For enthusiasts and professionals alike, having a clear visual representation of machinery elements is essential for efficient maintenance and repair. Grasping the intricate relationships between various components can significantly enhance your understanding of the overall functionality. This section delves into the various sections and mechanisms that make up a popular compact agricultural vehicle, providing insights into their roles and interconnections.

Maintaining a thorough grasp of each element not only ensures longevity but also optimizes performance. Knowing how different parts interact allows operators to troubleshoot issues quickly and effectively. With a focus on clarity, this resource will guide you through the essential components, highlighting their significance within the system.

Equipped with this knowledge, you will be better prepared to tackle challenges and execute necessary repairs with confidence. Familiarity with the layout and function of each section will empower you to maintain your equipment in peak condition, leading to enhanced productivity in your agricultural endeavors.

Kubota L3010 Overview

This section provides a comprehensive introduction to a specific model of compact tractors designed for versatility and efficiency in agricultural and landscaping tasks. Renowned for their robust performance, these machines are engineered to handle various applications, making them a preferred choice for many professionals and hobbyists alike.

Equipped with a powerful engine and advanced hydraulic systems, this model ensures excellent traction and maneuverability, even in challenging terrains. Its ergonomic design prioritizes operator comfort, allowing for prolonged use without fatigue. Additionally, the availability of numerous attachments enhances its functionality, enabling users to adapt the tractor for diverse purposes.

Maintenance and repair considerations are crucial for ensuring longevity and optimal performance. A clear understanding of the mechanical layout and individual components aids in troubleshooting and servicing, making it essential for owners to familiarize themselves with the construction of their equipment.

Overall, this tractor stands out in its category for reliability and performance, making it a valuable asset for anyone looking to enhance their productivity in various outdoor tasks.

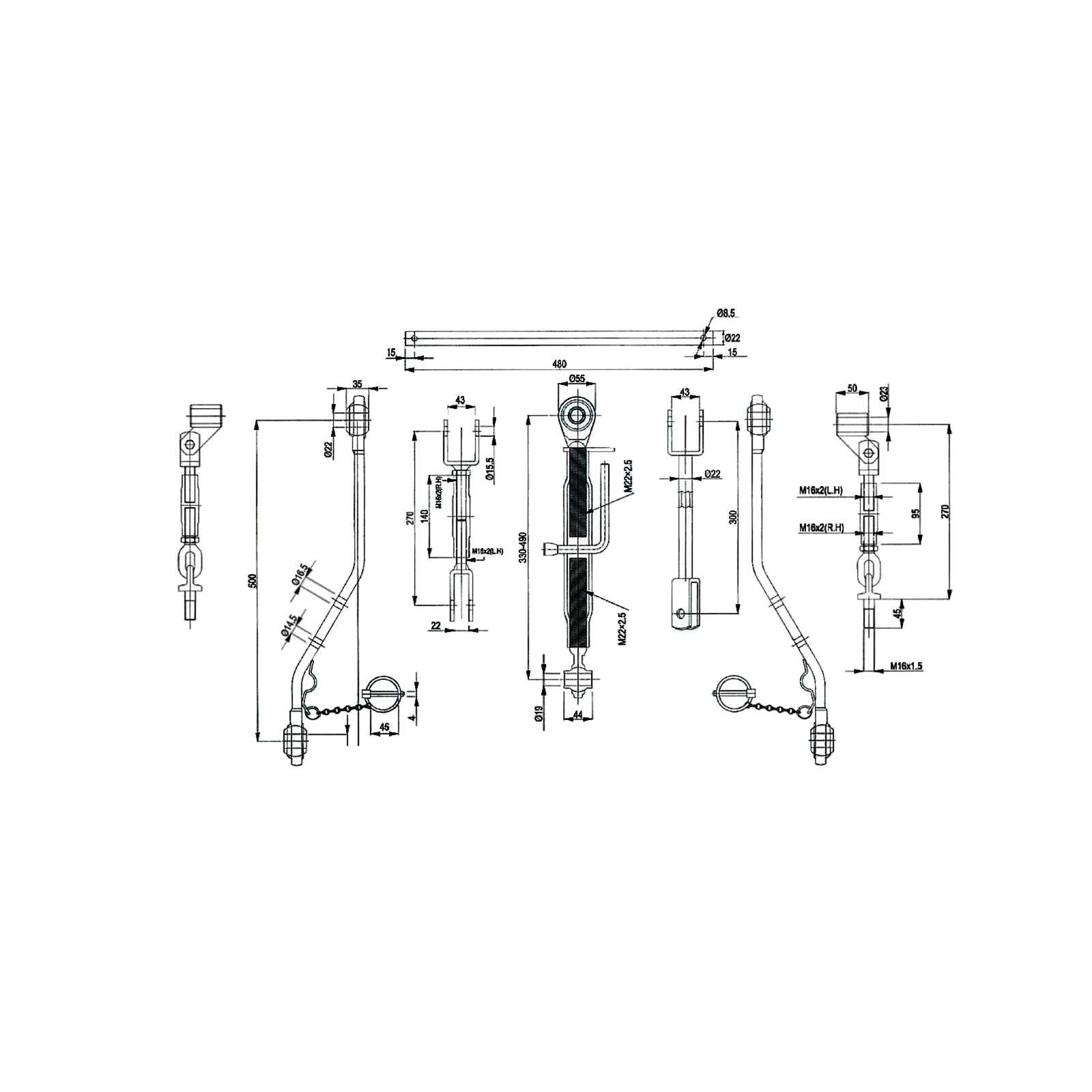

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for maintenance and repair. Visual representations facilitate easier identification of elements, helping users to navigate complex systems efficiently.

Enhancing Efficiency

- Streamlines repair processes.

- Reduces the time spent locating components.

- Improves accuracy in maintenance tasks.

Aiding in Troubleshooting

- Assists in diagnosing issues quickly.

- Highlights interconnections between various elements.

- Provides clarity on replacement procedures.

Ultimately, visual aids are essential for anyone looking to ensure the longevity and functionality of their equipment.

Common Issues with Kubota L3010

Tractors often face a variety of challenges that can affect their performance and reliability. Understanding these common problems can help owners maintain their machines effectively and avoid costly repairs.

- Starting Difficulties: Many operators encounter issues with ignition, which can stem from battery failure or faulty wiring.

- Overheating: Insufficient coolant levels or blocked radiators are frequent culprits that lead to excessive heat.

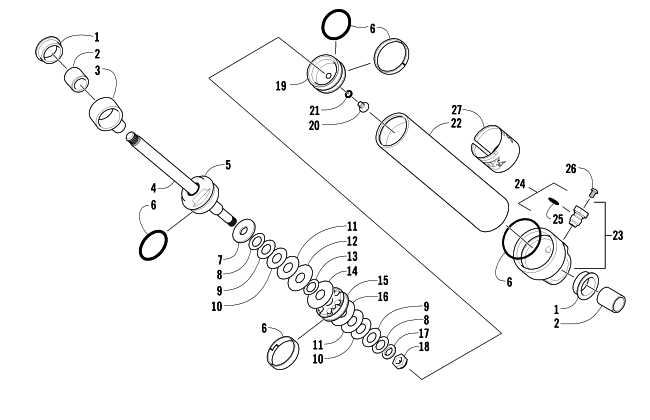

- Poor Hydraulic Performance: Inadequate fluid levels or worn seals can result in sluggish operation of hydraulic systems.

- Electrical Problems: Malfunctions in the electrical system may arise due to corroded connections or blown fuses.

- Transmission Issues: Difficulty in shifting gears can be attributed to low fluid levels or worn components.

Addressing these concerns promptly ensures optimal performance and longevity of the machinery.

Essential Maintenance Tips

Regular upkeep is crucial for ensuring the longevity and efficiency of your machinery. By implementing a systematic approach to maintenance, you can prevent costly repairs and enhance performance. This section will explore vital practices to keep your equipment in top shape.

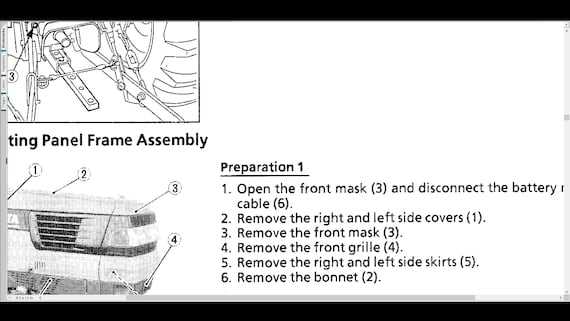

1. Routine Inspections: Conduct frequent checks on all components to identify wear and tear early. This proactive measure can save time and resources.

2. Cleanliness is Key: Keep all surfaces free from dirt and debris. Regular cleaning prevents contamination and promotes optimal functioning.

3. Fluid Levels: Regularly monitor and replenish essential fluids. Adequate lubrication is vital for preventing friction and overheating.

4. Replace Worn Parts: Timely replacement of damaged or worn components ensures smooth operation and reduces the risk of breakdowns.

5. Follow Manufacturer Guidelines: Always refer to the manufacturer’s recommendations for maintenance schedules and procedures to ensure proper care.

6. Training and Awareness: Ensure that operators are trained in basic maintenance practices. Knowledgeable users can spot issues before they escalate.

By incorporating these essential maintenance tips, you can effectively prolong the life of your machinery and maintain peak performance.

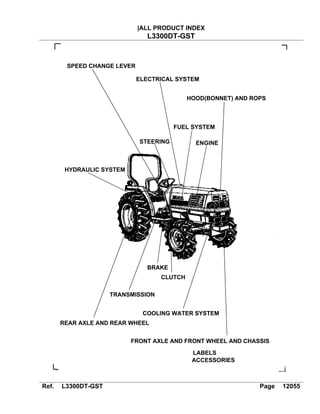

Key Components of the Tractor

Understanding the essential elements of a farming machine is crucial for efficient operation and maintenance. Each component plays a significant role in the overall functionality and performance, contributing to the ultimate effectiveness of the vehicle.

Major Parts

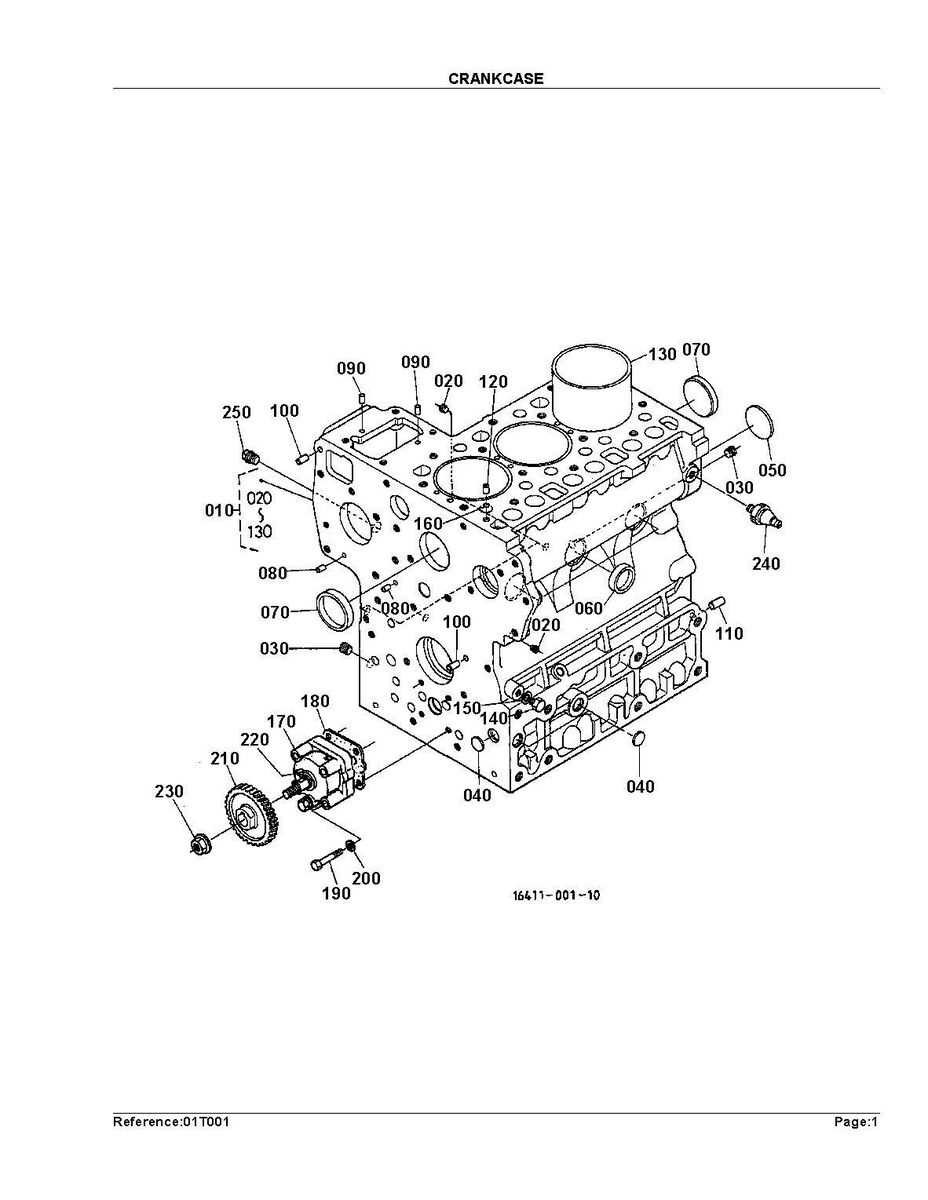

- Engine

- Transmission

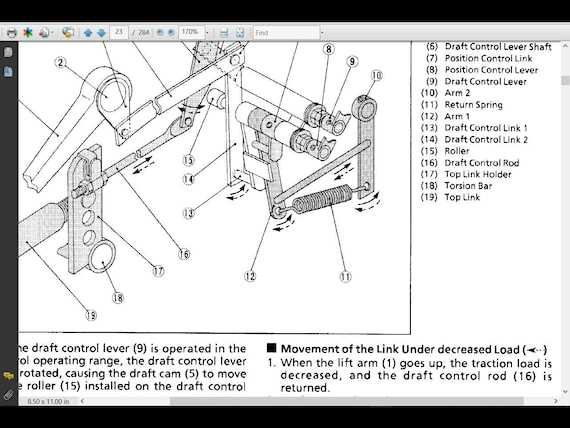

- Hydraulic System

- Chassis

- Steering Mechanism

Supporting Systems

- Electrical System

- Cooling System

- Fuel System

- Exhaust System

Each of these elements should be well-understood to ensure the machine operates smoothly and efficiently.

Where to Find Diagrams Online

Locating detailed visuals for machinery components can be essential for repairs and maintenance. Various resources are available on the internet, catering to both enthusiasts and professionals. These platforms provide access to comprehensive illustrations, helping users understand the structure and assembly of their equipment.

Official Manufacturer Websites

One of the most reliable sources is the official website of the manufacturer. Here, you can often find a dedicated section for technical resources, including illustrations and manuals. Ensure to search by model number for accurate results.

Online Forums and Communities

Participating in online communities can be invaluable. Many forums host discussions where users share links to resources, including illustrations. Engaging with fellow enthusiasts can lead you to hidden gems not easily found elsewhere.

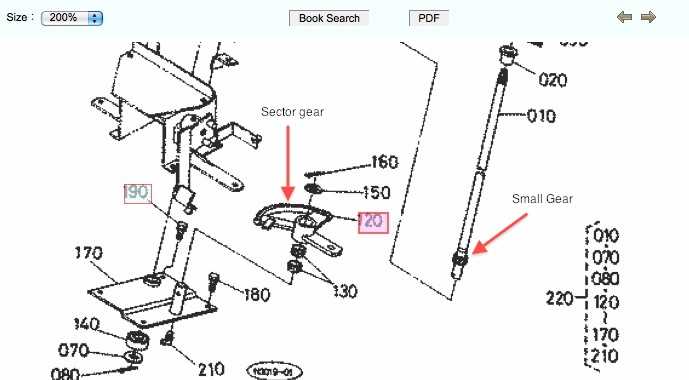

Understanding Part Numbers

Deciphering the alphanumeric codes associated with machinery components can be essential for effective maintenance and repair. These identifiers serve as a universal language, allowing users to quickly find the specific items they need. A solid grasp of these codes not only streamlines the procurement process but also enhances overall equipment functionality.

The Structure of Identification Codes

Most identification codes follow a systematic format that includes a combination of letters and numbers. The letters often denote the type of component or its category, while the numbers can indicate the size, model, or specific characteristics. Recognizing this structure can significantly reduce the time spent searching for the correct items.

Importance of Accuracy

Ensuring the accuracy of these identifiers is crucial. An incorrect code can lead to ordering the wrong component, resulting in delays and potential damage. Therefore, familiarizing oneself with the coding conventions not only aids in ordering but also contributes to the longevity and efficiency of the machinery.

DIY Repairs vs. Professional Help

When it comes to maintenance and fixes, many owners face the decision between tackling tasks themselves or seeking expert assistance. Both options have their pros and cons, which can significantly impact the overall outcome.

- DIY Repairs:

- Cost-effective solutions

- Personal satisfaction from completing tasks

- Opportunity to learn and build skills

- Professional Help:

- Expertise and experience

- Guaranteed quality of work

- Time-saving for busy individuals

Ultimately, the choice depends on one’s comfort level with tools, the complexity of the job, and the value placed on time versus cost. Delving into the specifics can help determine the best route for effective solutions.

Aftermarket Parts vs. OEM

When it comes to machinery components, users often face the choice between original equipment manufacturer (OEM) items and alternatives from third-party suppliers. Each option carries its own set of advantages and disadvantages, making it essential to evaluate them based on specific needs and circumstances.

Here are some key points to consider when comparing these two types of components:

- Quality:

- OEM items are typically designed to meet strict manufacturer standards.

- Aftermarket options may vary significantly in quality, with some matching or even exceeding OEM specifications, while others may fall short.

- Cost:

- OEM products often come at a premium price due to their brand recognition and warranty benefits.

- Aftermarket alternatives can offer significant savings, appealing to budget-conscious consumers.

- Availability:

- OEM items may have limited availability depending on the manufacturer’s distribution network.

- Aftermarket suppliers often provide a wider selection and more immediate access to various components.

- Compatibility:

- OEM parts are guaranteed to fit seamlessly with the original machinery.

- Aftermarket components can sometimes have compatibility issues, though many are designed specifically to match OEM specifications.

- Warranty:

- OEM products typically come with a warranty that covers defects and performance issues.

- Aftermarket options may offer varying warranty terms, which can affect long-term value.

Ultimately, the decision between original and alternative components should be guided by individual priorities, including budget constraints, quality expectations, and specific machinery requirements. Conducting thorough research and consulting with experienced professionals can aid in making the best choice for optimal performance and longevity.

Safety Precautions for Repairs

When undertaking maintenance or repairs on machinery, prioritizing safety is crucial to prevent accidents and injuries. Following proper procedures and using the right protective gear can significantly reduce risks and ensure a smooth process.

Essential Protective Gear

Always equip yourself with appropriate safety equipment such as gloves, goggles, and sturdy footwear. These items provide a barrier against potential hazards, ensuring that you are protected from sharp objects, chemicals, and heavy materials.

Workspace Organization

Maintain a clean and organized work environment to minimize distractions and hazards. Clear away unnecessary tools and materials, and ensure adequate lighting to help you focus on the task at hand. An orderly space allows for safe movement and reduces the likelihood of accidents.