The intricate assembly of machinery often requires a clear understanding of its internal structures and their functions. By exploring detailed illustrations, it becomes easier to navigate through the complex system of interconnected elements, ensuring each part is identified and maintained correctly.

This guide offers a structured insight into how various mechanical elements are positioned and interact with one another. Whether you’re performing maintenance or simply curious about how the system operates, a well-organized layout of components is key to efficient operation and long-term durability.

By familiarizing yourself with the internal arrangement, you can more effectively manage both routine inspections and potential repairs. Accurate representation of each element and its connection to others helps prevent common missteps, making this an invaluable tool for anyone dealing with complex equipment.

Overview of the Kubota B7100 HST Model

This compact utility machine is renowned for its reliability and versatility in various agricultural and landscaping tasks. Built with efficiency in mind, it offers a powerful yet easy-to-manage experience, making it suitable for both small and large-scale operations. The model stands out for its smooth performance, allowing operators to handle different terrains and tasks with minimal effort.

Key Features

Engineered for ease of use, this machine comes equipped with advanced components designed to improve productivity. Its robust design ensures that it can withstand heavy-duty work while maintaining user comfort. Key elements include a responsive transmission system, durable frame, and intuitive controls that make operating the machine straightforward for all experience levels.

Technical Specifications

| Feature | Description |

|---|---|

| Transmission Type | Hydrostatic drive, offering smooth transitions and control. |

| Engine Power | Designed for optimal output, suitable for diverse tasks. |

| Weight | Balanced for both stability and mobility. |

| Tire Configuration | Optimized for traction on varying surfaces. |

Main Components and Functions

The functionality of a compact utility vehicle relies on the effective coordination of various critical systems. These systems work together to ensure efficient operation, whether in the field or during more demanding tasks. Understanding the role and purpose of each system provides insights into the machine’s overall performance and capabilities.

Engine and Transmission

The engine serves as the powerhouse, providing the necessary torque and power for all operations. Paired with the transmission system, it allows for smooth control over speed and maneuverability. The connection between these two components is vital for adapting to different workloads and terrains.

Hydraulic and Electrical Systems

The hydraulic system plays an important role in controlling various mechanical movements, such as lifting attachments or steering. The electrical system ensures that

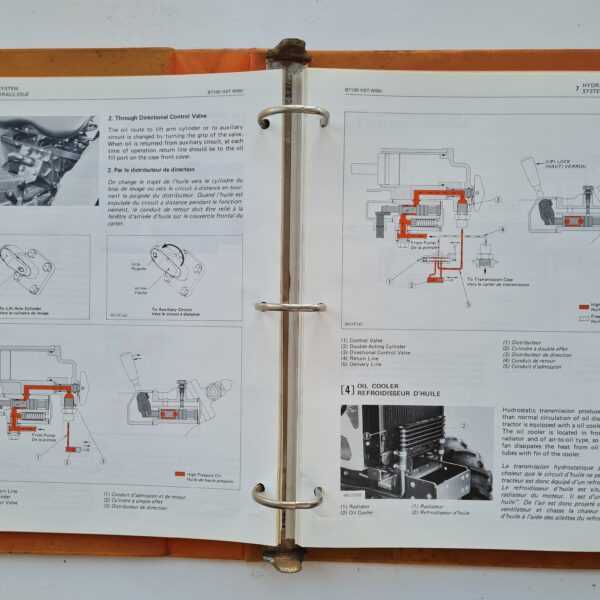

Understanding the Hydraulic System of the B7100 HST

The hydraulic mechanism of this compact machine plays a crucial role in its operation, enabling various essential functions. By converting mechanical energy into fluid power, it allows for precise control and movement of different components, making it highly efficient in handling tasks. This system is integral to both the power steering and lifting functions, ensuring smooth and consistent performance under varying conditions.

Key Components of the Hydraulic System

The system consists of several vital parts that work in harmony to deliver fluid pressure where it’s needed. A pump drives the flow of hydraulic fluid, which is directed through valves that regulate the pressure and flow. These valves control how much fluid reaches the actuators, which then perform the desired mechanical movements. Proper maintenance of these elements is essential for the longevity and efficiency of the equipment.

Importance of Fluid Maintenance

The hydraulic system relies heavily on the quality of the fluid it uses. Regular checks of fluid levels and ensuring its cleanliness are critical to prevent

Key Parts and Their Roles

Understanding the primary components of any machine is essential for ensuring proper maintenance and optimal performance. Each element plays a specific function, contributing to the overall operation of the equipment. By familiarizing yourself with these key elements, you can identify potential issues early and maintain the smooth functioning of the system.

The engine serves as the powerhouse, converting fuel into mechanical energy. This energy drives various other systems, including the transmission, which regulates speed and torque. The cooling system ensures that temperatures remain within safe limits, preventing overheating during extended use.

Another critical component is the hydraulic system, which provides the necessary pressure to lift and control attachments. The electrical system, responsible for powering lights and other electronic functions, relies on a network of wires and connections to distribute power efficiently. Lastly, proper lubrication ensures that all moving parts function smoothly, reducing friction and wear over time.

Engine Configuration in the Kubota B7100 HST

The power unit in this compact utility model is a robust and reliable piece of machinery designed for efficiency and durability. Its layout is centered around maximizing performance while ensuring ease of maintenance. With a focus on simple, yet effective design, this engine supports a variety of tasks, offering consistent output and longevity in demanding conditions.

| Engine Type | 3-cylinder, liquid-cooled |

|---|---|

| Displacement | Approximately 0.7 liters |

| Power Output | Around 16 horsepower |

| Cooling System | Liquid cooling for enhanced thermal management |

| Fuel Type | Diesel, known for its efficiency and durability |

| Starter System | Electric, providing reliable engine ignition |

The engine is compact but designed to deliver steady power output, making it ideal for tasks that require a balance of force and fuel economy. Its configuration ensures that operators can handle a wide range of agricultural and light construction jobs efficiently, with the motor delivering the necessary torque for challenging tasks.

Core Elements and Structure

The essential components and their arrangement play a crucial role in the overall functionality of machinery. Understanding these elements is vital for maintenance, repair, and efficient operation. This section delves into the fundamental aspects that comprise the framework, ensuring optimal performance and longevity.

Fundamental Components

At the heart of any machinery lie various integral units that work in harmony to deliver power and efficiency. These units can include engines, transmissions, and hydraulic systems, each designed to perform specific functions. Recognizing the importance of each component enables users to troubleshoot issues effectively and optimize operational capabilities.

Structural Arrangement

The configuration of these elements is equally important, as it determines the overall dynamics of the system. Proper alignment and connectivity between components ensure seamless interaction, reducing the risk of malfunction. Maintenance of these connections is essential, as it promotes a reliable and efficient operational environment. Understanding the structural layout aids in identifying potential weaknesses and enhances overall performance.

Transmission System Layout in the B7100 HST

This section delves into the configuration of the propulsion mechanism in a specific compact utility vehicle. Understanding the layout of this system is crucial for maintaining optimal performance and ensuring smooth operation. The design incorporates various components that work in tandem to transmit power efficiently from the engine to the wheels, facilitating enhanced maneuverability and control.

Key Components of the Propulsion Mechanism

The assembly consists of several essential elements, each playing a vital role in the overall function. These components include gears, shafts, and various linkages that connect the engine output to the driving wheels. Their precise arrangement ensures that power is delivered effectively, allowing for seamless acceleration and deceleration.

Overview of the Configuration

The transmission setup is designed for both durability and ease of service. By organizing the elements strategically, engineers have created a system that minimizes wear while maximizing efficiency. Below is a table summarizing the primary components and their functions within this system:

| Component | Function |

|---|---|

| Transmission Gears | Regulate power transfer and speed adjustment |

| Input Shaft | Connects the engine to the transmission |

| Output Shaft | Delivers power to the wheels |

| Linkages | Facilitate gear shifting and control |

How the Hydrostatic Mechanism Works

The hydrostatic system operates by using fluid pressure to transmit power and control movement. This innovative approach allows for smooth acceleration and precise control of machinery, making it an essential component in various applications.

At its core, the mechanism consists of a pump and a motor, which work together to convert mechanical energy into hydraulic energy and back. When the pump is engaged, it generates a flow of hydraulic fluid, which is then directed to the motor. This flow creates pressure that causes the motor to rotate, driving the wheels or other components of the equipment.

The speed and direction of movement can be easily adjusted by changing the flow rate of the hydraulic fluid. By manipulating the control lever, operators can achieve a wide range of speeds and responsiveness, enhancing overall efficiency and performance.

Additionally, the hydrostatic mechanism is designed to provide smooth transitions between forward and reverse motions. This feature is particularly advantageous in tight spaces, allowing operators to maneuver with precision without the need for complex gear shifting.

In summary, the hydrostatic mechanism offers a versatile and efficient means of powering machinery. Its reliance on fluid dynamics not only simplifies operation but also improves the overall handling and control of equipment.

Exploring the Electrical Wiring Setup

Understanding the electrical configuration of machinery is crucial for optimal performance and maintenance. A well-organized wiring system ensures that all components operate seamlessly and helps diagnose any issues that may arise. This section delves into the essential elements of the electrical setup, emphasizing its significance and functionality.

The wiring setup consists of various components that work together to power the machine and facilitate communication between parts. Key elements include:

- Battery: The primary source of power, supplying energy to start the engine and run electrical accessories.

- Ignition System: Responsible for igniting the fuel-air mixture, ensuring the engine starts efficiently.

- Wiring Harness: A bundle of wires that connect different electrical parts, streamlining the electrical connections throughout the machinery.

- Fuses: Protective devices that prevent electrical overloads and short circuits by interrupting the flow of current when necessary.

- Switches and Relays: Control mechanisms that enable the user to manage various functions and components effectively.

To ensure the reliability of the electrical wiring system, it is essential to regularly inspect connections for signs of wear, corrosion, or damage. Proper maintenance will enhance the longevity and efficiency of the equipment.

In summary, a comprehensive understanding of the electrical configuration is vital for effective operation and troubleshooting. By familiarizing oneself with the fundamental components and their functions, users can ensure their machinery runs smoothly and efficiently.

Critical Circuits and Their Locations

Understanding the essential pathways that facilitate the functioning of machinery is vital for effective maintenance and troubleshooting. These circuits serve as the backbone of operation, ensuring that various components communicate efficiently and perform their designated tasks. Recognizing the locations of these circuits can significantly enhance repair processes and overall equipment longevity.

Power Distribution Network

The power distribution network is a fundamental component, supplying electrical energy to various systems. This circuit is typically situated near the main control unit, making it easily accessible for inspections and modifications. Proper maintenance of this network is crucial, as any disruption can lead to malfunctioning of vital machinery parts.

Hydraulic Control Circuit

The hydraulic control circuit is responsible for the operation of fluid-based systems within the equipment. Located near the hydraulic pump, this circuit allows for the efficient transfer of hydraulic fluid, enabling various functions such as lifting and steering. Regular checks on this area can help prevent leaks and ensure optimal performance.

Fuel System Overview in the B7100 HST

The fuel delivery mechanism is essential for the efficient operation of any engine. In this context, it plays a crucial role in ensuring that the combustion process is optimal, thereby enhancing performance and reliability. Understanding the various components and their functions within this system provides valuable insight into maintaining and troubleshooting the machine.

At the heart of the system lies the fuel tank, which stores the necessary liquid. Fuel is then transported through a series of lines to the fuel filter, designed to remove impurities and particulates that could affect engine performance. Following filtration, the refined fuel is directed towards the fuel pump, which is responsible for delivering it at the required pressure.

Once the fuel reaches the engine, it enters the injection system, where it is atomized and mixed with air for efficient combustion. The timing and quantity of the fuel injected are critical for maintaining optimal engine operation, influencing both power output and fuel efficiency. Regular inspection and maintenance of each component within this system are vital for ensuring the longevity and effectiveness of the machine.

In summary, the delivery and management of fuel directly impact the performance of the engine. Awareness of the different elements that comprise this system not only aids in effective maintenance but also contributes to improved operational efficiency.

Main Components and Flow Dynamics

This section delves into the essential elements and their interactions within the system, highlighting the intricate relationships that govern performance and efficiency. Understanding these components is crucial for maintaining optimal functionality and addressing any operational issues that may arise.

Key Elements

Each major component plays a vital role in the overall operation, contributing to the seamless flow of power and control throughout the machinery. Recognizing the purpose and function of each part can facilitate better troubleshooting and maintenance practices.

Flow Mechanism

The movement of fluid through the system is essential for effective performance. Analyzing the flow dynamics provides insights into how energy is transferred and utilized, ensuring that the equipment operates within its intended parameters.

| Component | Function |

|---|---|

| Power Unit | Generates energy for operation |

| Transmission System | Transmits power to the wheels |

| Fluid Reservoir | Stores hydraulic fluid for circulation |

| Control Valves | Regulate fluid flow and pressure |

| Actuators | Convert hydraulic energy into mechanical movement |

Cooling System Structure and Components

The cooling mechanism plays a vital role in maintaining optimal operating temperatures within machinery. It prevents overheating, which can lead to severe damage and decreased efficiency. Understanding the layout and individual elements of this system is essential for effective maintenance and troubleshooting.

Key Elements of the Cooling Mechanism

This system consists of several critical components that work together seamlessly. The primary elements include a radiator, coolant reservoir, water pump, and various hoses. Each part has a specific function, contributing to the overall efficiency of the cooling process.

Functionality and Importance

The radiator serves as the main heat exchanger, dissipating heat away from the engine. The coolant reservoir maintains an adequate level of liquid for circulation, while the water pump ensures consistent flow throughout the system. Regular maintenance of these components is crucial for preventing overheating and ensuring optimal performance.