Every mechanical device relies on a carefully orchestrated combination of components to function effectively. The internal configuration is key to ensuring smooth operation and long-lasting performance. Without a clear understanding of how various elements are arranged, maintaining or repairing such equipment becomes a complex task.

Having a well-organized overview of the individual elements and their connections allows for easier troubleshooting and servicing. Whether you’re looking to optimize performance or replace worn-out components, recognizing the layout of each part is essential for keeping everything in working order.

In this guide, we will delve into the intricate network of components, exploring their roles and relationships. By the end, you will gain a better understanding of how to approach maintenance and repairs with confidence.

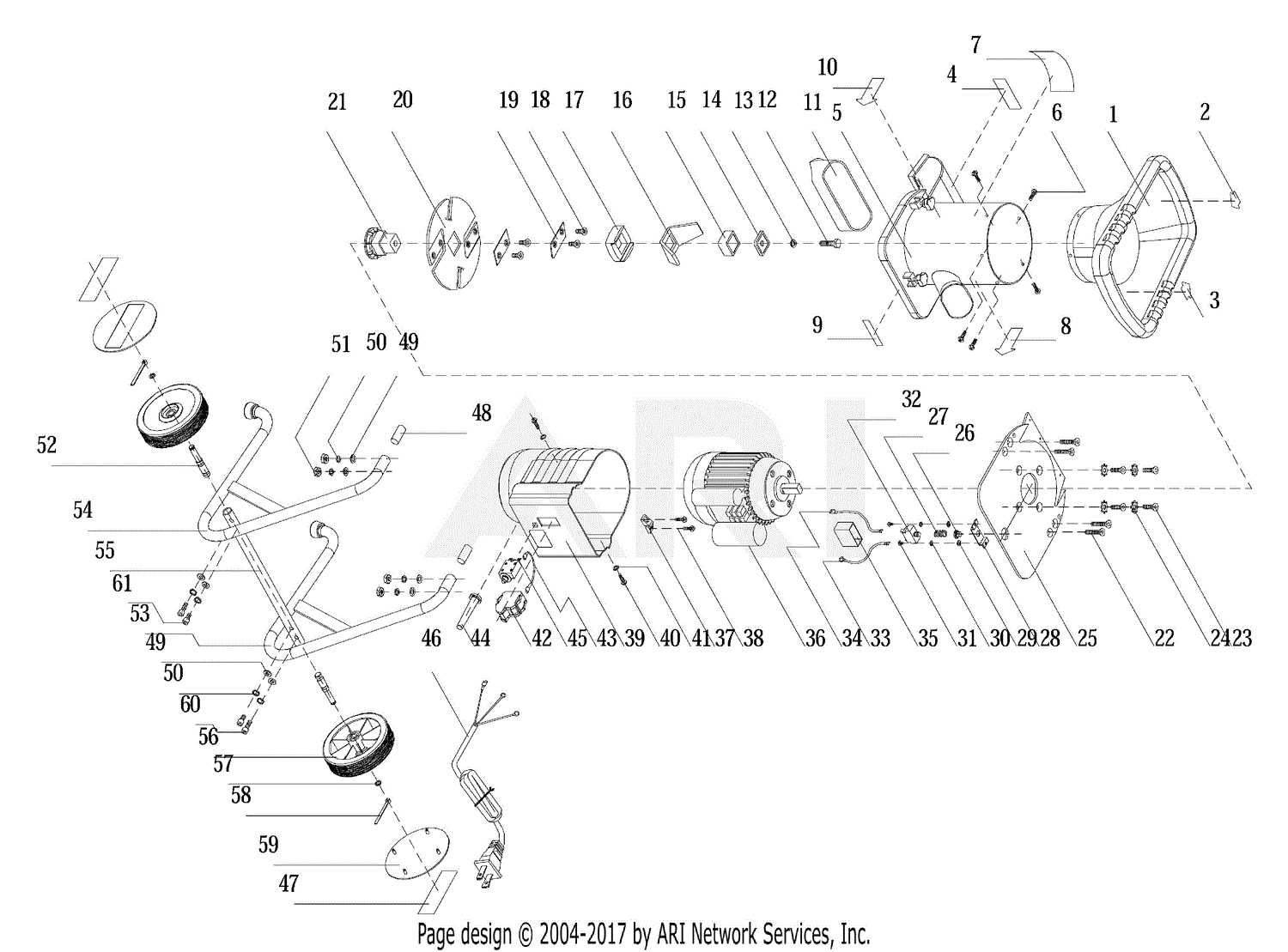

McCulloch Lawn Mower Parts Diagram

Understanding the arrangement of essential components within this mechanical device is crucial for optimal operation and maintenance. Each element serves a specific role, contributing to the overall performance and efficiency. By exploring the structure, users can quickly identify the necessary sections for repair or replacement.

Key Elements of the Device

At the core of the system are several critical elements that ensure smooth operation. From the cutting mechanism to the power source, each section plays an indispensable role. Identifying these components helps in troubleshooting and maintaining the equipment over time.

Maintaining and Replacing Components

Proper upkeep involves regular inspection and timely replacement of worn-out elements. By familiarizing yourself with the layout of the machine, you can easily detect issues before they lead to larger problems, ensuring long-term functionality and reliability.

Identifying Key Components of Your Mower

Understanding the primary elements of your machine is essential for both maintenance and efficient operation. Each part plays a critical role in ensuring smooth functionality, and knowing how these pieces interact can help in troubleshooting and repairs.

- Engine Unit: The heart of your equipment, responsible for powering the entire system.

- Blade Assembly: A sharp, rotating mechanism that cuts through vegetation, ensuring a clean finish.

- Fuel System: Supplies the necessary energy by storing and delivering fuel to the engine.

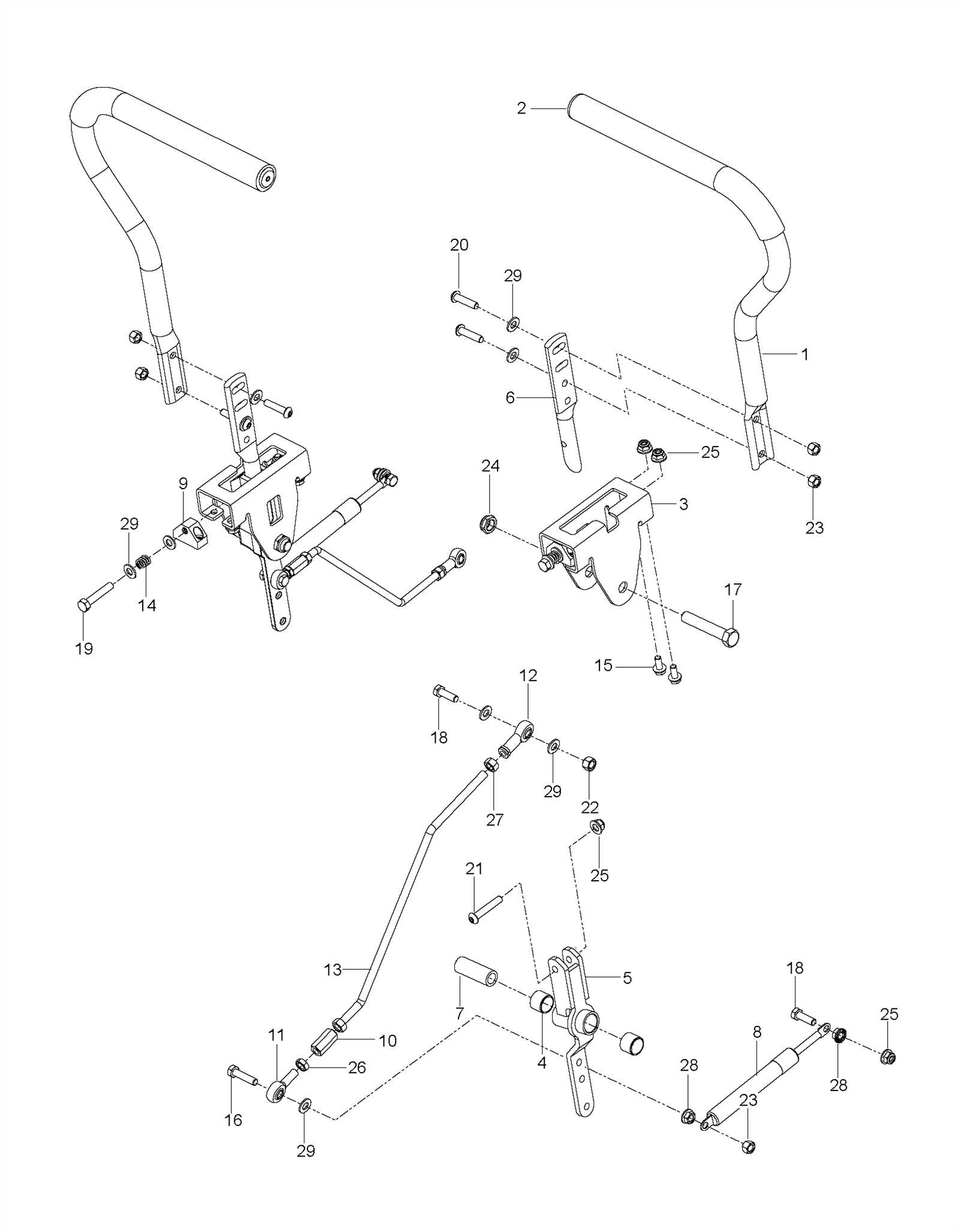

- Drive Control: Enables movement and direction control, ensuring the device moves at the desired pace.

- Handle and Controls: The interface through which the operator controls speed, direction, and power.

- Wheels: Provide stability and mobility, allowing smooth maneuverability across different terrains.

Understanding Blade Assembly and Its Role

The blade assembly is a critical component of any cutting machine, influencing its overall performance and efficiency. This section delves into the importance of the blade structure and how it contributes to effective operation. A well-designed assembly ensures precise cutting, enhancing the quality of the work and the longevity of the equipment.

Components of the Blade Assembly

The assembly typically consists of various elements, each serving a distinct function. These include the cutting blades, which are often made from durable materials to withstand wear and tear. Additionally, the attachment mechanism plays a vital role in securing the blades in place, preventing them from becoming loose during operation. Understanding these components can help users maintain and optimize their equipment effectively.

Importance of Maintenance

Regular maintenance of the blade assembly is essential for optimal performance. Dull or damaged blades can lead to inefficient cutting, requiring more power and potentially causing strain on the machine. By routinely inspecting and sharpening the blades, users can ensure a clean cut, improving the overall functionality and extending the lifespan of their equipment.

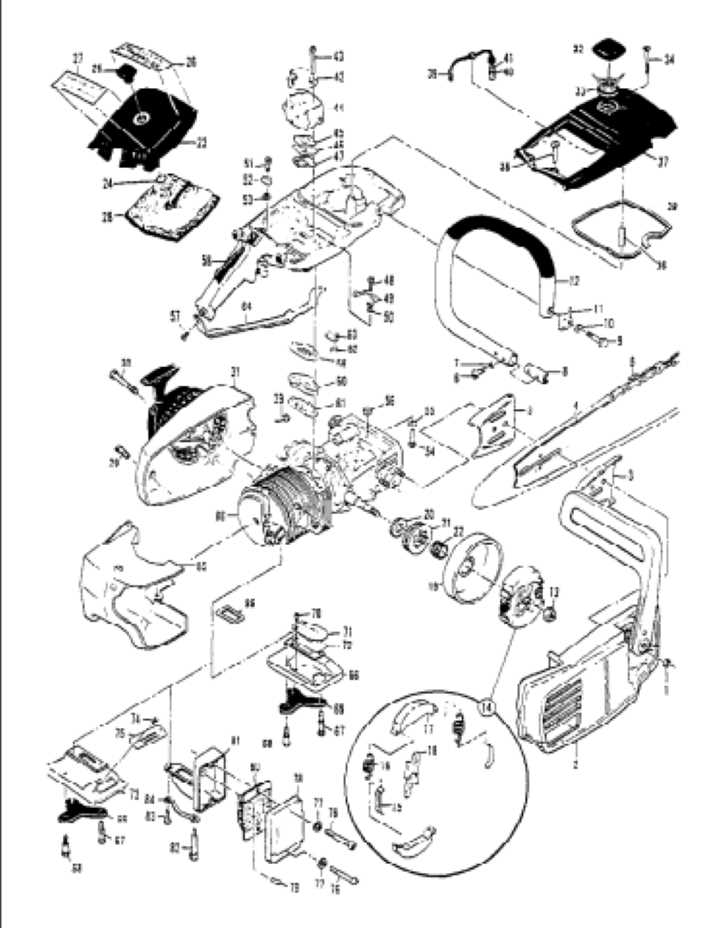

Exploring Engine Layout for Efficient Performance

The arrangement of components within a power unit plays a crucial role in maximizing operational efficiency. A well-thought-out configuration ensures that each element contributes to optimal performance while minimizing energy loss. Understanding how these elements interact can significantly enhance the overall effectiveness of the machinery.

Key factors in the design include the alignment of the ignition system, fuel delivery mechanisms, and cooling solutions. Each aspect must be meticulously planned to foster a seamless flow of energy and maintain functionality under various conditions.

| Component | Function |

|---|---|

| Ignition System | Initiates combustion, ensuring timely energy release |

| Fuel System | Delivers the correct mixture of air and fuel for efficient burning |

| Cooling Mechanism | Prevents overheating, maintaining optimal operating temperatures |

| Exhaust System | Directs waste gases away, enhancing engine breathing |

Ultimately, a carefully crafted arrangement leads to improved durability, lower emissions, and increased reliability, making it essential for users to understand the intricacies of their machinery’s configuration.

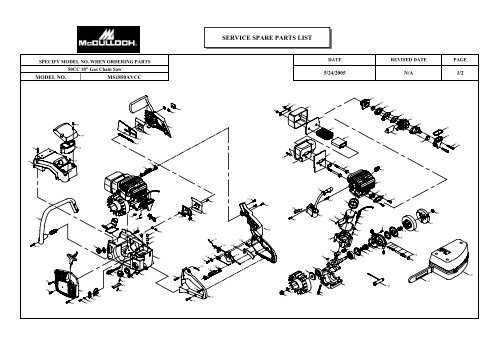

Fuel System and Tank Connections Overview

The fuel delivery network plays a critical role in the efficient operation of outdoor power equipment. This section outlines the essential components and connections that ensure the optimal flow of fuel from the reservoir to the engine, enabling reliable performance during operation.

Understanding the configuration of the fuel system is vital for maintenance and troubleshooting. Key elements include:

- Fuel Tank: The primary container that holds the liquid fuel necessary for operation.

- Fuel Lines: Hoses that transport fuel from the tank to the engine, ensuring a steady supply.

- Fuel Filter: A component that removes impurities from the fuel before it reaches the engine.

- Carburetor: A device that mixes air with fuel in the proper ratio for combustion.

- Fuel Pump: A mechanism that facilitates the movement of fuel from the tank to the engine.

Proper connections between these components are essential for effective fuel management. Regular inspection of hoses and fittings can prevent leaks and ensure that the system operates efficiently. Maintaining the integrity of the fuel system contributes significantly to the longevity and reliability of outdoor equipment.

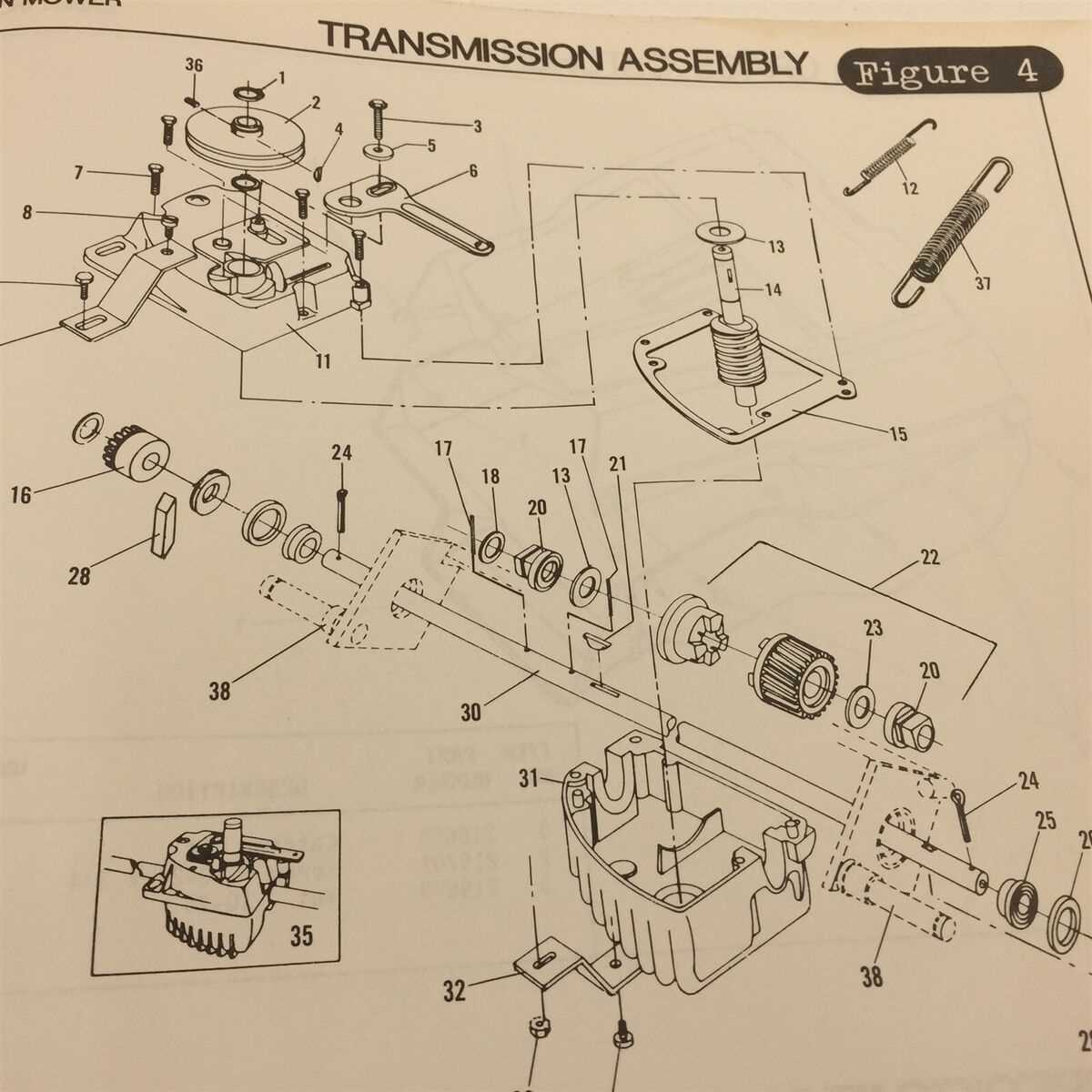

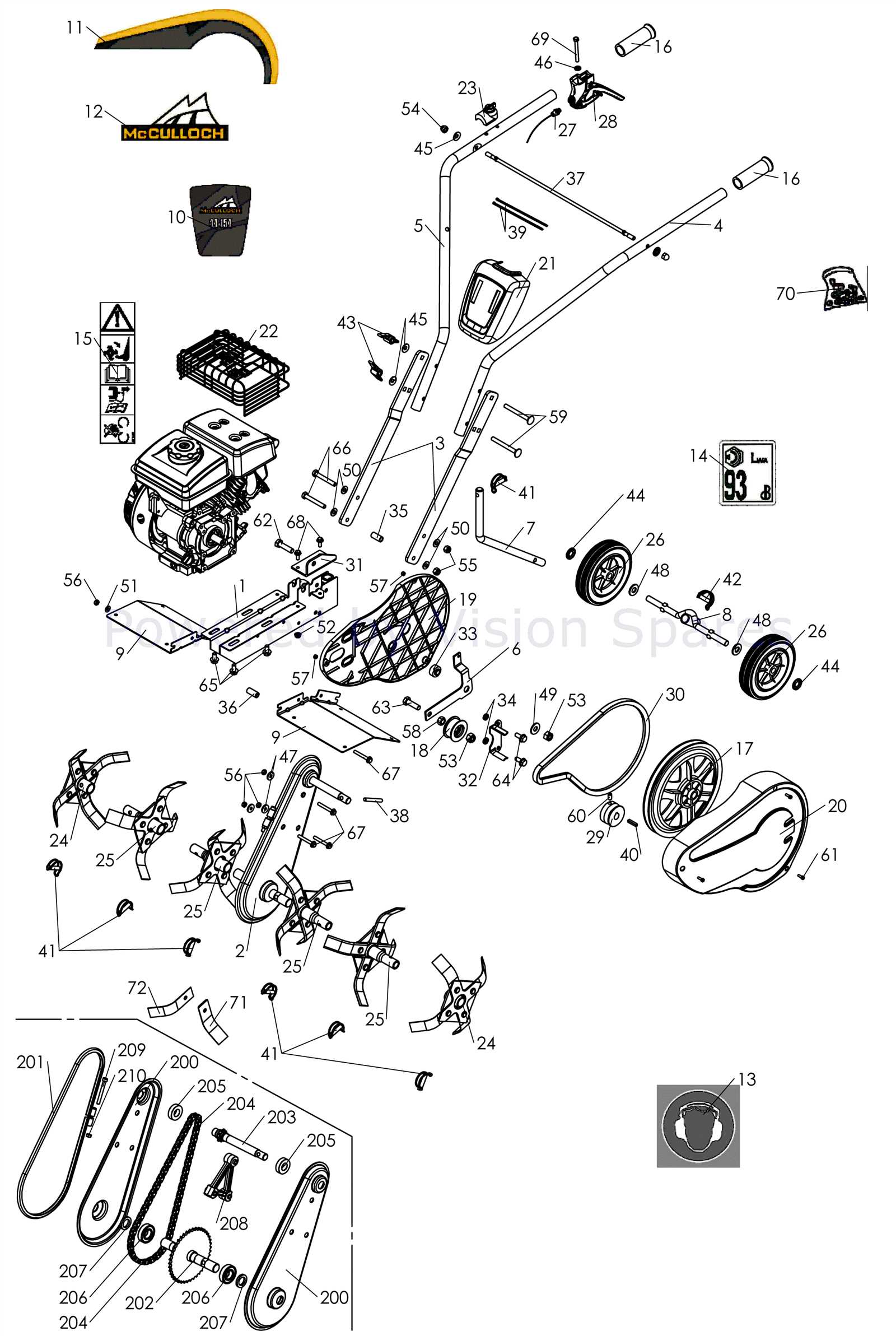

How the Drive Mechanism Works

The propulsion system is essential for the smooth operation of various machines that require movement over surfaces. This system helps transfer energy from the power source to the wheels, allowing effortless motion. Understanding how it functions is crucial for maintaining and optimizing performance.

- Energy Transfer: The core function involves converting the energy generated by the engine into mechanical force that moves the wheels. This is achieved through a series of gears and belts that synchronize the movement.

- Gear System: Gears within the mechanism adjust the speed and torque, depending on the terrain and user control. The configuration allows for both increased speed on flat surfaces and extra force for tougher conditions.

- Control Linkage: A system of levers and cables connects the operator’s controls to the drive system, enabling the user to adjust speed or stop the movement when necessary.

- Friction and Traction: Proper contact between the wheels and the ground is ensured by friction control, preventing

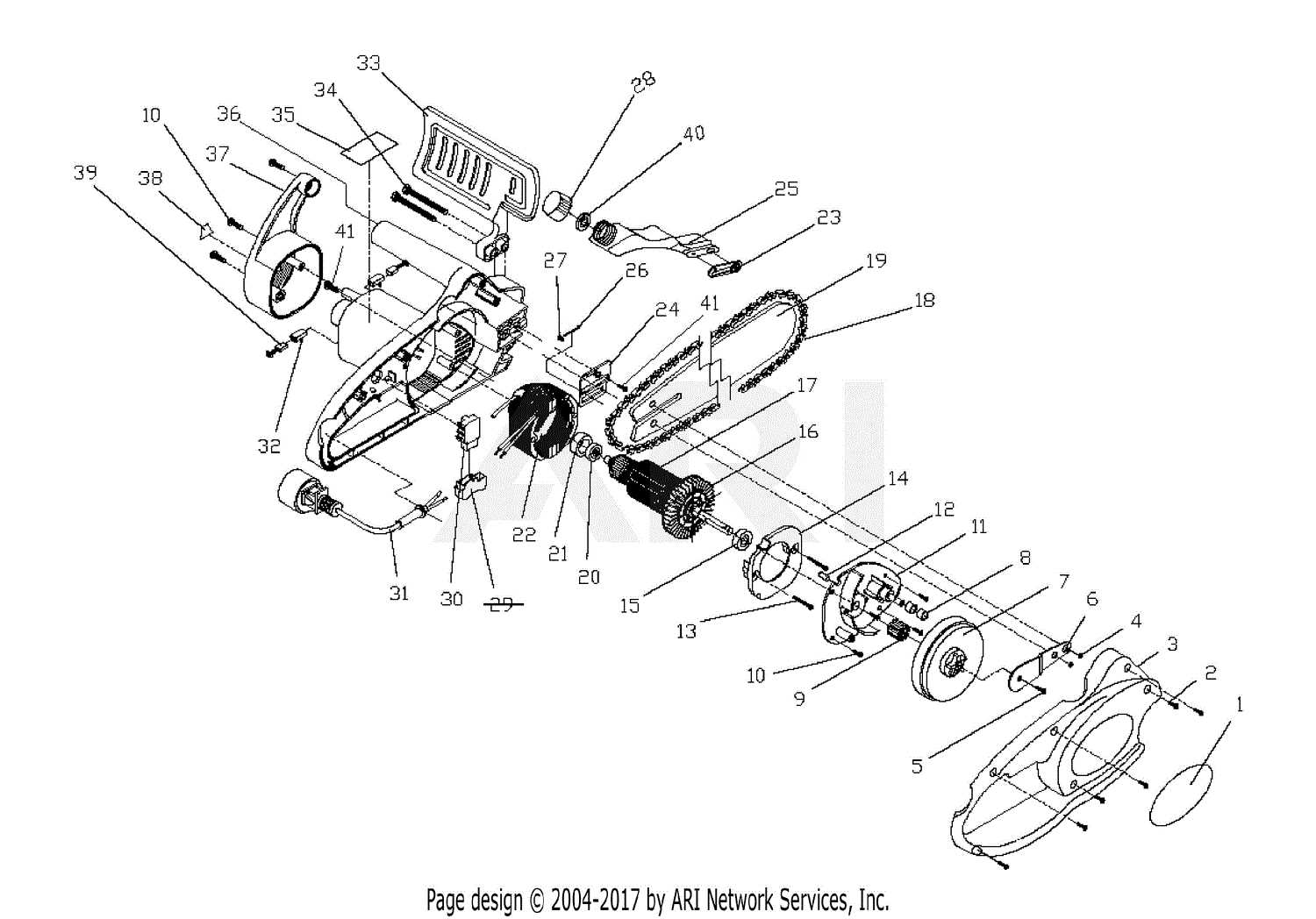

Wiring and Electrical Parts Breakdown

This section delves into the intricate components responsible for the electrical functions within the machine. Understanding these elements is essential for troubleshooting and maintenance, ensuring that the system operates smoothly and efficiently.

At the core of the electrical assembly are the wiring harnesses and connectors, which facilitate communication between various components. The quality and arrangement of these connections can significantly impact performance.

Component Description Ignition Switch Controls the power flow to the engine, allowing for startup and shutdown. Battery Stores electrical energy needed to start the engine and power accessories. Starter Motor Engages the engine to initiate combustion and start the machine. Fuse Protects the electrical circuit from overload by breaking the connection if current exceeds safe levels. Relay Acts as a switch that uses a low-power signal to control a high-power circuit. Analyzing the Air Filter and Intake System

The air filtration and intake mechanism plays a crucial role in the overall efficiency of an engine. This system is designed to ensure that clean air enters the combustion chamber, which is essential for optimal performance and longevity. By effectively filtering out dust and debris, it helps maintain the engine’s power and reduces wear over time.

Importance of Proper Air Filtration

A well-functioning filtration system is vital for preventing contaminants from entering the engine. Clean air contributes to better combustion, which in turn enhances fuel efficiency and reduces emissions. Neglecting this component can lead to serious issues, including reduced power output and increased fuel consumption.

Inspecting the Intake Components

Regular inspection of the intake system is recommended to ensure all components are functioning as intended. This includes checking for any blockages or damage to the filter and associated ducts. Maintaining a clean intake pathway not only improves performance but also extends the engine’s lifespan by minimizing unnecessary strain on its parts.

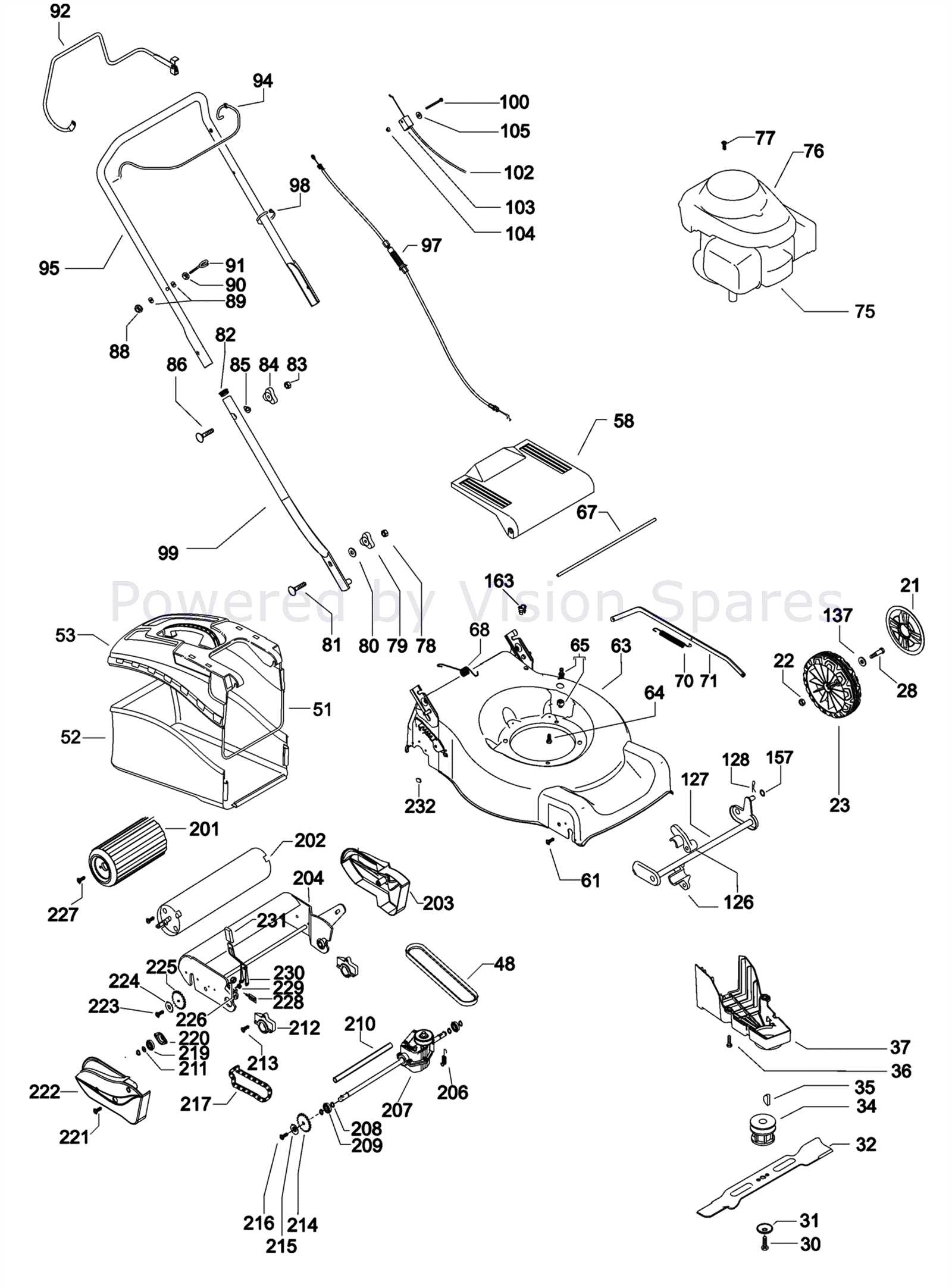

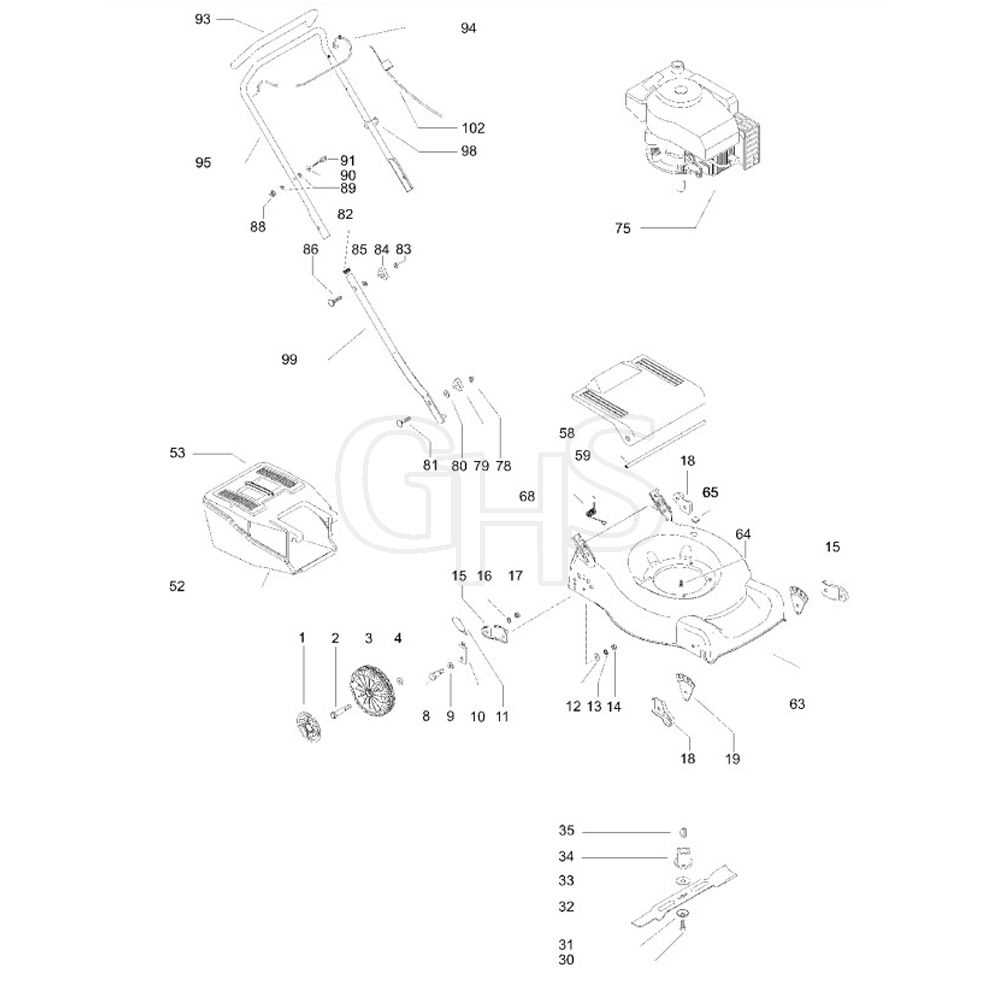

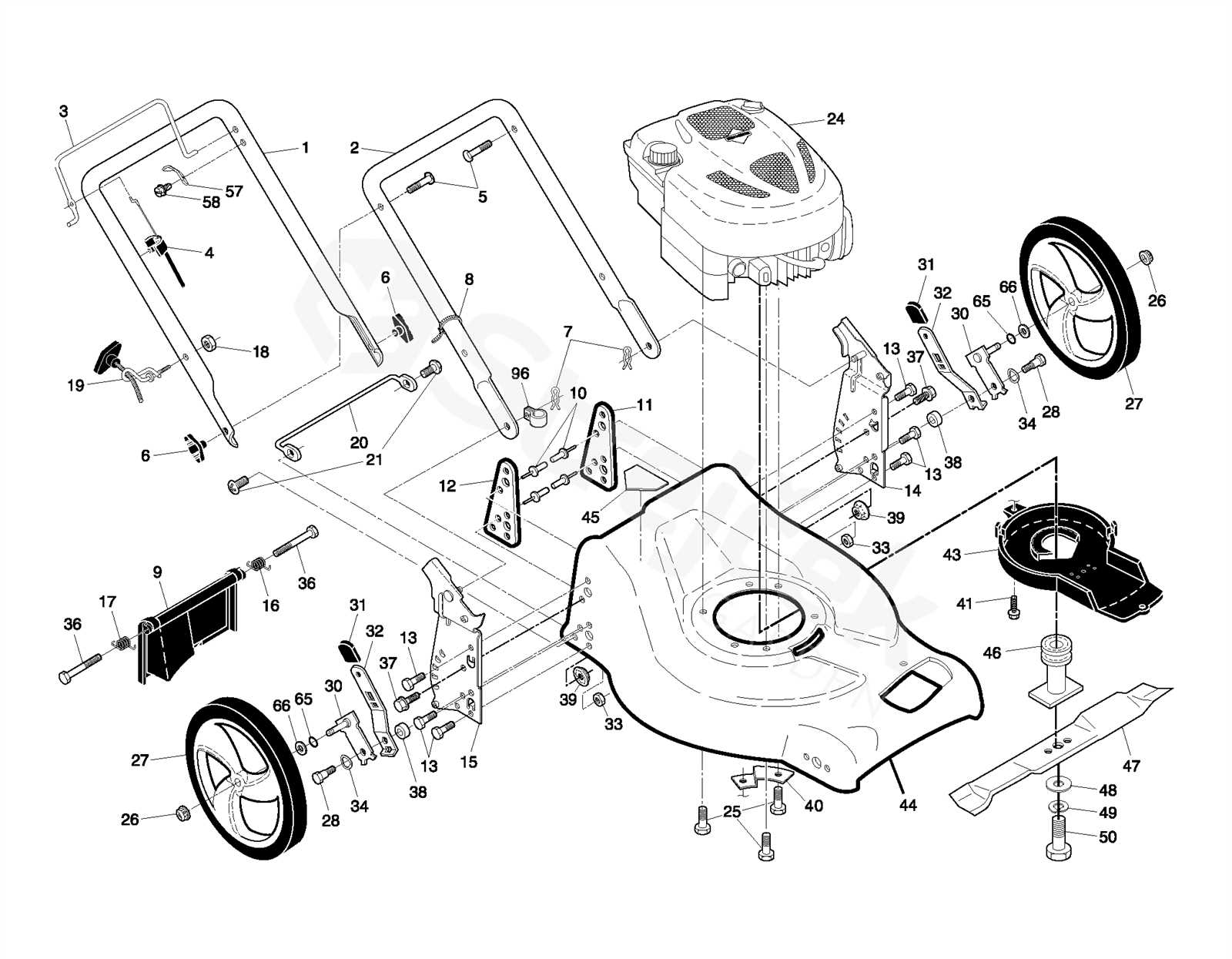

Deck Structure and Cutting Mechanism Explanation

The foundation and cutting system of a garden equipment unit play a crucial role in its overall performance and effectiveness. This section explores the intricate design of the base structure and the innovative techniques employed for trimming grass efficiently. Understanding these elements is essential for maintenance and optimal usage, ensuring a well-kept exterior space.

Overview of the Base Construction

The base structure is designed to provide stability and support for the entire apparatus. Typically made from durable materials, it is engineered to withstand the rigors of outdoor use while maintaining a lightweight profile. Key features include:

- Robust material composition

- Aerodynamic design for improved maneuverability

- Integrated support for the cutting system

Mechanics of the Cutting System

The cutting mechanism is a vital component that determines the efficiency of grass trimming. This system often consists of sharp blades, strategically positioned to ensure a clean and precise cut. The functionality is influenced by factors such as:

Feature Description Blade Type Different blade designs can enhance cutting performance, providing options for various grass types. Adjustable Height The ability to modify the cutting height allows for personalized grass length management. Drive Mechanism The propulsion system powers the blades and can vary from manual to automatic systems. Troubleshooting Common Mechanical Parts Issues

When dealing with mechanical equipment, encountering issues with various components is a common occurrence. Understanding the potential problems that can arise and how to address them can significantly enhance the efficiency and longevity of the machinery. This section will explore typical issues, their causes, and solutions to ensure optimal performance.

Identifying Common Problems

Recognizing symptoms of malfunction is the first step in effective troubleshooting. Here are some frequent indicators that may suggest mechanical difficulties:

- Unusual noises during operation

- Difficulty in starting the equipment

- Irregular power output

- Excessive vibration

Solutions and Preventative Measures

Once issues are identified, implementing the following solutions can help restore functionality:

- Inspect Connections: Ensure that all connections are secure and free from corrosion.

- Check for Blockages: Remove any debris that may be obstructing moving parts.

- Replace Worn Components: Identify and replace any damaged or worn-out elements.

- Regular Maintenance: Schedule routine checks to prevent future complications.

By staying vigilant and addressing issues promptly, users can maintain their equipment in excellent working condition, ultimately leading to enhanced performance and reliability.

Maintenance Tips for Long-Lasting Parts

Proper upkeep is essential for ensuring the durability and efficiency of mechanical components. By following a few straightforward practices, you can significantly extend the lifespan of your equipment and reduce the frequency of replacements. Regular attention to these elements not only enhances performance but also promotes a safe operating environment.

First and foremost, always keep the equipment clean. Accumulated dirt and debris can lead to wear and tear, affecting functionality. Regularly inspect and clean surfaces to prevent buildup. Additionally, lubricating moving components according to the manufacturer’s recommendations will help minimize friction and prolong their life. Make sure to use the appropriate type of lubricant to avoid damaging any surfaces.

Furthermore, it’s crucial to check for any signs of wear or damage regularly. Early detection of issues can prevent more significant problems down the line. If any component appears to be failing, address it promptly to avoid compromising the entire system. Finally, storing the equipment in a sheltered environment when not in use will protect it from harsh weather conditions, contributing to its longevity.