In the realm of machinery, having a clear understanding of the arrangement and functionality of engine components is essential. This knowledge not only aids in efficient maintenance but also enhances the overall performance of the equipment. A well-structured reference guide can serve as an invaluable resource for operators and technicians alike.

Visual representations of various engine elements offer a detailed perspective on their interconnections and roles within the system. Such illustrations can simplify complex assemblies, allowing users to identify specific parts quickly. Whether you are troubleshooting issues or planning maintenance, these resources are designed to provide clarity and support effective repairs.

Utilizing comprehensive visual guides ensures that users can approach their tasks with confidence. Familiarity with each element’s position and purpose promotes a deeper understanding of how the entire system operates. This foundational knowledge is crucial for anyone looking to optimize their machinery’s efficiency and longevity.

The engine model in question is designed for optimal performance and reliability in various applications. It offers a range of distinctive attributes that enhance its functionality, making it suitable for numerous tasks.

Performance and Efficiency

This engine is known for its impressive power output and fuel efficiency. Its advanced engineering ensures that it operates smoothly under different conditions, providing reliable performance.

- High torque for improved operational efficiency

- Low fuel consumption rate

- Durable construction for extended lifespan

Compact Design

The design of this engine model emphasizes space-saving features while maintaining robust capabilities. Its compact nature allows for easy installation in various machinery.

- Lightweight structure for better maneuverability

- Optimized dimensions for versatile application

- Simple integration with different systems

Specifications and Performance Metrics

This section provides a comprehensive overview of the technical characteristics and operational efficiency of the engine. Understanding these details is essential for evaluating the functionality and capabilities of the machinery.

- Engine Type: Four-stroke, water-cooled diesel engine

- Cylinder Arrangement: Inline configuration

- Displacement: Approximately 0.9 liters

- Power Output: Typically rated around 20 to 25 horsepower

- Torque: Maximum torque achieved at low RPM for effective performance

- Fuel System: Direct injection for enhanced efficiency

Performance metrics highlight the efficiency and reliability of the engine in various operational conditions. Key metrics include:

- Fuel Consumption: Efficient fuel usage ensures extended operational periods

- Emissions: Designed to comply with environmental regulations, minimizing harmful outputs

- Noise Level: Engine operates within acceptable noise limits for improved user comfort

- Maintenance Intervals: Regular maintenance schedules promote longevity and reliability

These specifications collectively illustrate the robustness and adaptability of the engine, making it suitable for a variety of applications in different environments.

Parts Identification for D905

Understanding the components of a specific engine model is essential for effective maintenance and repair. Identifying each element accurately ensures that the correct replacements can be sourced, leading to optimal performance and longevity of the machinery. This section provides guidance on recognizing the key features of the engine in question, helping users navigate the various components efficiently.

| Component Name | Description |

|---|---|

| Cylinder Head | The upper part of the engine that houses the valves and combustion chamber. |

| Fuel Injector | Responsible for delivering fuel into the combustion chamber in a fine mist. |

| Crankshaft | A key rotating shaft that converts linear motion into rotational motion. |

| Oil Filter | Filters impurities from the engine oil, ensuring clean lubrication. |

| Air Cleaner | Prevents dirt and debris from entering the engine, promoting efficient airflow. |

Commonly Replaced Components

In machinery maintenance, certain elements often require replacement due to wear and tear or performance issues. Understanding which components typically need attention can significantly enhance operational efficiency and extend the life of the equipment.

One of the frequently changed items is the fuel filter, which ensures that impurities do not enter the engine, thereby maintaining optimal performance. Additionally, the air filter is crucial for proper airflow, and replacing it regularly can prevent overheating and improve fuel efficiency.

Another essential component is the oil filter, which plays a vital role in keeping the engine lubricated and functioning smoothly. Over time, seals and gaskets can deteriorate, leading to leaks and decreased performance; hence, replacing these is a common maintenance task.

Belts and hoses are also often replaced due to their susceptibility to wear from heat and mechanical stress. Ensuring these parts are in good condition is critical for maintaining the overall functionality of the machinery.

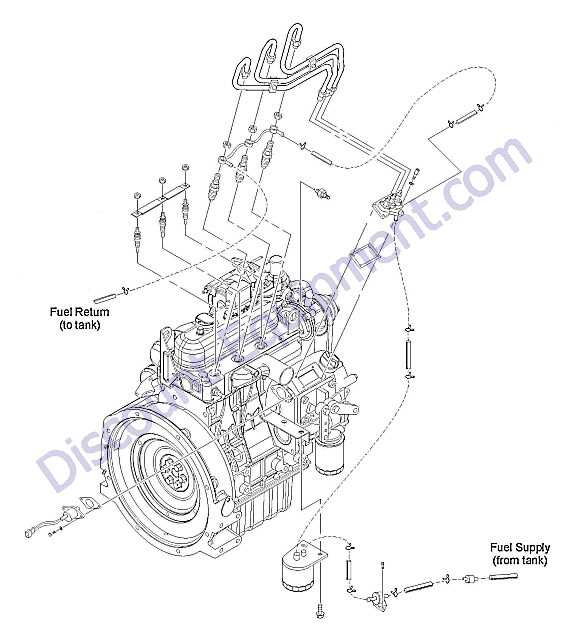

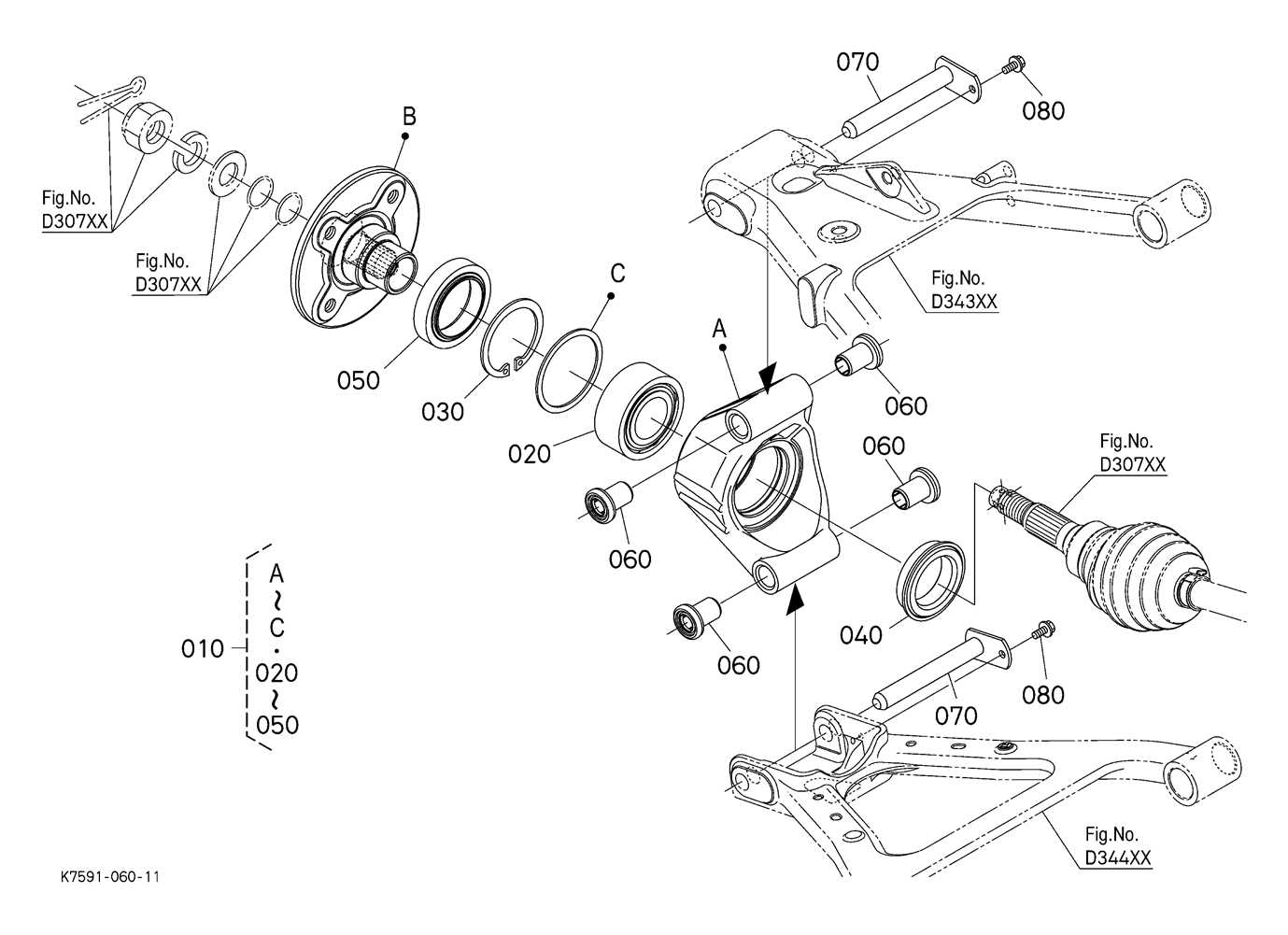

Visual Representation of Parts

This section provides an illustrative overview of various components associated with the equipment. Such visual aids facilitate a clearer understanding of how different elements interact within the system, enhancing comprehension and usability for operators and technicians alike.

Detailed illustrations serve as a valuable resource for identifying each element’s function and position, allowing users to quickly locate and assess components during maintenance or repairs. By referencing these visual guides, individuals can improve their efficiency in troubleshooting and servicing tasks.

Furthermore, these representations can assist in the learning process, especially for those new to the machinery. Having a clear image of the layout and function of each part supports knowledge retention and helps users become more familiar with the equipment’s overall design.

Analyzing the Parts Diagram

Understanding the layout of components is essential for efficient maintenance and repair of machinery. A detailed representation of the individual elements offers insights into their arrangement and interconnection. By studying this visual guide, operators can identify crucial parts and their respective functions, ensuring that they have the necessary information for effective troubleshooting and replacement tasks.

Importance of Component Identification

Accurate identification of each element allows for streamlined repairs and minimizes downtime. Familiarity with the configuration not only aids in recognizing potential issues but also enhances the overall efficiency of maintenance procedures. This knowledge empowers operators to make informed decisions when it comes to service or replacement, ultimately leading to improved performance and longevity of the equipment.

Utilizing the Visual Representation

When examining the visual representation, it is beneficial to focus on the relationships between various elements. Recognizing how components interact can lead to better troubleshooting strategies. Furthermore, this approach encourages a proactive mindset, where potential problems can be anticipated and addressed before they escalate, ensuring smooth operation and reliability.

Maintenance Tips for D905 Engine

Ensuring the longevity and optimal performance of your engine requires regular upkeep and careful attention. By following a structured maintenance routine, you can prevent potential issues and enhance the efficiency of the machinery. This section provides valuable insights on essential practices to keep your engine in peak condition.

Regular Oil Changes

Changing the lubricant at recommended intervals is crucial. Fresh oil reduces friction and wear on internal components, enhancing overall performance. It is advisable to check the oil level frequently and top it off when necessary.

Air Filter Maintenance

The air filtration system plays a vital role in maintaining engine health. Inspect the filter regularly and clean or replace it as needed to ensure proper airflow. A clean air filter improves combustion efficiency and protects the engine from debris.

Best Practices for Longevity

Maintaining the durability and functionality of your machinery is crucial for optimal performance and efficiency. By implementing a few essential strategies, you can significantly extend the lifespan of your equipment and ensure it operates smoothly for years to come.

Regular Maintenance: Consistent upkeep is vital. Schedule routine inspections and servicing to address any wear and tear before they escalate into major issues. This proactive approach will help identify potential problems early on.

Use Quality Components: Investing in high-quality replacements and accessories is essential. Utilizing superior parts not only enhances performance but also contributes to the overall health of the machine, reducing the frequency of repairs.

Proper Storage: When not in use, ensure your equipment is stored correctly. Protect it from harsh weather conditions and environmental factors that could lead to deterioration. A dry and sheltered space can prevent rust and other damage.

Follow Operating Guidelines: Always adhere to the manufacturer’s recommendations regarding operation and care. Familiarizing yourself with these guidelines will help you avoid misuse and keep your machinery functioning optimally.

Keep it Clean: Regularly cleaning your equipment prevents the buildup of dirt and grime, which can hinder performance. A clean machine is not only more efficient but also easier to inspect and maintain.

By adopting these best practices, you can maximize the longevity of your equipment, ensuring it remains a reliable asset for your operations.

Troubleshooting Common Issues

Addressing frequent problems that may arise with machinery can enhance performance and longevity. Understanding typical challenges and their solutions is essential for maintaining efficiency.

- Starting Difficulties:

If the engine does not start, check the fuel level and battery condition. Ensure all connections are secure and the ignition system is functioning properly.

- Overheating:

An engine that overheats may indicate a cooling system failure. Inspect coolant levels, hoses, and radiator for blockages or leaks.

- Unusual Noises:

Strange sounds can signal mechanical issues. Identify the source of the noise, and examine belts, bearings, and other moving parts for wear or damage.

- Excessive Vibration:

Vibration during operation may point to an imbalance. Check for loose components and ensure that all parts are properly aligned.

- Fluid Leaks:

Leaks can lead to serious damage. Monitor fluid levels regularly and address any leaks by replacing seals or gaskets as needed.

By systematically identifying and resolving these issues, operators can ensure optimal functionality and reduce downtime.

Identifying Problems with Parts

Recognizing issues with components is crucial for maintaining optimal performance in machinery. Early detection can prevent further damage and ensure that equipment operates efficiently. Understanding common signs of malfunction can help in diagnosing problems swiftly.

One of the most frequent indicators of trouble is unusual noise during operation. Rattling or grinding sounds often signal wear and tear or misalignment. Additionally, unexpected vibrations can suggest that a specific element is loose or damaged, leading to inefficiencies in performance.

Another vital aspect to monitor is fluid leakage. If you notice any liquids pooling beneath the equipment, it may indicate a compromised seal or connection. Addressing such leaks promptly is essential to avoid more significant complications.

Lastly, keep an eye on the overall performance metrics. Sudden changes in output, efficiency, or responsiveness can hint at underlying issues with specific components. Regular inspections and awareness of these signs will contribute to a longer lifespan for the machinery.

Replacement Parts Options

When it comes to maintaining machinery, understanding the available alternatives for components is crucial. Selecting high-quality replacements can enhance performance and extend the lifespan of the equipment. Various options exist in the market, each catering to different needs and budgets.

OEM Components

Original Equipment Manufacturer components are designed specifically for certain models, ensuring a perfect fit and optimal functionality. Investing in these items can provide peace of mind, as they meet strict quality standards and often come with warranties.

Aftermarket Alternatives

For those seeking more economical solutions, aftermarket alternatives present a viable choice. These components may vary in quality and price, offering flexibility for different repair needs. It is essential to research and choose reputable brands to ensure reliability and performance.