In the realm of agricultural equipment, comprehending the intricate relationships between various components is essential for optimal functionality and maintenance. A thorough exploration of these elements not only enhances operational efficiency but also extends the lifespan of the machinery.

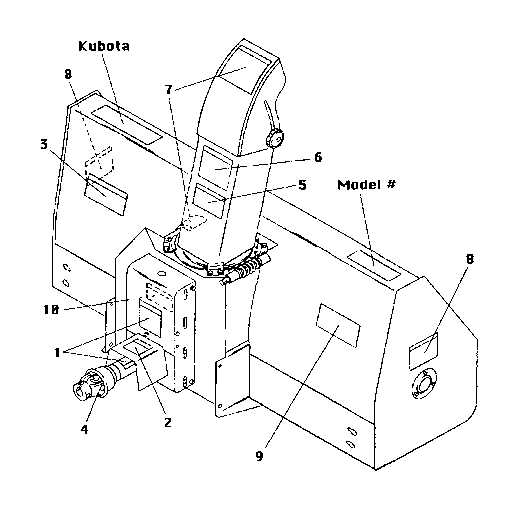

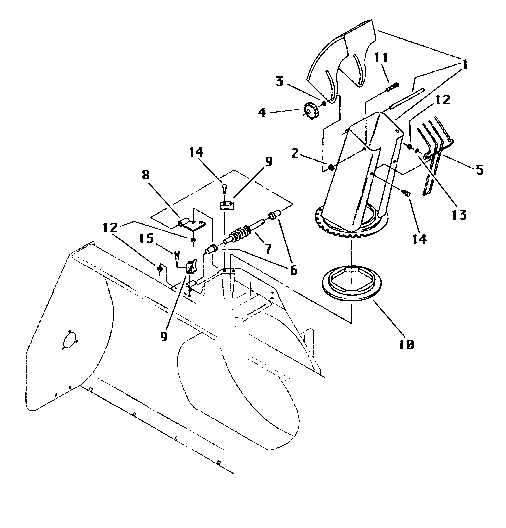

Visual representations of these assemblies provide valuable insights into their configurations and interconnections. By examining detailed illustrations, operators can easily identify each element and understand its role within the system.

This knowledge empowers users to perform accurate repairs and replacements, ensuring that their machines remain in peak condition. Furthermore, delving into the specifics of these structures allows for a more informed approach to upgrades and modifications, leading to enhanced performance and productivity.

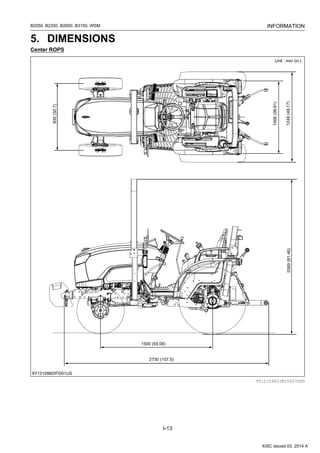

Kubota B2650 Overview

This section provides a comprehensive look at a compact yet powerful machine designed for versatility and efficiency. Ideal for various tasks, it combines advanced engineering with user-friendly features, making it suitable for both professional and personal use.

Key Features

The equipment is equipped with a robust engine that delivers impressive performance. Its ergonomic design ensures comfort during operation, while intuitive controls enhance usability. Additionally, a variety of attachments can be utilized to maximize functionality.

Applications

From landscaping to agricultural tasks, this model excels in multiple applications. Its adaptability allows users to tackle a range of projects, making it a valuable asset for those in need of reliability and strength.

Importance of Parts Diagrams

Understanding the assembly and components of machinery is crucial for effective maintenance and repair. Visual representations that detail the various elements of equipment provide users with a comprehensive view of how each part interacts with the whole. This clarity not only aids in troubleshooting but also enhances the efficiency of service tasks.

Enhanced Troubleshooting

When issues arise, having a clear visual reference can significantly expedite the diagnostic process. By pinpointing specific components, technicians can quickly identify potential problems, minimizing downtime. The ability to see how elements fit together allows for a systematic approach to repairs.

Effective Maintenance Planning

Regular upkeep is essential for longevity and optimal performance. Visual aids serve as a guide for routine checks and replacements. By highlighting critical areas that require attention, these illustrations ensure that users can prioritize their maintenance efforts, ultimately prolonging the life of the equipment.

Main Components of the B2650

This section explores the fundamental elements that constitute the machinery, focusing on their functionality and significance in overall performance. Understanding these components can enhance maintenance and operational efficiency.

Engine and Transmission

The power unit and its transmission system are vital for effective functioning. The engine provides the necessary force, while the transmission ensures smooth power delivery to the wheels.

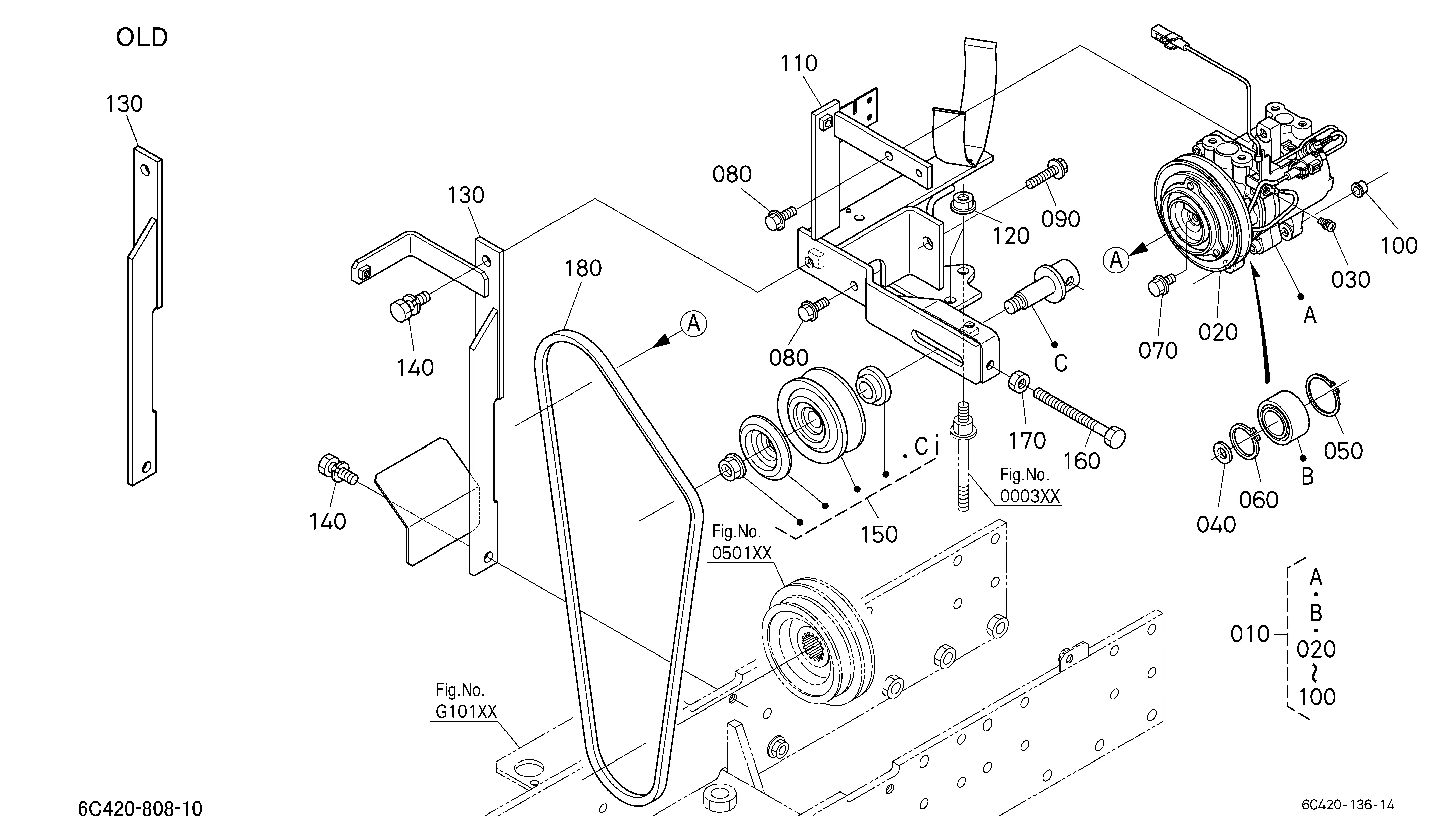

Hydraulic System

The hydraulic system plays a crucial role in powering attachments and assisting in lifting operations. Its design allows for efficient fluid movement, enabling a range of tasks.

| Component | Function |

|---|---|

| Engine | Generates power for operation |

| Transmission | Transfers engine power to wheels |

| Hydraulic Pump | Drives hydraulic attachments |

| Chassis | Supports all components |

Understanding the Hydraulic System

The hydraulic system plays a crucial role in the functionality of heavy machinery, providing the necessary power to operate various attachments and perform tasks efficiently. This complex network relies on fluid dynamics to transmit force, allowing for smooth and effective movement in different components.

Key elements of this system include pumps, cylinders, and valves, each contributing to the overall performance. Below is a table summarizing these components:

| Component | Function |

|---|---|

| Pump | Generates hydraulic pressure by moving fluid through the system. |

| Cylinder | Converts hydraulic energy into mechanical force for movement. |

| Valve | Controls the flow and direction of hydraulic fluid within the system. |

Understanding these components is essential for maintenance and troubleshooting, ensuring optimal operation of the machinery.

Engine Specifications and Features

This section delves into the intricate details and characteristics of the engine, highlighting its capabilities and technological advancements. Understanding these aspects is crucial for assessing performance and maintenance needs.

Technical Specifications

- Type: Diesel engine, four-stroke

- Cylinder Configuration: Inline, typically with four cylinders

- Displacement: Approximately 1.5 liters

- Power Output: Ranges around 25 to 30 horsepower

- Torque: Peak torque available at lower RPMs for enhanced efficiency

Key Features

- Fuel Efficiency: Designed for optimal fuel consumption, reducing operating costs.

- Emissions Control: Equipped with advanced systems to minimize environmental impact.

- Cooling System: Features a robust cooling mechanism to ensure reliable operation.

- Noise Reduction: Engine design includes noise-dampening technology for quieter performance.

- Durability: Constructed with high-quality materials to withstand rigorous usage.

Transmission System Explained

The transmission system is a crucial component of any vehicle, responsible for transferring power from the engine to the wheels. It enables the operator to control speed and torque, ensuring optimal performance under various conditions. Understanding its structure and function is essential for maintenance and troubleshooting.

Components of the Transmission

The primary elements include gears, shafts, and clutches. Gears adjust the output speed and torque, while shafts transmit the power generated by the engine. Clutches facilitate smooth engagement and disengagement, allowing for seamless gear changes.

Types of Transmission Systems

There are several varieties, including manual, automatic, and continuously variable transmissions (CVTs). Manual systems require the driver to shift gears, providing greater control. In contrast, automatic transmissions manage gear changes independently, enhancing ease of use. CVTs offer a smooth transition between gear ratios, optimizing fuel efficiency.

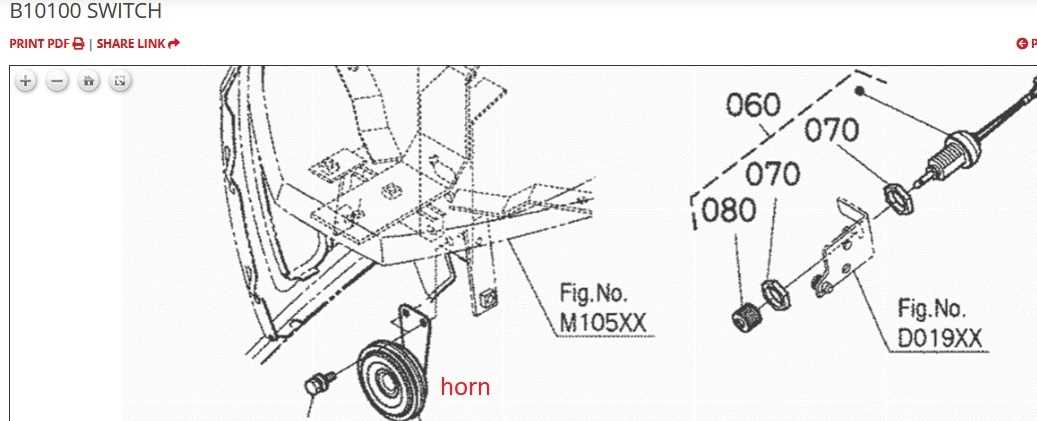

Electrical System Breakdown

The electrical framework of any machinery is crucial for its operation and efficiency. This segment will explore the essential components that constitute the electrical network, ensuring seamless functionality and reliability. Understanding this system not only aids in maintenance but also enhances the overall performance of the equipment.

Key Components

At the heart of the electrical system lies the battery, which serves as the primary power source. It supplies the necessary voltage to start the engine and powers various accessories. Coupled with the battery, the alternator plays a vital role by converting mechanical energy into electrical energy, ensuring that the battery remains charged during operation.

Wiring and Connections

The network of wires and connectors is indispensable, facilitating the flow of electricity throughout the system. Proper insulation is essential to prevent short circuits and ensure safety. Each wire is carefully routed to connect different components, such as lights, sensors, and control units, enabling them to function effectively. Regular inspections of these connections can prevent potential failures and extend the lifespan of the electrical system.

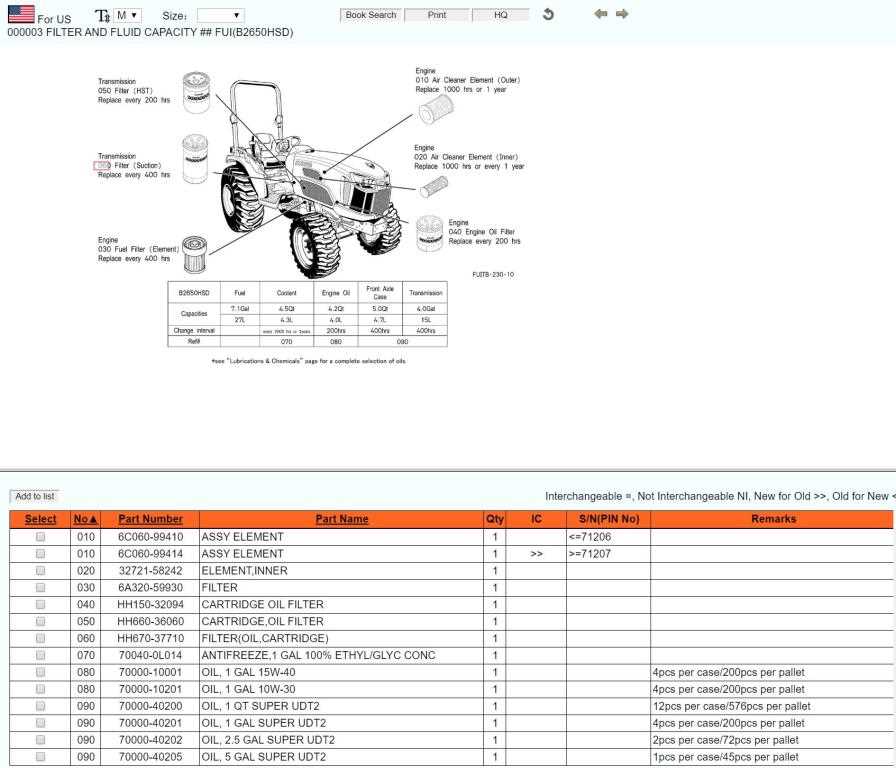

Common Maintenance Parts

Regular upkeep of machinery is essential to ensure optimal performance and longevity. Certain components play a crucial role in maintaining the efficiency and reliability of equipment. Familiarizing oneself with these vital elements can aid in timely replacements and service.

Filters are among the most frequently replaced items. They serve to keep fluids clean, preventing contaminants from causing damage to internal components. Oil filters, air filters, and fuel filters should be checked and replaced as per the manufacturer’s recommendations.

Another key aspect of maintenance involves belts. These components transfer power and motion between various parts of the machine. Inspecting them for wear and proper tension is crucial to avoid unexpected breakdowns.

Fluids are the lifeblood of any machinery. Regular checks and changes of engine oil, hydraulic fluid, and coolant are necessary to ensure smooth operation and to prevent overheating or other issues.

Lastly, batteries should not be overlooked. Maintaining a clean and fully charged battery is vital for reliable starts and operation, especially in colder climates.

By keeping a close eye on these essential components, one can ensure the machinery remains in peak condition, ready to tackle any task at hand.

Finding OEM vs Aftermarket Parts

When it comes to sourcing components for machinery, understanding the differences between original equipment and alternative options is crucial. Each choice comes with its own set of benefits and drawbacks that can significantly affect performance and maintenance.

Original equipment manufacturers (OEM) provide parts that are designed specifically for your machine. Here are some key advantages:

- Precision engineering for optimal fit and function

- Guaranteed quality and reliability

- Manufacturer warranty protection

On the other hand, aftermarket options can offer various benefits as well:

- Cost savings compared to OEM alternatives

- Wider variety of options and suppliers

- Potential for enhanced performance features

Ultimately, the decision between OEM and aftermarket components depends on your specific needs, budget, and the level of performance you desire. Delving into reviews and expert recommendations can help guide your choice effectively.

Diagram Navigation Tips

Navigating through complex illustrations can be daunting, but with the right strategies, you can enhance your understanding and efficiency. Familiarizing yourself with the layout and identifying key components will streamline your experience and help you locate essential elements quickly.

Understanding the Layout

Before diving in, take a moment to assess the overall structure. Many illustrations are divided into sections, each representing a specific area. Recognizing these sections allows for targeted exploration.

Utilizing a Reference Table

A reference table can greatly aid in locating components. Below is an example layout for better clarity:

| Component | Location |

|---|---|

| Engine Assembly | Top Right Section |

| Transmission | Bottom Left Section |

| Hydraulic System | Center Section |

Identifying Wear and Tear

Recognizing the signs of deterioration is crucial for maintaining the efficiency and longevity of your machinery. Regular inspections can help spot issues before they escalate, ensuring smooth operation and reducing the risk of costly repairs. Understanding the common indicators of wear can aid in timely interventions and promote optimal performance.

Common Signs of Wear

- Cracks and Fractures: Look for visible cracks on components, which can indicate material fatigue.

- Rust and Corrosion: Check for any rust spots or corrosion, particularly on metal parts, as these can compromise integrity.

- Excessive Play: Notice any excessive movement in joints or connections that should remain tight.

- Fluid Leaks: Monitor for any leaks, which may suggest seals or gaskets are failing.

- Unusual Noises: Listen for abnormal sounds during operation that may signal internal damage.

Routine Maintenance Practices

- Conduct regular visual inspections to catch early signs of deterioration.

- Keep a maintenance log to track wear patterns over time.

- Replace worn components promptly to prevent further damage.

- Utilize quality lubricants to reduce friction and wear.

- Consult with professionals for detailed assessments when needed.

Assembly and Disassembly Guide

This section provides a comprehensive overview of the procedures involved in the assembly and disassembly of agricultural machinery components. Understanding these processes is crucial for maintaining optimal performance and ensuring safety during repairs or modifications.

Preparation is essential before starting any assembly or disassembly task. Gather all necessary tools and ensure a clean workspace to avoid losing small parts. Refer to the manufacturer’s documentation for specific instructions relevant to the components you are working with.

When dismantling equipment, follow a systematic approach. Begin by disconnecting power sources and removing any attachments. Take care to label components and fasteners to facilitate reassembly. Use appropriate lifting techniques to handle heavy parts safely.

During the assembly phase, start by aligning components as specified in the guidelines. Ensure all parts are clean and free of debris before securing them in place. Gradually tighten fasteners in a crisscross pattern to distribute pressure evenly, which helps prevent warping or damage.

Finally, conduct a thorough inspection of the reassembled machinery to confirm that everything is functioning correctly. This step is vital for identifying potential issues before putting the equipment back into service.

Resources for Additional Information

For those seeking to enhance their understanding and access to technical materials, a variety of resources are available. These can include manuals, online forums, and manufacturer websites that provide detailed insights and specifications. Utilizing these tools can significantly aid in troubleshooting and maintenance processes.

Online platforms often host communities where users share experiences and solutions, making them valuable for both novices and experienced individuals. Additionally, official websites may offer downloadable resources such as guides and FAQs, which can be instrumental in finding specific details about components and systems.

Moreover, local dealers and service centers can serve as reliable sources for personalized assistance and recommendations. They can provide insights tailored to particular needs, ensuring that users receive the most accurate information for their specific situation.