When maintaining a powerful marine engine, understanding how each element interacts is crucial for optimal performance. Every piece plays a vital role in ensuring that the motor operates smoothly, offering reliability and efficiency on the water. In this guide, we explore how various mechanisms work together to create a unified system.

A close look at the core mechanisms reveals the complexity behind these motors. This detailed breakdown will assist you in identifying key elements, helping to ensure that the engine runs effectively. Knowing the exact function of each component can prevent common issues and extend the lifespan of the machine.

From essential elements to smaller yet vital parts, this guide covers everything needed to keep the engine in top condition. With a clear understanding of the system’s layout, you can address any challenges that arise, ensuring smooth and trouble-free performance on every journey.

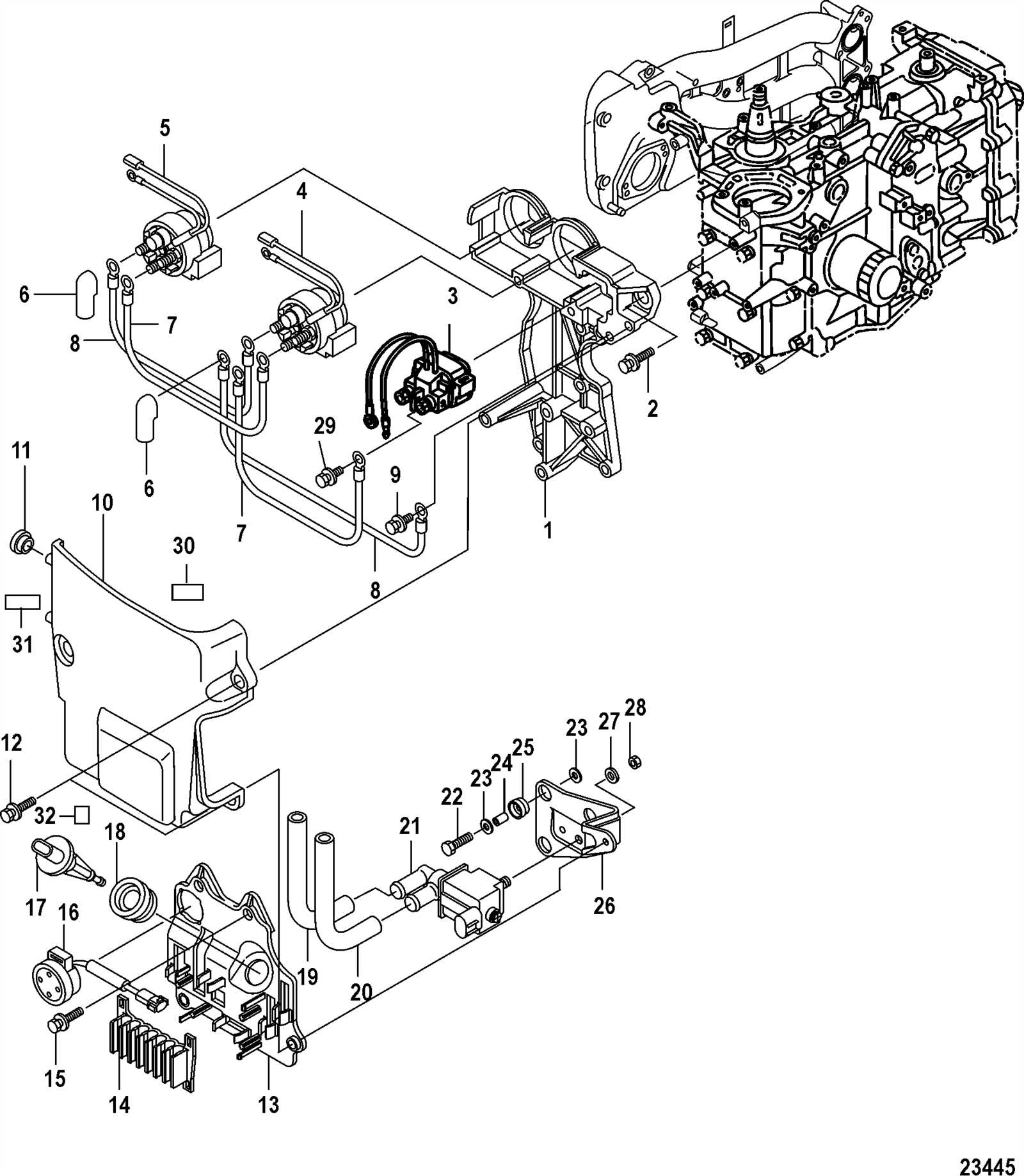

Overview of Mercury 60 HP 4-Stroke Components

Designed for reliable performance and efficiency, this engine model consists of an intricate assembly of mechanical and electronic systems. These elements work in harmony to deliver power, control, and fuel optimization, making it suitable for a variety of applications. Understanding the layout of key features helps users maintain, troubleshoot, and enhance the performance of the system.

Power Generation Unit: The heart of the system ensures smooth energy conversion and supports the essential operations needed for propulsion and handling. It plays a critical role in maintaining a balance between power output and fuel economy.

Cooling and Lubrication Mechanisms: To prevent overheating and ensure longevity, a dedicated series of channels and pumps continuously circulates fluids. These mechanisms help reduce friction and heat, promoting efficient functioning over long periods.

Control and Adjustment Interfaces: Various adjustable elements allow users to fine-tune performance according to specific conditions. These components are designed to give operators greater precision and control over the system’s output, ensuring adaptability and smooth operation.

Exhaust and Emission System: The structure responsible for managing byproducts of combustion helps in minimizing environmental impact. This system ensures compliance with emission standards while maintaining performance.

Identifying Key Engine Parts

Understanding the essential components of an engine is crucial for proper maintenance and troubleshooting. Each section plays a specific role in ensuring smooth operation, from managing fuel flow to optimizing mechanical performance. In this guide, we will explore the most important elements of the engine and their functions.

- Power Unit: The heart of the machine, converting energy into motion through precise movements and controlled combustion.

- Cooling System: This assembly helps regulate temperature, preventing overheating and maintaining efficiency during operation.

- Fuel Delivery Mechanism: Ensures a steady supply of fuel to the core, allowing for uninterrupted operation and optimal performance.

- Exhaust Pathway: Directs waste gases away from the engine, improving efficiency and reducing back pressure.

- Ignition System: This component initiates the process by providing the necessary spark to start the combustion cycle.

- Lubrication Network: Keeps the moving parts running smoothly by reducing friction and wear over time.

By familiarizing yourself with these critical sections, you can enhance your understanding of the machine’s functionality and ensure it operates at its best.

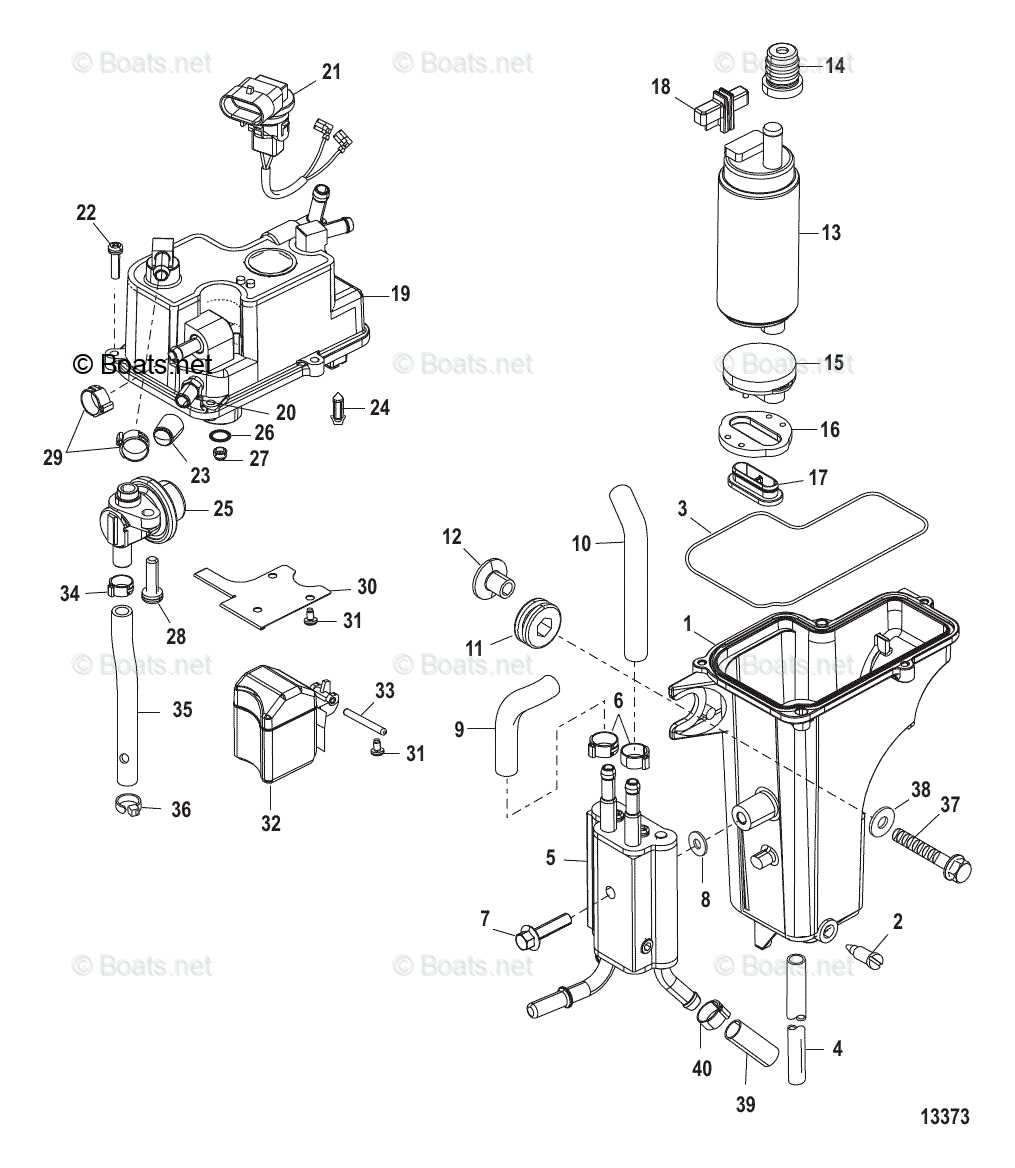

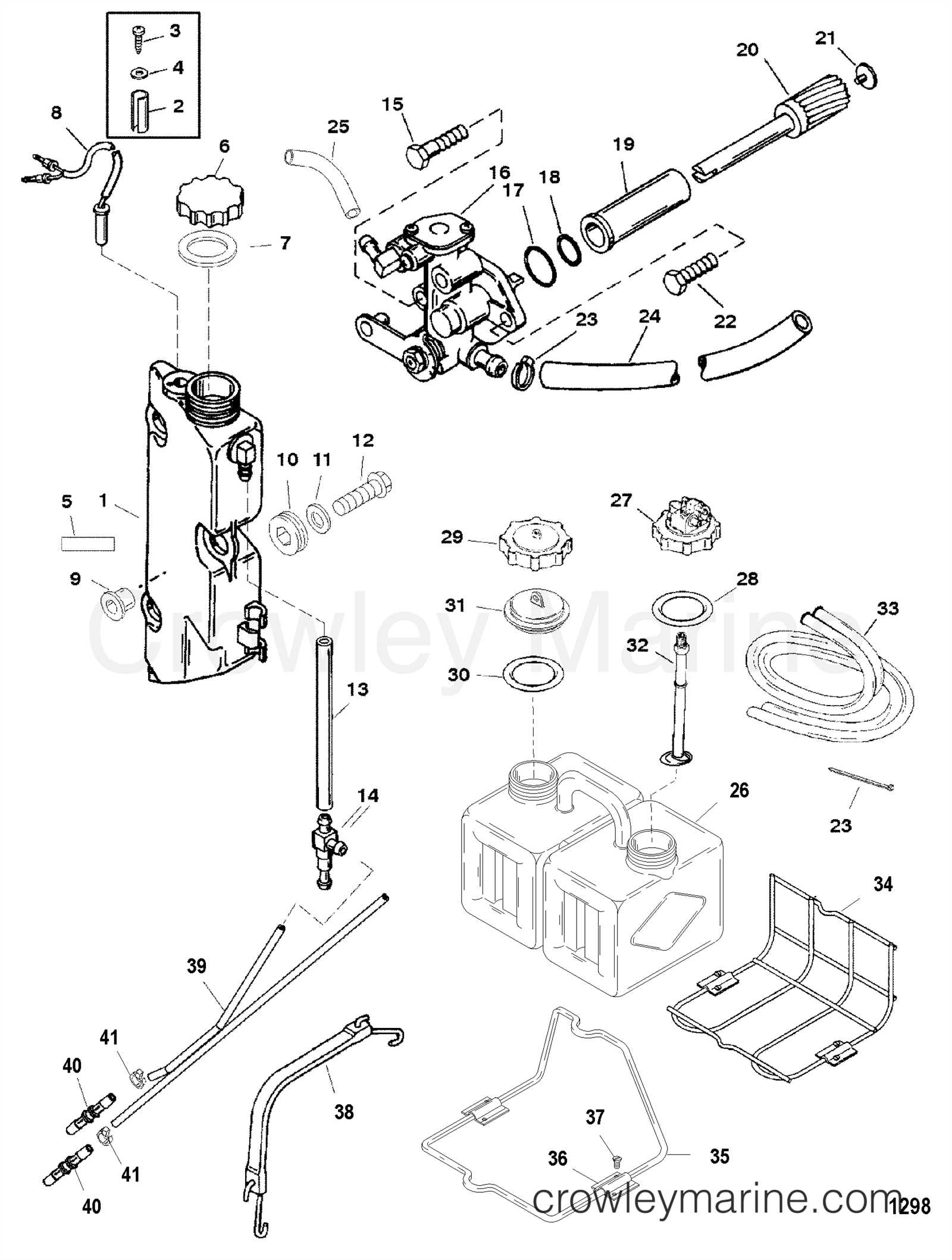

Understanding the Fuel System Layout

The fuel delivery network in marine engines is a critical aspect of ensuring efficient and smooth operation. Properly managing the flow of fuel from the tank to the engine enables optimal performance and longevity. This section will explore the key components involved in this system, focusing on how they interact to maintain continuous fuel supply under varying conditions.

Key Components of the Fuel Network

- Fuel Tank: The primary reservoir where the fuel is stored, equipped with a venting system to prevent pressure build-up.

- Fuel Line: A flexible conduit that transports fuel from the tank to the engine, typically reinforced for durability in marine environments.

- Primer Bulb: A manual pump that helps prime the system, especially during initial start-up or after periods of inactivity.

- Fuel Filter: A crucial element that prevents contaminants from entering the engine by filtering out particles from the fuel before it reaches the engine.

- Fuel Pump: This device regulates the flow of fuel, ensuring that the engine r

Cooling Mechanism: Parts and Function

The cooling system plays a vital role in maintaining optimal performance by regulating engine temperature. Its efficient operation is crucial for preventing overheating and ensuring longevity, as it continuously manages heat dissipation during operation. Understanding how the various components work together helps to appreciate the system’s role in keeping everything running smoothly.

Key Components of the System

- Water Pump: This element drives coolant through the engine, ensuring a consistent flow that helps maintain the desired temperature.

- Thermostat: A temperature-sensitive valve that regulates the flow of coolant based on the current engine conditions.

- Heat Exchanger: This component transfers excess heat from the engine to the surrounding water or air, effectively cooling the system.

- Impeller: Responsible for pushing coolant through the system, the impeller ensures steady circulation to avoid temperature spikes.

How the Mechanism Works

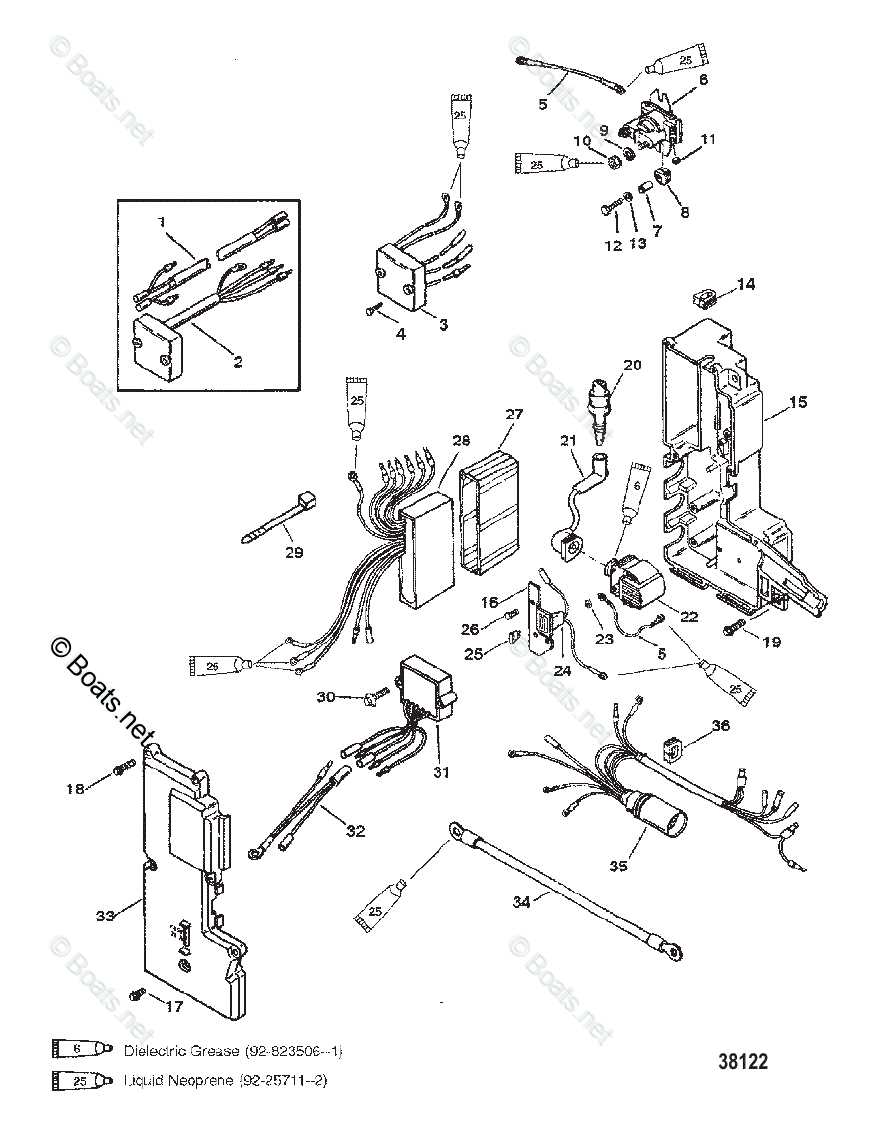

Exploring the Ignition System

The ignition system plays a crucial role in ensuring the engine starts smoothly and operates efficiently. It is responsible for generating the spark required to ignite the air-fuel mixture, which powers the engine. Understanding the components and their functions is key to diagnosing issues and maintaining performance.

Key Components

- Spark Plug: The device that delivers electric current from the ignition system to the combustion chamber, igniting the fuel.

- Ignition Coil: A transformer that boosts the battery’s low voltage to a high voltage, necessary to create the spark.

- Flywheel: Contains magnets that work with the ignition coil to generate electrical power.

- Timing System: Ensures that the spark occurs at the correct moment for optimal engine performance.

Common Issues and Maintenance

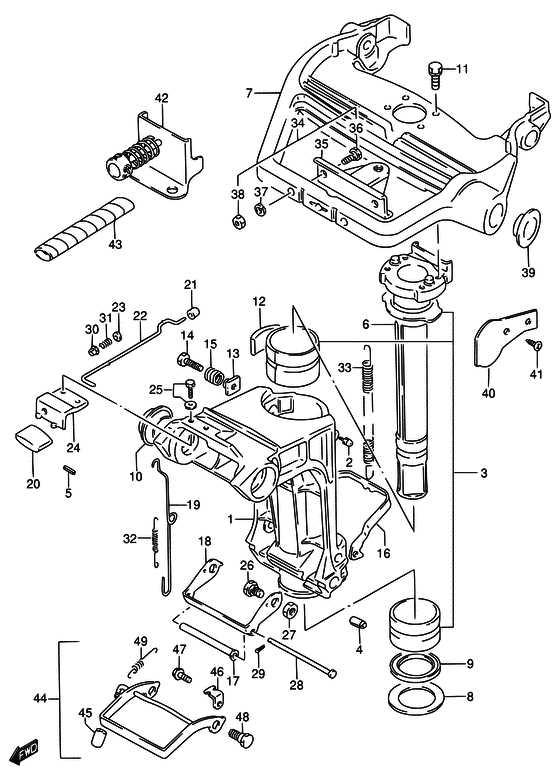

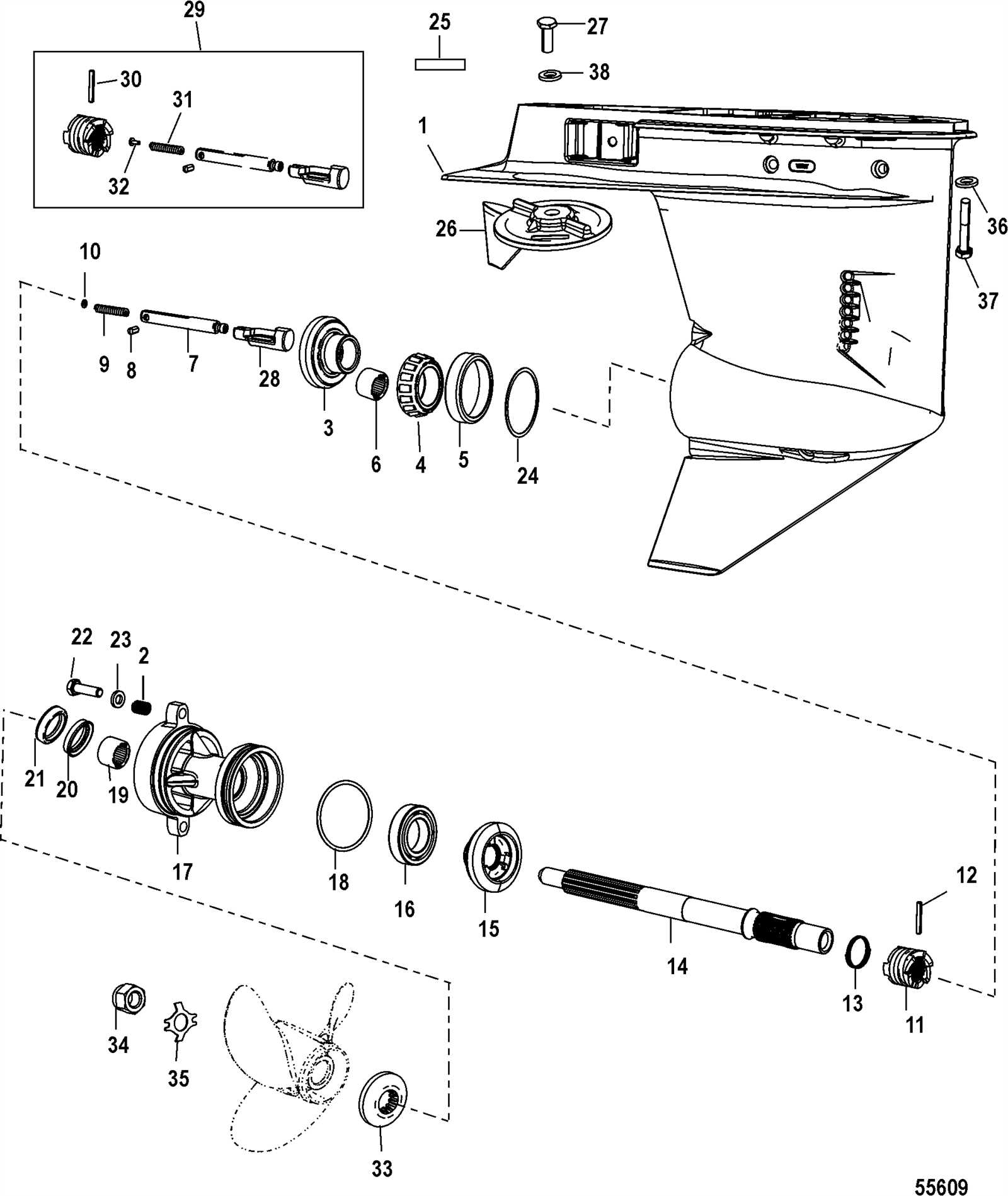

Lower Unit Breakdown and Components

The lower unit of an outboard motor plays a crucial role in transmitting power from the engine to the propeller. Understanding its structure and individual elements is essential for maintenance and repair tasks. This section delves into the various components found within this assembly, highlighting their functions and significance in the overall operation of the motor.

At the core of the lower unit lies the gear case, which houses the drive gears responsible for transferring rotational motion. The gear case is sealed to prevent water ingress, ensuring smooth operation. Attached to the gear case are the drive shaft and the propeller shaft, which work in tandem to convert the engine’s power into thrust.

Additionally, the lower unit contains essential components such as the water pump, which facilitates cooling by circulating water through the engine. This is vital for preventing overheating during operation. The shift mechanism, another key element, allows for the engagement and disengagement of the propeller, enabling forward and reverse movement.

Regular inspection and maintenance of these components can enhance performance and prolong the life of the motor. Understanding the intricacies of the lower unit equips users with the knowledge to troubleshoot issues effectively and carry out necessary repairs when needed.

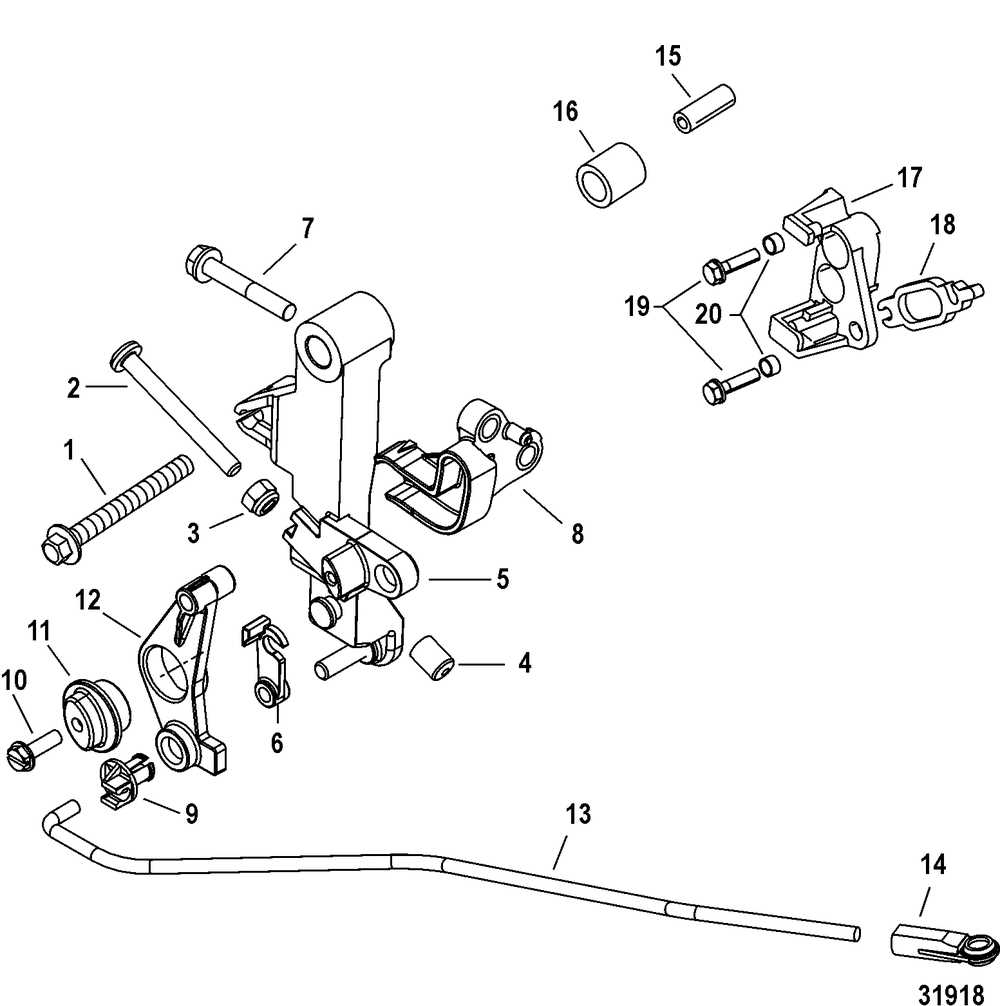

Steering and Control Parts Overview

The steering and control components of marine engines play a crucial role in ensuring smooth navigation and optimal performance. Understanding the function and layout of these elements can significantly enhance the boating experience, allowing for precise maneuvering and better handling in various water conditions.

Component Description Function Steering Wheel A circular control device that allows the operator to guide the vessel. Transmits the operator’s movements to the steering mechanism. Throttle Control A lever or button used to adjust engine power output. Regulates speed and acceleration of the boat. Gear Shift A mechanism that changes the gear ratio within the propulsion system. Facilitates forward, neutral, and reverse movements. Control Cables Flexible cables connecting the controls to the engine components. Transmits signals for throttle and gear changes. Steering Linkage A series of rods and joints that connect the steering wheel to the rudder. Transfers rotational movement to directional changes. Rudder A flat piece, typically mounted on the stern, used for steering. Controls the direction of the vessel by altering water flow. By familiarizing oneself with these essential components, operators can ensure effective control and enhance the overall performance of their marine vessel.

Electrical Wiring and Connection Map

This section provides an overview of the electrical layout and interconnections essential for optimal operation. Understanding the wiring configuration is crucial for troubleshooting and ensuring all components function harmoniously. A clear visualization of connections aids in the maintenance and repair processes, making it easier to identify potential issues.

Key Electrical Components

Familiarizing yourself with the primary electrical components can significantly enhance your understanding of the system. Below are some vital elements typically found in this setup:

Component Function Battery Supplies power to the electrical system. Ignition Coil Generates high voltage for the spark plugs. Fuse Protects the circuit from overload. Wiring Harness Connects various electrical components. Connection Overview

The connections between different components are pivotal for the proper functioning of the entire electrical system. Each connection point is designed to facilitate seamless communication between parts, ensuring reliability and efficiency. Proper attention to these connections can prevent electrical failures and enhance the longevity of the components.

Fuel Pump and Injector Placement

The arrangement of the fuel delivery system is crucial for optimal engine performance. Proper positioning of the components ensures efficient fuel flow and reliable operation. Understanding the layout of the fuel pump and injectors can significantly impact the engine’s responsiveness and efficiency.

The fuel pump is typically situated close to the fuel tank, allowing it to draw fuel effectively and maintain adequate pressure throughout the system. This placement minimizes the risk of vapor lock and ensures a consistent supply of fuel to the engine. In contrast, the injectors are strategically positioned within the intake manifold to facilitate precise fuel atomization and mixing with air, enhancing combustion efficiency.

Furthermore, the alignment of these components is designed to reduce the length of fuel lines, which helps decrease the chances of fuel leaks and pressure drops. Proper placement also aids in maintenance accessibility, allowing for easier servicing and part replacements when necessary. Overall, a well-thought-out configuration of the fuel pump and injectors contributes to the overall reliability and performance of the engine.

Propeller System: Key Elements

The propeller system plays a crucial role in the performance and efficiency of marine vessels. It consists of various components that work together to convert the engine’s power into thrust, enabling the craft to navigate smoothly through water. Understanding these key elements is essential for effective maintenance and optimal operation.

1. Blades: The blades are the primary elements that generate lift and propulsion. Their shape, size, and pitch significantly impact the vessel’s speed and maneuverability. Well-designed blades ensure efficient water displacement, enhancing overall performance.

2. Hub: The hub connects the blades to the shaft and serves as the central component of the propeller. It must withstand high levels of stress and torque, making its durability critical for reliable operation. Proper alignment and secure attachment to the shaft are vital to prevent vibrations and damage.

3. Shaft: The shaft transmits power from the engine to the propeller, translating rotational energy into forward motion. A robust shaft minimizes the risk of bending or breaking under load, ensuring smooth performance during operation.

4. Gear Ratio: The gear ratio influences the relationship between engine speed and propeller rotation. An appropriate ratio maximizes efficiency and allows the vessel to achieve optimal speeds while maintaining fuel economy.

5. Anode: Anodes are crucial for protecting the propeller system from corrosion. They sacrifice themselves to prevent damage to metal components, thereby extending the lifespan of the entire assembly.

Understanding these fundamental components of the propeller system is essential for anyone involved in the maintenance and operation of marine vessels. Proper attention to these elements can enhance performance, increase efficiency, and prolong the lifespan of the propulsion system.

Oil and Lubrication Pathways

The efficient operation of marine engines relies heavily on effective oil and lubrication systems. These systems ensure that all moving components are adequately coated, reducing friction and wear, which is crucial for optimal performance and longevity. Understanding the pathways through which oil circulates within the engine can help in maintaining and troubleshooting its functionality.

Lubrication System Overview

The lubrication system typically consists of various components working in harmony to distribute oil throughout the engine. Key elements include:

- Oil Pump: Responsible for circulating oil to all necessary parts.

- Oil Filter: Cleans the oil to prevent contaminants from entering the engine.

- Oil Reservoir: Stores the oil until it is needed for circulation.

- Oil Galleries: Channels through which oil flows to reach various components.

Importance of Proper Lubrication

Proper lubrication is vital for maintaining engine health. The benefits include:

- Reduced Wear: Ensures that moving parts are shielded from excessive friction.

- Temperature Control: Helps dissipate heat generated during operation.

- Corrosion Prevention: Provides a barrier against moisture and contaminants.

- Enhanced Performance: Supports smoother operation and responsiveness of the engine.

Common Wear and Replacement Parts

In the realm of marine engines, certain components are subject to regular wear and tear due to their crucial roles in the engine’s operation. Understanding which elements frequently require attention can enhance performance and prolong the lifespan of your outboard motor. This section highlights the most common items that may need to be replaced over time.

Key Components Needing Regular Maintenance

Among the vital components, fuel filters and impellers are often the first to show signs of wear. Fuel filters play a crucial role in ensuring that the fuel system remains clean, preventing contaminants from entering the engine. Regular inspection and timely replacement are essential for optimal performance.

Similarly, impellers are responsible for circulating water to keep the engine cool. Over time, these components can degrade, leading to inadequate cooling and potential overheating issues. Ensuring they are in good condition is critical for the health of the motor.

Additional Elements to Consider

Other components such as spark plugs and seals also require periodic checks. Spark plugs ignite the fuel-air mixture, and worn plugs can cause misfiring or inefficient combustion. Regular replacement ensures smooth operation and better fuel efficiency.

Seals, on the other hand, prevent leaks and maintain pressure within various systems. Over time, these seals can become brittle and lose their effectiveness, leading to potential fluid leaks. Monitoring their condition can help maintain the engine’s integrity and prevent costly repairs.

Upgrading and Maintaining Your Engine

Ensuring optimal performance and longevity of your marine power unit involves regular enhancements and diligent upkeep. By focusing on key areas, you can improve efficiency and prevent potential issues that may arise during operation.

Regular maintenance tasks include the following:

- Checking and replacing fuel filters to ensure clean fuel flow.

- Inspecting the cooling system to prevent overheating.

- Changing the oil and oil filter to maintain engine health.

- Examining spark plugs and ignition components for reliable starting and operation.

- Cleaning or replacing the air filter to promote proper airflow.

Upgrades can further enhance your unit’s performance:

- Installing a high-performance propeller for improved thrust and fuel efficiency.

- Upgrading to a more advanced electronic control unit for better fuel management.

- Adding a performance exhaust system to increase power output.

- Implementing a fuel injection system for better efficiency and responsiveness.

By prioritizing these strategies, you will ensure that your marine power unit remains reliable and operates at its best throughout its lifespan.