Maintaining and repairing your lawn care machine can be a daunting task, especially when navigating the intricacies of its internal structure. A comprehensive overview of the different components and their interconnections can significantly aid in troubleshooting issues and ensuring optimal functionality. By familiarizing yourself with this layout, you can enhance your understanding of how each part contributes to the overall performance of the equipment.

In this section, we will explore a detailed visual representation that outlines the various elements of your machine. This illustration will serve as a valuable reference, enabling you to identify specific components and their locations with ease. Whether you are looking to perform routine maintenance or tackle more complex repairs, having a clear understanding of the assembly is essential for effective management of your equipment.

As you delve into the intricacies of the machine’s layout, you will discover the relationships between the different elements, enhancing your ability to address potential problems. Gaining insights into the configuration not only empowers you to make informed decisions during repairs but also fosters a deeper appreciation for the engineering that goes into creating efficient and reliable machinery.

Overview of Components

This section provides an insightful look into the various elements that make up the machinery, highlighting their functions and importance. Understanding these components is essential for maintenance and optimal performance, ensuring that the equipment operates efficiently and effectively.

Key Elements

The critical components of this machinery are designed for durability and reliability. Each part plays a significant role in the overall functionality, contributing to seamless operation. Regular inspection and timely replacement of worn-out elements are crucial for maintaining the equipment’s longevity.

| Component Name | Description | Function |

|---|---|---|

| Engine | Power unit that drives the entire system. | Provides necessary power for operation. |

| Transmission | Gearbox that regulates speed and torque. | Transfers power from the engine to the wheels. |

| Deck | Housing that protects and supports the cutting mechanism. | Ensures effective cutting and prevents debris spread. |

| Wheels | Round components that enable movement. | Facilitate navigation across various terrains. |

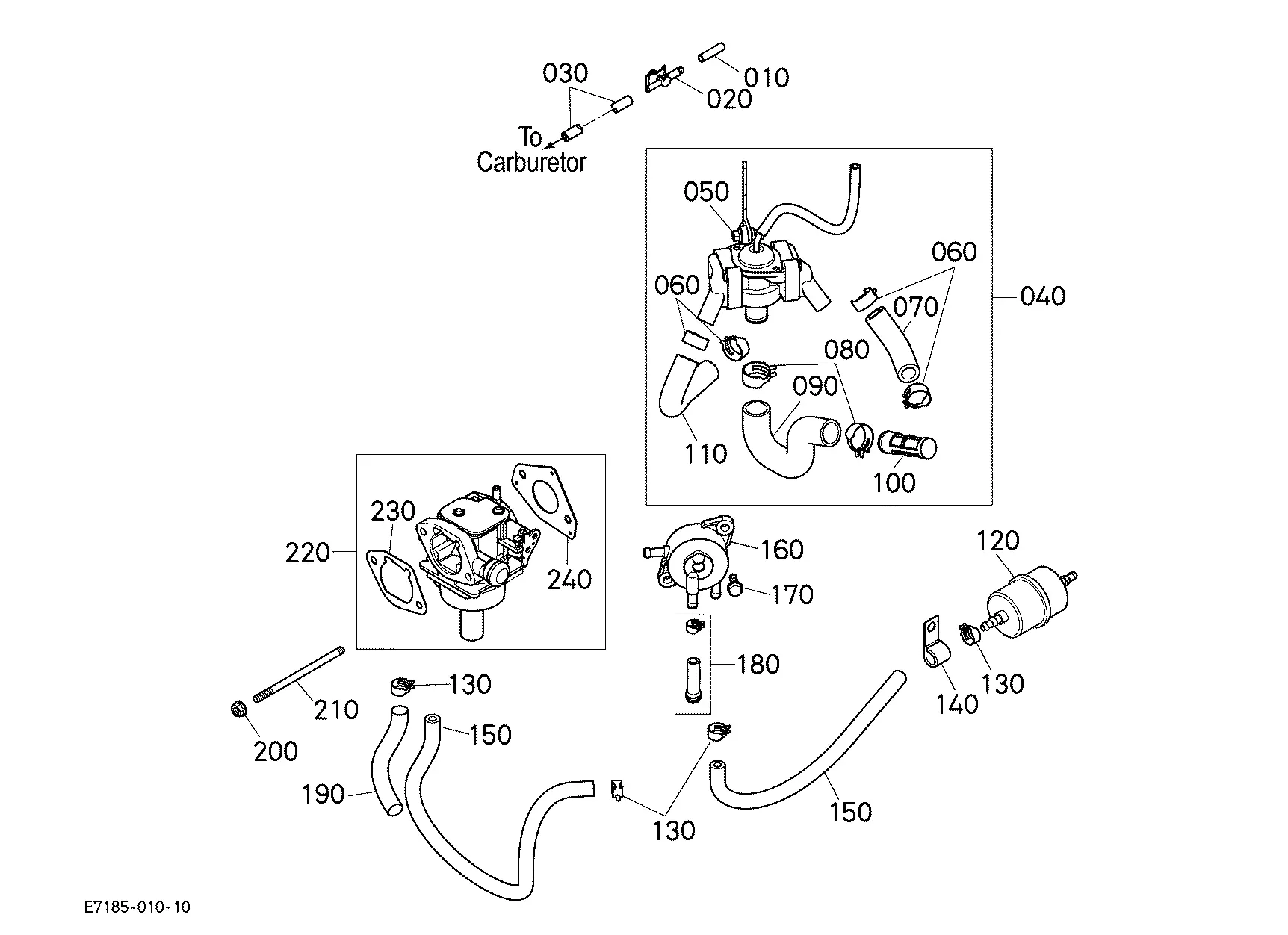

| Fuel System | Assembly responsible for fuel storage and delivery. | Supplies fuel to the engine for combustion. |

Maintenance Tips

To ensure optimal performance, regular maintenance of these components is vital. Check for wear and tear, clean or replace filters, and ensure proper lubrication. Regular servicing can prevent unexpected breakdowns and extend the lifespan of the machinery.

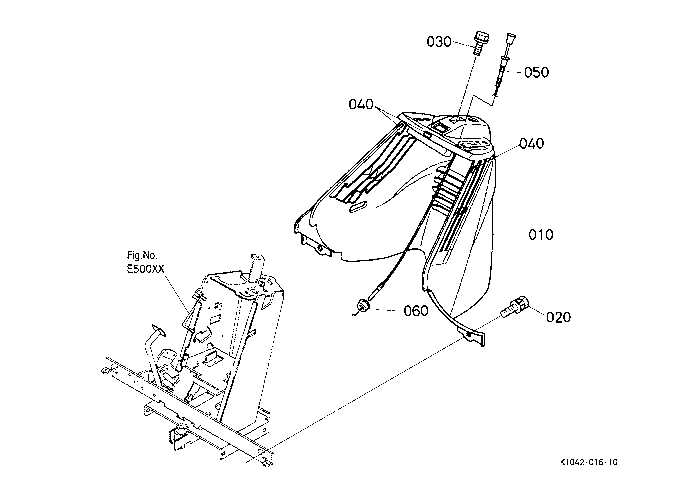

Understanding the Parts Diagram

The visual representation of components within a machine serves as a crucial tool for anyone involved in maintenance or repairs. This illustration not only helps identify individual elements but also provides insight into how these elements interact within the overall system. By comprehending this visual guide, users can streamline their repair processes and enhance their understanding of the machinery’s functionality.

Key Components and Their Functions

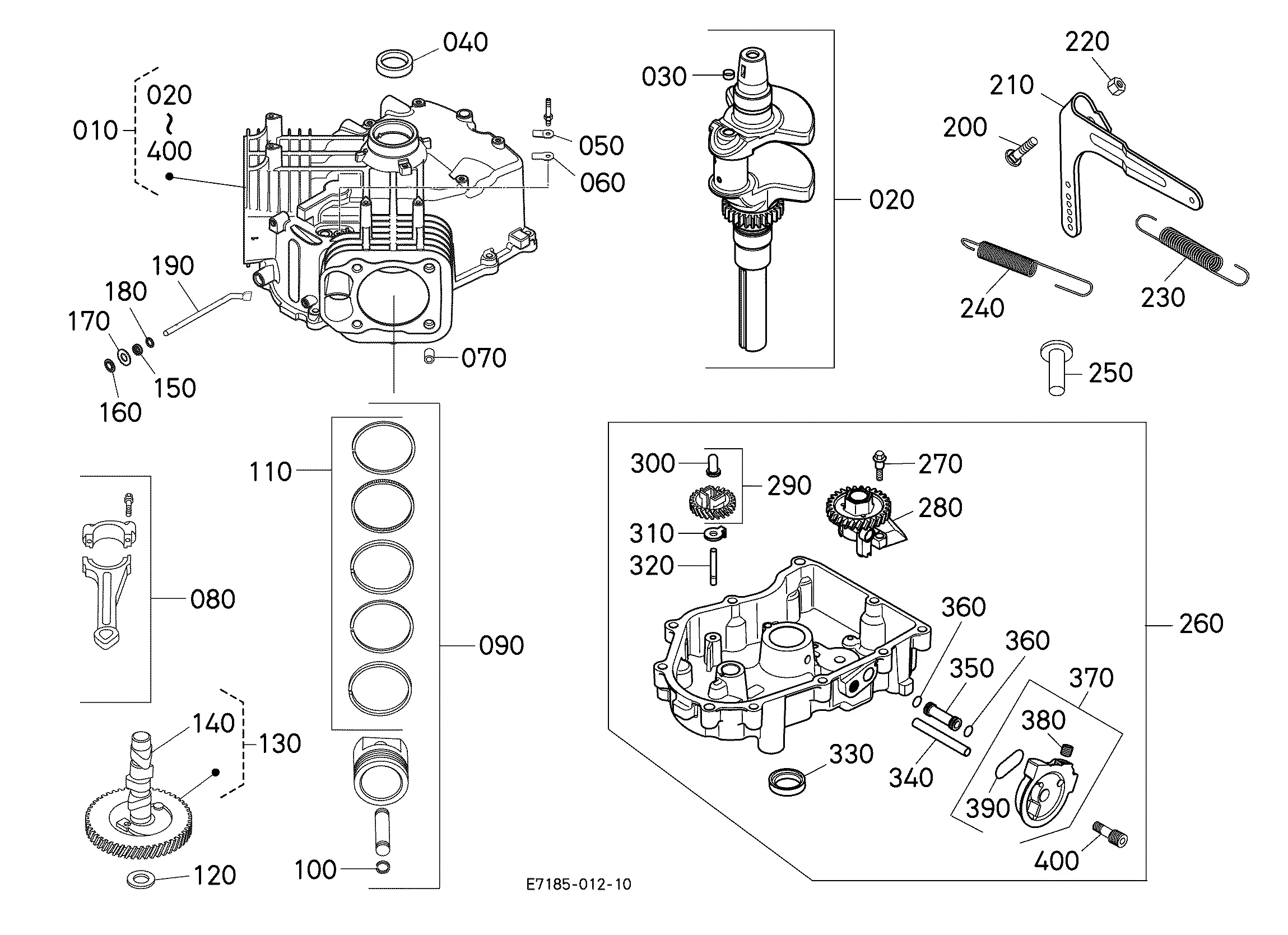

- Engine Assembly: This is the heart of the machinery, responsible for generating power and facilitating movement.

- Transmission System: This system transfers power from the engine to the wheels, enabling efficient operation.

- Control Mechanisms: These include levers and switches that allow the operator to manage various functions smoothly.

- Chassis: The framework that supports all other components and ensures structural integrity.

- Cooling System: This system regulates temperature to prevent overheating during operation.

Utilizing the Visual Reference

When working with the visual reference, consider the following steps:

- Identify the components relevant to your task by cross-referencing the visual with the maintenance manual.

- Take note of the connections between elements to understand their interaction better.

- Use this knowledge to pinpoint potential issues or areas requiring attention during repairs.

By following these guidelines, users can maximize the effectiveness of their repair efforts and maintain their machinery in optimal condition.

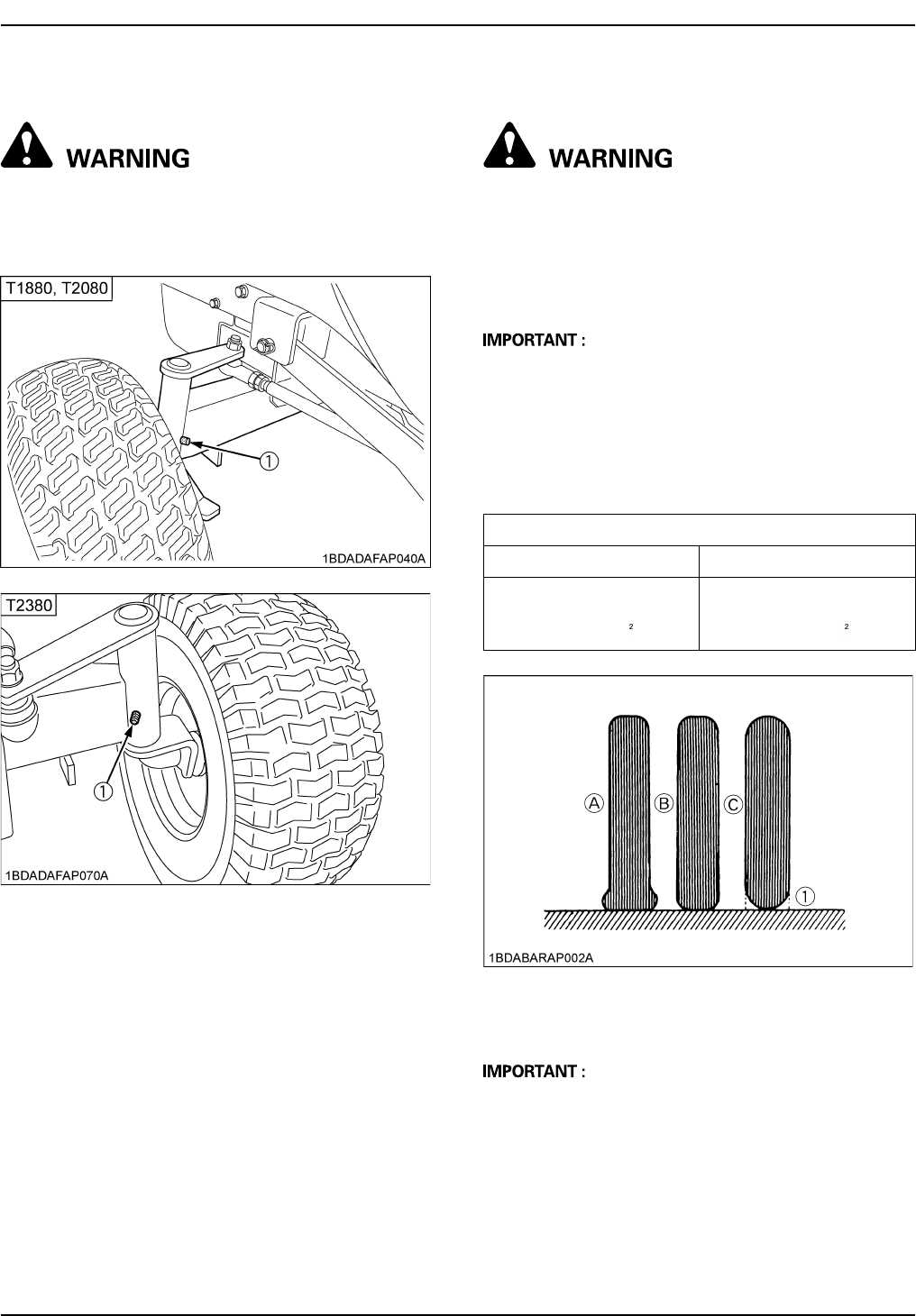

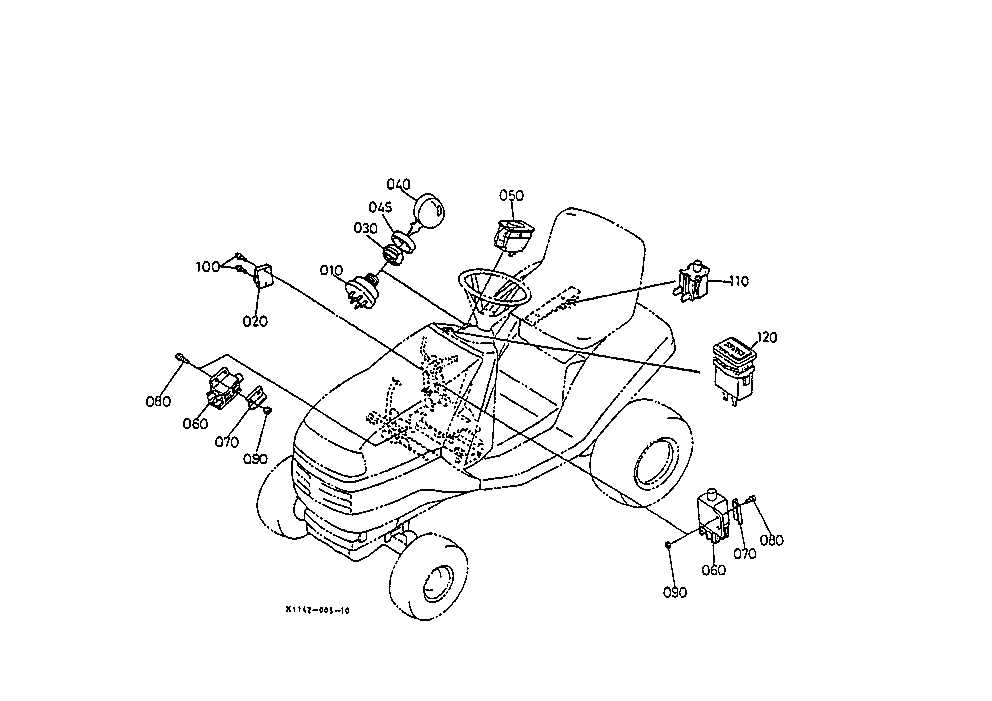

Main Components of the T2080

The understanding of the essential elements of this specific lawn care equipment is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring smooth operation and longevity. Below are the primary features that contribute to the effectiveness of the machine.

Key Features

- Engine: Provides the necessary power for operation.

- Transmission: Ensures smooth movement and control.

- Deck: The cutting mechanism responsible for trimming grass efficiently.

- Wheels: Allow for mobility and stability during use.

- Controls: User interfaces that enable easy operation and adjustments.

Additional Elements

- Fuel System: Supplies energy to the engine for optimal performance.

- Electrical System: Powers all electronic components and lighting.

- Chassis: The frame that supports and houses all the other components.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

- Cutting Height Adjuster: Allows users to customize the grass cutting height according to preference.

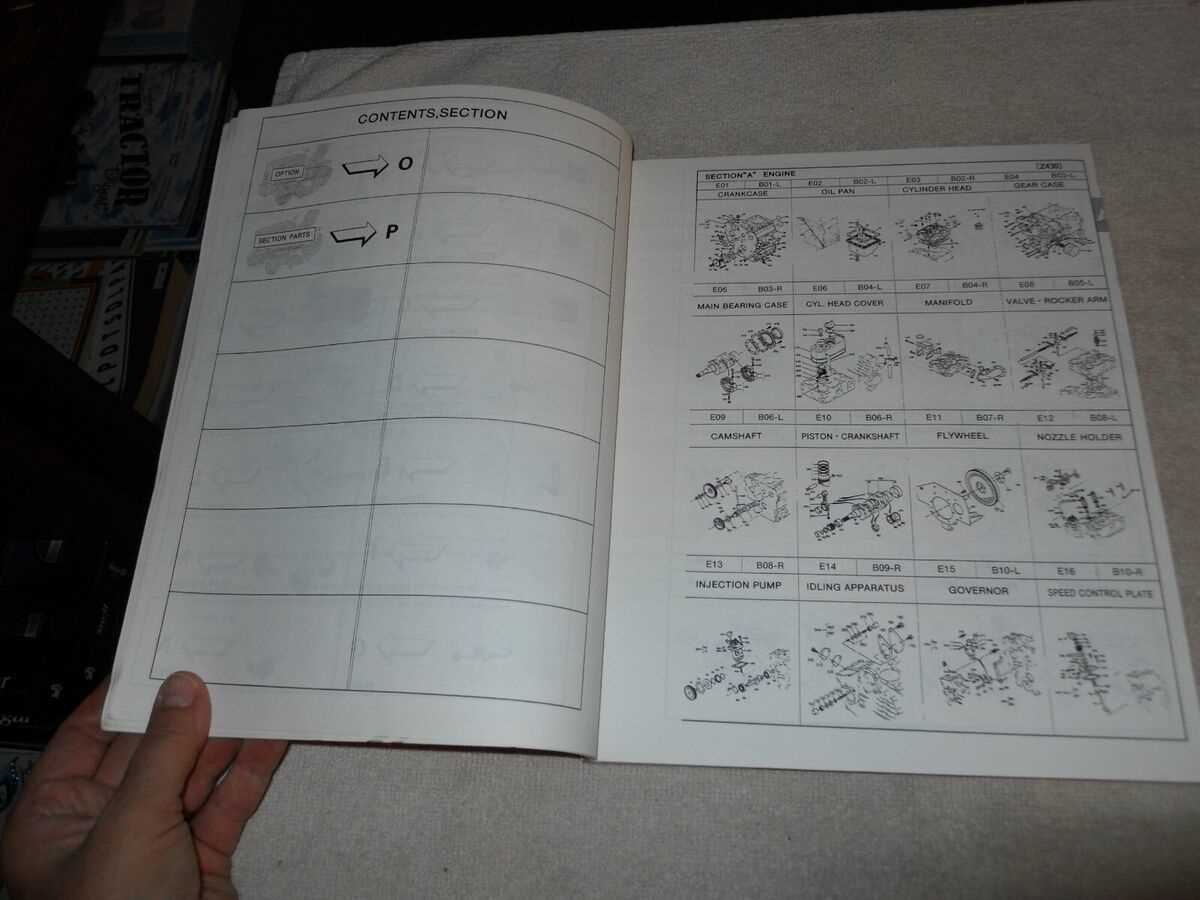

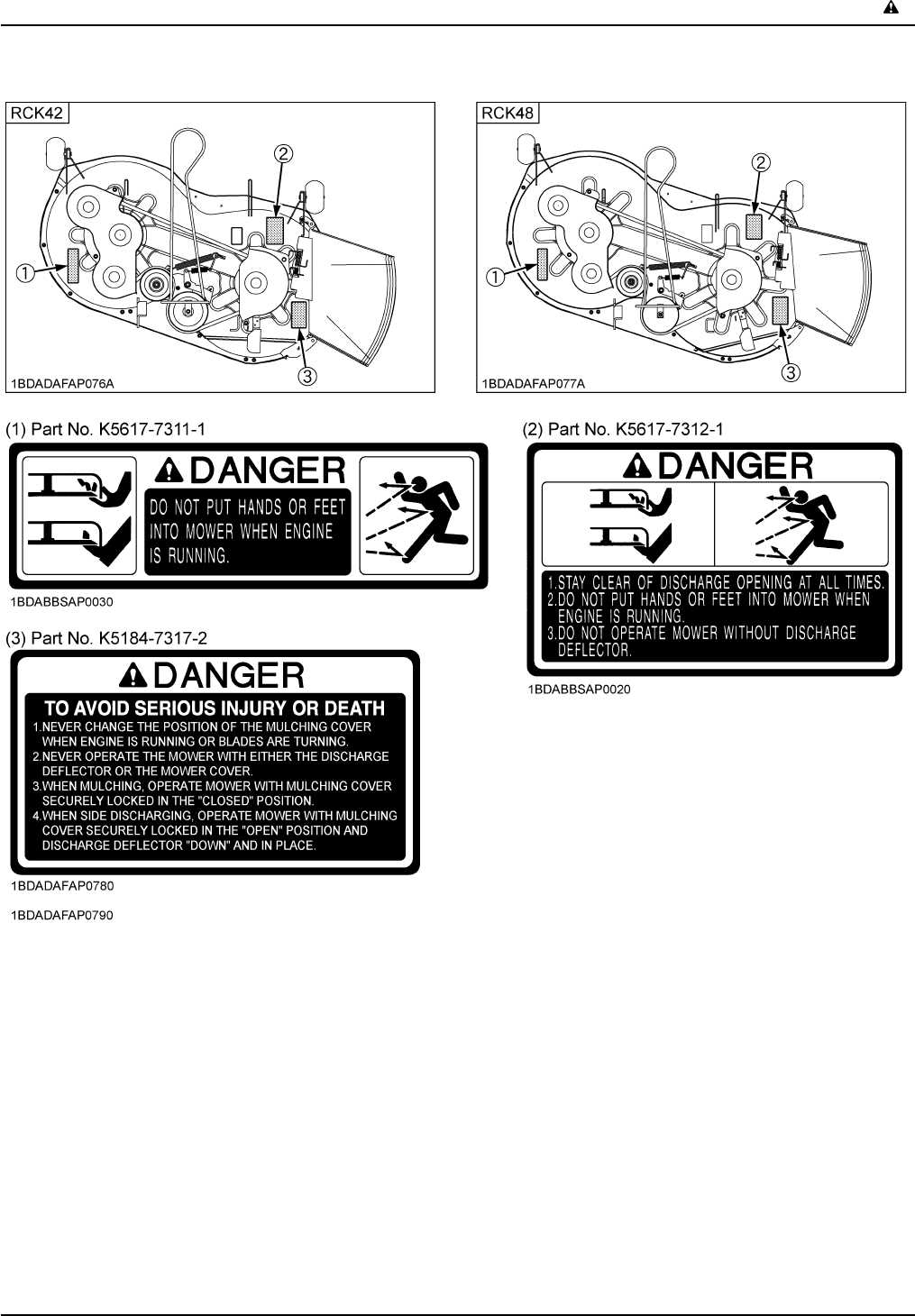

How to Read the Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. This visual guide illustrates how various elements are interconnected, helping users identify specific parts and their functions within a system. A clear comprehension of this representation facilitates troubleshooting and enhances overall efficiency in handling mechanical issues.

1. Familiarize Yourself with Symbols: Each element on the schematic is represented by a unique symbol. Take time to learn what each symbol signifies, as this knowledge is crucial for navigating the entire illustration. Key symbols often include circles for components, lines for connections, and arrows indicating flow direction.

2. Follow the Connections: Trace the lines connecting the symbols to understand how each part interacts with others. Pay attention to junctions where lines intersect, as these points often represent important connections or branching paths in the system.

3. Identify Component Values: Many schematics include numerical values or labels associated with specific components. These may indicate sizes, capacities, or other specifications. Make note of these details, as they can be vital for replacement or repair tasks.

4. Use a Legend: Often, diagrams will include a legend or key that explains the symbols and annotations used throughout the representation. Consult this resource to clarify any confusion regarding unfamiliar symbols or terminology.

5. Cross-reference with Manuals: When in doubt, consult the accompanying service manuals or guides for additional context. These resources can provide insights into the operational aspects of the components and may offer troubleshooting tips relevant to the schematic.

By following these steps, users can effectively interpret the visual representation, leading to better decision-making during repairs or maintenance tasks.

Common Replacement Parts Needed

Maintaining outdoor power equipment often requires the replacement of specific components to ensure optimal performance and longevity. Identifying the most commonly needed items can help owners prepare for repairs and reduce downtime. Understanding these essentials can facilitate smoother maintenance routines and enhance the overall efficiency of the machinery.

Key Components for Maintenance

Several critical elements are frequently required for upkeep. These components include those that support the engine, transmission, and overall functionality of the equipment. Familiarity with these items can aid in swift replacements when necessary.

| Component | Description | Purpose |

|---|---|---|

| Air Filter | Prevents dirt and debris from entering the engine | Enhances engine performance and efficiency |

| Spark Plug | Ignites the air-fuel mixture in the engine | Essential for starting and running the engine smoothly |

| Oil Filter | Removes contaminants from the engine oil | Protects engine components from wear |

| Belt | Transfers power from the engine to various systems | Ensures proper operation of cutting and drive systems |

| Blade | Cuts grass and other vegetation | Maintains the desired lawn height and appearance |

Understanding Replacement Needs

Recognizing which components may require replacement over time is crucial for effective maintenance. Regular inspections can help detect wear and tear, allowing for proactive replacements. Ensuring the availability of these commonly needed items can significantly enhance the performance and reliability of the equipment.

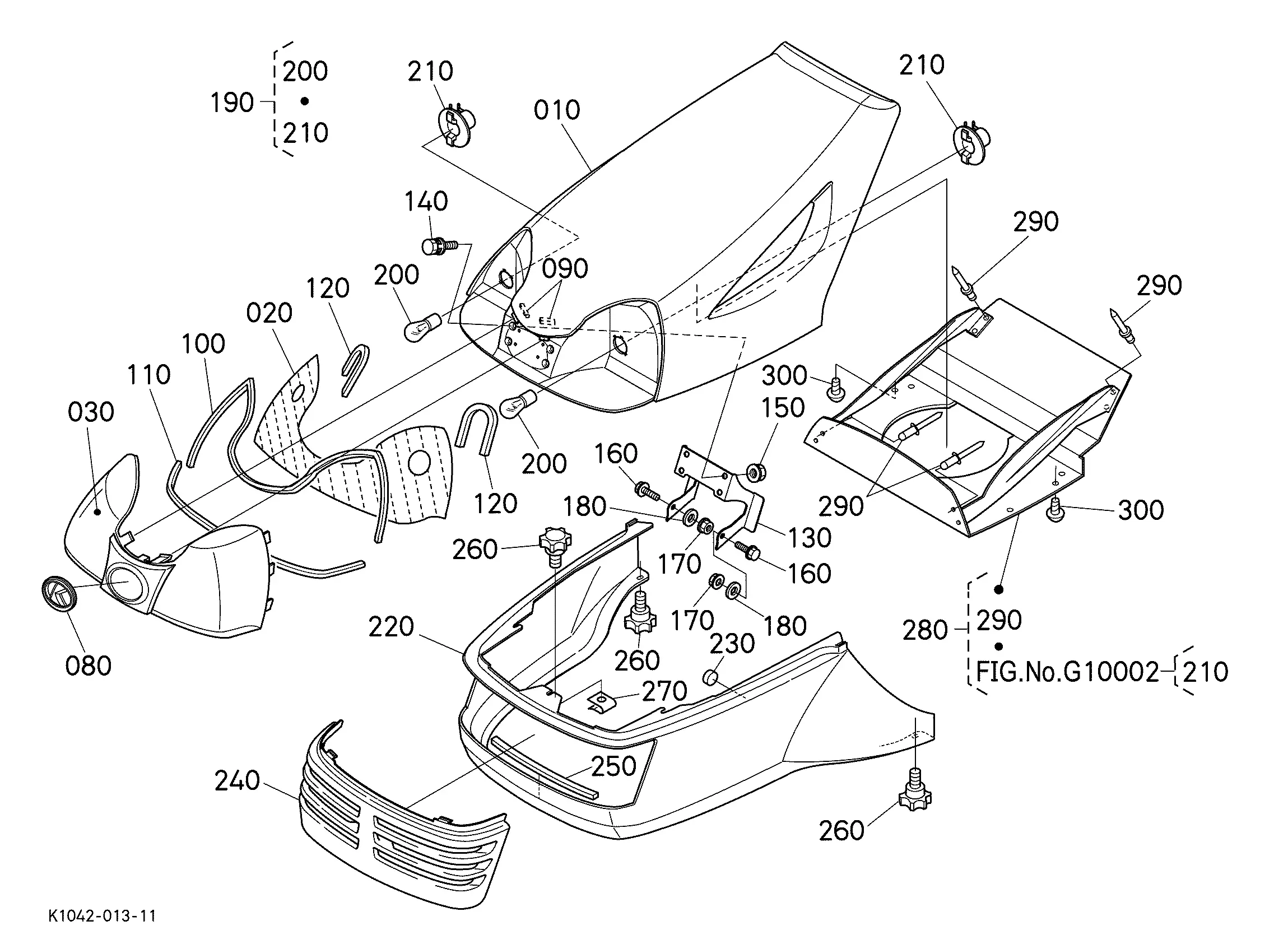

Assembly and Disassembly Instructions

When working on machinery, understanding the process of assembling and disassembling components is crucial for maintaining efficiency and safety. This section provides a comprehensive overview of the necessary steps to effectively manage the assembly and disassembly of various elements within the equipment. Following these guidelines will ensure that all parts are handled properly and reassembled correctly, minimizing the risk of damage or operational failure.

Preparation is Key: Before beginning, gather all necessary tools and equipment. Ensure that the workspace is clean and organized to facilitate a smooth process. Review the manufacturer’s manual for specific instructions related to your equipment model. Familiarizing yourself with the components involved will enhance your understanding of their functions and how they interact with one another.

Disassembly Steps: Start by disconnecting any power sources to prevent accidental activation. Remove any protective coverings or panels, taking care to keep track of screws and fasteners. As you disassemble each part, label them or take photos to help during reassembly. Carefully detach components, ensuring that no additional parts are damaged in the process. Follow a logical order, working from the outside in, to avoid confusion.

Assembly Steps: Begin the reassembly by reversing the disassembly steps. Align components accurately and ensure that all fasteners are tightened securely to prevent loosening during operation. It is advisable to refer back to your labeled components and photos to ensure accuracy. Once everything is reassembled, double-check connections and fittings to confirm that they are secure.

Final Checks: After completing the assembly, perform a thorough inspection of the entire unit. Test functionality in a safe environment to verify that everything operates as intended. Regular maintenance checks should be scheduled to prolong the life of the equipment and ensure ongoing performance.

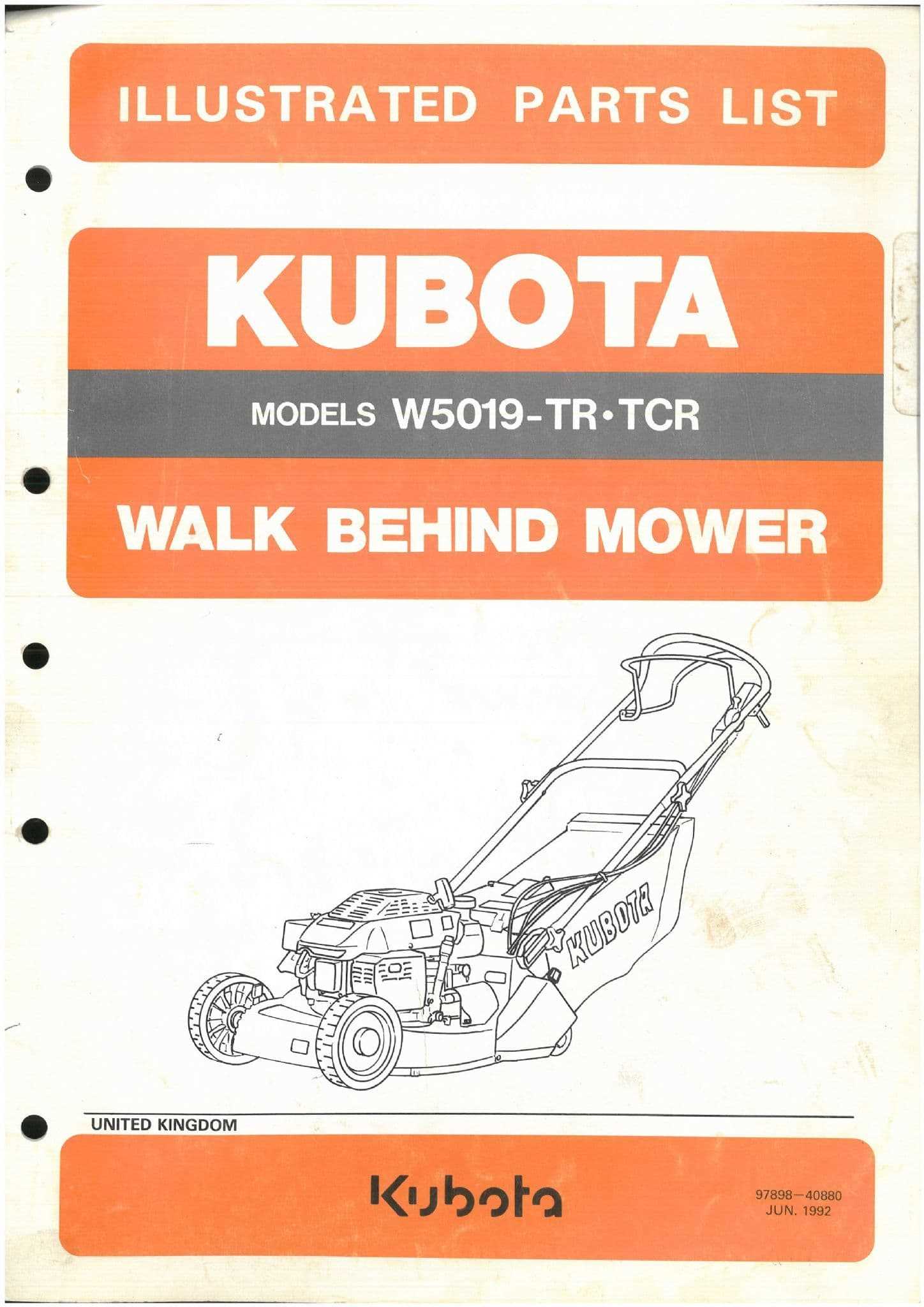

Identifying Parts by Number

Understanding the components of a machine can greatly enhance maintenance and repair efficiency. Each element is assigned a unique identification number, making it easier to locate, order, and replace specific items when necessary. This systematic approach streamlines the process and ensures that users have the correct items for their specific needs.

Below is a table illustrating common component identifiers and their corresponding descriptions:

| Identifier | Description |

|---|---|

| 001 | Engine assembly |

| 002 | Transmission unit |

| 003 | Deck housing |

| 004 | Front wheel |

| 005 | Rear wheel |

| 006 | Battery pack |

| 007 | Fuel tank |

Using these identifiers, one can easily navigate the inventory of components and ensure proper replacements are made, thereby maintaining optimal functionality.

Where to Purchase Components

Finding quality replacement elements for your equipment is crucial for maintaining its functionality and performance. Various sources provide access to these essential items, ensuring you can restore your machine to optimal condition without compromising quality. Whether you prefer local retailers or online suppliers, understanding your options will help streamline the procurement process.

Local Dealerships and Retailers

Your nearest dealerships and specialized retailers often carry a selection of components. Visiting these locations allows you to consult with knowledgeable staff who can guide you in selecting the appropriate parts for your specific needs. Additionally, purchasing locally can offer the advantage of immediate availability, saving you time on shipping delays.

Online Suppliers

The internet provides a wealth of options for sourcing replacement elements. Numerous websites specialize in equipment components, allowing you to compare prices, read reviews, and explore a wider range of products. Make sure to choose reputable online retailers that guarantee the quality of their offerings and provide customer support for any inquiries.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the prolonged performance and reliability of any machinery. By implementing a consistent maintenance routine, users can prevent potential issues and extend the lifespan of their equipment. This section highlights key practices that can contribute to optimal functioning and durability.

1. Regular Cleaning: Keeping the machinery clean is crucial. Accumulated dirt and debris can lead to overheating and decreased efficiency. Make it a habit to inspect and clean the exterior and accessible components frequently.

2. Fluid Checks: Monitor and maintain proper fluid levels, including oil, coolant, and hydraulic fluids. Regularly checking for leaks and ensuring fluids are free of contaminants can prevent major failures.

3. Scheduled Lubrication: Lubricate moving parts as per the manufacturer’s recommendations. Adequate lubrication reduces friction and wear, promoting smoother operation and longevity.

4. Component Inspections: Perform routine inspections of critical components such as belts, filters, and blades. Identifying wear and tear early can help in taking corrective measures before they escalate into larger issues.

5. Follow the Manual: Always refer to the manufacturer’s manual for specific maintenance guidelines. Adhering to the recommended maintenance schedule will ensure that all aspects of the machinery are addressed appropriately.

6. Store Properly: When not in use, store equipment in a dry and sheltered location. This protects it from environmental factors that could lead to deterioration.

By adhering to these maintenance practices, users can significantly enhance the reliability and operational efficiency of their machinery, ensuring that it remains in optimal condition for years to come.

Common Issues and Solutions

Every machinery has its challenges, and addressing these can significantly enhance performance and longevity. Understanding typical problems and their remedies is crucial for effective maintenance. Below are some frequent concerns encountered by users along with practical solutions to ensure optimal operation.

Engine Starting Difficulties

One common issue is trouble starting the engine. This may stem from various factors such as a drained battery, faulty ignition components, or insufficient fuel supply. To resolve this, check the battery’s charge and connections, inspect the ignition system for wear, and ensure that the fuel is fresh and at the proper level. Additionally, examining the fuel lines for blockages can be beneficial.

Overheating Issues

Another prevalent challenge is overheating, which can lead to severe damage if not addressed promptly. Common causes include a malfunctioning cooling system, low coolant levels, or debris obstructing airflow. Regularly inspect the cooling system for leaks, maintain appropriate coolant levels, and clear any debris from air intake areas. Utilizing a temperature gauge can also help monitor the engine’s performance and prevent overheating.

Compatibility with Other Models

Understanding the interchangeability of components between different machines can significantly enhance maintenance efficiency and reduce costs. Many users find themselves in situations where they need to source parts for their equipment and may wonder about the compatibility with similar models. This section explores the relationships between various models and highlights essential considerations for ensuring optimal performance.

Interchangeable Components

Several components in these machines are designed with versatility in mind, allowing for cross-compatibility with various models. This includes items such as belts, filters, and blades. When selecting parts, it is crucial to refer to specifications that indicate whether an item is suitable for use in other equipment. Checking compatibility not only helps in securing the right fit but also enhances operational reliability.

Performance Considerations

While compatibility is vital, it is equally important to consider how the use of components from different models might affect overall performance. Using non-original parts can sometimes lead to unforeseen challenges, such as variations in efficiency or durability. Always consult with experts or reference detailed guides to ensure that the chosen components will meet the necessary standards for performance and safety.

Resources for Further Learning

Expanding your knowledge about machinery maintenance and repair can significantly enhance your skills and confidence. Various educational materials and platforms can provide valuable insights into specific equipment components and their functionalities. Engaging with these resources will empower you to make informed decisions and perform effective maintenance tasks.

For those interested in comprehensive guides and detailed information, online forums and community websites offer a wealth of shared experiences and expert advice. Participating in discussions can deepen your understanding and expose you to practical solutions from fellow enthusiasts and professionals.

Additionally, video tutorials on platforms such as YouTube can provide visual guidance, demonstrating step-by-step procedures for repairs and maintenance tasks. These resources are particularly beneficial for visual learners, as they showcase real-life applications and techniques.

Books and manuals focused on small engine maintenance can also serve as excellent references. Look for titles that cover similar machinery, as they often contain insights applicable to your specific model. Technical manuals may include valuable diagrams and troubleshooting tips to help you address common issues effectively.

Lastly, consider enrolling in workshops or online courses that specialize in engine repair and maintenance. These structured programs can provide you with a deeper understanding of machinery and enhance your practical skills through hands-on experience.

Expert Recommendations and Advice

When it comes to maintaining and repairing small machinery, having a thorough understanding of the essential components can significantly enhance performance and longevity. Seeking guidance from experienced professionals can provide invaluable insights, ensuring that any work done is both effective and safe. Here are some expert suggestions that can help streamline the process of working with various machinery models.

1. Prioritize Regular Maintenance

Consistent upkeep is key to preventing issues before they arise. Experts recommend setting a maintenance schedule that includes routine checks and servicing. This not only extends the life of your equipment but also enhances its efficiency. Focus on the following areas:

| Component | Recommended Action | Frequency |

|---|---|---|

| Oil Level | Check and refill as necessary | Every 25 hours of operation |

| Filters | Inspect and replace when dirty | Every 50 hours of operation |

| Belts and Cables | Examine for wear and tension | Every 100 hours of operation |

2. Use Quality Replacement Items

When replacements are needed, using high-quality components is crucial. Cheaper alternatives may save money initially, but they often lead to more significant issues down the line. Experts suggest sourcing original or reputable aftermarket items to ensure compatibility and reliability. Additionally, always consult the manufacturer’s specifications for any replacements.