When maintaining or upgrading your 40 horsepower marine engine, understanding its key elements is crucial. Whether you’re looking to enhance performance or simply ensure smooth operation, knowing the structure and how each element contributes to the system can make a significant difference.

Each component plays a vital role in the engine’s overall functionality. From mechanical elements that drive power to smaller connectors ensuring seamless integration, the engine is a finely tuned machine. Proper care and attention to detail are essential to keeping everything in optimal condition.

In this guide, we’ll delve into the intricacies of various elements of the engine, offering insights into their roles, maintenance, and how to identify potential issues. This approach will help you keep your engine in peak form and ready for any aquatic adventure.

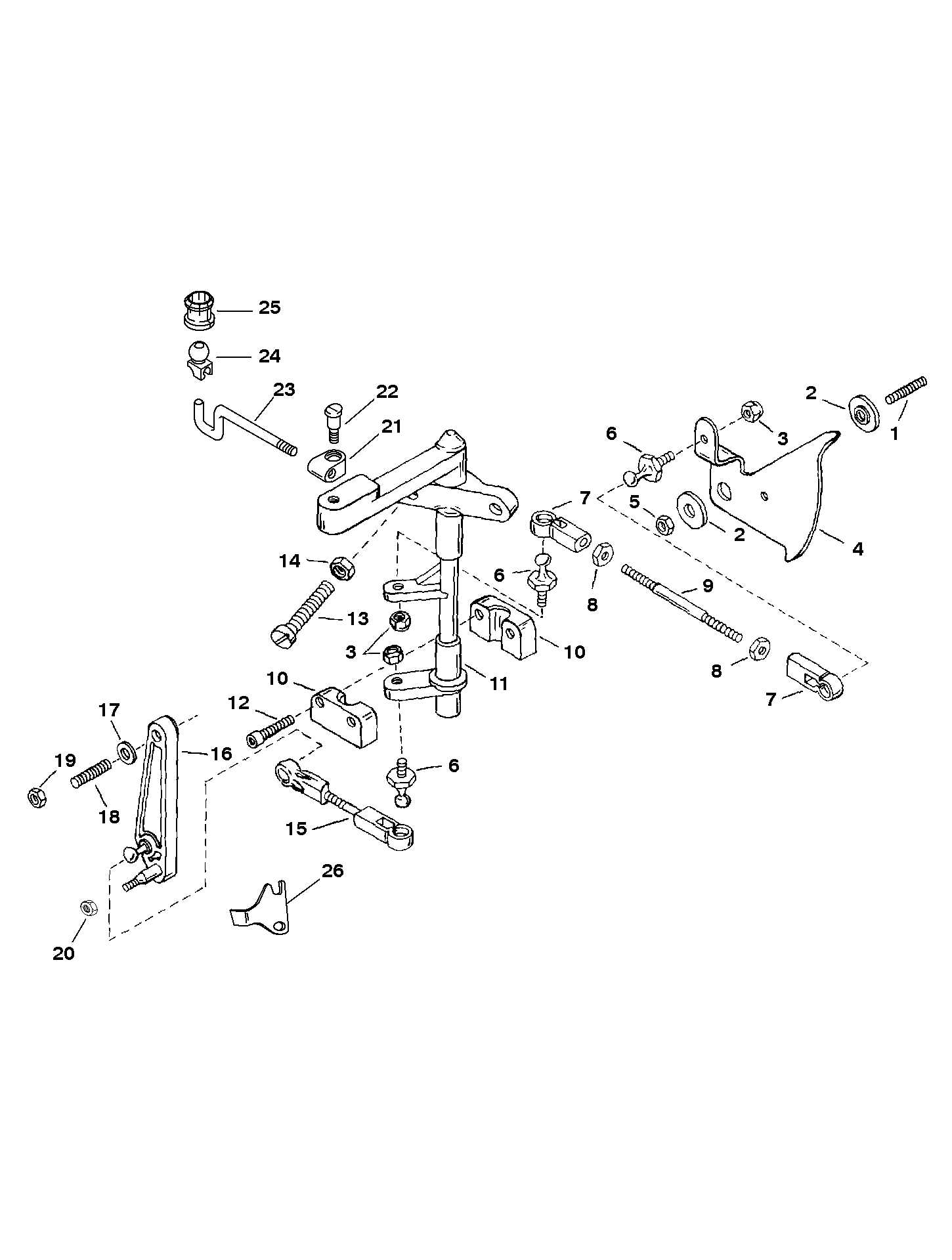

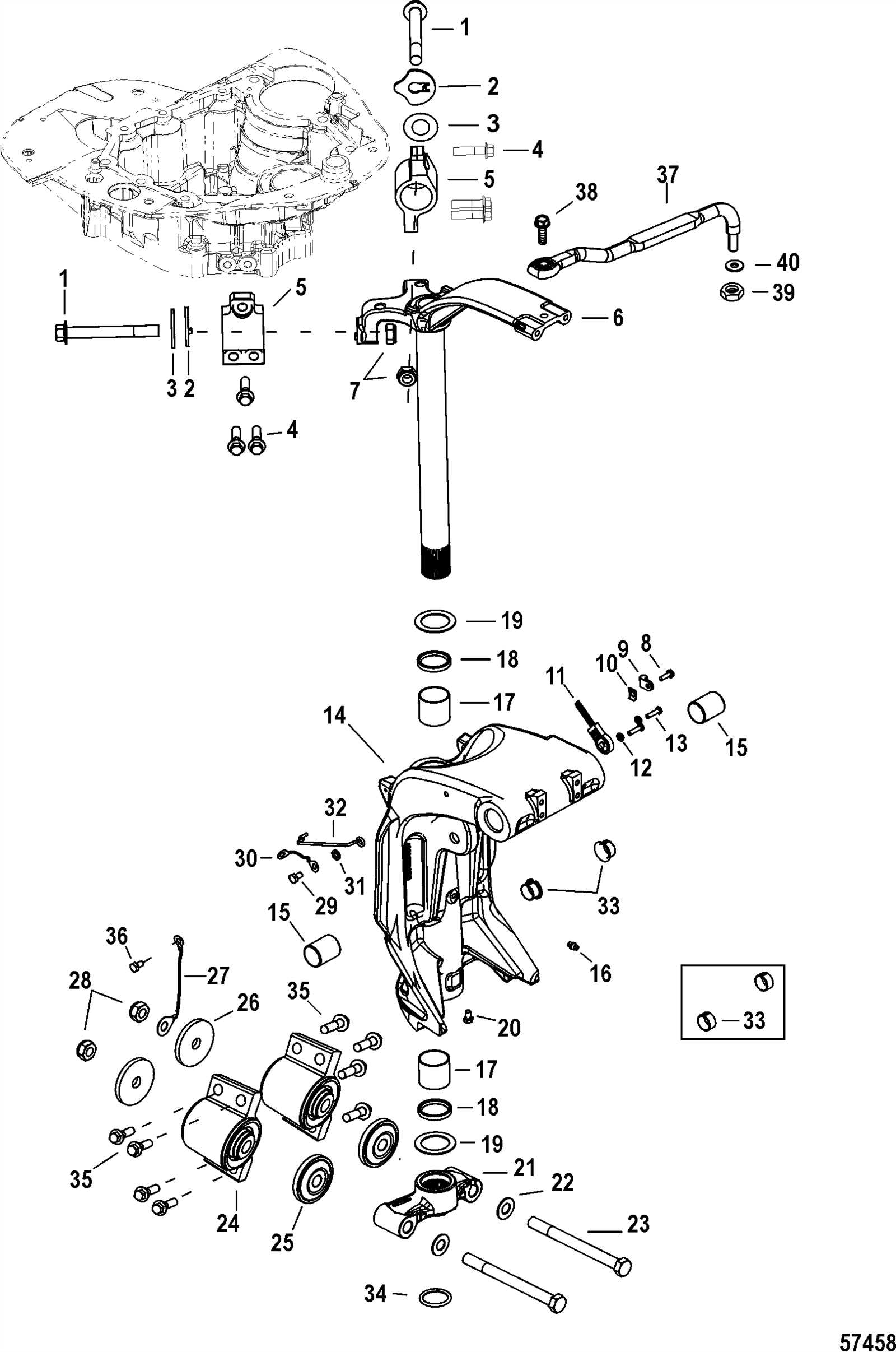

Understanding Mercury Outboard Engine Components

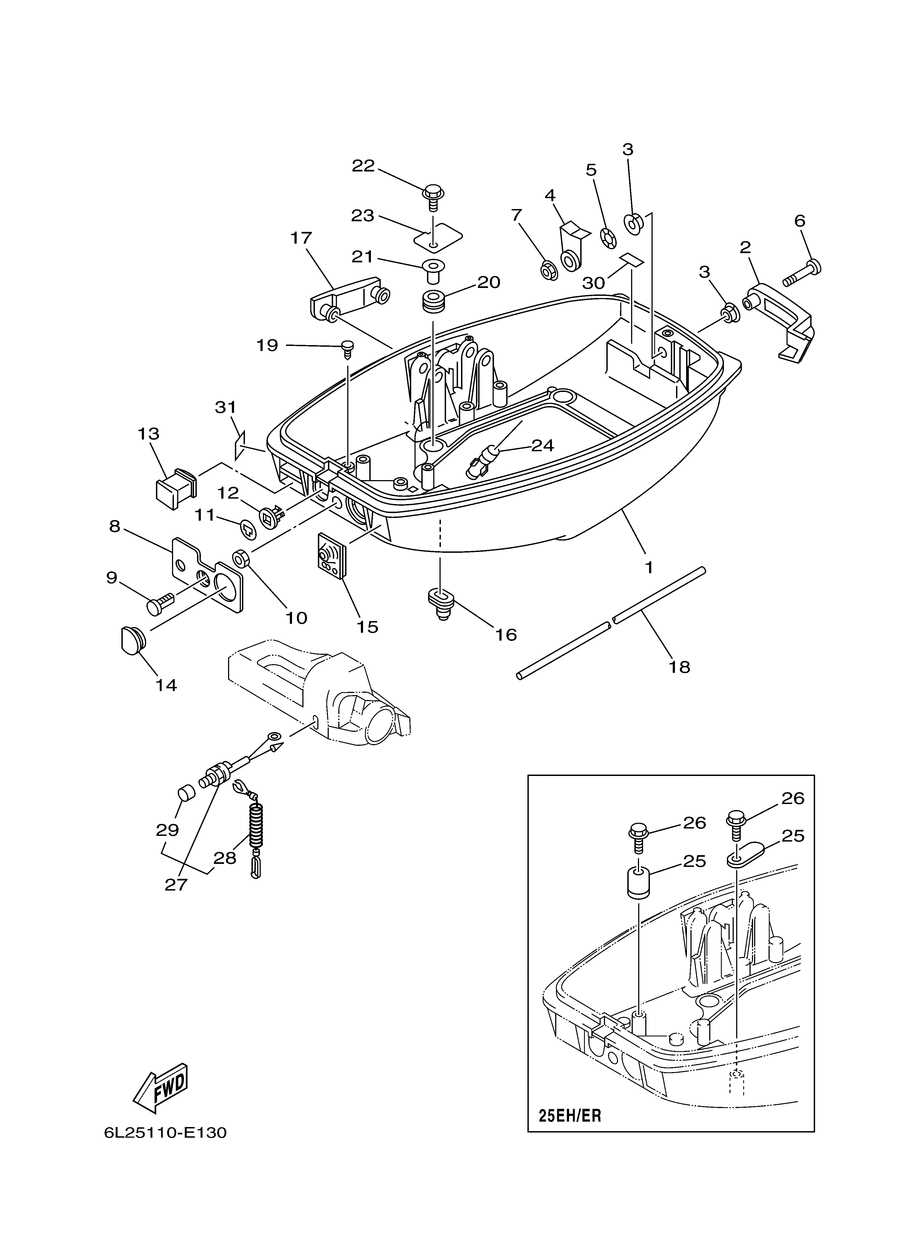

Recognizing the various elements within a marine engine is essential for anyone looking to maintain or repair their vessel. Each part works together to ensure smooth operation, making it crucial to grasp their functions and interactions. This knowledge aids in troubleshooting issues and performing routine care.

Key Engine Elements

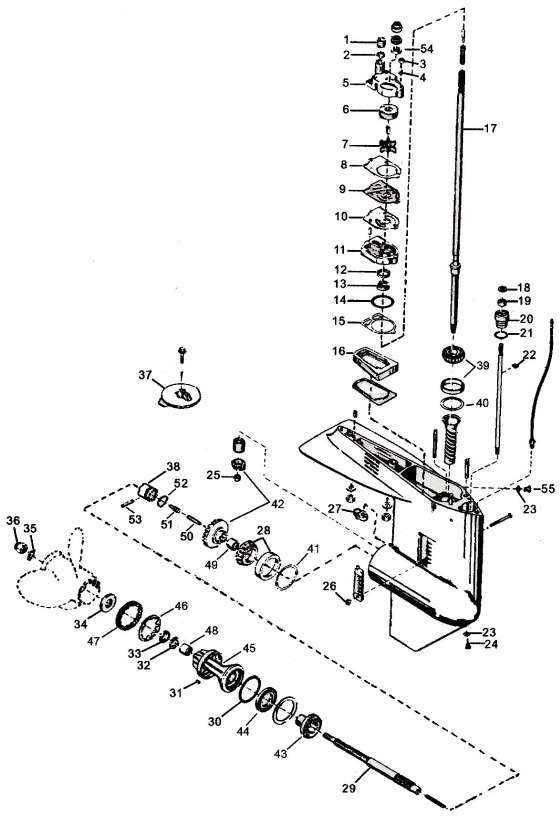

- Powerhead: The heart of the motor, responsible for generating energy and driving the propeller.

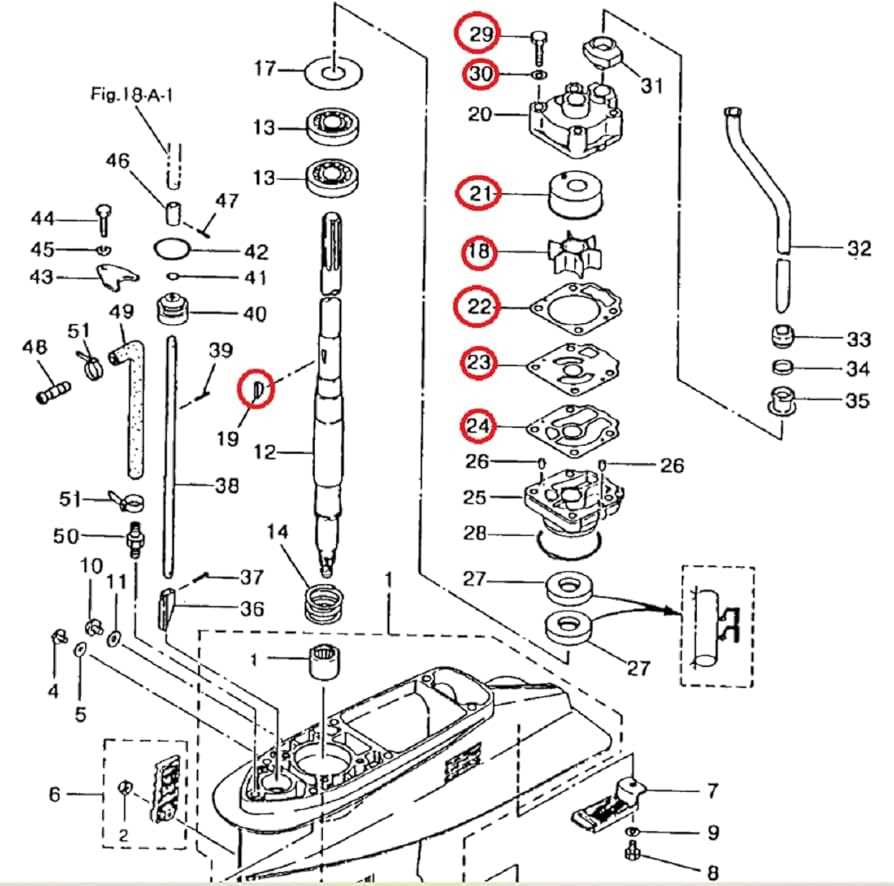

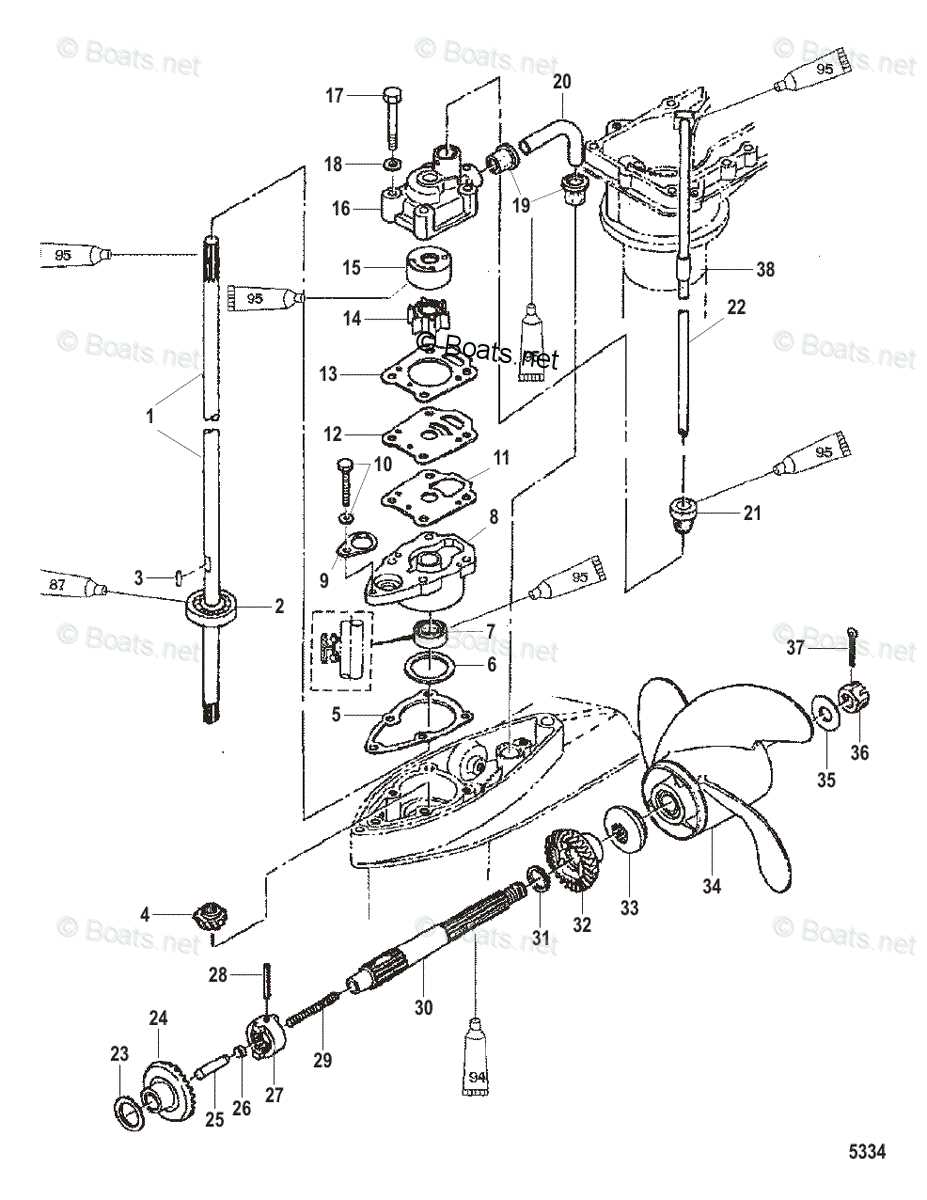

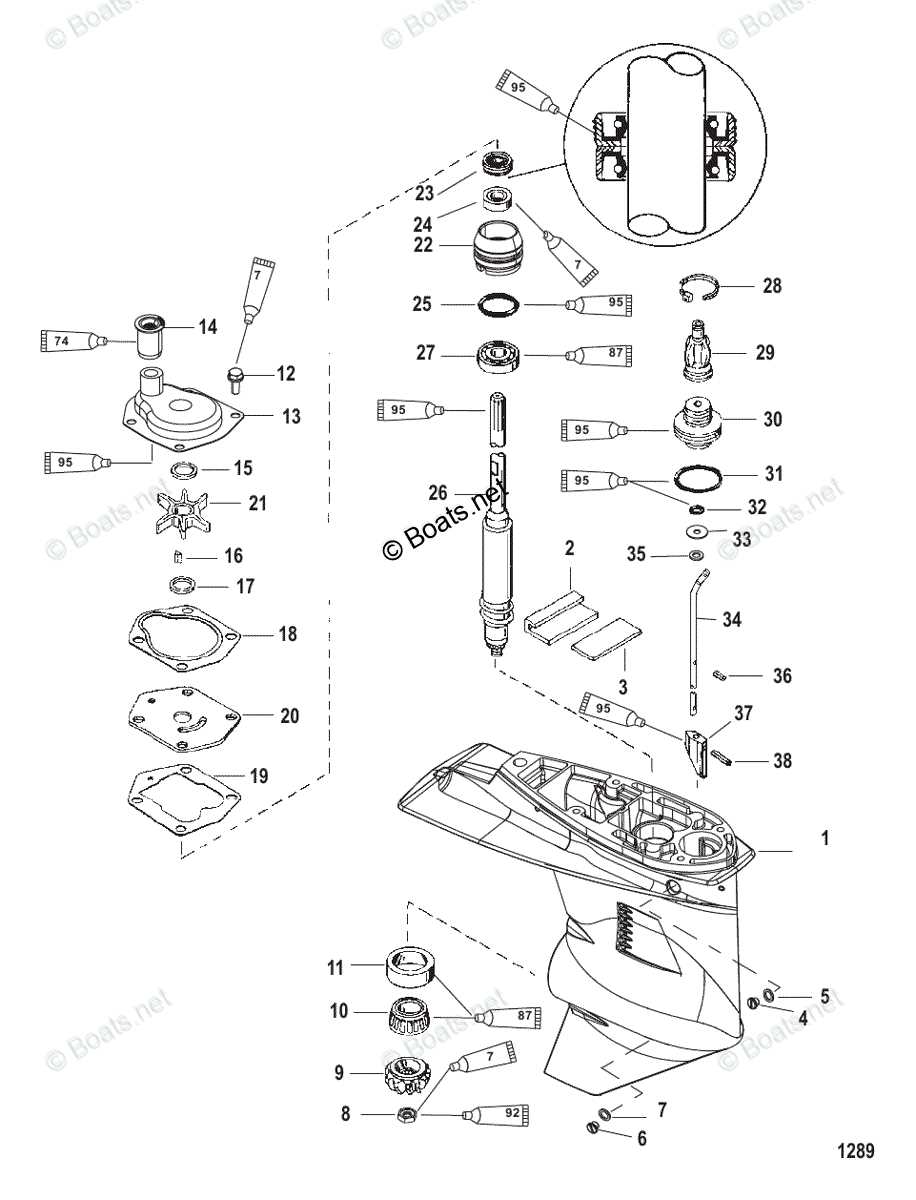

- Lower Unit: Contains gears and the propeller shaft, playing a vital role in controlling the boat’s movement.

- Cooling System: Ensures the motor maintains an optimal temperature, preventing overheating.

Maintenance Considerations

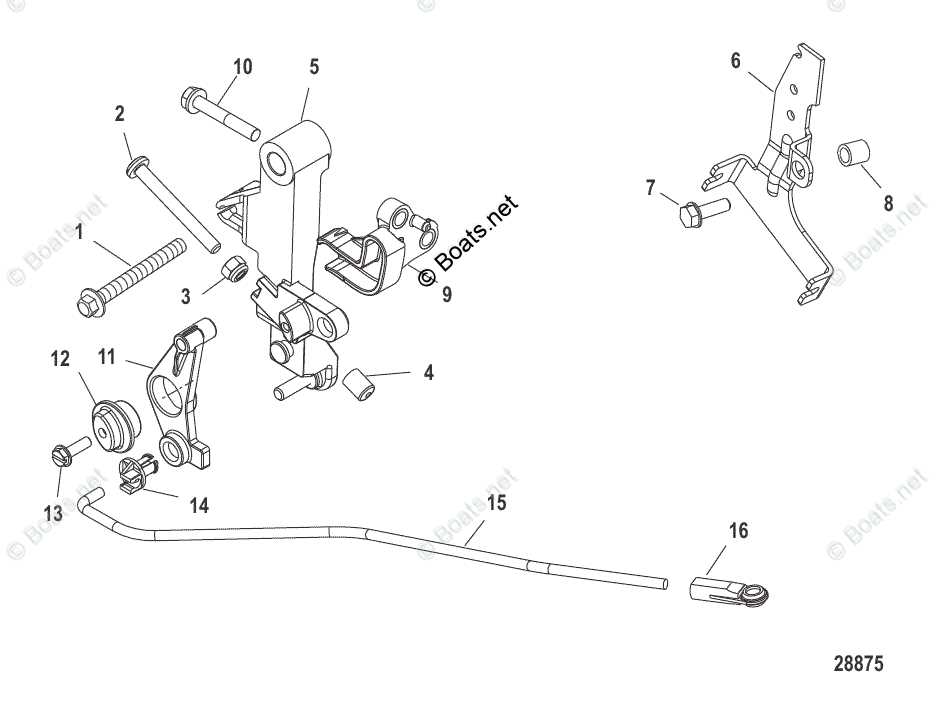

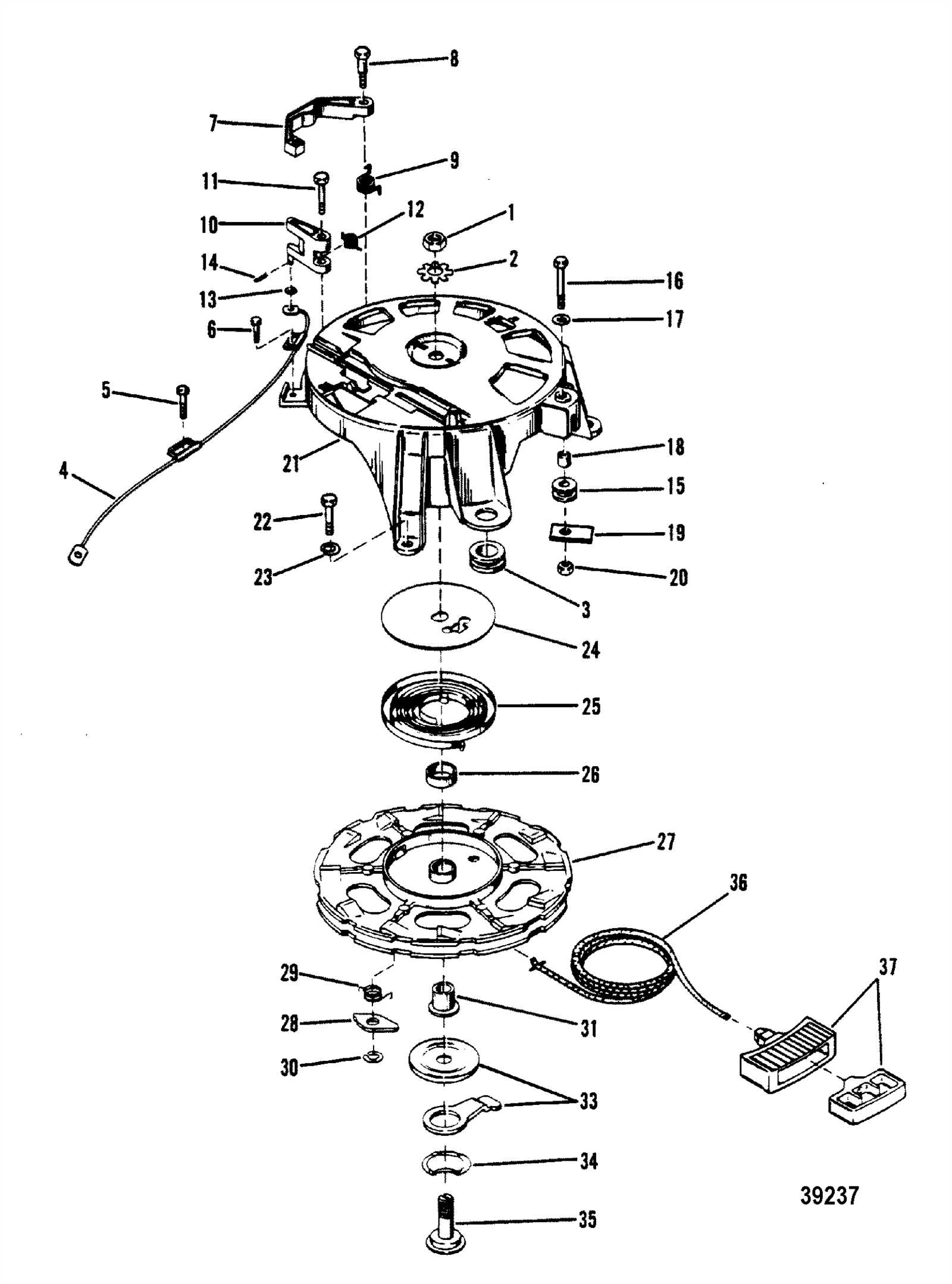

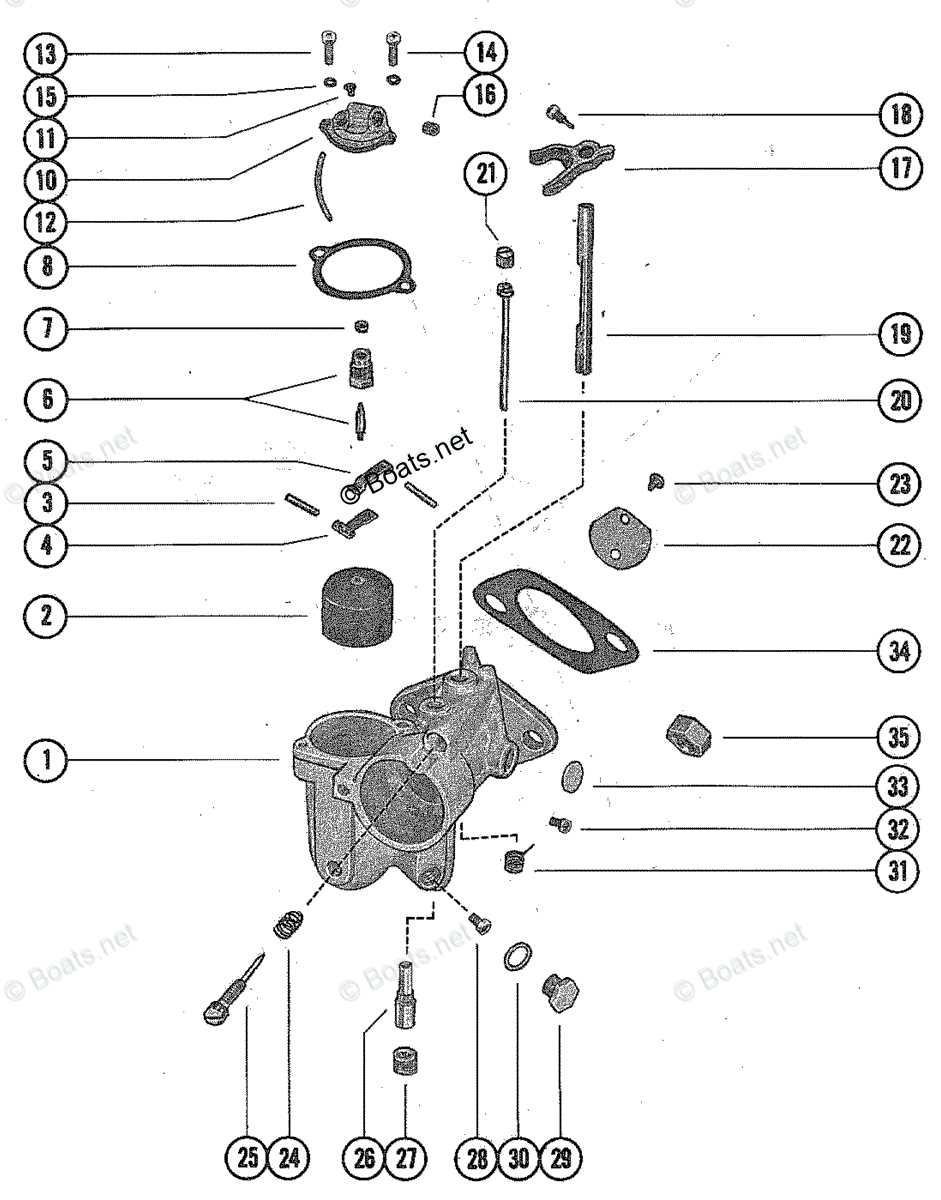

Key Parts in a 40 HP Outboard

A high-powered marine engine relies on multiple components working together to ensure smooth and reliable performance. Understanding the crucial elements that contribute to the engine’s functionality can help maintain its efficiency and longevity. Below is an overview of the most essential features found in a typical 40 horsepower unit.

Engine Block and Powerhead

The core of the engine is the powerhead, which generates the mechanical force needed to propel the boat. This area includes key moving parts like pistons and cylinders that convert fuel into motion.

Cooling and Lubrication Systems

These systems prevent overheating and reduce friction, ensuring the engine runs smoothly. Water is often drawn in to cool the engine, while oil flows through to

How to Identify Essential Engine Elements

Understanding the key components of a marine engine is crucial for both regular maintenance and troubleshooting. Each element plays a vital role in ensuring smooth operation, and recognizing them helps you address issues quickly and efficiently. By familiarizing yourself with the fundamental structures, you can extend the life of your motor and avoid potential problems on the water.

Power Source: The central component driving the machine is the engine block. It houses multip

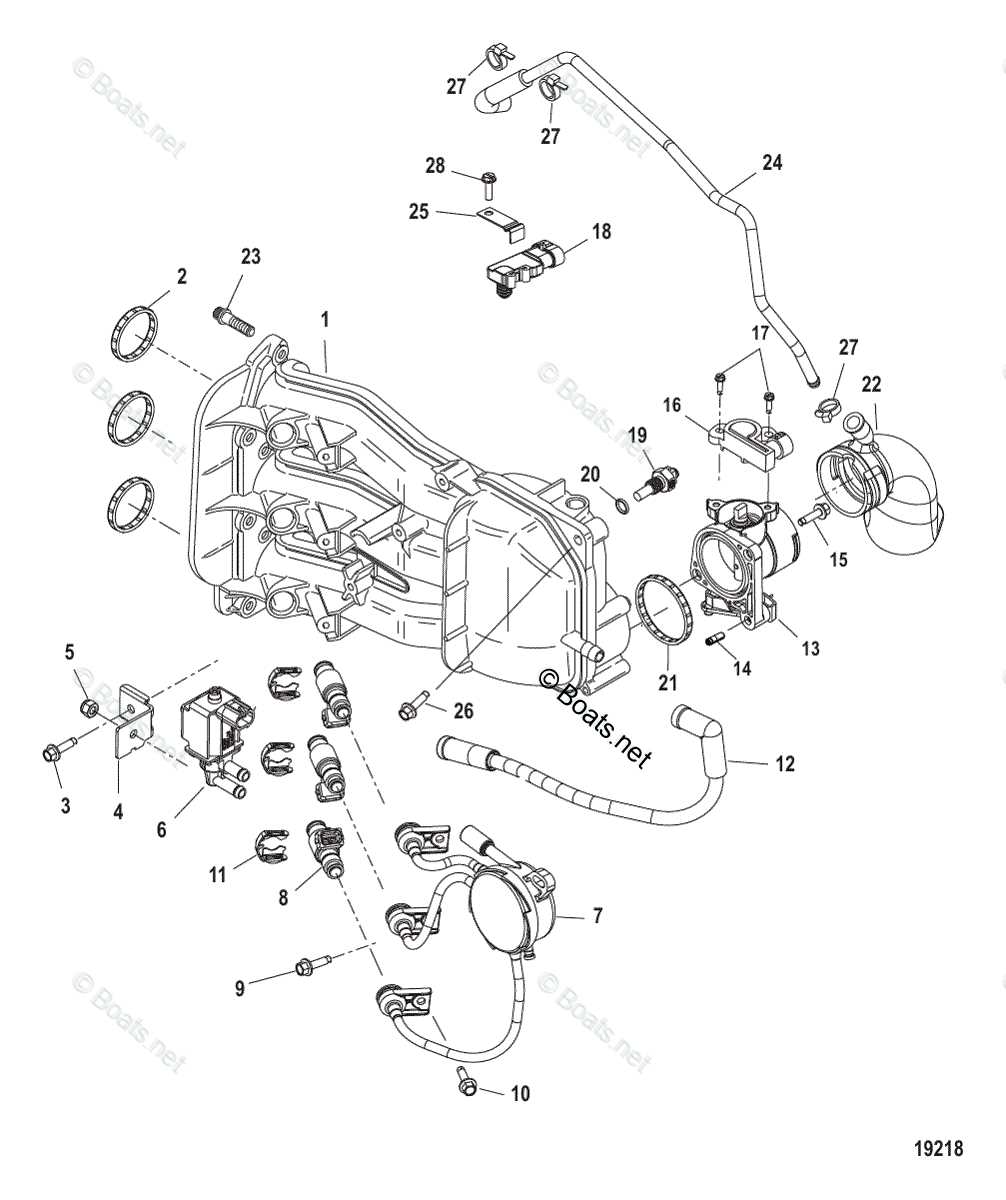

Fuel System Components for Mercury Engines

The fuel system in marine motors plays a crucial role in ensuring smooth operation and efficient power delivery. Its various elements work together to regulate fuel flow and maintain optimal performance in different conditions.

- Fuel Tank: The storage reservoir that supplies the engine with the necessary amount of fuel. Proper maintenance ensures longevity and safety.

- Fuel Line: Tubing that connects the tank to the motor, allowing consistent fuel flow. High-quality materials prevent leaks and damage.

- Fuel Filter: Designed to trap contaminants, ensuring clean fuel reaches the engine. Regular replacement is essential for peak performance.

- Fuel Pump: This component ensures fuel is delivered to the engine at the correct pressure and rate, which is vital for eff

Commonly Replaced Parts in Outboard Motors

Maintenance of marine propulsion systems often involves the replacement of various components to ensure smooth operation and longevity. Routine check-ups help identify which elements may need attention, preventing unexpected breakdowns and keeping performance at an optimal level.

Propellers are among the most frequently swapped items. They can become damaged from impacts or wear out over time, affecting speed and fuel efficiency. Replacing or repairing these components helps restore proper movement in the water.

Fuel systems also require regular attention. Over time, filters can clog, and lines may degrade, impacting fuel flow. Addressing these issues ensures efficient fuel delivery and reduces the risk of engine stalling.

Ignition systems components, such as spark plugs and coils, can wear out due to regular use. Ensuring they are in good

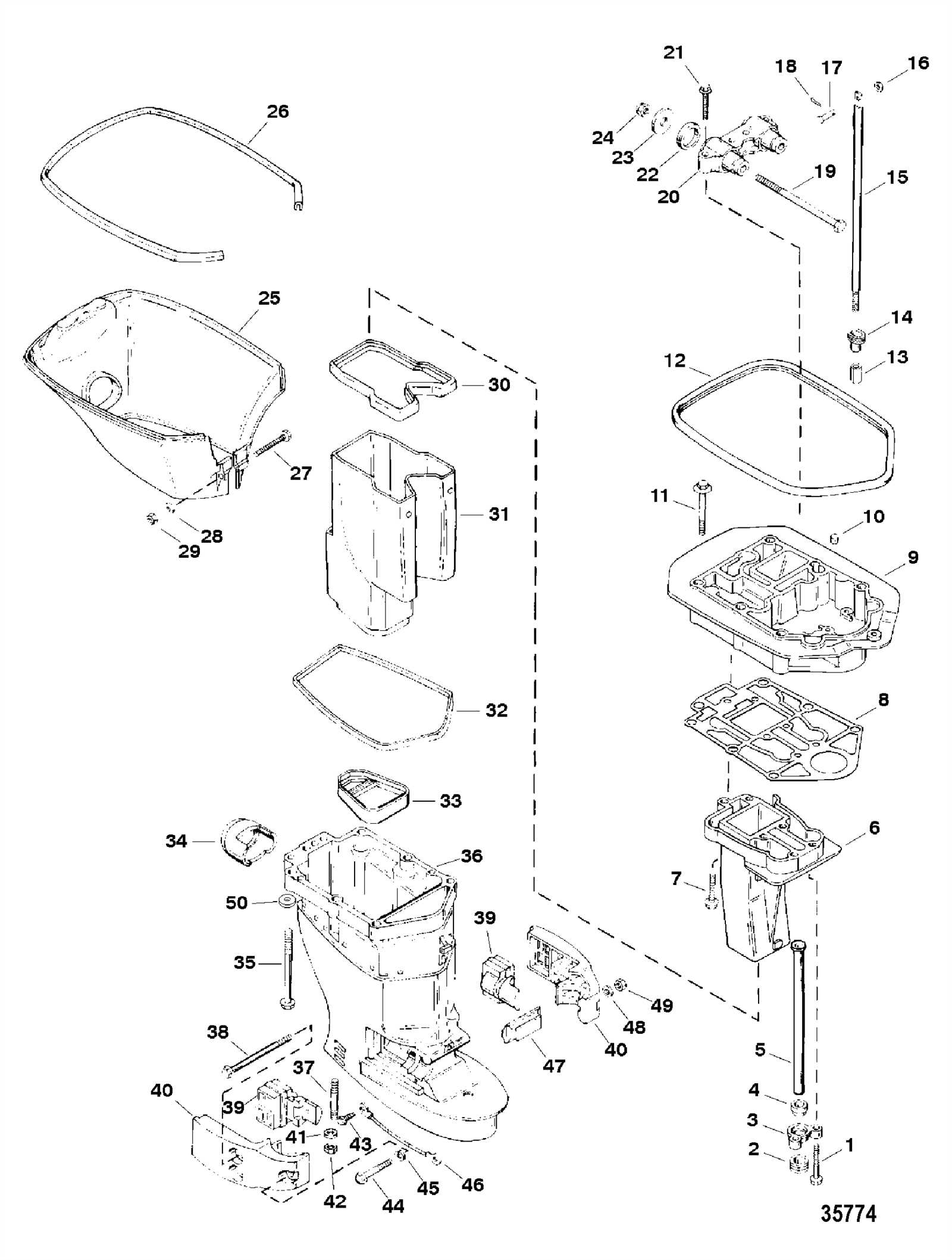

Maintenance Tips for Your 40 HP Mercury

Regular upkeep is essential for ensuring the longevity and efficiency of your marine engine. By following a few simple guidelines, you can maintain peak performance and prevent costly repairs. This section provides useful recommendations to help you care for your motor effectively.

Regular Inspections

- Check fluid levels regularly, including oil and fuel.

- Inspect the propeller for any signs of damage or wear.

- Examine the cooling system to ensure it is functioning correctly.

Seasonal Maintenance

- Change the oil and filter at least once a year.

- Replace spark plugs to ensure efficient ignition.

- Clean the fuel system and replace fuel filters as needed.

By adhering to these guidelines, you can enhance the reliability and lifespan of your motor. Regular care and attention to detail will ensure smooth sailing for many seasons to come.

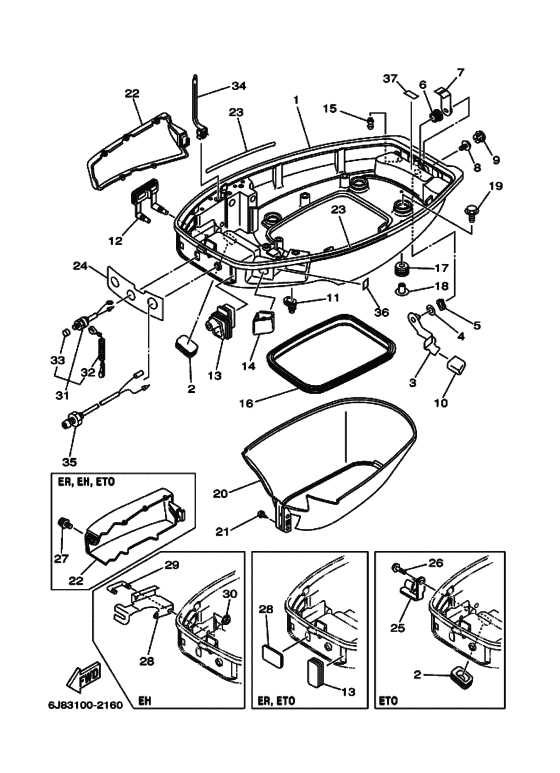

Where to Find Accurate Parts Diagrams

Locating precise schematics for marine engine components is essential for effective maintenance and repairs. Understanding where to find reliable resources can greatly simplify the process of identifying the necessary elements for your vessel’s performance.

Online Resources

The internet offers a wealth of information for enthusiasts and professionals alike. Numerous websites specialize in providing detailed illustrations and comprehensive guides for various engine models. Official manufacturer sites often include downloadable manuals and visual references that are indispensable for accurate identification.

Community Forums and Groups

Engaging with fellow boating enthusiasts can yield valuable insights. Many online forums and social media groups are dedicated to marine equipment. These platforms allow users to share their experiences and resources, often featuring images and detailed descriptions that can aid in locating specific components.

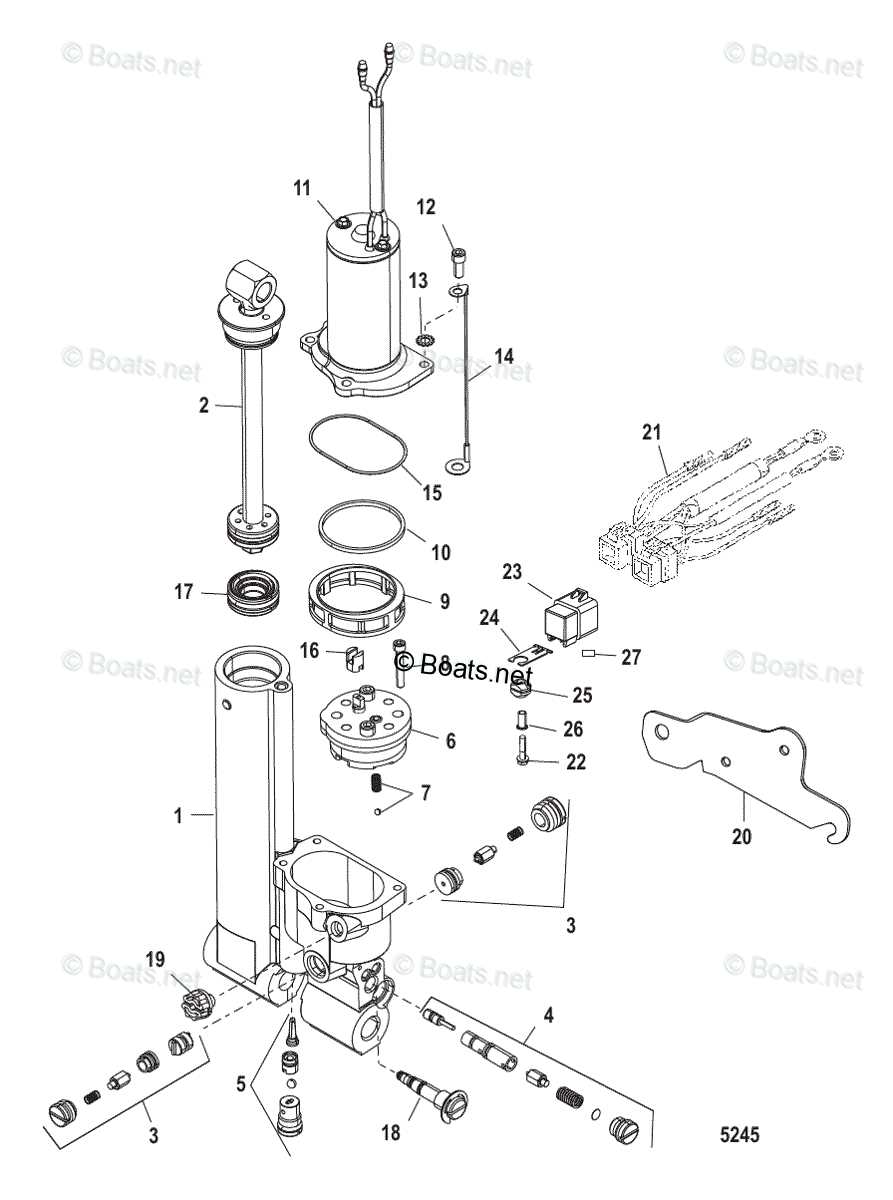

Electrical System Breakdown for Mercury Engines

The electrical system of marine engines plays a crucial role in ensuring optimal performance and reliability. This system encompasses various components that work together to facilitate the engine’s operation, ignition, and overall functionality. Understanding the intricacies of these elements is essential for effective maintenance and troubleshooting.

Component Function Battery Stores electrical energy to start the engine and power electrical systems. Ignition System Produces a spark to ignite the fuel-air mixture, enabling combustion. Wiring Harness Connects all electrical components, ensuring proper signal and power distribution. Regulator/Rectifier Maintains voltage levels and converts AC power from the stator to DC for the battery. Switches Control the operation of various electrical systems, including lights and accessories. Signs of Wear in Outboard Parts

Understanding the indicators of deterioration in marine engines is crucial for maintaining optimal performance and longevity. Recognizing these signs early can prevent costly repairs and ensure safe operation. Various components may exhibit specific symptoms that signal the need for inspection or replacement.

Common signs include unusual noises, which often indicate friction or misalignment within moving elements. Additionally, visual inspections can reveal cracks, discoloration, or corrosion, suggesting that a part may be compromised. Fluid leaks around seals or gaskets are also critical warnings that should not be overlooked, as they can lead to further damage if left unaddressed.

Another important aspect to monitor is the performance of the engine during operation. Decreased power output or irregular idling may suggest that internal mechanisms are wearing down. By staying vigilant and recognizing these symptoms, owners can take proactive measures to ensure the reliability of their vessels.

Proper Lubrication of Mercury Outboard Components

Ensuring the correct lubrication of essential components is vital for the longevity and optimal performance of marine engines. Regular maintenance involving appropriate lubricants helps minimize wear and tear, thereby enhancing reliability during operation. Understanding which elements require lubrication and the suitable types of lubricants is crucial for maintaining the efficiency of the engine.

The primary areas requiring attention include the gears, shafts, and bearings. Using high-quality lubricants designed specifically for marine environments will aid in preventing corrosion and providing a protective barrier against moisture. Additionally, applying the right amount of lubricant is essential; excessive lubrication can lead to buildup and impede movement, while insufficient lubrication can result in friction and damage.

Regular inspections should be part of the maintenance routine to identify any signs of wear or leaks. By promptly addressing these issues and reapplying lubricants as necessary, users can ensure that their engines operate smoothly and efficiently for many seasons. Overall, prioritizing proper lubrication practices will contribute significantly to the performance and durability of marine machinery.

Troubleshooting Common Issues with Engine Parts

Engine malfunctions can arise from a variety of sources, affecting overall performance and reliability. Understanding typical problems that can occur with various components is essential for effective maintenance and repair. By identifying these issues early, users can ensure their machinery operates smoothly and efficiently, minimizing downtime and costly repairs.

Identifying Performance Issues

Common symptoms of engine trouble include reduced power, difficulty starting, or unusual noises during operation. These indicators may suggest issues with components such as the ignition system, fuel delivery, or lubrication mechanisms. A thorough examination of each element can help pinpoint the root cause of the problem, enabling timely interventions.

Maintenance Tips for Longevity

Regular inspection and maintenance are crucial in preventing potential issues. Routine checks of fluid levels, filters, and electrical connections can enhance the longevity of various components. Additionally, following manufacturer guidelines for servicing can help users maintain optimal functionality and avoid unexpected breakdowns.