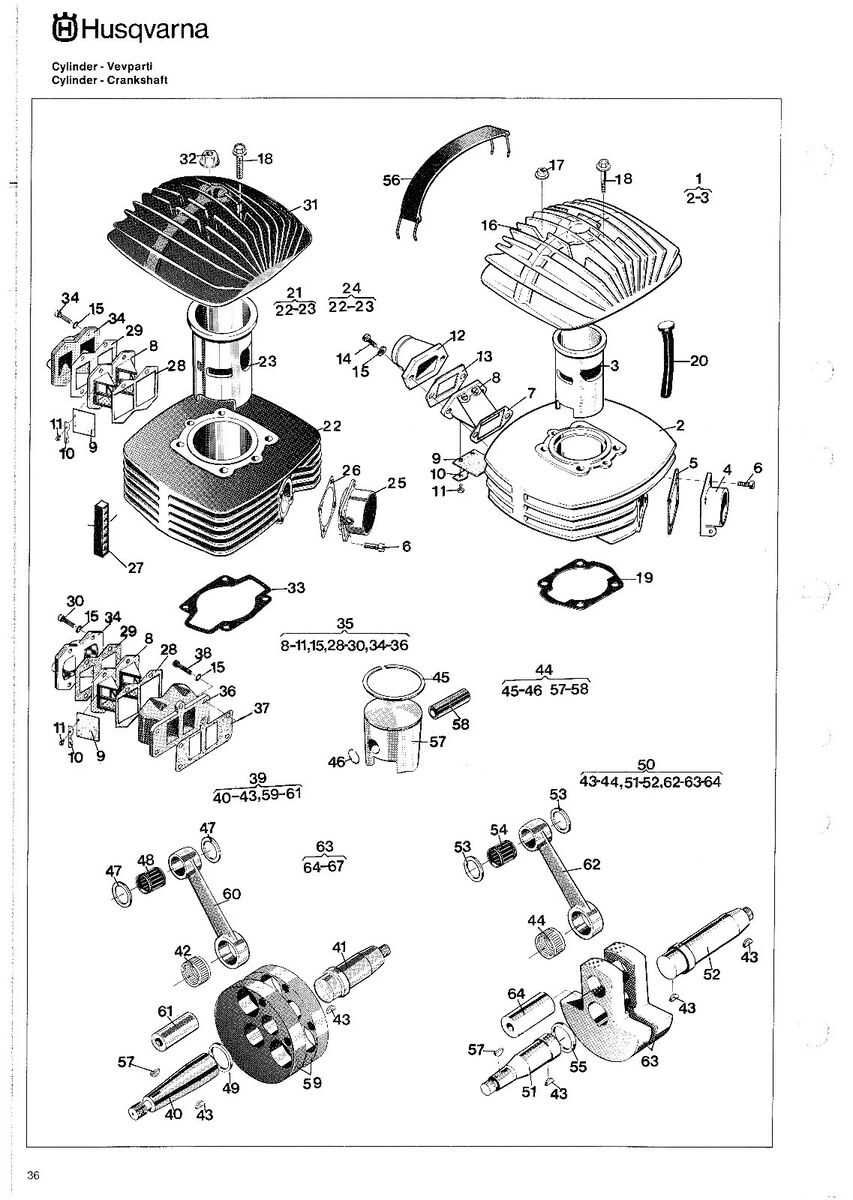

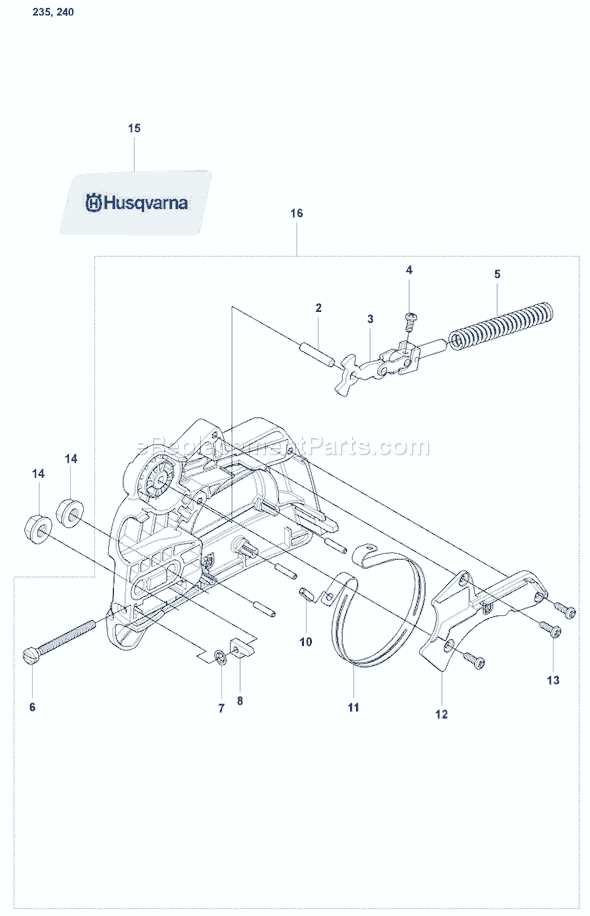

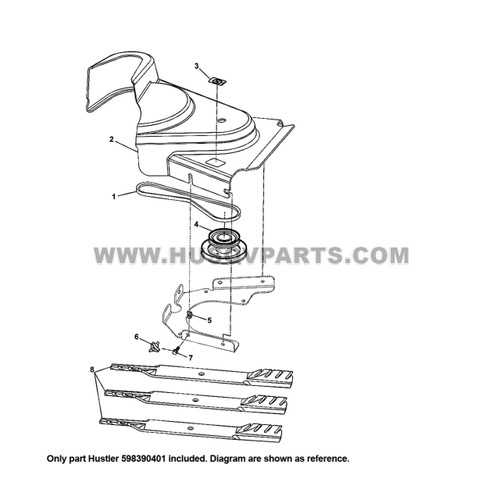

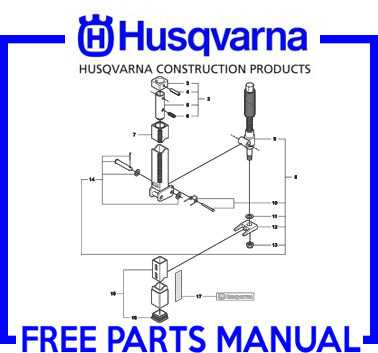

Understanding Husqvarna Parts Diagrams

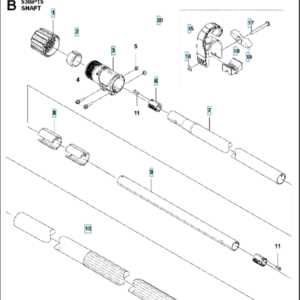

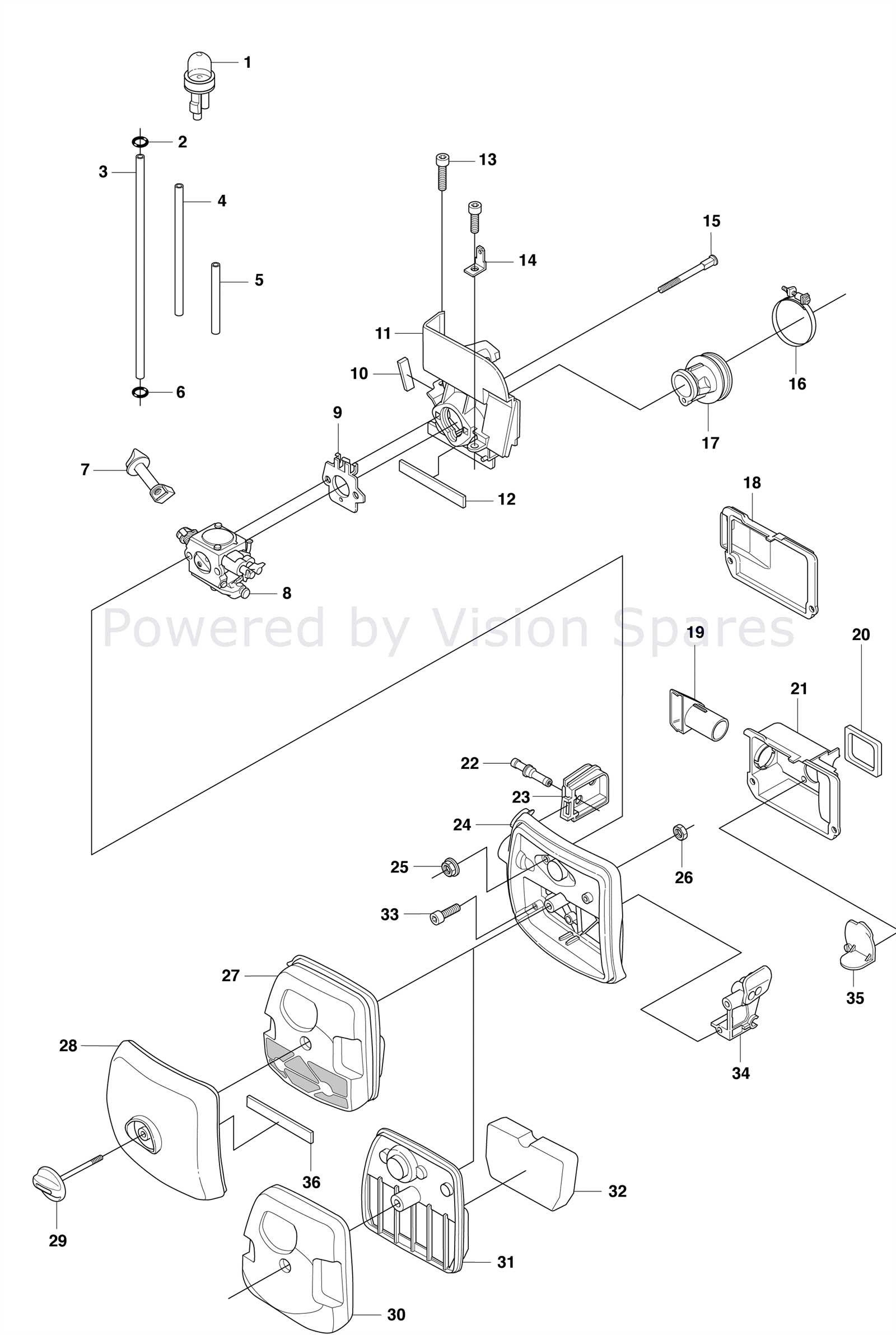

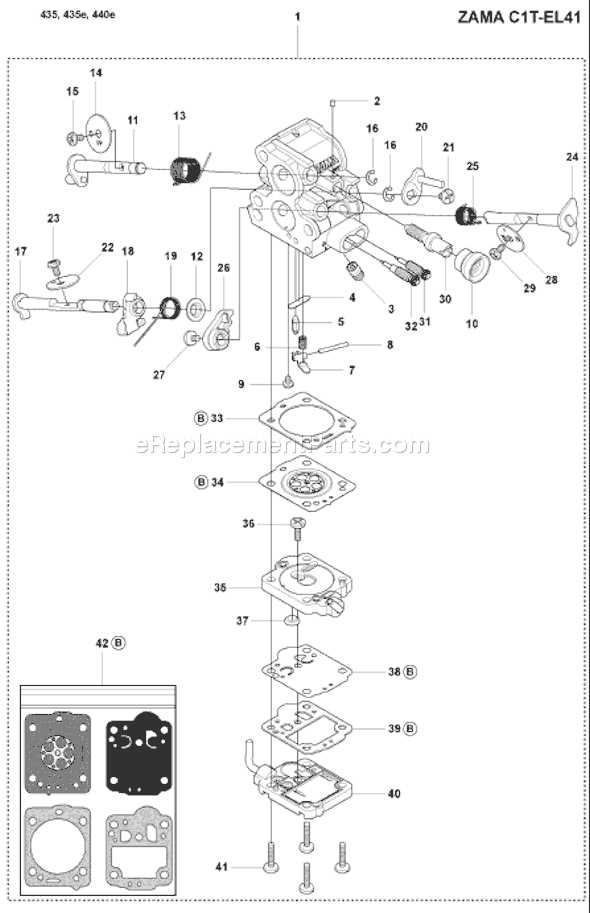

Exploring the intricacies of machinery components can significantly enhance maintenance and repair efficiency. A visual representation of these elements serves as a crucial tool for anyone looking to comprehend the assembly and functionality of their equipment. By examining these illustrations, users can pinpoint specific pieces and understand their roles within the overall system.

Importance of Visual References

Utilizing visual aids can streamline the identification process during repairs. When one encounters a malfunction, these representations allow for quicker troubleshooting and ensure that the correct replacements are sourced. Ultimately, this minimizes downtime and extends the lifespan of the machinery.

How to Interpret the Illustrations

To effectively analyze these visual references, one must familiarize themselves with common symbols and labeling conventions. Delving into the details can reveal connections between components and highlight essential maintenance tips. Understanding these visuals empowers users to engage in informed decision-making regarding repairs and upgrades.

Benefits of Using Parts Diagrams

Utilizing visual representations of components offers numerous advantages for maintenance and repair tasks. These illustrations serve as essential tools for understanding the intricate relationships between different elements within machinery or equipment. By providing clarity, they streamline the process of identifying and ordering necessary components, thus enhancing overall efficiency.

Enhanced Clarity: Visual aids simplify complex structures, making it easier to comprehend how various elements fit together. This clarity reduces confusion, particularly for individuals unfamiliar with the machinery.

Improved Efficiency: By offering a quick reference for locating specific components, these visuals minimize the time spent searching for information. This leads to faster repairs and less downtime.

Accurate Ordering: When replacements are needed, having a detailed representation ensures that the correct parts are identified and ordered, reducing the risk of errors and unnecessary expenditures.

Educational Value: For those new to machinery maintenance, these visual tools can serve as a valuable educational resource. They promote a better understanding of how different parts interact and function, fostering greater competence in handling repairs.

In summary, employing visual representations of components not only enhances clarity and efficiency but also contributes to more informed decision-making during maintenance and repair activities.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These visual aids provide a clear overview of various elements and their relationships, making it easier to identify and source replacements when necessary.

Begin by familiarizing yourself with the layout. Each section typically includes labels or numbers corresponding to specific items. Take note of the key or legend, which explains these references in detail. This will help you navigate the illustration more effectively.

Next, observe the grouping of similar elements. Components may be clustered together based on function or location, allowing for quicker identification of related parts. Pay attention to the orientation, as it can influence how items fit together during assembly.

Finally, use this resource as a guide when looking for replacements. Cross-reference the labels with product listings or catalogs to ensure you find the exact components needed for your repairs. By mastering this tool, you enhance your ability to maintain and optimize your equipment efficiently.

Common Parts in Husqvarna Models

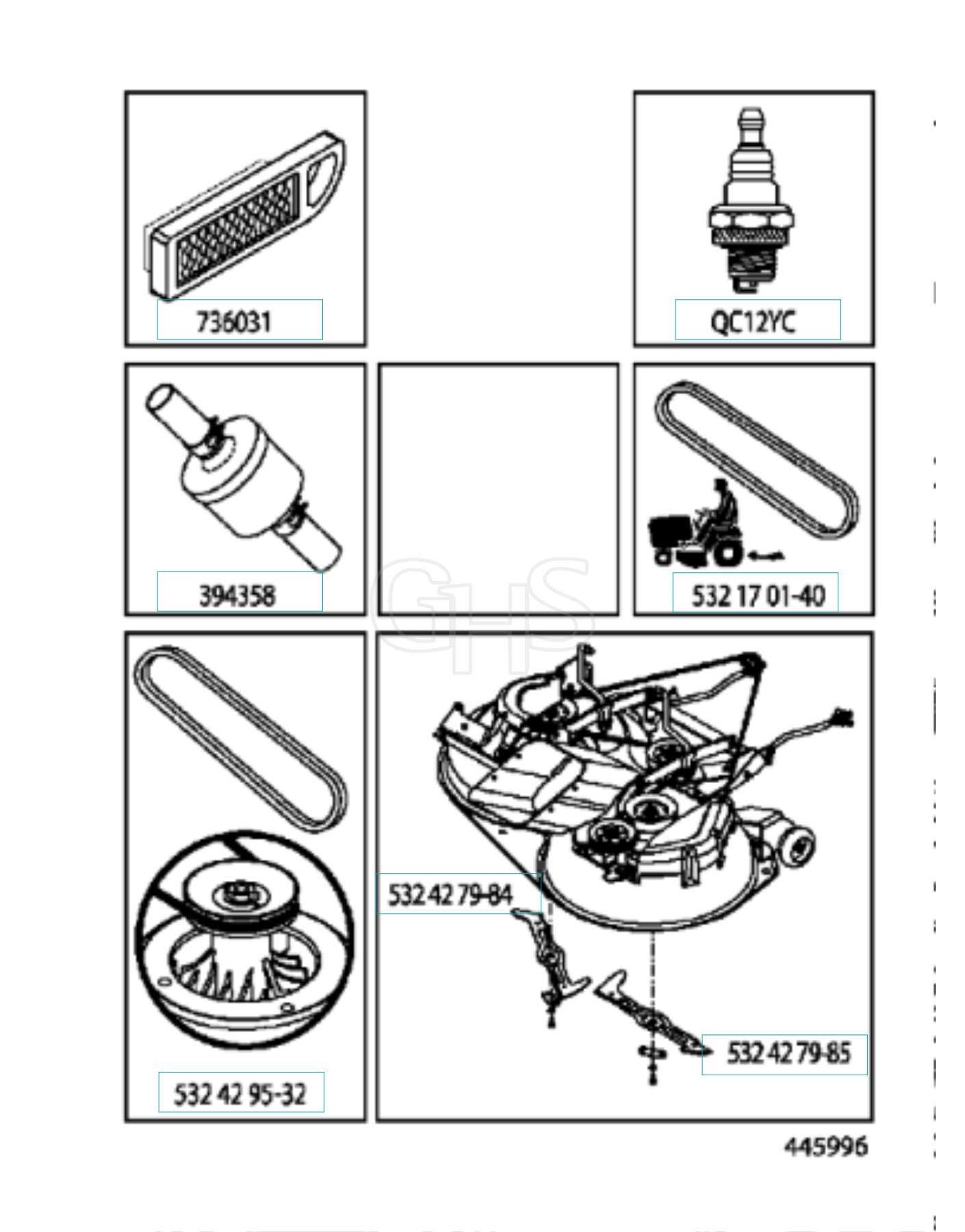

Understanding the essential components of various models can greatly enhance maintenance and repair efforts. Familiarity with these elements allows users to ensure optimal performance and longevity of their equipment.

Engine Components

Key elements like the spark plug, air filter, and fuel lines play a crucial role in engine functionality. Regular checks and replacements can prevent common issues and enhance efficiency.

Chassis and Accessories

Parts such as the frame, wheels, and handlebars contribute to the overall stability and handling. Upgrading or replacing these can improve user experience and safety significantly.

Identifying Replacement Components Easily

When it comes to maintaining equipment, recognizing the correct elements for replacement is crucial for ensuring optimal performance. Understanding how to locate and identify these components can significantly streamline the repair process, saving both time and effort. With the right approach, anyone can navigate the complexities of machinery upkeep with confidence.

Tips for Efficient Identification

To facilitate the identification of replacement items, consider the following strategies:

| Strategy | Description |

|---|---|

| Consult Manuals | User manuals often contain detailed information on components, including their specifications and part numbers. |

| Online Resources | Numerous websites provide extensive databases where you can search for specific parts based on models or descriptions. |

| Visual Comparison | Taking a close look at existing components can help you match shapes, sizes, and features, aiding in accurate identification. |

| Expert Consultation | Reaching out to professionals or forums can provide insights and advice from experienced users who have faced similar issues. |

Understanding Component Functions

Gaining a basic understanding of how each component functions within the machinery can also aid in identifying which parts need replacement. This knowledge allows for better decision-making regarding what to replace and when, ensuring the longevity of your equipment.

Tips for Finding Specific Parts

Locating particular components for your equipment can often be a challenging task. Understanding the best strategies and resources available can simplify the process, saving both time and frustration. This guide will provide you with essential tips to efficiently search for the specific items you need.

Utilize Online Resources

The internet is an invaluable tool when searching for specific components. Start by visiting manufacturer websites, as they often provide comprehensive listings and detailed information about their products. Additionally, third-party retailers can have extensive inventories, often with user-friendly search options. Forums and online communities related to your equipment can also be a treasure trove of information, as experienced users frequently share insights and recommendations.

Check Local Dealers and Repair Shops

While online searches are useful, don’t overlook the potential of local dealers and repair shops. Establishing a relationship with these professionals can offer benefits such as personalized service and expert advice. They may have access to exclusive items not readily available online. Inquire about any upcoming sales or stock changes, as well as any options for ordering specific items directly from the manufacturer.

Importance of Accurate Diagrams

Precision in technical illustrations is crucial for effective maintenance and repair tasks. Well-crafted visuals serve as essential references that enhance understanding and efficiency, ensuring that users can correctly identify components and their functions. Accurate representations significantly reduce the risk of errors during assembly or disassembly, ultimately leading to successful outcomes in repairs and servicing.

Key benefits of reliable illustrations include:

- Clarity: Clear visuals help users comprehend complex systems, making it easier to locate specific elements.

- Time-saving: Accurate references allow for quicker identification of components, speeding up the overall process.

- Reduced Mistakes: Detailed illustrations minimize the likelihood of errors, ensuring that each part is handled correctly.

- Improved Learning: New users can better understand assembly procedures, enhancing their skills and confidence.

Overall, the value of precise technical illustrations cannot be overstated. They are integral to ensuring effective operations and maintenance, providing users with the necessary tools to work efficiently and correctly.

Resources for Diagram Access

Accessing detailed illustrations of machinery components is essential for effective maintenance and repair. Various platforms and resources are available to help users find these valuable visual aids, making the process of identifying and sourcing parts much more manageable. Utilizing these resources can streamline repairs and enhance understanding of the equipment.

One of the primary sources is the official manufacturer’s website, which often provides comprehensive catalogs and user manuals. These documents typically include exploded views that clarify the arrangement and function of each component. Additionally, many manufacturers offer online support through forums and customer service, allowing users to ask questions and share insights.

Third-party websites and online retailers also serve as valuable repositories for visual references. Some specialize in aftermarket components and often include detailed illustrations alongside product listings. Community-driven platforms may host user-generated content, including diagrams and repair guides, which can be particularly useful for uncommon models.

Furthermore, video tutorials on platforms like YouTube can provide a dynamic way to visualize the assembly and disassembly processes. These resources often complement written instructions, offering real-world demonstrations that enhance learning and retention.

Lastly, local libraries and bookstores may carry reference manuals and guides that include visual aids for various models. Exploring these options can yield additional insights and resources to aid in effective troubleshooting and repairs.

Maintaining Your Husqvarna Equipment

Regular upkeep of your machinery is essential for optimal performance and longevity. By following a few straightforward practices, you can ensure that your tools operate efficiently and serve you well for many seasons. Attention to detail in maintenance not only enhances functionality but also prevents costly repairs down the line.

Routine Inspections

Performing frequent checks on your equipment can help identify potential issues before they escalate. Look for signs of wear, loose components, or unusual noises during operation. Keeping an eye on these details allows for timely interventions, preserving both the machine and your investment.

Cleaning and Storage

Proper cleaning after each use is crucial. Remove debris and residue to prevent damage and ensure smooth operation. Additionally, when storing your equipment, keep it in a dry, sheltered place to protect it from the elements. Utilizing appropriate covers can also prolong its lifespan by shielding it from dust and moisture.

Adhering to these maintenance tips will contribute to the reliability and efficiency of your tools, allowing you to focus on the tasks at hand rather than unexpected breakdowns.

Comparing Diagrams Across Models

When exploring the intricate designs of various machinery, it’s essential to recognize the similarities and differences between their layouts. Analyzing these schematics allows users to gain a deeper understanding of functionality and compatibility, ensuring informed decisions during maintenance or upgrades.

Identifying Common Components

By examining the illustrations, one can identify recurring elements across different designs. This highlights not only shared features but also variations that may affect performance. Understanding these connections can lead to enhanced operational efficiency.

Evaluating Compatibility

Assessing the relationships between different configurations is crucial for users considering part interchangeability. Recognizing how components fit within various assemblies can streamline repairs and improve overall reliability, ultimately benefiting long-term usability.

Repair Techniques Using Diagrams

Understanding the intricate details of machinery can greatly enhance the repair process. Visual representations serve as essential tools for identifying components and procedures. Utilizing these illustrations simplifies the steps needed for effective maintenance and restoration.

- Step-by-Step Guidance: Visual aids break down complex tasks into manageable parts.

- Identification of Components: Diagrams help in recognizing specific elements and their functions.

- Enhanced Accuracy: Clear visuals minimize the risk of errors during repairs.

By incorporating these visual tools, technicians can achieve a more efficient and precise approach to fixing machinery.