The cutting deck system is a key component responsible for efficient lawn maintenance. It operates by housing a set of rotating blades that work together to achieve an even and precise trim. This section provides a comprehensive look at how the system functions and how its various elements interact to deliver optimal cutting performance.

Below is a simplified table that outlines the primary components involved in the system and their roles in maintaining effective operation:

| Component |

Function |

| Blades |

Cut the grass evenly at the desired height. |

| Spindle Assembly |

Supports the blades and allows them to rotate smoothly. |

| Belt |

Transfers power from the engine to the cutting deck. |

Steering and Front Wheel Mechanism

The steering system plays a crucial role in ensuring smooth navigation and maneuverability, allowing the operator to direct the machine with ease. This mechanism connects the controls to the front wheels, translating movement from the operator into precise directional changes. A well-maintained system ensures both safety and efficiency during operation.

Key components within this system include the steering gear, linkage, and front axle, all of which work together to facilitate turning. These elements must function in harmony to avoid any difficulties in control or imbalance in the front wheels.

Proper alignment and regular inspection of the steering and front wheel assembly can greatly enhance the overall handling experience. When these mechanisms operate seamlessly, the result is a smoother, more controlled ride, even across uneven terrain.

Exploring the Seat and Comfort Features

The design of riding equipment is crucial for ensuring both ease of use and long-term comfort. When spending extended hours on any machinery, the seating and overall comfort elements play a key role in reducing fatigue and improving user experience. This section delves into how ergonomic considerations contribute to user comfort during operation.

Ergonomically Designed Seat

The seat is crafted to offer maximum support during prolonged use, incorporating padding that reduces strain on the lower back. The contour of the seat ensures proper posture, allowing the user to maintain a natural position throughout their task. Adjustability options provide a personalized fit, ensuring users of different heights can operate comfortably.

Enhanced Comfort Features

Beyond the seat itself, additional features focus on creating a more comfortable environment for the operator. These include vibration reduction elements that minimize the impact of terrain and durable materials that provide both cushioning and longevity. Together, these features ensure a smoother, more enjoyable experience during every use.

Electrical System Components Breakdown

The electrical system of a lawn care machine plays a crucial role in its overall functionality and performance. Understanding the various elements within this system can greatly enhance maintenance and troubleshooting efforts. Each component contributes to the seamless operation, ensuring that the machine operates efficiently and reliably.

At the heart of the electrical setup, the battery serves as the primary power source, providing the necessary energy to start the engine and power various accessories. It is essential to ensure that the battery is adequately charged and in good condition to avoid operational issues.

The ignition system is another vital part, responsible for initiating the combustion process. This system typically includes components such as the ignition coil, spark plug, and wiring harness, all of which must be in optimal working order for the engine to start smoothly.

Furthermore, the charging system maintains the battery’s charge during operation. It often consists of a voltage regulator and alternator, which work together to ensure that the battery receives the right amount of charge while preventing overloading.

In addition, various switches and relays play a significant role in controlling the electrical flow. These components enable the operator to manage different functions, such as starting the engine or activating lights, enhancing the overall user experience.

Lastly, the wiring harness is the network that connects all these components, allowing for communication and power distribution. Proper inspection and maintenance of this harness are essential to prevent shorts or disconnections that could impair functionality.

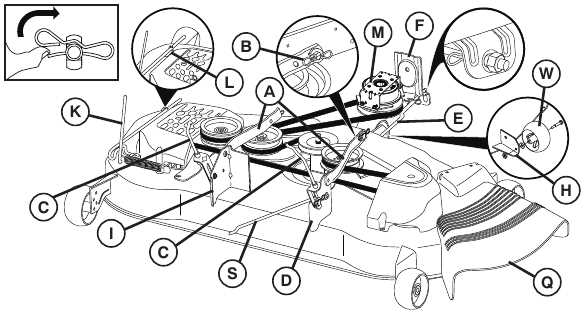

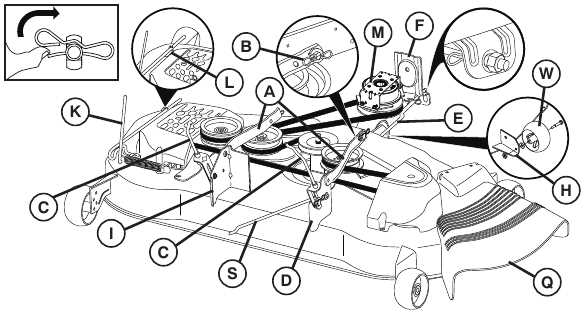

Blades and Drive Belt Assembly

The efficiency of a lawn mower greatly depends on its cutting mechanism and power transmission system. The components responsible for these functions must be well-maintained and properly aligned to ensure optimal performance. Understanding the relationship between the cutting tools and the drive belt is essential for achieving a well-manicured lawn.

The cutting implements play a critical role in shaping the grass, and their sharpness directly influences the quality of the cut. Regular inspection and sharpening of these tools are crucial to maintain their effectiveness. Damage or wear can lead to uneven cuts, making it necessary to replace them promptly.

Equally important is the drive belt, which transmits power from the engine to the cutting assembly. A well-functioning belt ensures smooth operation and reliable performance. Signs of wear, such as fraying or cracking, should not be ignored, as they can compromise the entire mowing experience. Regular maintenance of these essential components is vital for a successful gardening endeavor.

Fuel System Parts and Maintenance

The efficient functioning of the fuel mechanism is crucial for optimal engine performance. Regular upkeep ensures that all components operate smoothly, reducing the risk of issues that can lead to costly repairs. This section delves into the various elements of the fuel delivery system and provides guidance on maintaining them effectively.

Key Components of the fuel delivery mechanism include the fuel tank, filter, pump, and carburetor. Each part plays a vital role in ensuring that the engine receives the right amount of fuel at the correct pressure. The fuel tank stores the fuel, while the filter removes impurities, allowing clean fuel to flow to the pump. The pump, in turn, transfers the fuel to the carburetor, where it is mixed with air for combustion.

Maintenance Tips for the fuel system are essential for enhancing the longevity of the engine. Regularly check the fuel filter for clogs and replace it as needed to prevent restricted flow. Inspect the fuel lines for cracks or leaks that could compromise performance. Additionally, clean the carburetor periodically to remove any buildup that may hinder fuel flow. Proper storage of fuel, using stabilizers, can also help maintain its quality and prevent issues during startup.

Tires, Wheels, and Axle Structure

The foundation of any riding mower’s mobility lies in its tire, wheel, and axle configuration. These components work together seamlessly to provide stability, traction, and smooth navigation across various terrains. Understanding their design and functionality is crucial for maintenance and optimal performance.

Understanding the Wheel Design

The wheels play a pivotal role in ensuring that the machine operates efficiently. Typically, they are constructed from durable materials that can withstand wear and tear while providing excellent grip. The tread pattern is designed to enhance traction on different surfaces, making it easier to maneuver during mowing tasks. Additionally, the diameter and width of the wheels affect the overall handling and stability of the unit.

The Importance of Axles

Axles are essential for connecting the wheels to the chassis and allowing for smooth rotation. A well-engineered axle system distributes weight evenly, which is vital for maintaining balance and preventing excessive wear. Regular inspection and maintenance of these components can prevent costly repairs and ensure longevity. Proper alignment and lubrication are also key factors in preserving the integrity of the axle structure.

Understanding the Clutch and Braking System

The mechanism responsible for controlling motion and stopping actions in lawn care machines plays a crucial role in their overall functionality. This system comprises various components that work in harmony to ensure smooth operation, allowing the operator to manage speed and halt effectively when necessary.

The engagement and disengagement of the drive are facilitated by the clutch assembly. This mechanism allows the user to transfer power from the engine to the wheels seamlessly, providing the ability to control movement without stalling the engine. Proper adjustment and maintenance of the clutch are essential to prevent slippage, ensuring efficient performance.

Equally important is the braking system, which ensures safety during operation. This system employs a series of levers and linkages that activate when the operator presses the brake pedal. Regular checks and maintenance of the brake components are vital to ensure that the machine can stop promptly and effectively, enhancing the user’s safety and the longevity of the equipment.

Battery and Charging System Overview

The battery and charging system plays a crucial role in ensuring the reliable operation of any outdoor power equipment. This mechanism not only stores electrical energy but also supplies power to various components, allowing for seamless functionality. Understanding the interplay between the battery, charging unit, and related elements is essential for effective maintenance and performance.

The energy storage unit typically features lead-acid or lithium-ion technology, which provides the necessary voltage to start the engine and power electrical accessories. The charging mechanism ensures that the battery remains topped up during use, converting mechanical energy into electrical energy. This cycle is vital for extending the lifespan of the battery and ensuring optimal performance during operation.

How to Replace Key Components Efficiently

When it comes to maintaining and repairing machinery, understanding the efficient replacement of essential parts is crucial. This process not only extends the lifespan of the equipment but also ensures optimal performance. By following a systematic approach, individuals can streamline the replacement task, saving time and minimizing potential issues during the procedure.

Identifying Necessary Components

The first step in any replacement task is to accurately identify which components require attention. This involves examining the machinery for wear and tear signs, such as unusual noises or decreased efficiency. A thorough inspection will help prioritize replacements, allowing you to focus on the most critical elements first. Make sure to consult the manufacturer’s guidelines for a comprehensive overview of the essential components and their functions.

Gathering Required Tools and Materials

Before beginning the replacement process, ensure that all necessary tools and materials are on hand. This preparation not only saves time but also prevents interruptions during the task. Common tools may include wrenches, screwdrivers, and safety equipment. Additionally, having replacement components ready will facilitate a smoother workflow, allowing you to complete the task efficiently and effectively.