When it comes to maintaining your riding mower, having a clear understanding of its various elements is essential. Each component plays a crucial role in ensuring optimal performance and longevity. By familiarizing yourself with these key parts, you can effectively troubleshoot issues and perform necessary maintenance.

Visual aids can significantly enhance your comprehension of the machinery. A well-organized illustration showcasing the different sections allows for a more straightforward identification of specific components. This knowledge empowers you to make informed decisions during repairs or upgrades, ensuring your mower remains in peak condition.

Whether you are an experienced mechanic or a novice user, grasping the intricacies of your equipment fosters confidence in its operation. By diving into the details of the machinery, you equip yourself with the skills needed to keep your mower running smoothly and efficiently.

Understanding Husqvarna YTH26V54 Components

When examining the intricate machinery of a riding mower, it’s essential to recognize the various elements that contribute to its functionality. Each component plays a vital role in ensuring smooth operation, making it crucial for users to familiarize themselves with these essential parts. By understanding how these elements interact, operators can maintain their equipment more effectively and troubleshoot issues as they arise.

Key Elements of the Mower

Among the significant components of the mower are the engine, transmission, and cutting deck. The engine serves as the powerhouse, providing the necessary energy to propel the machine and engage the cutting blades. The transmission system facilitates the transfer of power, allowing for variable speeds and improved maneuverability. Meanwhile, the cutting deck houses the blades that perform the essential task of trimming grass, ensuring an even finish on the lawn.

Maintenance Considerations

Regular upkeep of these critical parts is essential for optimal performance. Inspecting the engine for oil levels and any signs of wear can prevent costly repairs. Additionally, ensuring the transmission fluid is at the appropriate level contributes to smooth operation. Lastly, maintaining the cutting deck by sharpening blades and cleaning debris ensures efficient grass cutting. By understanding these components and their care, operators can extend the lifespan of their machinery.

Overview of Lawn Tractor Parts

Lawn tractors are essential machines for maintaining expansive green spaces. Understanding the various components that make up these machines can enhance their functionality and longevity. Each element plays a crucial role in the overall operation, ensuring efficient performance and ease of use.

Key Components of Lawn Tractors

One of the primary features of lawn tractors is the cutting deck, which houses the blades responsible for trimming grass to a uniform height. This assembly is often adjustable, allowing users to customize cutting lengths according to their preferences. Another vital section is the transmission system, which facilitates the movement of the tractor across various terrains, making it easier to navigate both flat and hilly landscapes.

Maintenance and Replacement

Regular upkeep of the tractor’s components is crucial for optimal performance. Elements such as belts, filters, and spark plugs may require periodic replacement to avoid mechanical issues. Understanding these parts not only helps in maintenance but also empowers users to perform minor repairs independently, leading to a more efficient and cost-effective lawn care experience.

Common Issues and Solutions

Every lawn mower can experience a variety of problems over time, which may hinder its performance. Understanding these common challenges can help you troubleshoot effectively and keep your machine running smoothly. Here are some frequent issues encountered by users and practical solutions to address them.

Engine Not Starting

If the engine fails to start, it can be frustrating. This issue may arise due to a drained battery, faulty ignition system, or fuel supply problems. Here are steps to resolve this:

- Check the battery charge and connections.

- Inspect the ignition switch for any faults.

- Ensure that the fuel is fresh and the line is clear.

Uneven Cutting

Another common concern is uneven cutting of grass, which may result from a dull blade or improper deck height. To achieve a uniform cut, consider the following:

- Sharpen or replace the mower blades.

- Adjust the cutting height settings appropriately.

- Inspect the wheels and deck for damage or wear.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine Not Starting | Drained battery | Recharge or replace the battery |

| Engine Not Starting | Faulty ignition | Check and replace the ignition switch |

| Uneven Cutting | Dull blades | Sharpen or replace the blades |

| Uneven Cutting | Incorrect deck height | Adjust the cutting height settings |

Identifying Key Replacement Parts

When it comes to maintaining outdoor equipment, knowing how to identify essential components is crucial for effective repairs. Understanding the various elements that make up your machinery can simplify the replacement process and enhance overall performance.

Here are some common categories of vital components that may need to be replaced:

- Engine Components: These include parts like spark plugs, filters, and gaskets, which are essential for optimal engine performance.

- Transmission Elements: Gears, belts, and pulleys fall under this category, playing a critical role in the movement and functionality of your equipment.

- Cutting Mechanism: Blades and blade spindles are key to ensuring a clean cut, making them important for any maintenance routine.

- Electrical Systems: Batteries, switches, and wiring should be regularly checked to ensure proper operation and safety.

By familiarizing yourself with these categories, you can more easily recognize when a part may need replacing and find the right items for your repairs.

Maintenance Tips for Longevity

Regular upkeep is essential for enhancing the lifespan of your outdoor equipment. By adhering to a consistent maintenance routine, you can ensure optimal performance, reduce wear and tear, and prevent costly repairs. Below are key practices that contribute to the durability of your machinery.

Routine Inspections

Conducting frequent inspections allows you to identify potential issues before they escalate. Examine belts, blades, and other components for signs of damage or excessive wear. Addressing minor problems early can save you time and money in the long run.

Proper Cleaning and Storage

Keeping your equipment clean is vital for its longevity. Remove debris, grass clippings, and dirt after each use. Additionally, storing your machine in a dry, sheltered area protects it from harsh weather conditions and minimizes the risk of rust and corrosion. Regularly check and change filters as necessary to maintain optimal function.

Investing time in maintenance not only prolongs the life of your machinery but also enhances its efficiency and reliability. By implementing these simple yet effective practices, you can enjoy a more productive experience with your outdoor tools.

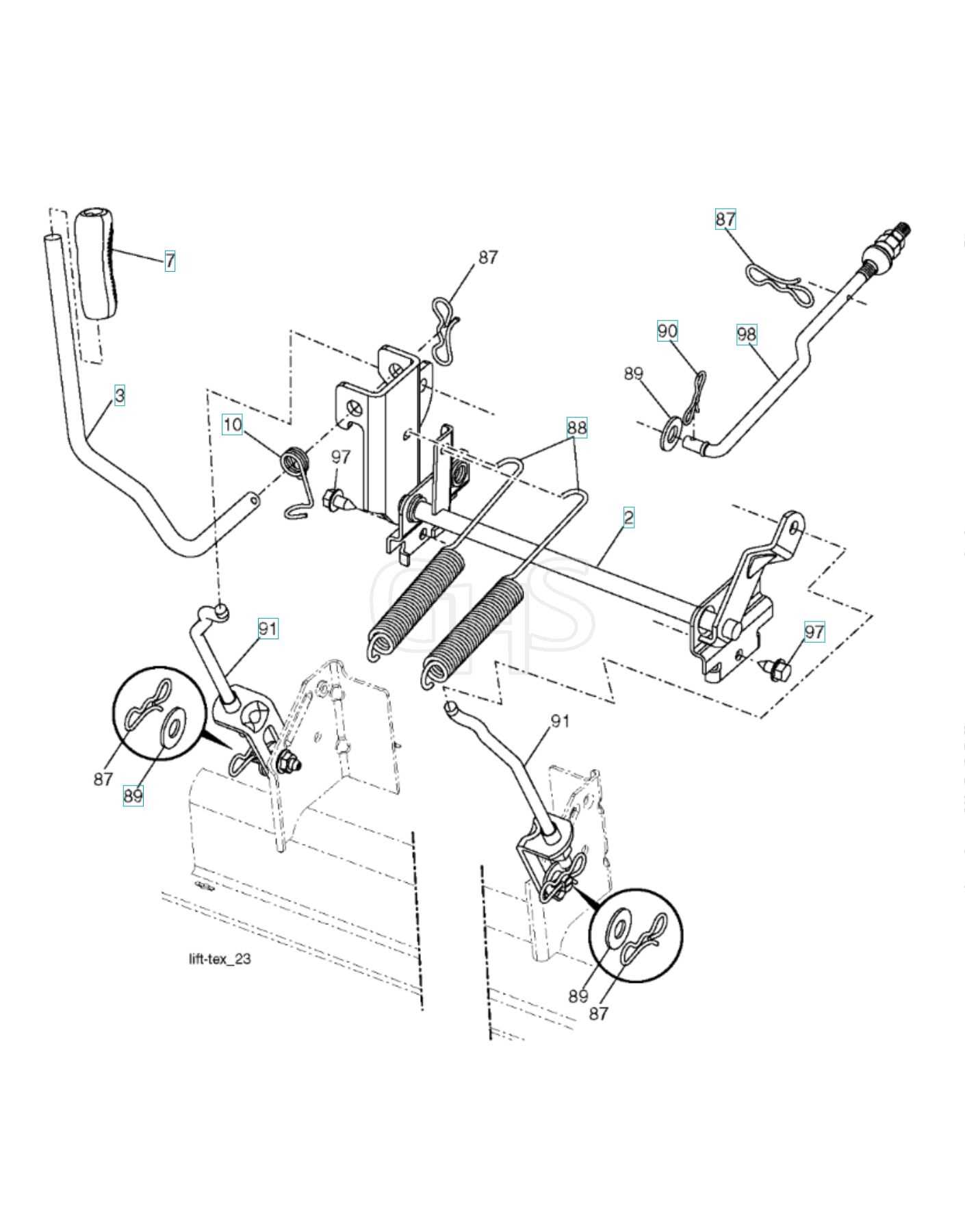

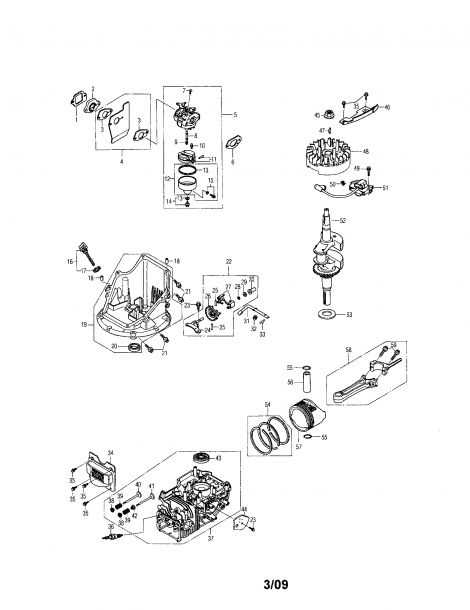

Parts Diagram Explanation

This section aims to clarify the layout of components within a specific machinery model. Understanding the arrangement and interaction of various elements is crucial for effective maintenance and repair. A visual representation can significantly assist users in identifying the specific parts needed for their tasks.

Identification of Components: The graphical illustration provides a clear view of each element, enabling users to easily locate and recognize them. This is especially beneficial when ordering replacements or understanding how parts interact within the overall system.

Maintenance and Repair: Familiarity with the setup is essential for anyone engaged in upkeep or troubleshooting. Knowing where each component is situated helps in diagnosing issues efficiently. Additionally, it streamlines the replacement process, reducing the time spent on repairs.

Ordering Parts: When it comes to procuring replacements, having a visual reference allows for accurate identification of the required items. This minimizes errors and ensures that the correct pieces are obtained promptly, facilitating a smoother repair experience.

Conclusion: A comprehensive visual guide is invaluable for users seeking to enhance their understanding of the machinery. It empowers them to perform necessary maintenance tasks with confidence and precision.

How to Read Diagrams Effectively

Understanding visual representations is crucial for successful navigation through technical information. These illustrations serve as guides, enabling users to identify components and their relationships within a system. By mastering the art of interpretation, individuals can streamline their troubleshooting and assembly processes.

Key Elements to Focus On

- Legends and Symbols: Familiarize yourself with the icons and their meanings. Each symbol often represents a specific element or action.

- Lines and Connections: Pay attention to how different parts are connected. Solid lines may indicate direct relationships, while dashed lines could denote optional connections.

- Labels: Look for descriptive labels that provide clarity on the functions and specifications of each element.

Steps for Effective Interpretation

- Begin by reviewing the overall layout to understand the structure.

- Identify the key components highlighted in the illustration.

- Analyze the connections to grasp how each part interacts with others.

- Refer to accompanying texts or manuals for additional context when needed.

By concentrating on these aspects, you can enhance your ability to interpret visual aids, leading to better understanding and effective problem-solving.

Where to Find Quality Parts

When it comes to maintaining and repairing your outdoor equipment, sourcing reliable components is essential. Quality replacements ensure optimal performance and longevity of your machinery. Here are some avenues to explore for finding the best supplies.

Online Retailers

Numerous online platforms offer a wide range of components for various equipment types. These websites often provide detailed descriptions and compatibility information, making it easier to find what you need. Additionally, user reviews can help you gauge the quality of the items before making a purchase.

Local Dealers

Visiting local dealers can be beneficial for hands-on inspections of the products. Local suppliers often have knowledgeable staff who can assist in identifying the right replacements for your needs. Establishing a relationship with these businesses can also lead to better customer service and support in the long run.

| Source | Advantages |

|---|---|

| Online Retailers | Wide selection, competitive pricing, customer reviews |

| Local Dealers | Personalized service, hands-on inspection, expert advice |

| Manufacturer Websites | Genuine products, warranty support, detailed specifications |

| Salvage Yards | Cost-effective options, hard-to-find items, environmental benefits |

Cost Analysis of Replacement Parts

Understanding the financial implications of replacing components in outdoor equipment is crucial for maintaining both performance and budget. This section examines the expenses associated with acquiring new elements, emphasizing the importance of making informed choices. By analyzing various factors, users can gain insights into potential costs and savings over time.

Factors Influencing Costs

Several elements contribute to the overall expense of component replacement. First, the quality of the parts plays a significant role; premium options may come at a higher price but can enhance durability and functionality. Additionally, the availability of specific components in local markets versus online platforms can affect pricing due to shipping and handling fees.

Long-Term Investment

Investing in high-quality replacements may seem costly initially, but it often leads to long-term savings. Quality components typically require less frequent replacements, reducing overall expenditure over time. Furthermore, enhanced performance can lead to increased efficiency, which may translate to savings in fuel or energy costs.

Comparison of Options

When considering replacement options, comparing different suppliers and brands is essential. Some may offer warranties or guarantees, adding value to the purchase. Furthermore, seeking recommendations or reviews can aid in selecting the best alternatives, ensuring that users make cost-effective decisions that do not compromise performance.

DIY Repair vs. Professional Service

When it comes to fixing machinery, enthusiasts often face the choice between tackling repairs themselves or hiring a skilled technician. Each option comes with its own set of advantages and disadvantages that can impact both the process and the outcome of the repair.

Benefits of DIY Repair

- Cost Savings: Taking on repairs independently can significantly reduce expenses, as you avoid labor fees associated with hiring professionals.

- Learning Experience: Engaging in hands-on repairs allows individuals to gain valuable knowledge about the machinery, potentially leading to improved troubleshooting skills in the future.

- Flexibility: DIY projects can often be scheduled at your convenience, without the need to coordinate with a service provider’s availability.

Advantages of Professional Service

- Expertise: Professionals possess specialized training and experience, ensuring repairs are conducted correctly and efficiently.

- Time Efficiency: Hiring a technician can save time, particularly for complex repairs that may take an amateur significantly longer to complete.

- Warranty Protection: Many services offer warranties on their work, providing peace of mind and potential future savings if issues arise post-repair.

Safety Considerations During Repairs

When undertaking maintenance or repair tasks on machinery, it is crucial to prioritize safety to prevent accidents and injuries. Proper preparation, use of personal protective equipment, and understanding the equipment’s mechanisms are essential steps to ensure a safe working environment.

Preparation and Personal Protective Equipment

Before starting any work, assess the area to ensure it is clean and free from hazards. Always wear appropriate safety gear, including gloves, goggles, and sturdy footwear. This equipment helps protect against potential injuries from sharp objects or flying debris.

Understanding the Equipment

Familiarize yourself with the machinery and its components. Reviewing the owner’s manual and maintenance guidelines can provide valuable insights into safe operation practices. Additionally, always disconnect the power source before making any repairs to prevent accidental start-ups.

Ordering Parts Online: A Guide

In today’s digital age, acquiring components for your machinery has never been more straightforward. The convenience of online shopping allows enthusiasts and professionals alike to find the necessary items from the comfort of their homes. This section provides a comprehensive overview of how to efficiently navigate the process of purchasing replacement items online.

Research and Compatibility: Before making a purchase, it is essential to conduct thorough research. Ensure that the item you intend to buy is compatible with your equipment. Checking the specifications and consulting the user manual can help avoid costly mistakes. Look for reliable sources that offer detailed descriptions and customer reviews to gauge the quality of the products.

Choosing a Reputable Supplier: Selecting a trustworthy online retailer is crucial for a successful transaction. Look for vendors with a solid reputation, positive feedback, and clear return policies. Additionally, ensure that they provide secure payment options to protect your financial information.

Understanding Shipping and Delivery: When ordering items, pay attention to shipping costs and estimated delivery times. Some suppliers may offer free shipping on orders above a certain amount, while others might have expedited options for urgent needs. Being aware of these details can help you make an informed decision.

After-Purchase Support: Quality customer service can significantly enhance your online shopping experience. Opt for retailers that offer assistance after the sale, whether it be through live chat, email, or phone support. This ensures that you have access to help should any issues arise with your order.

Customer Reviews of Replacement Parts

When it comes to maintaining outdoor equipment, user feedback on substitute components plays a crucial role in the decision-making process. Customers often share their experiences regarding the durability, efficiency, and compatibility of various aftermarket options. This section delves into insights provided by users, highlighting their satisfaction and any concerns they might have encountered with alternative products.

Positive Experiences

Many users express contentment with their choices, noting that certain replacement items have significantly improved the performance of their machinery. Reviews frequently highlight aspects such as ease of installation and enhanced functionality, which contribute to a smoother operation. Customers often recommend specific brands based on their personal experiences, praising the longevity and reliability of these replacements.

Areas for Improvement

While positive reviews are common, some users mention challenges they faced with particular substitutes. Issues like incompatibility with specific models or diminished performance compared to original components are occasionally reported. Feedback in this area serves as a valuable resource for prospective buyers, guiding them toward more reliable options and helping them avoid potential pitfalls.