The effectiveness of any pulling mechanism relies on a well-organized system of elements working together seamlessly. Recognizing how these elements interact and function is crucial for anyone looking to maintain or repair their equipment. This section delves into the essential components, offering insight into their arrangement and purpose.

Every piece of equipment is made up of various elements, each designed to perform specific tasks. By understanding the layout and roles of these components, users can ensure their device operates optimally. Furthermore, familiarity with the structure enables better troubleshooting and enhances overall performance.

In this guide, readers will find detailed descriptions of the different segments involved in the mechanism. With this knowledge, operators will be empowered to make informed decisions regarding repairs and replacements, ultimately prolonging the life of their machinery.

Overview of Polaris 2500 Winch

This section provides a comprehensive overview of a powerful tool designed for heavy-duty applications. With its robust construction and high-performance capabilities, this device is engineered to assist in lifting, pulling, and towing tasks in various environments. Its versatility makes it an essential asset for outdoor enthusiasts and professionals alike, enhancing efficiency in challenging situations.

Key Features and Benefits

One of the standout characteristics of this device is its impressive pulling capacity, allowing users to tackle substantial loads with ease. Additionally, it incorporates advanced technology that ensures reliable operation and durability, even under extreme conditions. The user-friendly design further contributes to its appeal, enabling effortless installation and operation.

Applications and Usage

This tool finds applications across multiple sectors, from recreational activities such as off-roading and trail riding to professional settings like construction and agriculture. Its ability to handle diverse tasks makes it a valuable companion for anyone needing dependable lifting and pulling solutions. Users can rely on its strength and efficiency to overcome obstacles and complete projects effectively.

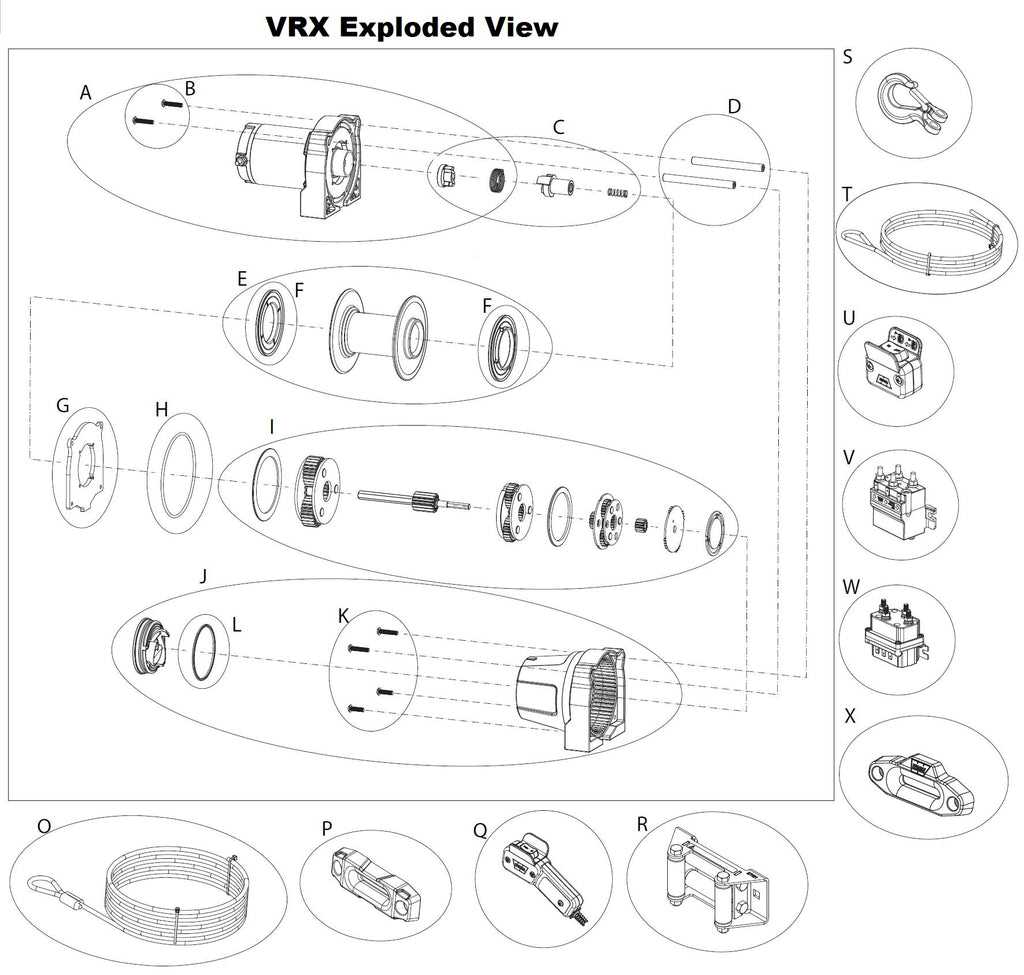

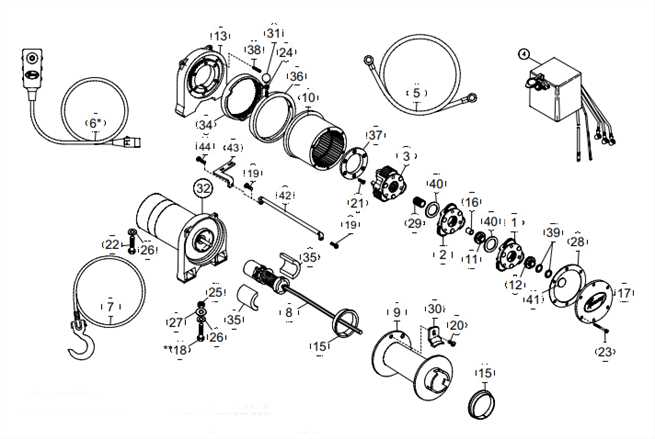

Components of the Winch Assembly

The assembly of a pulling mechanism consists of various essential elements that work in unison to provide effective operation. Each component plays a significant role in ensuring the efficiency and reliability of the entire system. Understanding these elements is crucial for maintenance and troubleshooting, allowing users to maximize performance and longevity.

Key Elements in the Mechanism

At the heart of the assembly lies the motor, which powers the entire system. This component is responsible for generating the necessary force to execute the pulling function. Additionally, the drum is where the cable is wound, facilitating the movement during operation. Proper inspection and maintenance of these key elements ensure seamless performance.

Supporting Components and Accessories

Alongside the primary elements, several supporting components enhance the functionality of the assembly. The controller, for instance, allows for precise management of the motor’s operation. Coupled with gears and pulleys, these accessories contribute to the overall efficiency, enabling users to tackle various tasks with ease. Regular checks and timely replacements of these parts can significantly impact performance.

Detailed Parts Breakdown

This section provides a comprehensive analysis of the various components involved in a specific type of mechanical device. Understanding the intricacies of these elements is essential for effective maintenance and optimal performance. Each component plays a crucial role in the overall functionality, and recognizing their interconnections can enhance repair processes and efficiency.

To begin, we will categorize the components based on their functions and characteristics. The core assembly includes essential mechanisms that facilitate movement and control, ensuring seamless operation. Additionally, auxiliary elements support the primary functions, contributing to enhanced reliability and durability.

Moreover, it is vital to familiarize oneself with the available accessories that can further improve the system’s versatility. Each accessory can serve multiple purposes, adapting to various tasks and conditions. This adaptability is key to maximizing the effectiveness of the device in diverse environments.

By examining each component and its function, users can gain valuable insights into the overall structure. This knowledge not only aids in troubleshooting but also empowers individuals to make informed decisions when seeking replacements or upgrades. A thorough understanding of the assembly encourages proactive maintenance and fosters a deeper appreciation for the craftsmanship involved.

Understanding Wiring and Connections

Properly managing electrical wiring and connections is crucial for optimal functionality and safety. A thorough comprehension of the various components and how they interact can significantly enhance performance and reliability.

When dealing with electrical systems, it’s essential to recognize the primary elements involved:

- Power Source: The origin of electrical energy that drives the entire system.

- Control Switches: Devices that allow users to manage the flow of electricity to various components.

- Relays: Electromechanical switches that control larger currents using smaller signals.

- Connectors: Points where wires are joined, ensuring a secure and reliable connection.

To facilitate effective wiring, consider the following guidelines:

- Identify Wiring Needs: Determine the appropriate gauge and type of wire based on the load requirements.

- Plan Layout: Organize the arrangement of wires and components to minimize clutter and ensure accessibility.

- Check Compatibility: Ensure that all components are compatible with one another to avoid malfunctions.

- Regular Maintenance: Inspect connections periodically to prevent corrosion and wear.

A comprehensive understanding of these aspects not only ensures efficient operation but also extends the lifespan of the entire system. Always prioritize safety by following proper guidelines during installation and maintenance.

Maintenance Tips for Longevity

To ensure the extended lifespan and reliable performance of your equipment, regular upkeep is essential. Implementing a consistent maintenance routine can prevent potential issues and enhance functionality. Below are effective strategies to promote durability and efficiency.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Monthly | Check for wear, damage, or loose components to identify issues early. |

| Cleaning | After Each Use | Remove dirt, debris, and moisture to prevent corrosion and buildup. |

| Lubrication | Every 3 Months | Apply appropriate lubricant to moving parts to minimize friction and wear. |

| Electrical Check | Every 6 Months | Inspect wiring and connections for integrity and proper function. |

| Storage | Seasonal | Store in a dry, sheltered area to protect against environmental elements. |

Common Issues and Troubleshooting

When operating heavy-duty equipment, users may encounter various challenges that hinder performance. Identifying and resolving these issues is crucial for ensuring efficiency and longevity. This section will outline some frequent problems and provide guidance on how to address them effectively.

Frequent Problems

- Insufficient pulling power

- Unusual noises during operation

- Inconsistent cable movement

- Electrical malfunctions

Troubleshooting Steps

- Check Connections: Ensure all electrical connections are secure and free of corrosion.

- Inspect Components: Examine the main parts for signs of wear or damage.

- Test Power Supply: Verify that the power source is functioning correctly and providing adequate voltage.

- Review Operating Conditions: Assess the environment and load conditions to ensure they are within operational limits.

By following these troubleshooting steps and being aware of common challenges, users can maintain optimal performance and extend the life of their equipment.

Upgrading Winch Accessories

Enhancing the functionality of your hoisting equipment can significantly improve its performance and usability. By investing in quality components, users can ensure greater reliability, increased efficiency, and a more enjoyable experience when tackling various tasks. Upgrading accessories allows for customization that meets specific needs, ensuring that the equipment operates at its best in challenging environments.

Choosing the Right Add-ons

When selecting enhancements, consider the types of activities you engage in. Accessories such as stronger cables, improved pulleys, and advanced control systems can make a noticeable difference. Opting for durable materials ensures longevity and resistance to wear, which is essential for heavy-duty operations.

Maintenance and Compatibility

Regular maintenance of upgraded components is crucial for optimal performance. Ensure that all accessories are compatible with existing equipment to avoid operational issues. Regular inspections and timely replacements can prolong the life of your gear, providing peace of mind during use.

Safety Considerations When Using Winch

Using a heavy-duty pulling mechanism requires careful attention to safety protocols to prevent accidents and ensure efficient operation. Understanding potential risks and implementing safety measures is essential for a secure working environment.

Here are some key safety considerations:

- Read the Manual: Always familiarize yourself with the manufacturer’s instructions and guidelines specific to the equipment you are using.

- Wear Protective Gear: Utilize appropriate safety equipment, such as gloves, goggles, and sturdy footwear, to minimize the risk of injury.

- Inspect Equipment: Regularly check all components for wear and tear, ensuring that they are in good working condition before each use.

- Clear the Area: Ensure that the workspace is free from obstacles and that bystanders are at a safe distance to avoid accidents.

- Use Proper Techniques: Employ safe handling techniques, such as not exceeding the load capacity and securing the load correctly.

- Stay Alert: Maintain focus on the task at hand and be aware of your surroundings to quickly respond to any unexpected situations.

- Practice Emergency Procedures: Be prepared for emergencies by knowing how to shut down the equipment and respond to potential hazards.

By adhering to these safety guidelines, operators can enhance their protection and that of others while effectively utilizing the equipment.

Installing the Winch Properly

Ensuring a proper installation of your towing mechanism is crucial for optimal performance and safety. A well-executed setup enhances the functionality of the equipment, allowing for efficient operation during various tasks. This section outlines the essential steps and considerations for achieving a secure and effective installation.

Preparing for Installation

Before beginning the installation, gather all necessary tools and components. Review the installation manual thoroughly to understand specific requirements. It is advisable to work in a well-lit area with ample space to maneuver. Additionally, wearing safety gear is recommended to protect against potential hazards during the setup process.

Step-by-Step Installation Process

Start by securely mounting the equipment onto a suitable platform, ensuring that all bolts and fasteners are tight. Align the mechanism with the appropriate anchor points, and check for any obstructions that might interfere with operation. Once the initial setup is complete, connect the wiring harness as indicated in the manual, ensuring proper polarity to prevent damage. Finally, conduct a thorough inspection of all connections and components to confirm that everything is properly installed before operation.

Cleaning and Care Instructions

Maintaining the longevity and optimal performance of your equipment requires regular attention and proper care. By following a few essential guidelines, you can ensure that your machinery remains in excellent condition and functions efficiently over time.

Begin by routinely inspecting all components for any signs of wear, dirt, or corrosion. It is crucial to keep the exterior clean to prevent buildup that could hinder functionality. Use a soft cloth and mild detergent to wipe down surfaces, avoiding abrasive materials that may scratch the finish.

Additionally, check and lubricate moving parts regularly to reduce friction and enhance performance. Ensure that any protective covers or seals are in place and free from damage, as these play a vital role in safeguarding internal mechanisms from the elements.

Store the equipment in a dry, sheltered location when not in use to protect it from moisture and environmental factors. Following these simple yet effective practices will contribute significantly to the reliability and durability of your equipment.

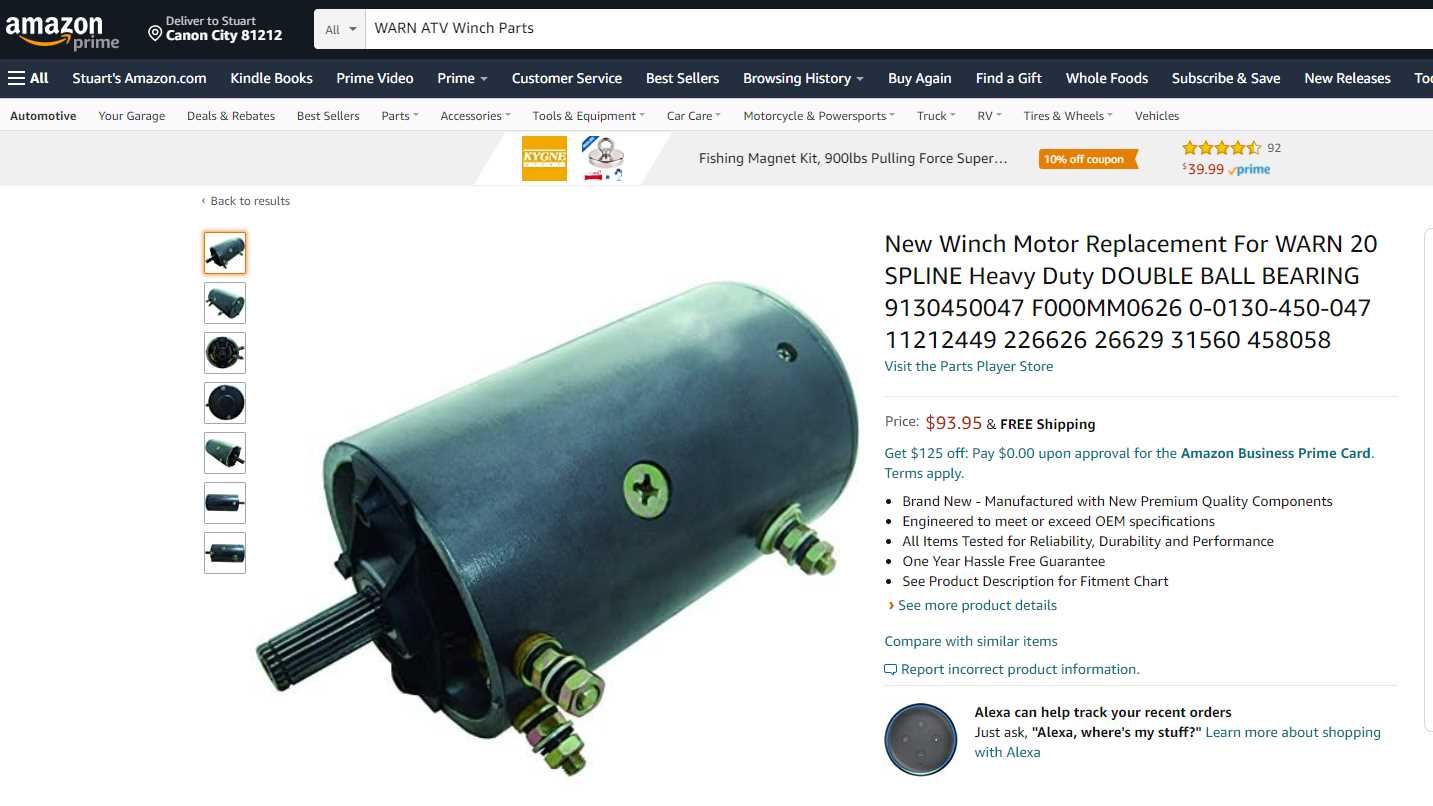

Replacement Parts Availability

Ensuring the availability of essential components is crucial for maintaining the functionality and performance of outdoor equipment. Users often seek reliable sources for acquiring these vital items, as the right replacements can significantly impact the longevity and efficiency of their devices. This section highlights various avenues for obtaining necessary components.

Authorized Dealers

One of the most dependable methods for sourcing components is through authorized dealers. These outlets typically offer genuine replacements, ensuring compatibility and quality. Additionally, they can provide expert advice regarding specific needs and compatibility.

Online Retailers

The rise of e-commerce has transformed the way users access essential items. Numerous online platforms provide a vast selection of replacements, often at competitive prices. Customers should verify the credibility of these retailers to ensure the authenticity of the components.

| Source | Benefits |

|---|---|

| Authorized Dealers | Genuine items, expert assistance |

| Online Retailers | Wide selection, competitive pricing |

| Local Shops | Immediate availability, community support |

| Second-hand Markets | Cost-effective options, unique finds |

Comparative Analysis with Other Models

This section delves into the evaluation of various systems in relation to similar devices available on the market. By examining key attributes such as performance, durability, and design, we can highlight significant differences and advantages that distinguish each model from one another. This analysis serves as a valuable resource for potential users seeking to make informed decisions based on their specific needs and preferences.

Performance Metrics

When assessing the efficiency of different systems, it’s essential to consider their power output, speed, and load capacity. These metrics vary significantly among competing models, impacting their overall usability in diverse environments. For instance, some systems may excel in rapid retrieval capabilities, while others focus on sustained strength for heavy-duty applications, making them suitable for various tasks.

Durability and Build Quality

The longevity and resilience of equipment play a crucial role in determining its reliability. Many models incorporate high-quality materials that resist wear and tear, ensuring consistent performance over time. A comparative review reveals how certain brands prioritize rugged construction, offering enhanced protection against environmental factors, thereby extending the life cycle of the equipment.