When dealing with the internal mechanics of small marine engines, understanding the structure and arrangement of various elements is crucial for both maintenance and repair. Whether it’s ensuring optimal performance or addressing specific technical challenges, a clear understanding of each element’s role within the engine system is vital.

This section offers detailed insights into the configuration of essential elements within a specific outboard engine model. With clear explanations and a structured approach, it becomes easier to navigate the complex web of interconnected systems, helping you address issues efficiently and keep your equipment running smoothly.

By examining the layout and interconnection of the key mechanical elements, you can gain a deeper appreciation of how these machines work. This guide breaks down the most critical aspects, making it easier to perform repairs or replacements when needed, ensuring long-term reliability.

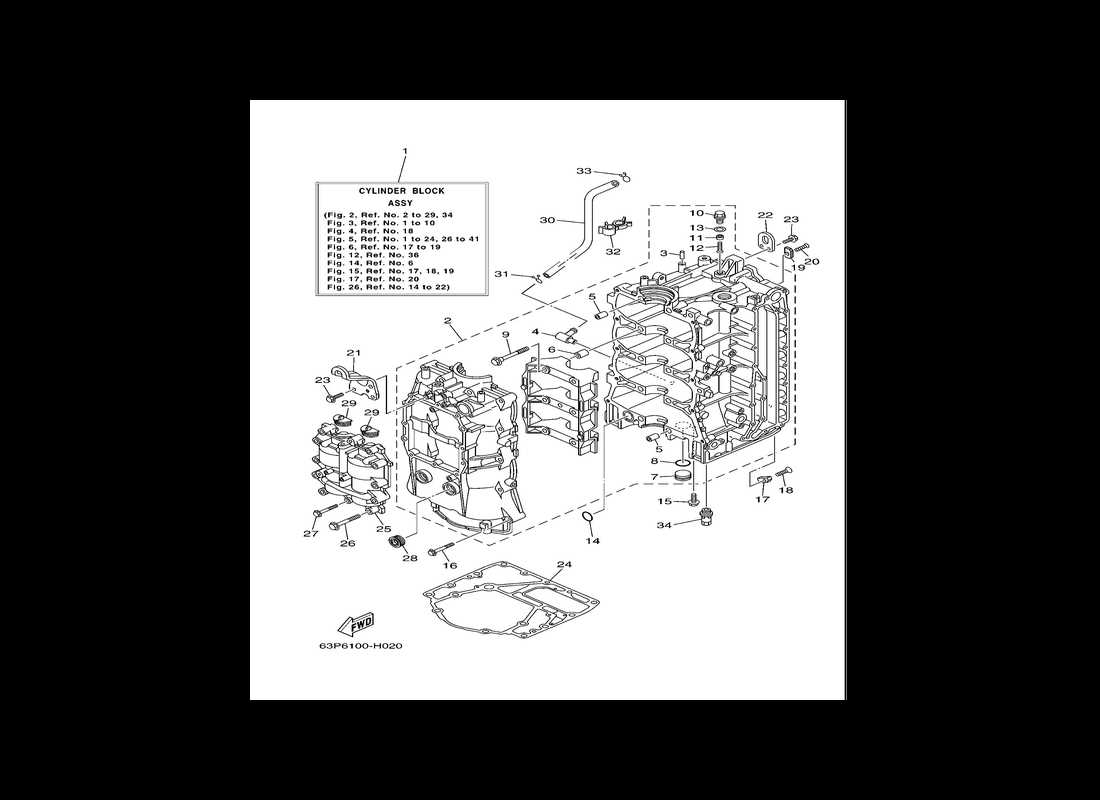

Overview of Mercury 50 HP 2-Stroke Engine Components

The internal structure of this powerful engine includes various interconnected elements that work in harmony to ensure smooth functionality. Each individual unit plays a specific role in the operation, contributing to the overall efficiency and performance. By understanding the primary systems involved, you can better appreciate how all these pieces come together to generate the necessary output for the vessel’s propulsion.

Key Systems and Functions

Among the essential units, the power delivery system is at the heart of the design. This segment is responsible for transforming energy into mechanical force, driving the movement. Coupled with this is the cooling mechanism, which prevents the assembly from overheating during operation, ensuring durability and consistency in performance.

Supportive Mechanisms

Supporting systems such as the lubrication and fuel delivery arrangements are equally critical. The lubrication setup keeps all moving

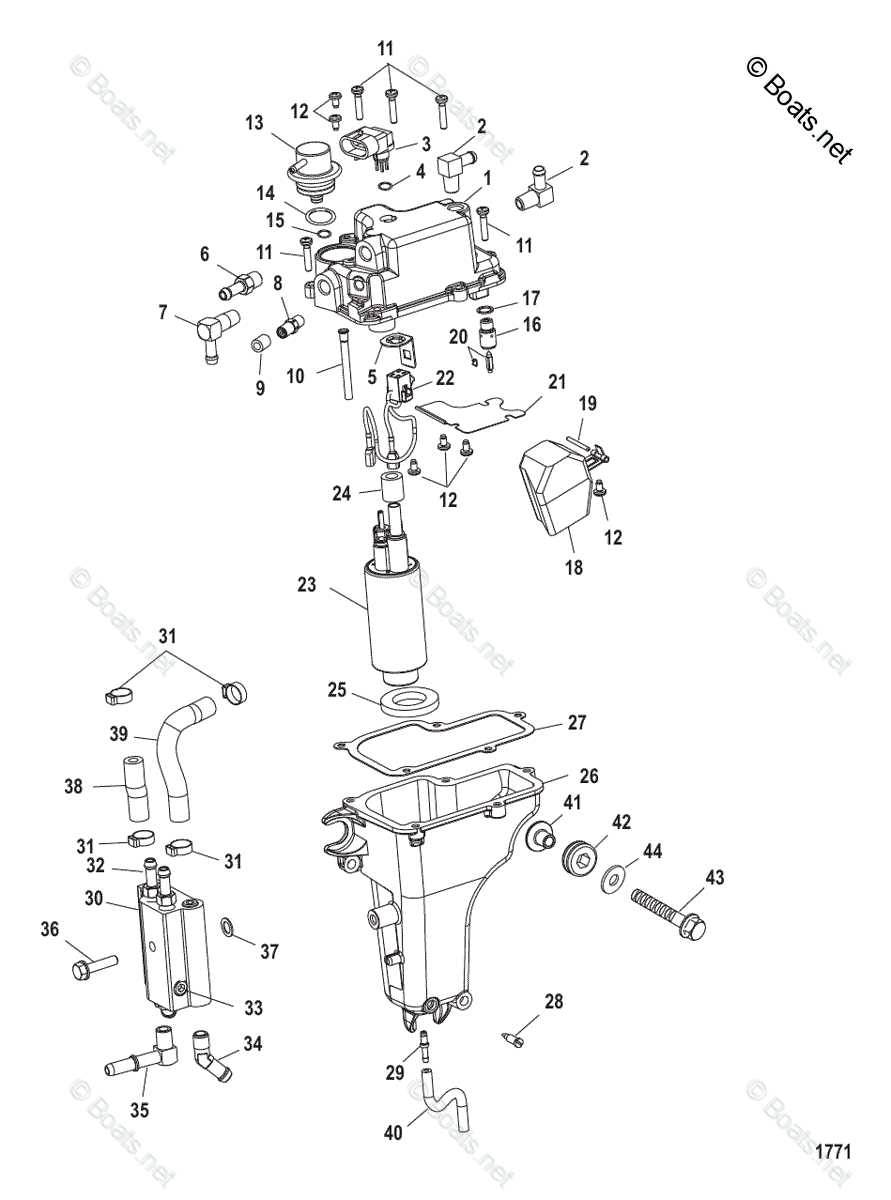

Understanding the Fuel System Layout

The fuel system is a crucial component that ensures the proper delivery of fuel to the engine, enabling smooth operation. It includes several interconnected elements, each playing a vital role in maintaining efficiency and performance. By comprehending the arrangement and functionality of these components, it becomes easier to diagnose potential issues and ensure optimal maintenance.

Main Components of the Fuel System

- Fuel Tank: Stores the liquid needed for combustion, ensuring a steady supply during operation.

- Fuel Line: Connects the storage container to the engine, transporting the liquid through a series of hoses and fittings.

- Fuel Pump: This device moves the liquid from the tank to the engine, maintaining proper pressure for consistent flow.

- Fuel Filter: Removes

Ignition System and Key Components

The ignition system is essential for initiating the engine’s operation by providing the necessary electrical power to ignite the fuel mixture. This process involves several interconnected elements working together to ensure reliable starting and smooth performance. Understanding these elements helps in maintaining efficient engine functionality and troubleshooting issues.

- Spark Plugs: These components create the spark needed to ignite the fuel-air mixture. They require a consistent electrical charge to function properly and are directly influenced by the condition of the ignition system.

- Ignition Coils: These coils convert the low voltage from the battery into a much higher voltage needed to create

Examining the Cooling Mechanism Design

To ensure optimal performance and longevity of marine engines, a well-engineered cooling system is crucial. The mechanism responsible for regulating temperature relies on a series of components working in harmony to dissipate heat effectively. In this section, we will explore the key elements and their roles in maintaining the ideal operating temperature during various conditions on the water.

The design of this temperature regulation system incorporates pathways for fluid circulation, controlled by pumps and valves, that channel coolant through the engine. These elements work together to prevent overheating, particularly in high-load scenarios, and ensure smooth operation.

Component Function Coolant Pump Drives the circulation of fluid to regulate temperature. Thermostat Opens or closes to maintain the Carburetor Function and Breakdown

The primary role of a carburetor is to blend air and fuel in precise proportions to ensure optimal combustion. This process is crucial for smooth engine performance, as it regulates the ratio of the air-fuel mixture based on the engine’s needs during different phases of operation. Understanding how this system functions helps in diagnosing and addressing any inefficiencies or malfunctions that may arise.

Air Intake and Mixing: The carburetor draws air through an intake passage where it is mixed with fuel in a controlled manner. A narrowing section, known as the venturi, increases airspeed, reducing pressure, which aids in drawing fuel from the chamber into the airstream. This mixture is then directed into the engine’s combustion chamber.

Fuel Delivery: Fuel enters the carburetor through a small channel where it is atomized by the passing airflow. Adjustments to fuel flow are made by components like jets, which control

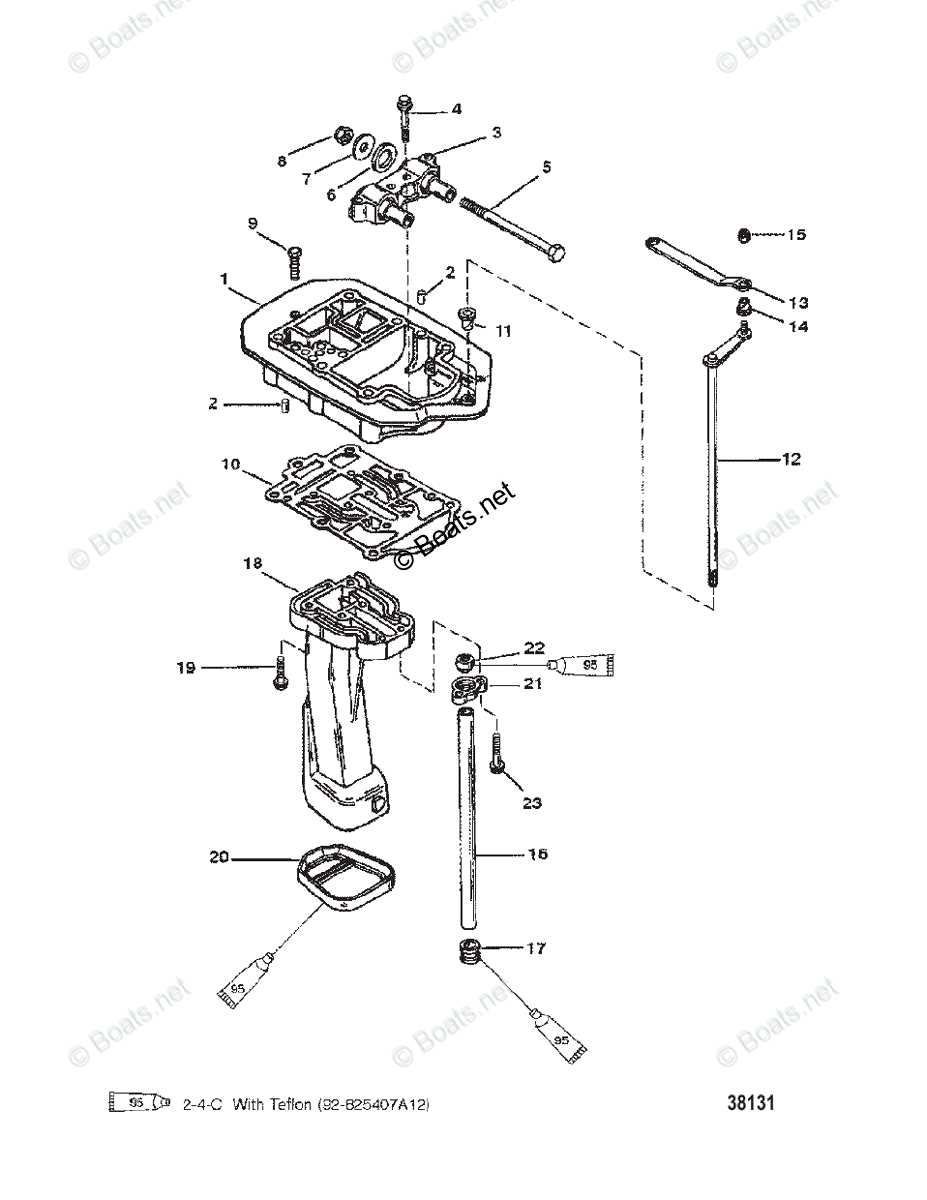

Gearcase Assembly and Parts

The gearcase is a critical component of any marine engine, responsible for transferring power from the engine to the propeller. It houses essential components that enable the smooth operation of the vessel, ensuring proper movement and performance in various water conditions. The assembly includes a series of interconnected elements that work together to provide efficiency and durability during operation.

Key components within the gearcase include the drive shaft, propeller shaft, and the various bearings and seals that maintain proper alignment and prevent leaks. These elements must be maintained regularly to ensure optimal performance and to avoid costly repairs due to wear and tear.

Additionally, lubrication is vital for the longevity of the gearcase assembly. Regular checks and maintenance of the lubricant levels help keep the internal components functioning smoothly, reducing the risk of friction and overheating.

Steering and Control Linkage

The steering and control linkage plays a crucial role in ensuring smooth operation and accurate maneuvering of the watercraft. This system connects the helm to the engine, allowing the operator to direct the vessel and control its various functions effectively. Proper alignment and condition of the components in this system are vital for maintaining responsive handling and operational safety.

At the core of this system, the steering arm and associated rods transmit motion from the helm to the engine, guiding it in the desired direction. The control cables, which are also part of this assembly, manage throttle and shift functions, giving the operator the ability to adjust speed and engage or disengage gears. Regular inspection and maintenance of these parts are essential to avoid wear and tear that could lead to difficulties in maneuvering.

Exhaust System Diagram and Parts

The exhaust system plays a vital role in managing the flow of gases that result from the combustion process. It ensures that these gases are expelled efficiently, reducing harmful emissions and enhancing engine performance. Understanding the layout and components of this system is essential for maintenance and optimal functioning of the motor.

Components of the Exhaust System

The primary elements of the exhaust mechanism include the exhaust manifold, which collects gases from the engine’s cylinders. These gases then travel through a series of pipes designed to guide them towards the outlet. At the outlet, the muffler reduces noise levels, while the expansion chamber helps in optimizing engine output by controlling backpressure.

Maintenance and Troubleshooting

Regular inspection of these components ensures smooth operation and can prevent problems such as clogging or corrosion. Replacing damaged or worn-out elements, such as the gasket or pipe seals, helps maintain the system’s efficiency and extends the life of the entire motor.

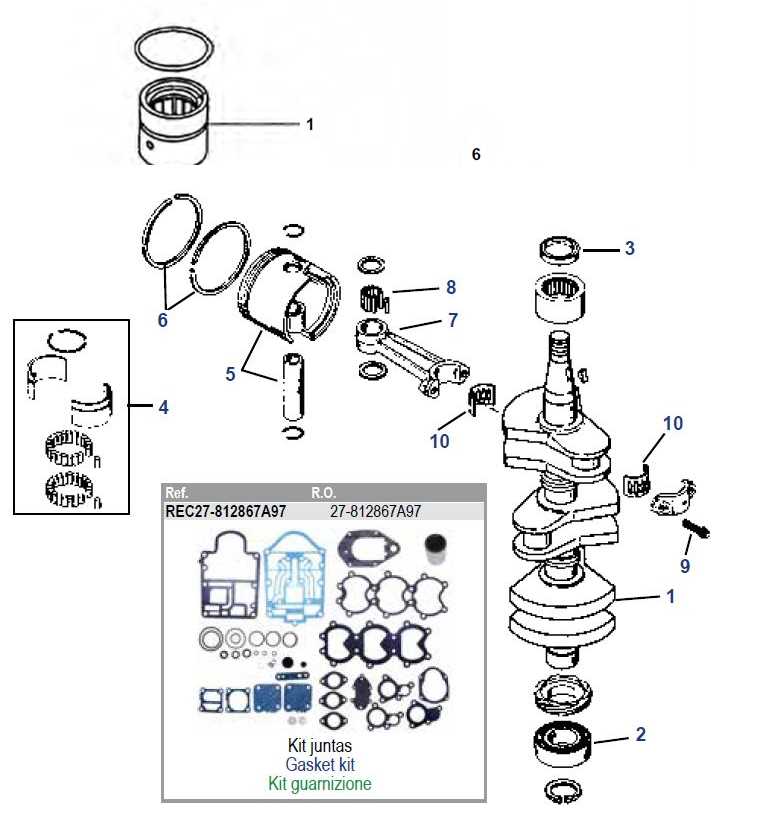

Piston and Cylinder Assembly Overview

The piston and cylinder unit is a fundamental component in the engine, playing a crucial role in converting energy to mechanical motion. This assembly is responsible for ensuring efficient compression and power generation, acting as the heart of the combustion process. Understanding its structure and functionality is essential for diagnosing performance issues and maintaining engine longevity.

Piston Mechanics

The piston moves within the cylinder, driving the crankshaft with its back-and-forth motion. It is designed to withstand high pressures and temperatures, providing the necessary force to convert fuel combustion into mechanical energy. Piston rings attached to the piston seal the combustion chamber, preventing leakage of gases and maintaining optimal pressure within the cylinder.

Cylinder Structure

The cylinder itself forms the chamber in which the piston operates. Its surface must be smooth yet durable to allow the piston to move efficiently while minimizing friction. Any wear or damage to the cylinder wall can lead to performance loss and increased fuel consumption. Regular inspection and maintenance of this unit are critical to ensuring smooth operation.

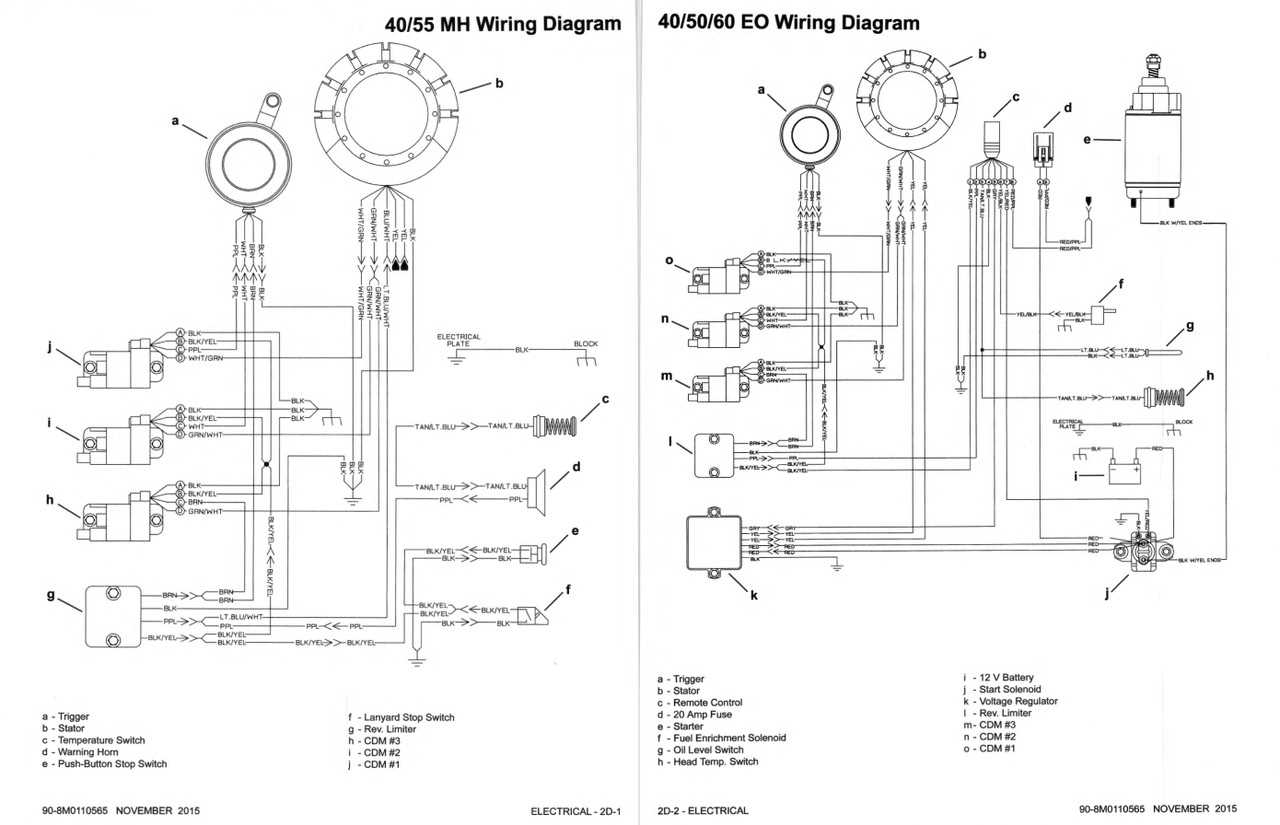

Electrical System Components Explained

The electrical system of a marine engine plays a crucial role in ensuring optimal performance and reliability. Understanding the various components involved helps in troubleshooting and maintenance, contributing to the longevity of the engine. Each part works harmoniously to facilitate the ignition process, manage power distribution, and enhance the overall functionality of the vessel.

Key Components of the Electrical System

At the heart of the electrical setup is the battery, which stores energy and supplies it when needed. This component is essential for starting the engine and powering electronic devices onboard. Next is the starter motor, which transforms electrical energy into mechanical energy to crank the engine. Additionally, the alternator generates electricity while the engine runs, replenishing the battery and supporting onboard systems.

Ignition and Control Elements

The ignition coil is another vital element, responsible for converting low battery voltage into the high voltage needed to create a spark in the combustion chamber. Coupled with the spark plug, it initiates the combustion process, enabling the engine to run efficiently. Furthermore, wiring harnesses connect these components, ensuring proper communication and functionality across the entire system.

Propeller and Driveshaft Structure

The assembly that converts engine power into thrust is essential for the optimal performance of watercraft. Understanding the components involved in this mechanism is crucial for effective maintenance and troubleshooting. This section explores the intricacies of the propulsion system, focusing on the propeller and driveshaft elements that play a vital role in ensuring smooth operation.

Propeller Design and Function

The propeller is a key element that directly interacts with the water to generate thrust. Its design affects the efficiency and performance of the vessel. Common attributes include the number of blades, diameter, and pitch, all of which contribute to the overall effectiveness of propulsion. Selecting the right propeller type is essential for achieving desired speeds and handling characteristics.

Driveshaft Mechanics

The driveshaft serves as a conduit for transferring rotational energy from the engine to the propeller. Its construction typically involves a robust material to withstand high torque and resist wear. The driveshaft may include universal joints that allow for flexibility in alignment, ensuring smooth power transmission even under varying conditions.

Component Description Propeller Device that generates thrust by pushing water backward. Driveshaft Rod transmitting engine power to the propeller. Blades Flat surfaces that interact with water to create motion. Universal Joints Components allowing flexibility in the driveshaft alignment. Oil Injection System and Related Parts

The oil injection mechanism is crucial for ensuring optimal lubrication in marine engines. This system is designed to deliver the precise amount of lubricant needed for efficient operation, reducing wear and enhancing performance. By automating the process, it minimizes the risk of insufficient lubrication, which can lead to engine damage.

Components of the Lubrication Mechanism

The primary components of the lubrication system include the oil reservoir, pump, and delivery lines. The oil reservoir stores the lubricant, ensuring a consistent supply. The pump regulates the flow of oil to various engine parts, while the delivery lines transport the lubricant to critical areas requiring protection against friction.

Maintenance and Troubleshooting

Regular maintenance of the lubrication system is essential for optimal functionality. This involves checking the oil levels, inspecting the pump for any signs of wear, and ensuring that the delivery lines are free of blockages. If the engine exhibits symptoms like increased noise or reduced performance, it may indicate an issue with the lubrication system that requires immediate attention.