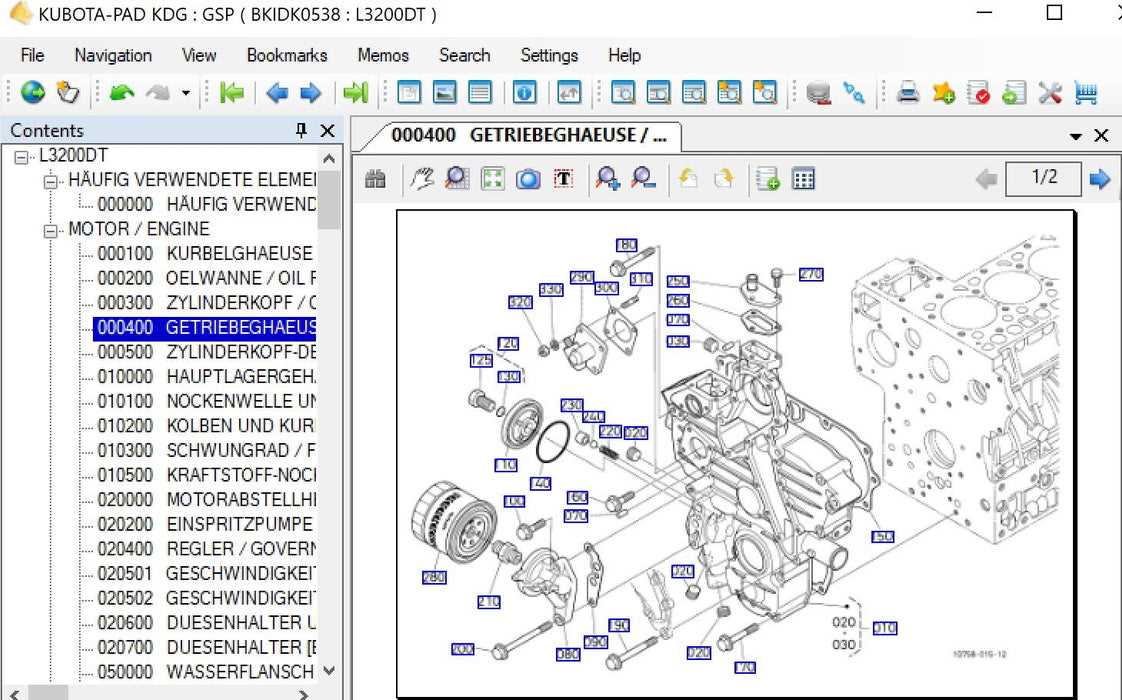

When it comes to maintaining machinery, having a clear understanding of its internal structure is essential. This section provides a comprehensive overview of the various elements that make up the machine, helping users to navigate the complexities of its design. By familiarizing yourself with the configuration of components, you can ensure optimal performance and longevity.

Each piece within the assembly plays a crucial role in the overall functionality. Whether you are looking to troubleshoot an issue or perform routine maintenance, recognizing the specific functions and locations of these elements can greatly enhance your efficiency. Knowledge of the configuration allows for informed decision-making and effective repairs.

Furthermore, having access to a visual representation of the structure aids in understanding how different parts interact. This insight not only simplifies the maintenance process but also empowers users to undertake repairs with confidence. Engaging with the layout of the equipment fosters a deeper appreciation for its engineering and operational principles.

This section highlights the significant attributes of a robust and efficient machine designed for a variety of tasks. With a blend of power, precision, and user-friendly design, it stands out as a reliable choice for those seeking performance and durability.

- Powerful Engine: Equipped with a strong engine, this model ensures optimal performance even in challenging conditions.

- Durable Construction: Built with high-quality materials, it offers longevity and resilience against wear and tear.

- Versatile Attachments: Compatible with a range of attachments, it enhances functionality and allows for various applications.

- Easy Maintenance: Designed for straightforward upkeep, it minimizes downtime and ensures consistent operation.

- Ergonomic Design: Features an intuitive layout that prioritizes user comfort and efficiency during operation.

Overall, the attributes outlined above make this machine an exceptional option for individuals who value reliability and versatility in their equipment.

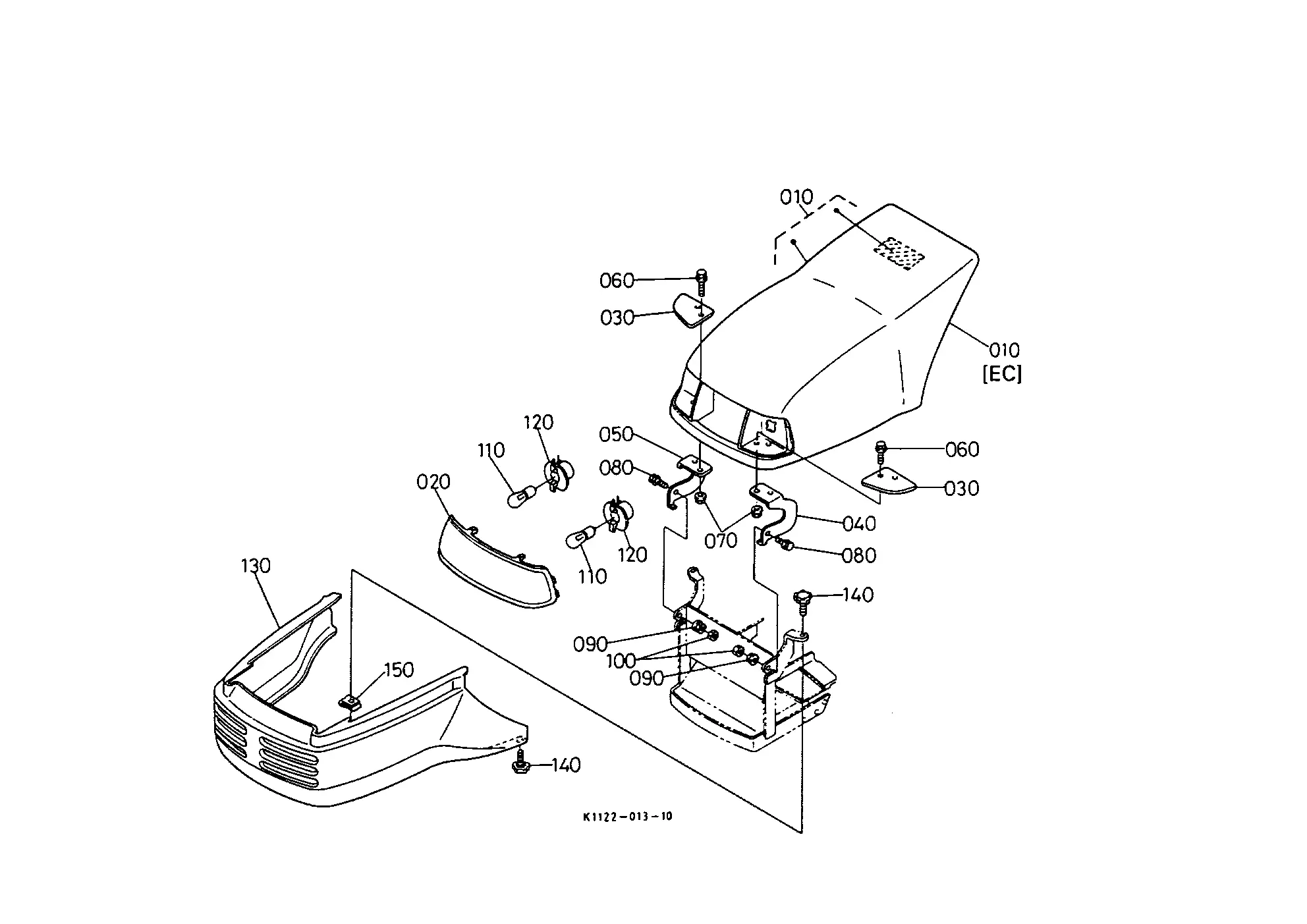

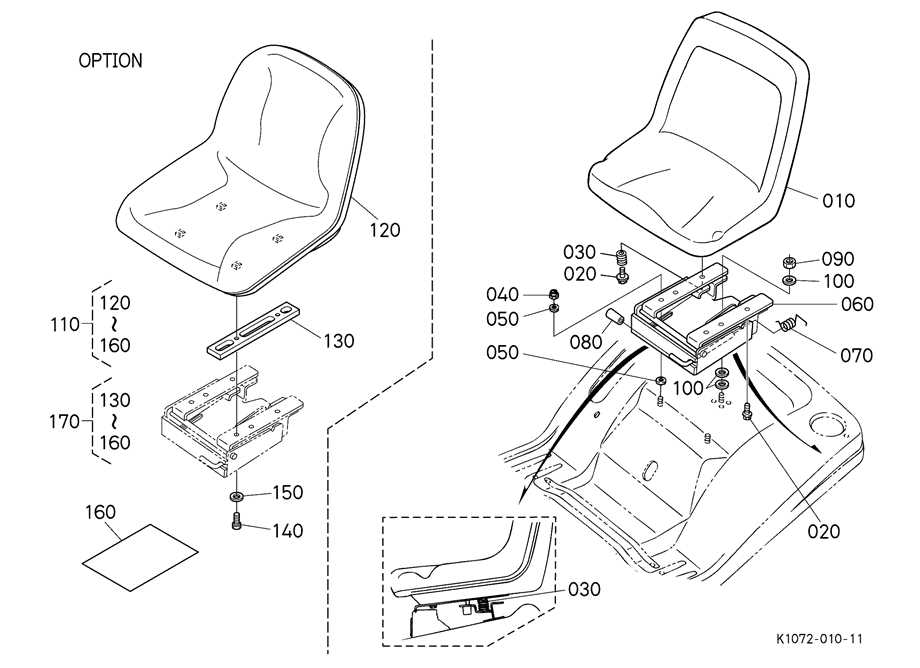

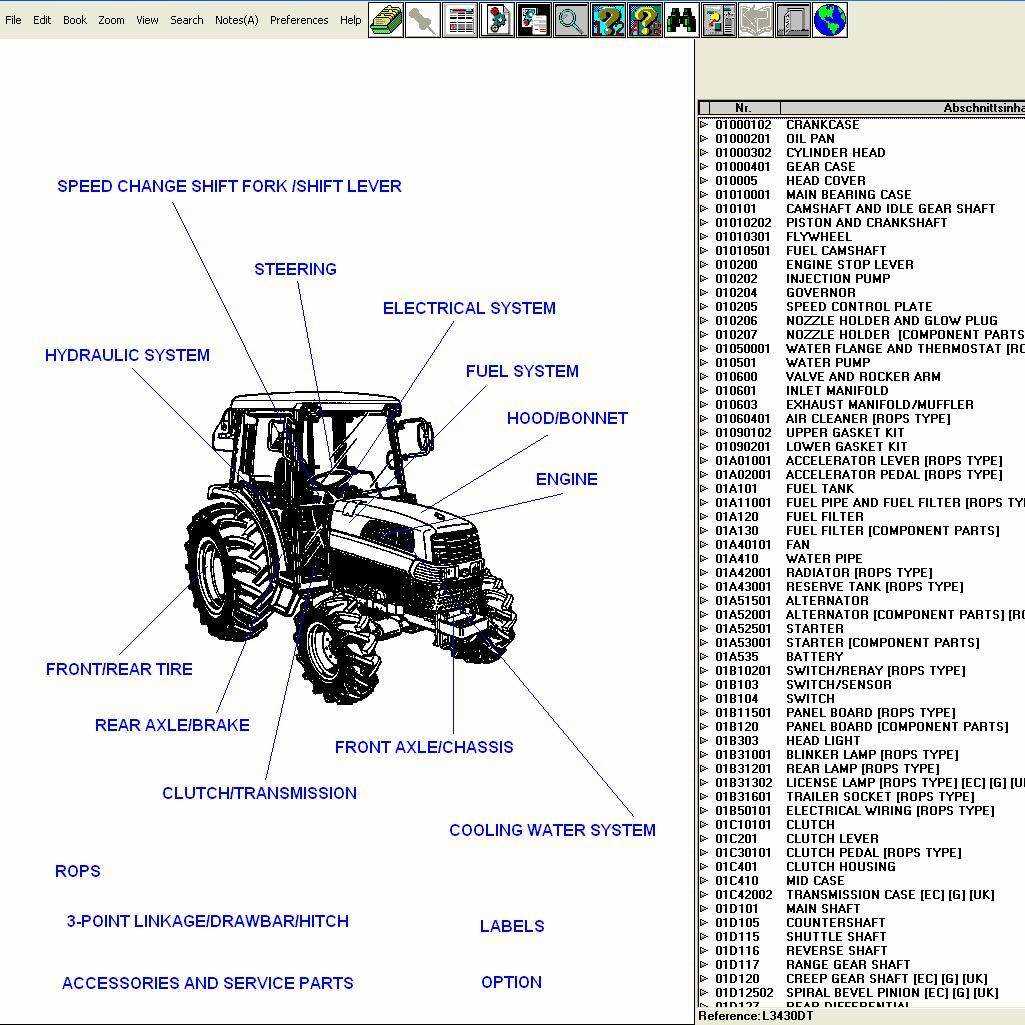

Importance of Parts Diagrams

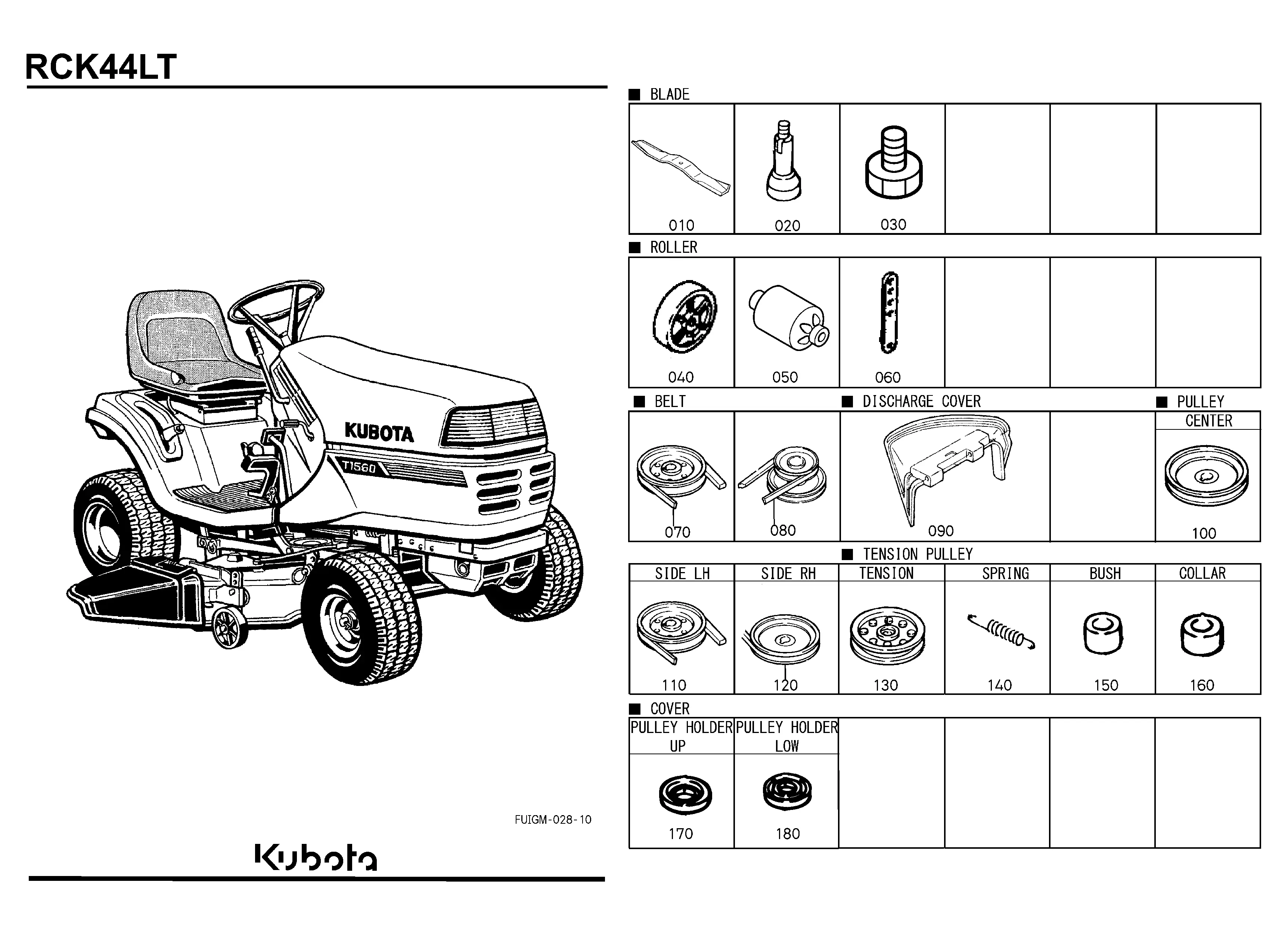

Understanding the layout and components of any machinery is crucial for efficient maintenance and repairs. Visual representations of elements provide invaluable insight into their arrangements and functions. These illustrations serve as guides, enabling users to identify and understand the role of each segment within the assembly.

Having access to well-structured visuals enhances the troubleshooting process, allowing individuals to quickly pinpoint issues and determine the necessary actions. Additionally, these resources facilitate the ordering of replacements, ensuring that the correct items are acquired without delay.

| Benefits | Description |

|---|---|

| Clarity | Visual aids simplify the understanding of complex structures. |

| Efficiency | Quickly locate issues and necessary replacements, reducing downtime. |

| Accuracy | Ensure correct parts are ordered, minimizing errors in maintenance. |

| Learning Tool | Helps new users familiarize themselves with machinery components. |

Common Parts and Their Functions

This section explores the essential components found in various machinery and their respective roles. Understanding these elements is crucial for maintaining optimal performance and ensuring longevity. Each piece serves a unique purpose, contributing to the overall functionality and efficiency of the equipment.

Key Components

Each component plays a vital role in the operation of the equipment, allowing for seamless interaction between systems. Familiarity with these elements enhances troubleshooting and repair processes, empowering users to address issues more effectively.

| Component | Function |

|---|---|

| Engine | Drives the machinery, converting fuel into mechanical energy. |

| Transmission | Transfers power from the engine to the wheels, enabling movement. |

| Hydraulic System | Powers various attachments and lifts, utilizing fluid pressure. |

| Battery | Stores electrical energy to power electrical components and start the engine. |

| Cooling System | Regulates engine temperature, preventing overheating during operation. |

Conclusion

Recognizing the key components and their functions enables users to maintain equipment effectively and ensure optimal performance. Regular inspection and understanding of these parts can lead to better management and prolong the lifespan of the machinery.

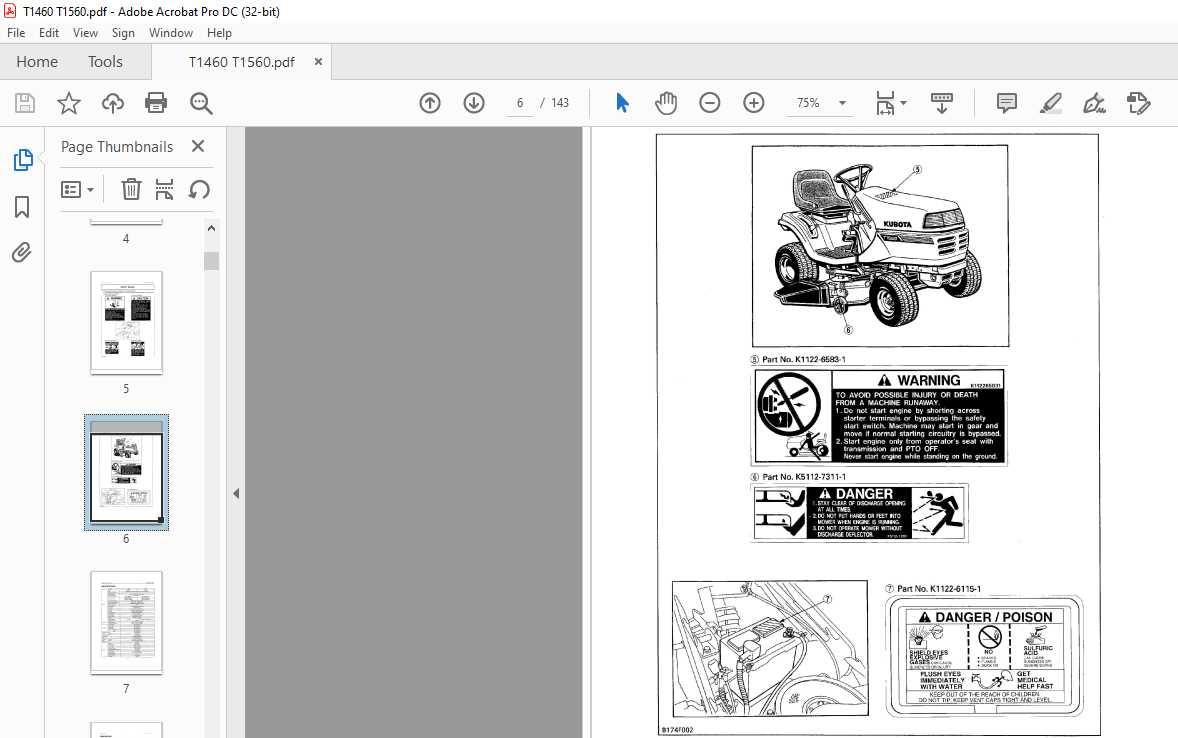

How to Interpret the Diagram

Understanding visual representations of mechanical components is crucial for effective maintenance and repair. These illustrations serve as a valuable resource, guiding users through the intricate relationships and functions of various elements within a system.

Identifying Components

Begin by familiarizing yourself with the symbols and notations used in the illustration. Each element is typically represented by a specific icon or shape, which corresponds to its function. Recognizing these representations allows for quicker identification of parts, facilitating more efficient troubleshooting.

Understanding Relationships

After identifying individual elements, focus on how they interact with one another. Arrows and lines often indicate connections or pathways between components. Pay attention to these connections as they provide insight into how different parts work together, enhancing your overall understanding of the system’s operation.

Identifying Essential Components

Understanding the crucial elements of machinery is vital for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance, making it essential to recognize their functions and relationships within the system.

Core Elements

The core elements are fundamental to the overall functionality of the equipment. Recognizing these components allows users to troubleshoot issues more effectively and implement necessary adjustments or repairs. Familiarity with these parts ensures smooth operation and enhances the lifespan of the machinery.

Maintenance and Care

Regular inspection and care of key elements contribute to the longevity of the equipment. By identifying wear and tear, users can proactively address potential problems, preventing costly repairs and downtime. Understanding the importance of each component encourages responsible usage and maintenance practices.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular attention and care. By following specific maintenance practices, you can enhance the lifespan of your machinery, minimize downtime, and optimize performance. These guidelines will help you maintain your equipment in excellent condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace engine oil to ensure smooth operation and reduce wear. |

| Air Filter Inspection | Every 25 hours | Check and clean the air filter to prevent dirt from entering the engine. |

| Battery Check | Monthly | Inspect battery terminals for corrosion and ensure proper connections. |

| Tire Pressure Check | Weekly | Maintain recommended tire pressure for optimal traction and efficiency. |

| Belts and Hoses Inspection | Every 100 hours | Examine for signs of wear or damage and replace as necessary. |

Regular adherence to these tasks will promote a reliable operation, ultimately resulting in prolonged service life and reduced repair costs. Establishing a routine maintenance schedule can yield significant benefits, ensuring your equipment remains functional and efficient for years to come.

Ordering Replacement Parts

When it comes to maintaining machinery, acquiring suitable components is essential for optimal performance. Identifying the necessary replacements can enhance the longevity and efficiency of your equipment. Understanding the ordering process can simplify this task significantly.

Start by identifying the required components. This may involve reviewing any documentation or reference materials that provide details about the specific items needed. Ensure that you have the correct specifications, as this will help avoid ordering errors.

Once you know what you need, explore various suppliers. Numerous vendors offer components for different models and brands. Compare prices, availability, and delivery options to make an informed decision. It’s beneficial to read customer reviews to gauge the reliability of each supplier.

After selecting a supplier, place your order with precision. Double-check your order details before finalizing the transaction to ensure accuracy. Providing accurate shipping information will help avoid delays.

Lastly, keep track of your order status. Most suppliers provide tracking options, allowing you to monitor the shipment. Upon receiving your components, inspect them to confirm they match your order. Proper handling and installation will ensure your equipment operates smoothly.

Resources for Kubota Owners

For individuals who own machinery, accessing reliable information and support is crucial for maintenance and operation. A variety of resources are available to ensure that owners can effectively care for their equipment and maximize its performance.

Here are some valuable avenues to explore:

- Official Websites: Many manufacturers offer comprehensive resources on their platforms, including product specifications, maintenance tips, and troubleshooting advice.

- Online Forums: Community-driven forums provide a space for users to share experiences, seek advice, and discuss best practices with fellow owners.

- Local Dealerships: Authorized dealerships often have knowledgeable staff who can assist with inquiries, service options, and genuine replacement components.

- Video Tutorials: Various platforms host instructional videos that demonstrate maintenance procedures and repair techniques, making learning more accessible.

- Printed Guides: Hard copies of guides can be beneficial for hands-on reference and can often be found at local retailers or through online vendors.

Utilizing these resources can significantly enhance the ownership experience, providing essential support for any challenges that may arise.

Finding Technical Support Online

Accessing assistance for your machinery can be streamlined by leveraging digital resources. The internet provides a wealth of information, from troubleshooting guides to community forums, ensuring you can resolve issues efficiently.

Here are several effective strategies to locate support:

- Manufacturer Websites: Visit the official website of the equipment manufacturer. Often, they provide comprehensive resources, including FAQs and contact details for support.

- User Forums: Engage with communities on platforms dedicated to machinery enthusiasts. These forums are invaluable for sharing experiences and solutions.

- Social Media Groups: Join relevant groups on social media where users discuss their equipment. These groups can provide quick answers and support.

- YouTube Tutorials: Search for video guides that demonstrate repairs or common issues. Visual aids can enhance understanding and offer step-by-step instructions.

- Online Retailers: Explore online retailers that specialize in machinery. They often have customer service representatives who can assist with inquiries related to products.

By utilizing these online resources, you can efficiently find the support needed to maintain and troubleshoot your equipment, ensuring optimal performance.