In the realm of heavy equipment, having a comprehensive overview of various elements is crucial for effective maintenance and repair. This section aims to provide an insightful look into the essential components that constitute machinery, enhancing understanding and facilitating informed decision-making for operators and technicians alike.

Identifying each element of a machine plays a significant role in ensuring its optimal performance. By familiarizing oneself with the intricate details and arrangement of these elements, one can easily recognize potential issues and address them promptly. This knowledge not only improves efficiency but also extends the lifespan of the equipment.

The visual representation of these components serves as a valuable resource. It simplifies the complex relationships between different parts, allowing users to navigate the intricacies of machinery with confidence. In this way, the information provided becomes an indispensable tool for anyone involved in the operation or maintenance of such equipment.

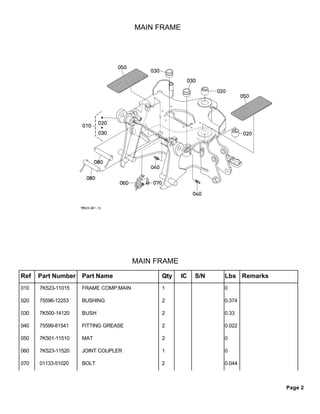

Parts Overview

This section provides a comprehensive look at the various components that make up the machinery. Understanding the different elements is crucial for effective maintenance and operation. Each part plays a significant role in ensuring optimal performance and longevity.

Below is a list of key components typically found in this type of equipment:

- Engine Assembly

- Hydraulic System

- Transmission Components

- Electrical System

- Frame and Chassis

Each of these categories contains several individual pieces that contribute to the overall functionality of the machine. Regular inspection and proper care of these elements are essential for seamless operation.

For efficient repairs or replacements, it’s advisable to consult the relevant manuals or schematics that provide detailed information on each component’s specifications and compatibility.

Importance of Accurate Parts Identification

Correctly recognizing components is crucial for effective maintenance and repair of machinery. Precision in identifying each element ensures optimal functionality and longevity of equipment.

When parts are accurately specified, it leads to several significant advantages:

- Efficiency: Knowing the exact specifications allows for quick sourcing and replacement, reducing downtime.

- Cost-effectiveness: Proper identification prevents unnecessary purchases and minimizes the risk of errors during installations.

- Performance: Using the right components enhances the overall performance and reliability of the equipment.

- Safety: Accurate identification helps in avoiding potential hazards that could arise from using incorrect or incompatible parts.

Furthermore, understanding the intricacies of each component promotes better decision-making when performing repairs or upgrades. It empowers operators and technicians with the knowledge to tackle issues confidently, fostering a more productive work environment.

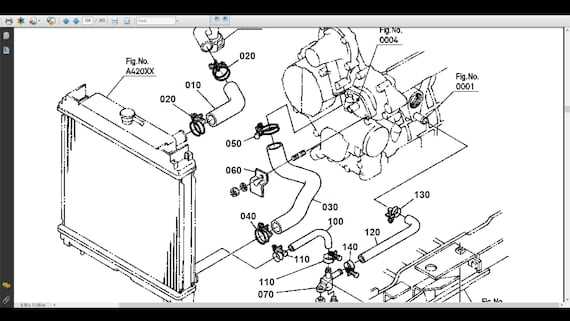

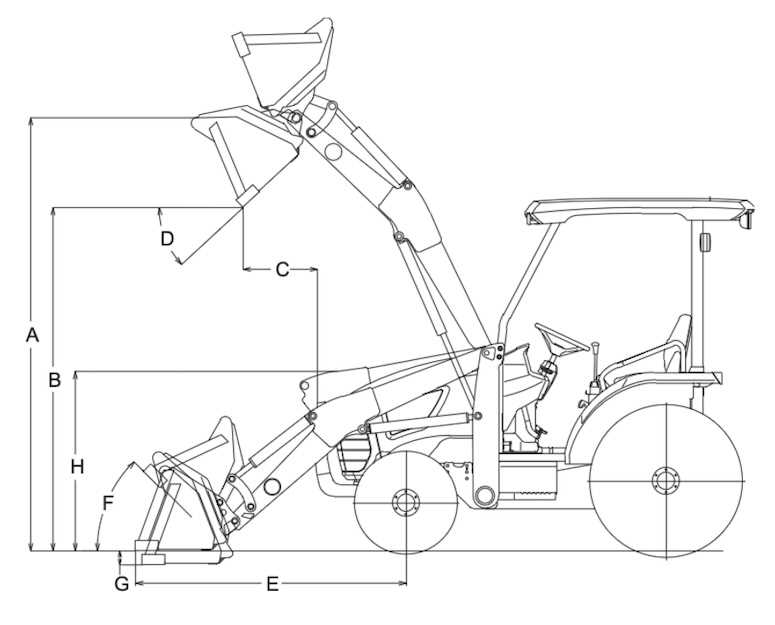

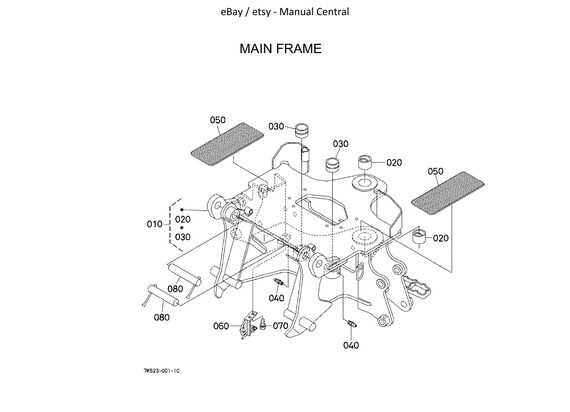

Understanding Kubota B26 System Layout

Comprehending the arrangement of components in a compact utility machine is crucial for effective maintenance and operation. This section provides insights into the various systems and their interconnections, enhancing the user’s familiarity with the equipment. A well-structured layout not only facilitates ease of access for repairs but also ensures optimal performance during operation.

Key Components and Their Functions

The functionality of any machinery relies on its core elements working harmoniously. Essential components include the hydraulic system, engine, and transmission. Each part plays a pivotal role, with the hydraulic system responsible for powering attachments, the engine providing the necessary energy, and the transmission ensuring smooth movement across different terrains. Understanding how these systems interact allows users to troubleshoot effectively and maintain the machine’s reliability.

Maintenance Considerations

Regular inspection of the system layout is vital for sustaining operational efficiency. Users should pay attention to fluid levels, filter conditions, and the integrity of hoses and belts. By recognizing the significance of each component and its place within the overall structure, operators can perform timely interventions, prolonging the life of the equipment and enhancing productivity.

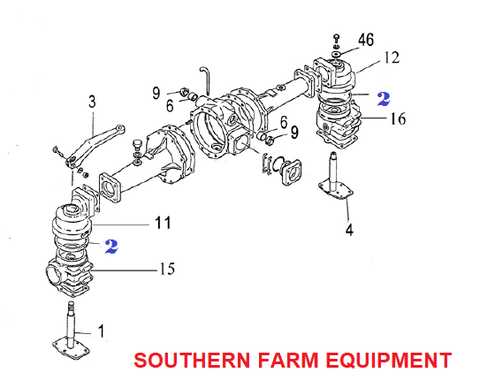

Common Components and Their Functions

This section aims to explore the various essential elements found in compact machinery and their respective roles. Understanding these components is crucial for ensuring optimal performance and maintenance of equipment.

One of the primary elements is the engine, which serves as the powerhouse, converting fuel into mechanical energy to drive the entire system. Coupled with the engine, the transmission plays a vital role in controlling the speed and torque, allowing for smooth operation under varying load conditions.

The hydraulic system is another significant aspect, providing the necessary force to operate attachments and perform tasks such as lifting and digging. It relies on fluid mechanics to transmit power efficiently.

Additionally, the electrical system, which includes the battery and wiring, is responsible for powering lights, sensors, and starting mechanisms, ensuring that all electronic components function effectively.

Finally, the chassis serves as the structural framework that supports all components, providing stability and durability during operation. Together, these parts contribute to the overall functionality and reliability of the machinery.

Locating the Parts Diagram Online

Finding a visual reference for machinery components can significantly enhance the repair and maintenance process. Numerous resources are available on the internet, providing detailed illustrations and information on the various elements of equipment. Utilizing these resources effectively can streamline tasks and ensure that the correct pieces are identified and sourced.

Utilizing Manufacturer Websites

One of the most reliable sources for component visuals is the official website of the manufacturer. Often, these sites offer comprehensive catalogs or interactive tools where users can search for specific models. By entering the equipment’s model number, users can access accurate images and descriptions that will aid in identifying necessary components.

Exploring Online Forums and Communities

Online communities and forums dedicated to machinery enthusiasts can also be valuable. These platforms frequently feature discussions, tips, and shared resources, including diagrams and illustrations contributed by other users. Engaging with these communities can provide additional insights and recommendations for locating specific visual guides.

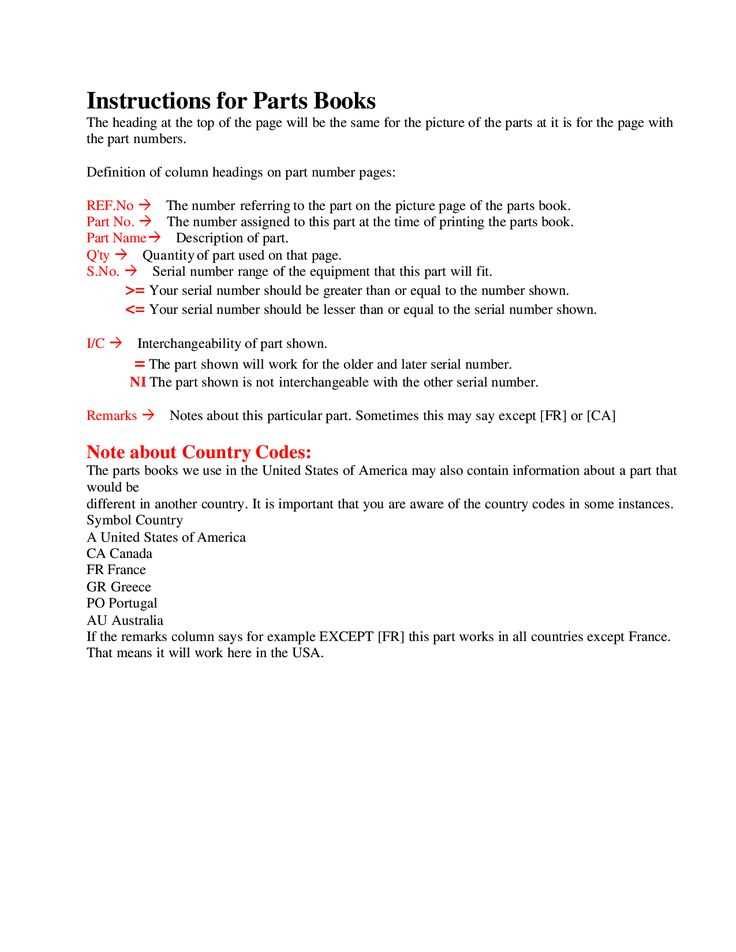

Interpreting the Parts Diagram Symbols

Understanding the symbols used in a component schematic is essential for effective maintenance and repair. These representations convey crucial information about various elements and their interconnections, enabling users to identify parts accurately. Familiarity with these symbols can significantly enhance the troubleshooting process and improve overall efficiency when working on machinery.

Common Symbolic Representations

The schematic often includes standard symbols that represent different types of components. For instance, circular shapes might indicate bearings, while squares may represent housings or brackets. It is vital to recognize these symbols to understand how each element functions within the system.

Decoding Connection Indicators

In addition to component symbols, connection indicators play a significant role in the interpretation of the schematic. Lines connecting different shapes denote relationships, such as mechanical linkages or hydraulic lines. By carefully examining these indicators, one can determine how components interact, facilitating a more efficient approach to repairs.

Essential Maintenance Parts for Kubota B26

Regular upkeep is vital for ensuring optimal performance and longevity of any machinery. Having the right components on hand not only simplifies the maintenance process but also enhances the efficiency of the equipment. Below are key elements that should be considered for routine servicing and care.

Critical Components

- Engine Oil Filter

- Air Filter

- Fuel Filter

- Hydraulic Fluid

- Battery

Maintenance Accessories

- Grease Gun

- Wrenches and Sockets

- Replacement Belts

- Safety Equipment

Ensuring access to these essential items will facilitate efficient maintenance procedures and contribute to the reliability of your machinery. Regular checks and timely replacements of these components can prevent unexpected breakdowns and enhance operational capabilities.

Aftermarket vs. OEM Parts Choices

When maintaining machinery, selecting components is crucial for ensuring optimal performance and longevity. Two primary options exist: original manufacturer components and alternative solutions. Understanding the advantages and disadvantages of each can guide users in making informed decisions that suit their specific needs and budgets.

Advantages of OEM Components

Original manufacturer solutions often guarantee compatibility and reliability. These components are designed to meet the precise specifications set by the original equipment producer, ensuring seamless integration. Users can expect superior performance and often a longer lifespan, backed by warranties provided by the manufacturer.

Benefits of Aftermarket Solutions

Alternative components can offer a cost-effective option for users. Many aftermarket products are designed to exceed original specifications, potentially enhancing performance. Additionally, these alternatives may provide a wider variety of choices, enabling users to select products that align better with their specific requirements.

| Aspect | OEM Components | Aftermarket Solutions |

|---|---|---|

| Compatibility | High | Variable |

| Cost | Higher | Lower |

| Warranty | Often provided | Variable |

| Performance | Reliable | Can exceed OEM |

Tips for Ordering Replacement Parts

When it comes to acquiring components for your machinery, ensuring the correct selection is crucial for optimal performance. Understanding the nuances of sourcing essential items can save both time and resources.

Begin by identifying the specific requirements for the components you need. Consult your equipment’s manual or documentation to gather details about the specifications and any unique characteristics necessary for compatibility.

Utilize reputable suppliers known for their reliability and quality. Researching customer reviews and testimonials can provide insights into their service levels and product authenticity. Establishing a relationship with a trusted vendor can also lead to better support and advice in future transactions.

When placing an order, double-check the information to avoid errors. Verify part numbers, descriptions, and quantities to ensure that you receive the correct items promptly. Keeping a record of previous purchases can also help streamline future orders.

Finally, consider the shipping options available. Some suppliers offer expedited delivery for urgent needs, while others may provide cost-effective solutions for non-urgent requests. Balancing speed and cost can enhance your overall experience in acquiring necessary components.

Common Issues with Kubota B26 Parts

In the realm of compact machinery, various components can experience challenges that affect performance and efficiency. Understanding these common problems can aid in timely maintenance and repair, ensuring the longevity of the equipment.

Frequent Problems

Several issues may arise from wear and tear or environmental factors. Components like hydraulic systems and electrical connections are particularly vulnerable. It’s crucial to regularly inspect these parts for signs of damage or malfunction.

Maintenance Tips

Regular upkeep can prevent many of the issues that arise with equipment components. Here are some essential maintenance tips:

| Component | Common Issue | Maintenance Tip |

|---|---|---|

| Hydraulic System | Fluid Leaks | Check seals and hoses regularly for wear. |

| Electrical System | Corroded Connections | Clean terminals and inspect wiring for damage. |

| Engine | Overheating | Ensure proper coolant levels and radiator cleanliness. |

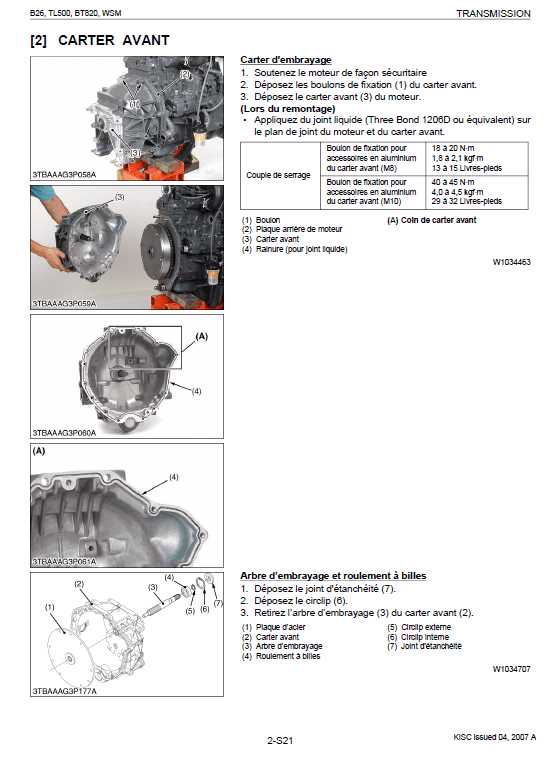

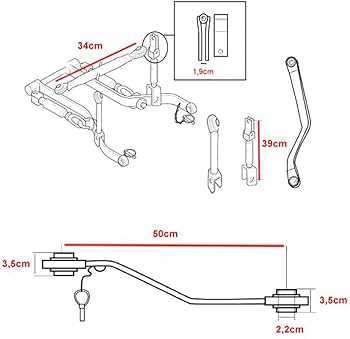

Visual Guide to Assembly and Disassembly

This section provides a comprehensive visual reference for effectively assembling and disassembling machinery components. By following the outlined steps, users can ensure a smooth process while minimizing the risk of damage to parts. Understanding the correct order and methods will enhance efficiency and prolong the lifespan of the equipment.

Step-by-Step Assembly Instructions

- Begin by gathering all necessary tools and components.

- Carefully inspect each element for any signs of wear or damage.

- Follow the designated sequence for assembling the parts, ensuring each connection is secure.

- Double-check all fastenings and joints for proper alignment.

Disassembly Procedure

- Start by disconnecting power sources and ensuring safety precautions are in place.

- Utilize the appropriate tools to remove each component methodically.

- Label each part as it is removed to facilitate reassembly.

- Store components in a safe location to prevent loss or damage.

Resources for Kubota B26 Repairs

When it comes to maintaining and fixing machinery, having access to the right resources is essential for ensuring efficiency and effectiveness. Numerous tools, manuals, and online platforms can aid in troubleshooting and repairing equipment, enabling users to achieve optimal performance.

Essential Tools and Equipment

- Wrenches and Sockets

- Screwdrivers of Various Sizes

- Diagnostic Tools

- Safety Gear

Helpful Online Platforms

- Forums and Community Groups

- Manufacturer’s Website for Manuals

- Video Tutorials on Repair Techniques

- Online Parts Retailers for Components

By utilizing these resources, users can enhance their understanding and capabilities in conducting repairs, ensuring their machinery remains in peak condition.

Frequently Asked Questions About Components

This section addresses common inquiries regarding the various elements used in machinery. Understanding these components is essential for effective maintenance and repair. Here, we provide clear answers to frequent questions to assist users in their endeavors.

What are the essential elements for machinery upkeep?

Key components for maintaining equipment include filters, belts, and hydraulic parts. Regular inspection and timely replacement of these items help ensure optimal functionality.

How can I identify the correct elements for my equipment?

To identify suitable components, consult the owner’s manual or an online resource that provides comprehensive information about compatible items. Cross-referencing with manufacturer specifications can also aid in making informed decisions.

| Component Type | Function | Replacement Frequency |

|---|---|---|

| Filters | Remove impurities from fluids | Every 100 hours of operation |

| Belts | Transmit power between moving parts | Check every 200 hours; replace if worn |

| Hydraulic Parts | Control fluid power for operation | Inspect annually; replace as needed |