Understanding the various elements that make up mechanical systems is crucial for ensuring their proper functioning and longevity. Each component plays a vital role in the overall operation, and maintaining these parts in optimal condition is key to achieving smooth and efficient performance. Proper upkeep and timely replacements help avoid unnecessary downtime and extend the lifespan of the machine.

Maintenance and care of individual elements are necessary for optimal performance. Regular inspection ensures that all parts are working as intended, preventing unexpected failures. This approach not only boosts efficiency but also minimizes long-term costs associated with repairs or replacements.

Additionally, knowing how different sections interact with each other enhances the overall understanding of the system’s dynamics. This knowledge aids in identifying potential issues early and allows for more precise adjustments, leading to a more reliable and efficient operation.

This model offers a range of standout capabilities that ensure efficient and reliable operation. Designed for a smooth and powerful performance, it caters to a variety of tasks with precision and ease. The combination of advanced technology and user-friendly design makes it a versatile choice for demanding users.

- Powerful engine designed for optimal efficiency and consistent output.

- Enhanced maneuverability for easy navigation around obstacles.

- Durable construction, ensuring long-lasting reliability under different conditions.

- Comfortable seating and ergonomic controls for improved user experience.

- Advanced cutting system for precise and clean results on various surfaces.

These features, combined with its overall robust design, make this model a strong choice for those seeking performance and durability in their equipment.

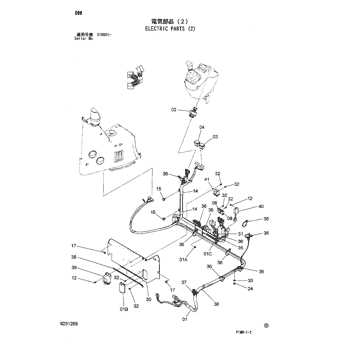

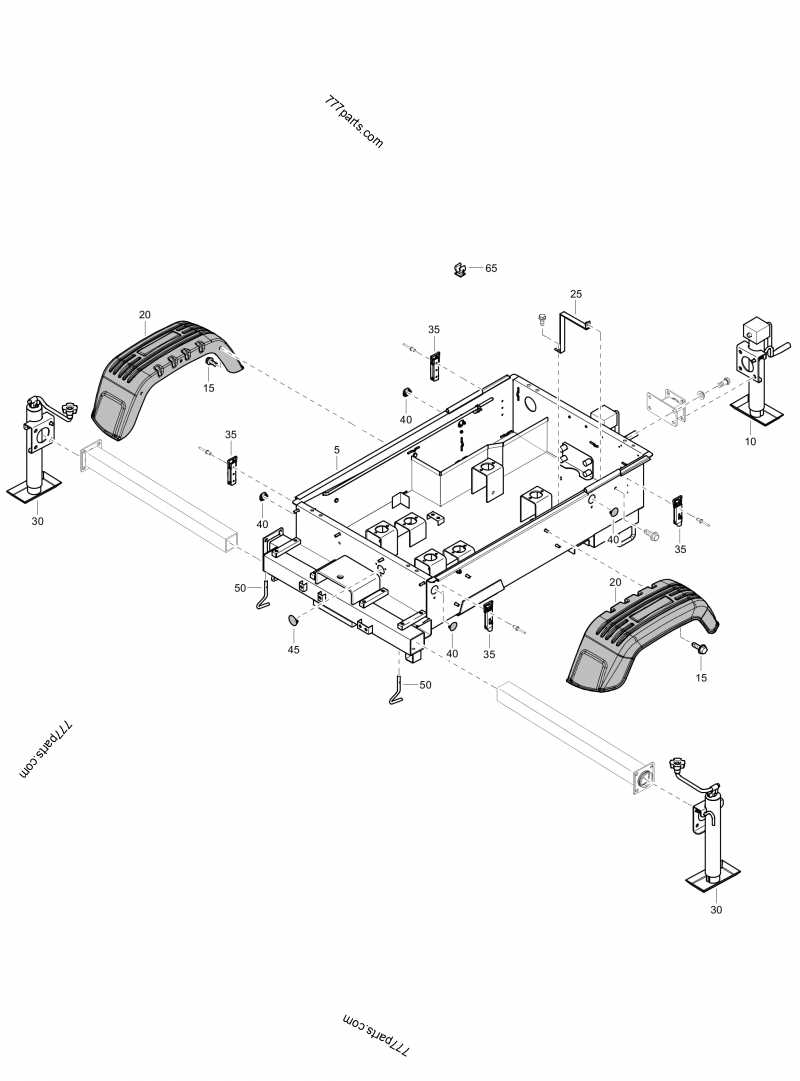

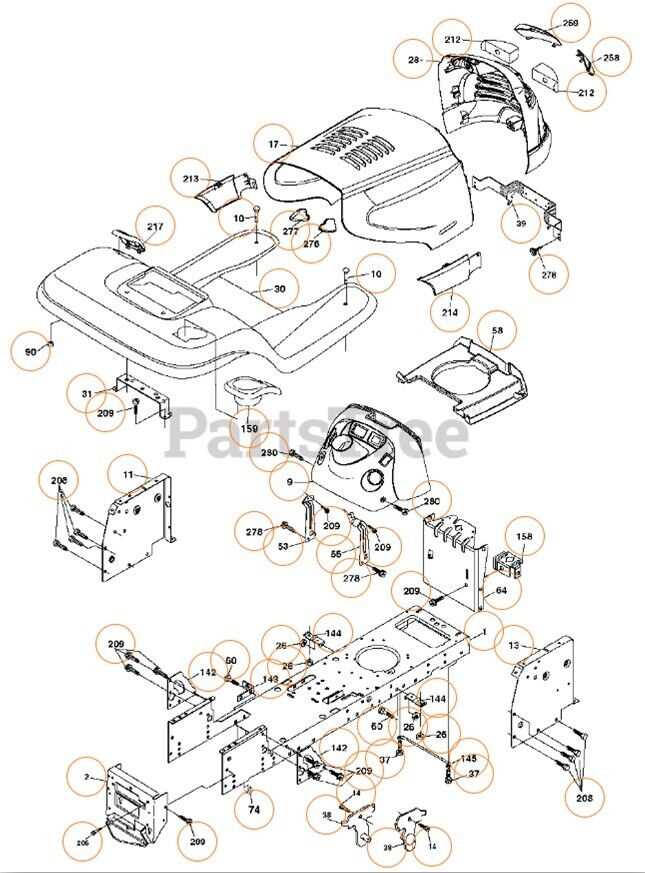

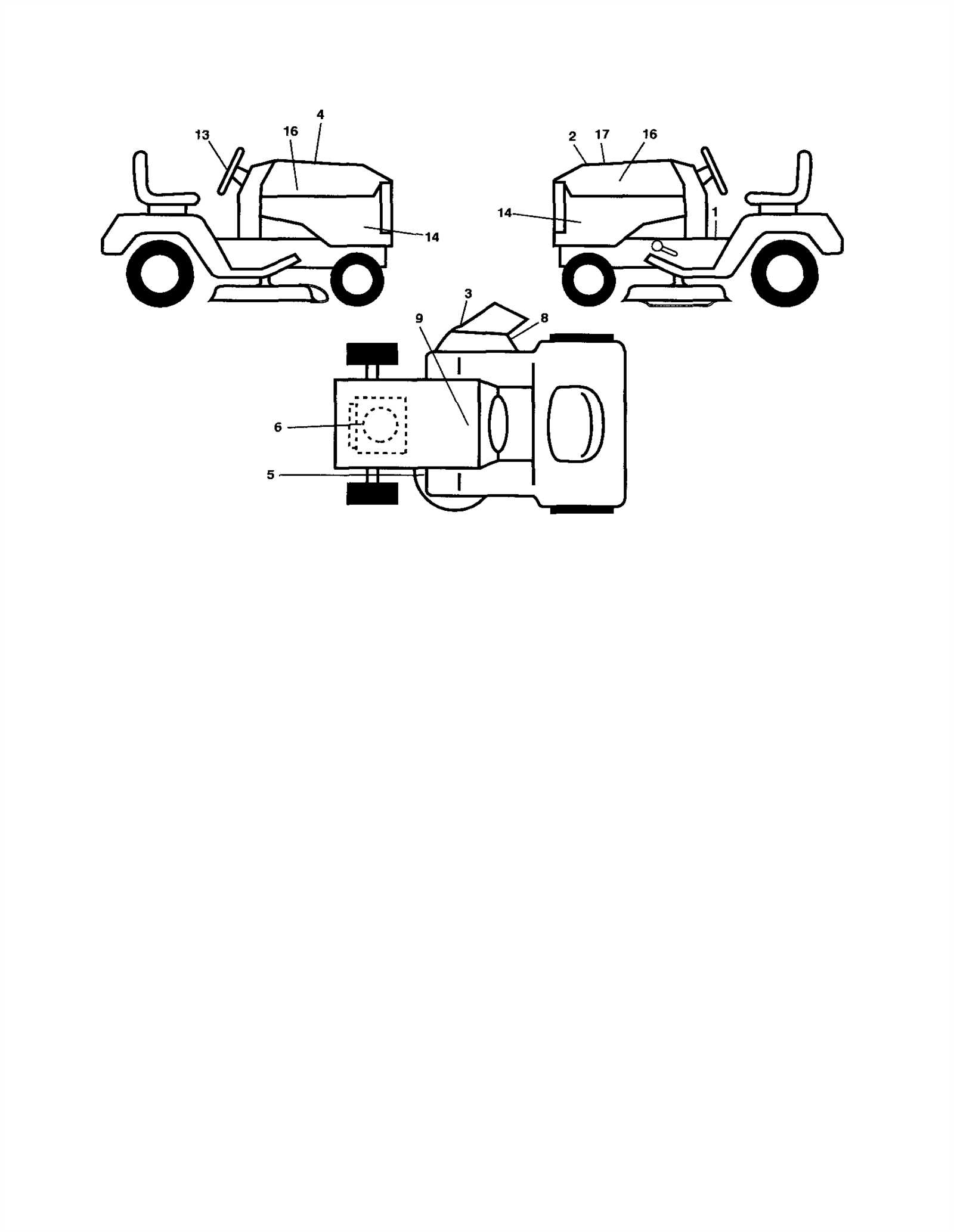

Importance of Parts Identification

Recognizing and understanding various components is crucial for ensuring the proper functioning of equipment. Correct identification aids in maintaining operational efficiency, reduces downtime, and prevents unnecessary repairs. It also allows for timely replacements, ensuring the system runs smoothly without interruptions. This process is essential for both routine upkeep and more significant maintenance tasks, as it ensures that the right component is addressed at the right time, minimizing long-term issues.

By knowing how each piece fits into the larger structure, users can troubleshoot problems more effectively and ensure that their equipment remains in optimal condition for an extended period. Furthermore, understanding component details helps in sourcing replacements quickly, reducing delays in repairs and lowering overall costs associated with misdiagnosis or incorrect replacements.

Common Issues with YTH2454 Parts

Regular use of lawn tractors can lead to wear and tear on various components. It’s important to recognize the most frequent problems that can occur over time, especially with mechanical and electrical elements. Addressing these issues early on can prevent larger, more costly repairs down the line.

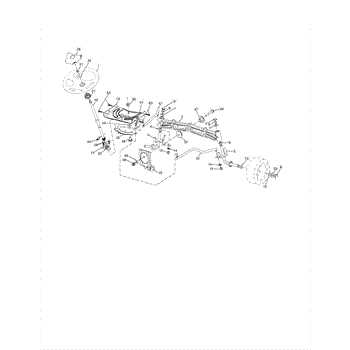

Mechanical Challenges

- Belt slippage during operation, which can reduce efficiency.

- Worn-out blades causing uneven cutting or reduced performance.

- Transmission issues leading to difficulty in shifting or loss of power.

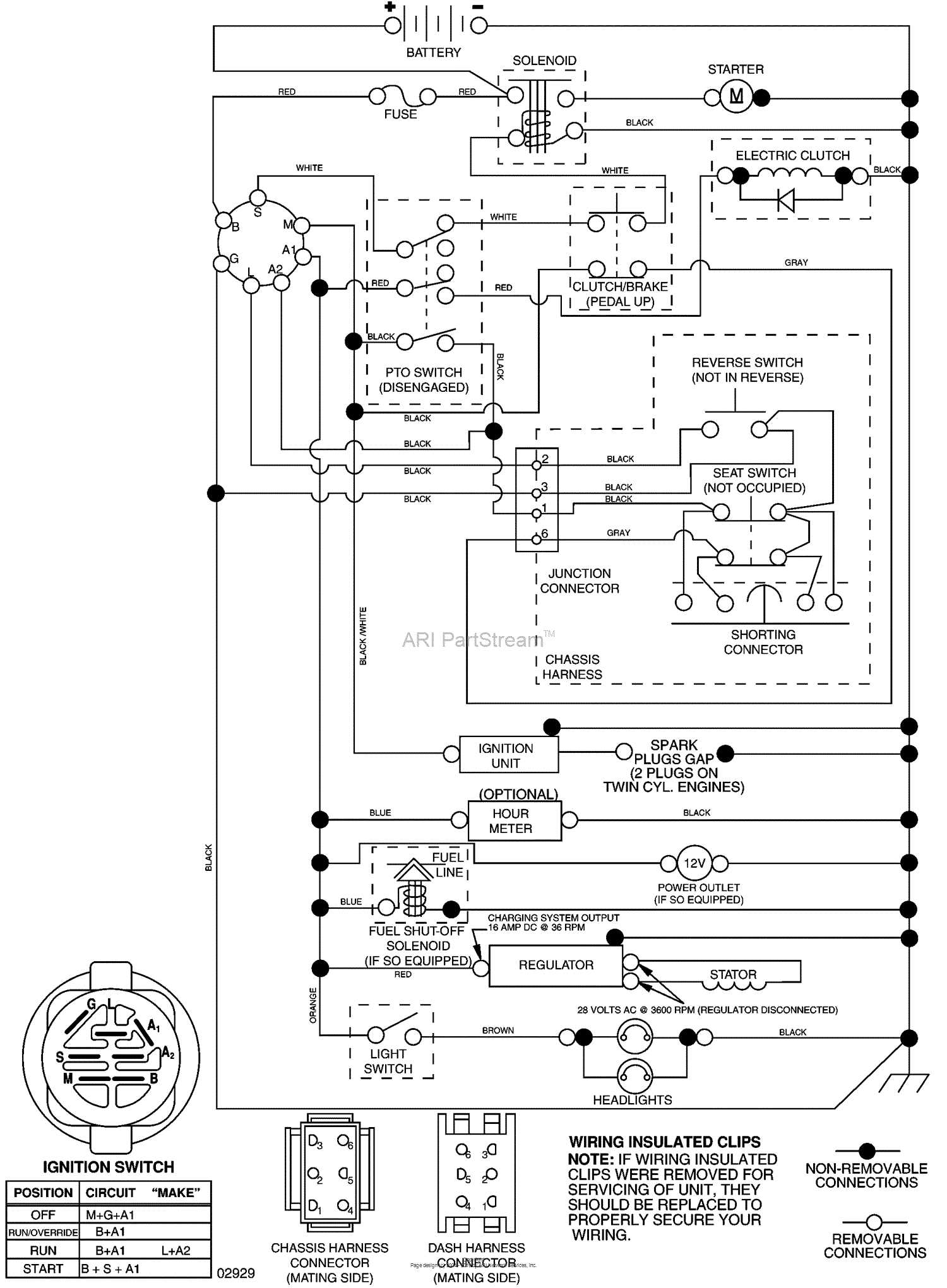

Electrical Problems

- Battery drain or failure, making it hard to start.

- Faulty wiring causing intermittent functionality of key systems.

- Ignition problems leading to difficulties in starting the engine.

By performing regular maintenance and inspecting these components, you can ensure a smoother operation and extend the lifespan of the machine.

How to Access the Parts Diagram

To easily locate essential maintenance components for your equipment, you need to understand the correct steps for accessing the visual layout of its components. This will help ensure proper upkeep and avoid potential issues. Follow the instructions provided through the available resources to find the detailed layout you need.

Steps for Accessing the Diagram

Begin by identifying the model of the equipment you’re working with. Once you have that information, you can navigate the provided support platform. You will typically find a section dedicated to various maintenance details, including a comprehensive schematic of your equipment’s structure.

Additional Resources

| Resource | Link

Essential Maintenance Tips for Longevity

Regular upkeep is key to ensuring your machine runs smoothly and lasts for many years. By following a few important steps, you can prevent wear and tear, reduce downtime, and avoid costly repairs. This guide will outline practical maintenance advice that extends the lifespan of your equipment.

|

|---|