When it comes to maintaining and repairing a lawn tractor model, comprehending the intricate layout of its various elements is essential. This knowledge not only aids in efficient troubleshooting but also ensures that the machine operates smoothly for years to come. By familiarizing oneself with the assembly and individual parts, users can confidently engage in maintenance tasks or replacements.

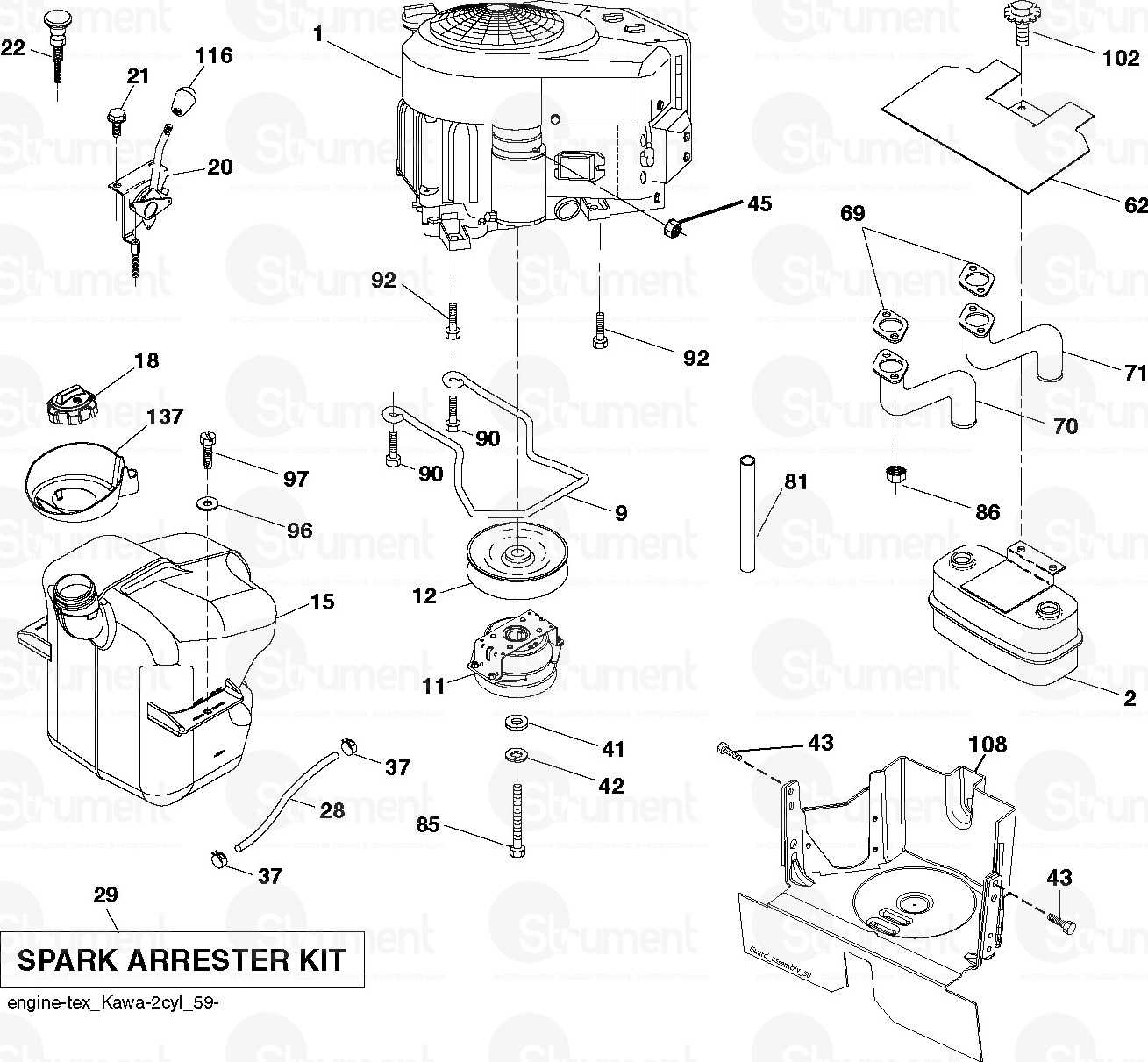

Each element plays a crucial role in the functionality of the equipment, contributing to its overall performance. From the engine to the cutting system, understanding how these components interact can help owners optimize their equipment’s efficiency. A visual representation of the assembly can be an invaluable resource, providing a clearer insight into the tractor’s structure.

In this section, we will explore the various features of this particular model, detailing how each part fits into the broader operational framework. This examination aims to equip users with the knowledge needed to navigate their maintenance journeys effectively, enhancing their overall experience with the equipment.

Understanding Husqvarna YTH2246 Components

This section delves into the various elements that contribute to the functionality and performance of a well-known lawn care machine. Familiarity with these components enhances the user experience and ensures effective maintenance and operation.

Key Elements of the Machine

Each part plays a critical role in the overall efficiency of the equipment. Recognizing the significance of these elements can aid in troubleshooting and replacement when necessary. Here are some of the essential components:

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the entire machine, providing the necessary force for operation. |

| Transmission | Responsible for transferring power from the engine to the wheels, enabling movement. |

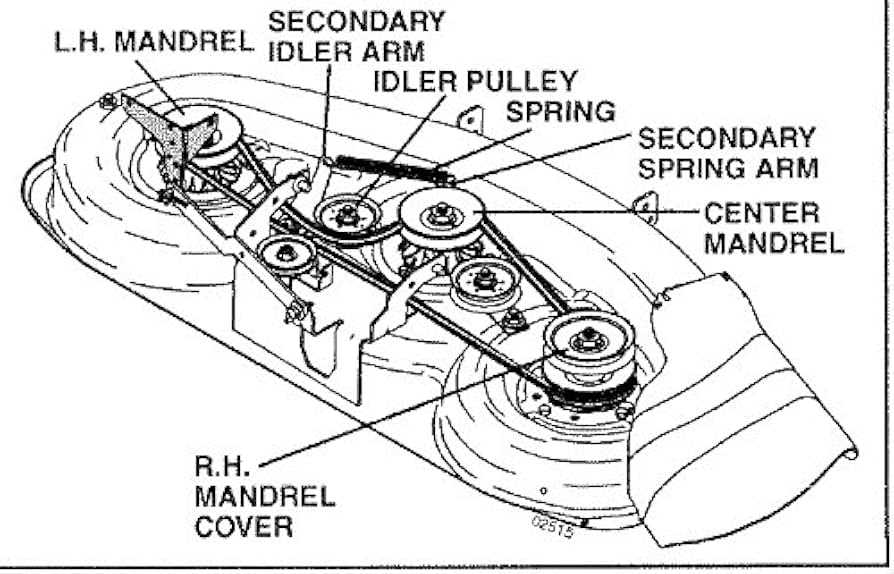

| Deck | The cutting platform where grass is trimmed, designed for optimal cutting performance. |

| Wheels | Facilitate mobility, ensuring smooth navigation across various terrains. |

Importance of Regular Maintenance

Maintaining these components is vital for longevity and performance. Regular checks and timely replacements can prevent unforeseen issues and enhance the overall lifespan of the equipment.

Overview of Husqvarna YTH2246 Parts

This section provides a comprehensive look at the essential components of a specific lawn care machine. Understanding the various elements involved is crucial for maintenance and repairs, ensuring optimal performance throughout its lifespan. Each part plays a significant role in the overall functionality, contributing to a seamless mowing experience.

Key Components

Among the critical elements are the engine, transmission, and cutting system. The engine is responsible for powering the machine, while the transmission ensures smooth movement across various terrains. The cutting system, featuring blades and related accessories, facilitates efficient grass trimming, enhancing the aesthetic appeal of lawns.

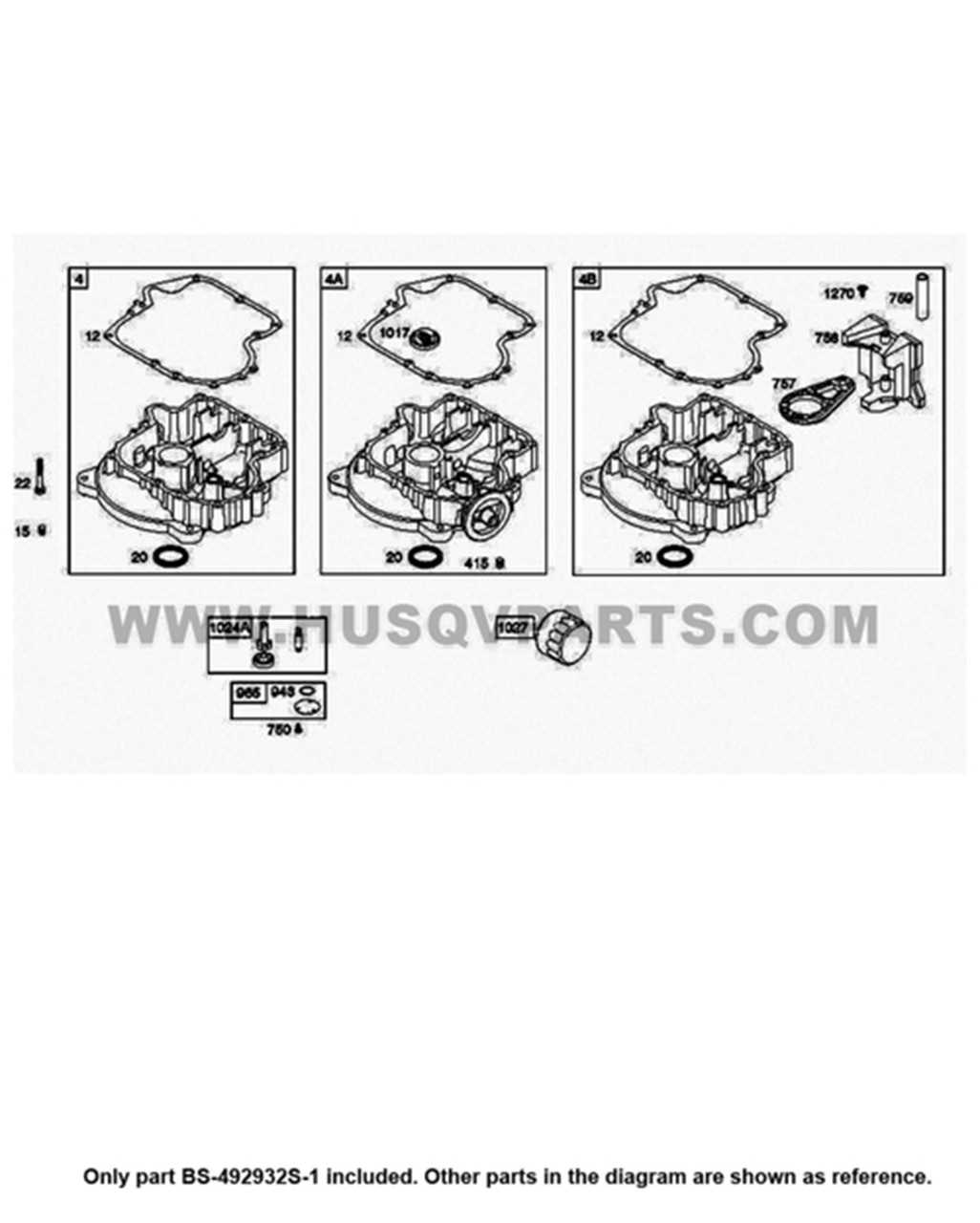

Maintenance and Replacement

Regular upkeep of these components is essential for longevity. Identifying wear and tear early can prevent more significant issues down the line. Proper maintenance includes checking fluid levels, inspecting belts, and replacing dull blades. Adhering to recommended service schedules can ensure the machine remains in peak condition.

Importance of a Parts Diagram

Understanding the structure of machinery is essential for effective maintenance and repair. Visual representations of components can significantly enhance a user’s ability to identify, access, and replace specific elements. These illustrations serve as a crucial tool for both novices and seasoned technicians, streamlining the process of troubleshooting and repair.

Enhanced Understanding

Visual aids facilitate a deeper comprehension of how various components interact within a machine. By referring to these guides, users can:

- Identify individual elements and their functions.

- Gain insights into the overall assembly of the equipment.

- Recognize potential areas of wear and damage.

Efficient Maintenance and Repair

Utilizing visual representations can lead to more efficient repair processes. Benefits include:

- Quicker identification of needed replacements.

- Reduction in the risk of errors during reassembly.

- Improved ability to source compatible components.

In conclusion, visual guides are invaluable resources that contribute to the longevity and performance of machinery, ensuring that users can effectively manage maintenance and repairs with confidence.

Common Issues with YTH2246 Models

The riding mower is a popular choice among homeowners due to its efficiency and ease of use. However, like any machine, it can encounter various problems that may affect its performance and longevity. Understanding these common issues can help owners troubleshoot and maintain their equipment more effectively.

One frequent challenge is the mower not starting, which may stem from battery issues, fuel problems, or ignition system failures. Ensuring that the battery is charged and the fuel is fresh can often resolve these issues.

Another common concern involves the cutting performance. Uneven cutting can result from dull blades, incorrect mower height settings, or deck obstructions. Regular blade maintenance and proper adjustment of the cutting height can enhance the mowing experience.

Additionally, owners may face issues with the drive system. Problems such as slipping or a lack of power can arise from worn belts or insufficient lubrication. Regular inspections and timely replacements are essential to keep the mower running smoothly.

Finally, keeping an eye on the electrical system is crucial, as loose connections or faulty wiring can lead to various operational problems. A thorough check of the electrical components can help prevent unexpected failures.

How to Read the Diagram Effectively

Understanding technical illustrations can significantly enhance your maintenance and repair skills. By grasping the essential components and their relationships, you can ensure that your equipment operates smoothly and efficiently.

Start by familiarizing yourself with the layout of the illustration. Identify the various sections, as these often group related elements together, making it easier to locate specific items. Take note of any labels or codes that indicate part numbers or functions. This will help streamline the search for replacements or upgrades.

Next, pay attention to the connection points and how components interact with one another. Understanding how parts fit together can clarify the assembly process and assist in troubleshooting any issues that arise. Finally, refer to the accompanying documentation for further context, which can provide valuable insights into the operation and maintenance of your machine.

Identifying Key Components in Diagrams

Understanding the various elements within technical illustrations is essential for effective maintenance and repair. These visuals serve as guides, showcasing crucial parts and their relationships, facilitating easier troubleshooting and assembly processes.

Recognizing essential features within these visuals is vital for both novices and experienced users. Each component is typically labeled or marked, allowing for quick identification. Familiarity with these notations can significantly enhance one’s ability to navigate the complex structure of machinery.

Utilizing visual aids can also aid in clarifying the role of each part. By breaking down the assembly into manageable segments, users can develop a better understanding of how each element contributes to overall functionality. This approach not only simplifies repairs but also promotes efficient upkeep of equipment.

Replacing Worn Out Parts

Maintaining the efficiency of your outdoor equipment is crucial for its longevity and performance. Over time, components can wear down, affecting the overall functionality. Regularly checking and replacing these worn elements can ensure that your machine operates smoothly and effectively.

Signs of Wear and Tear

Identifying when to replace components is essential for preventing further damage. Here are some common indicators that parts may need replacement:

- Increased vibration during operation

- Unusual noises, such as grinding or squeaking

- Decreased performance or power output

- Visible signs of wear, such as cracks or corrosion

Steps for Replacement

When it’s time to replace components, following a systematic approach can simplify the process:

- Gather necessary tools and replacement components.

- Refer to the equipment manual for specific instructions.

- Disconnect the power source to ensure safety.

- Remove the old component carefully, taking note of how it is positioned.

- Install the new part, ensuring it is secure and properly aligned.

- Reconnect the power source and test the equipment.

Where to Find Quality Replacement Parts

When it comes to maintaining outdoor equipment, sourcing high-quality components is crucial for ensuring optimal performance and longevity. Finding reliable suppliers and understanding the options available can make a significant difference in the upkeep of your machinery.

Online Retailers and Marketplaces

One of the most convenient ways to discover high-quality components is through online retailers and marketplaces. Many platforms specialize in offering a wide range of parts for various equipment brands, providing detailed descriptions and user reviews to help you make informed decisions.

Local Dealerships and Repair Shops

Local dealerships and repair shops often have access to authentic components and can provide personalized service. Visiting these establishments allows you to ask questions and receive recommendations tailored to your specific needs.

| Source | Advantages | Considerations |

|---|---|---|

| Online Retailers | Wide selection, convenience, competitive pricing | Shipping times, potential for quality variability |

| Local Dealerships | Expert advice, authentic components, immediate availability | Higher prices, limited selection |

Maintenance Tips for YTH2246 Owners

Proper upkeep is essential for ensuring the longevity and efficiency of your lawn care equipment. Regular maintenance helps prevent unexpected breakdowns and promotes optimal performance. Here are some effective strategies for owners looking to keep their machines in top condition.

-

Regular Inspections:

Frequently check for any signs of wear or damage. Look over belts, blades, and other components to ensure everything is functioning correctly.

-

Clean the Undercarriage:

After each use, remove grass clippings and debris from the underside of the machine. This prevents build-up that can lead to rust and other issues.

-

Change the Oil:

Monitor the oil levels and replace it according to the manufacturer’s recommendations. Fresh oil reduces friction and promotes smoother operation.

-

Sharpen Blades:

Keep the cutting blades sharp for a cleaner cut and healthier grass. Dull blades can damage the grass and increase wear on the engine.

-

Check Tire Pressure:

Ensure that the tires are inflated to the correct pressure. Proper tire maintenance helps improve traction and overall handling.

-

Store Properly:

When not in use, store the equipment in a dry, sheltered area. Protecting it from the elements prolongs its lifespan and maintains performance.

By following these maintenance tips, owners can enhance the reliability and efficiency of their lawn care equipment, ensuring a beautiful yard for years to come.

Benefits of Using Original Parts

Utilizing authentic components in machinery ensures optimal performance and longevity. These specially designed elements offer enhanced reliability and compatibility, which are essential for maintaining the overall functionality of the equipment. Relying on original items can lead to significant advantages in terms of efficiency and durability.

Quality Assurance is one of the most notable benefits. Authentic items are manufactured to precise specifications, ensuring they meet the highest standards. This level of quality minimizes the risk of malfunctions and breakdowns, providing peace of mind to the user.

Another advantage is Improved Performance. Genuine components work seamlessly with existing machinery, enhancing operational efficiency. This integration not only optimizes the machine’s capabilities but also extends its lifespan, leading to lower maintenance costs over time.

Furthermore, using original elements contributes to Warranty Protection. Many manufacturers stipulate that only authentic parts should be used to maintain warranty coverage. By adhering to this guideline, users can avoid potential disputes and ensure they receive the full benefits of their warranty.

In addition, there is a strong emphasis on Safety. Authentic components are rigorously tested to meet safety standards, reducing the risk of accidents or failures during operation. This focus on safety helps protect both the user and the environment.

In conclusion, opting for original components is a smart choice for anyone looking to maintain their machinery effectively. The benefits of quality assurance, improved performance, warranty protection, and enhanced safety make it a worthwhile investment for the long-term care of equipment.

Resources for Further Information

When seeking knowledge about machinery maintenance and repair, a variety of sources can enhance understanding and provide valuable insights. This section aims to guide you towards helpful materials that can support your endeavors in keeping your equipment in optimal condition.

Online Forums and Communities

Participating in online forums dedicated to machinery enthusiasts can be beneficial. These platforms allow users to share experiences, ask questions, and exchange advice. Engaging with a community can provide practical tips and solutions based on real-life scenarios.

Manufacturer’s Manuals and Guides

Consulting the official documentation from manufacturers is crucial for accurate information. These manuals typically include detailed instructions, troubleshooting tips, and maintenance schedules. Having access to these resources ensures that you are following recommended practices for effective care.

Utilizing various resources will empower you to manage your machinery with confidence. Whether through community support or official guidelines, staying informed is key to successful operation.