Maintaining a well-kept yard requires an understanding of the various mechanisms involved in lawn care machinery. These machines are designed with intricate systems that enable efficient operation and reliable performance. Familiarity with their structure is essential for troubleshooting and repairs, ensuring that your equipment remains in optimal working condition.

In this section, we will explore the individual elements that contribute to the functionality of these innovative devices. Each component plays a critical role, and recognizing how they interact can enhance your maintenance skills and extend the lifespan of your equipment.

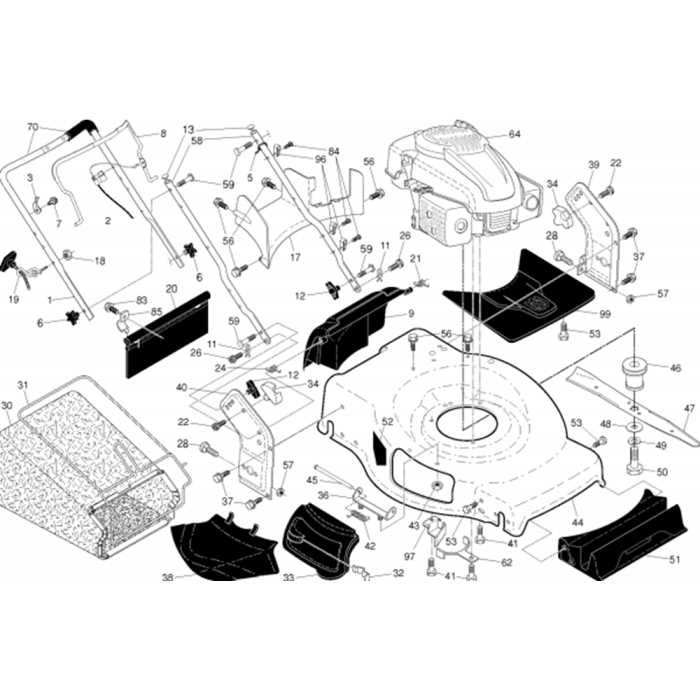

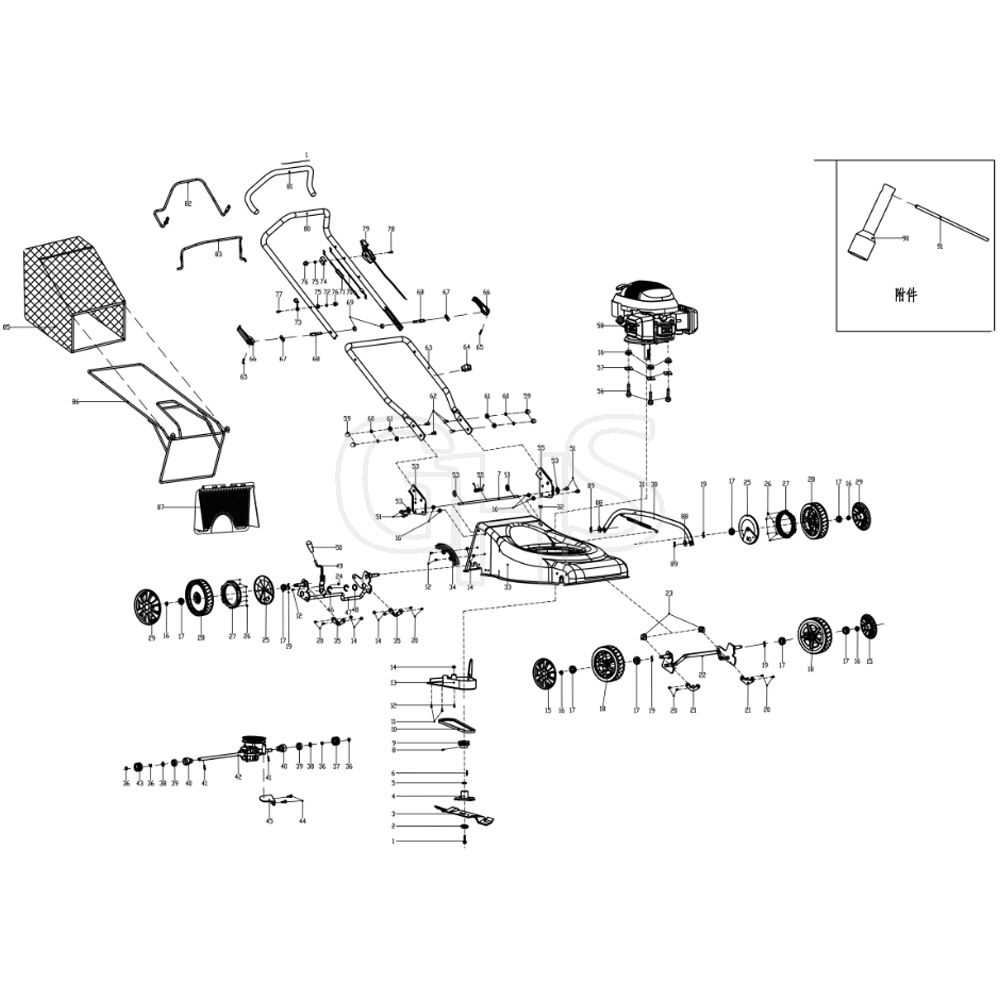

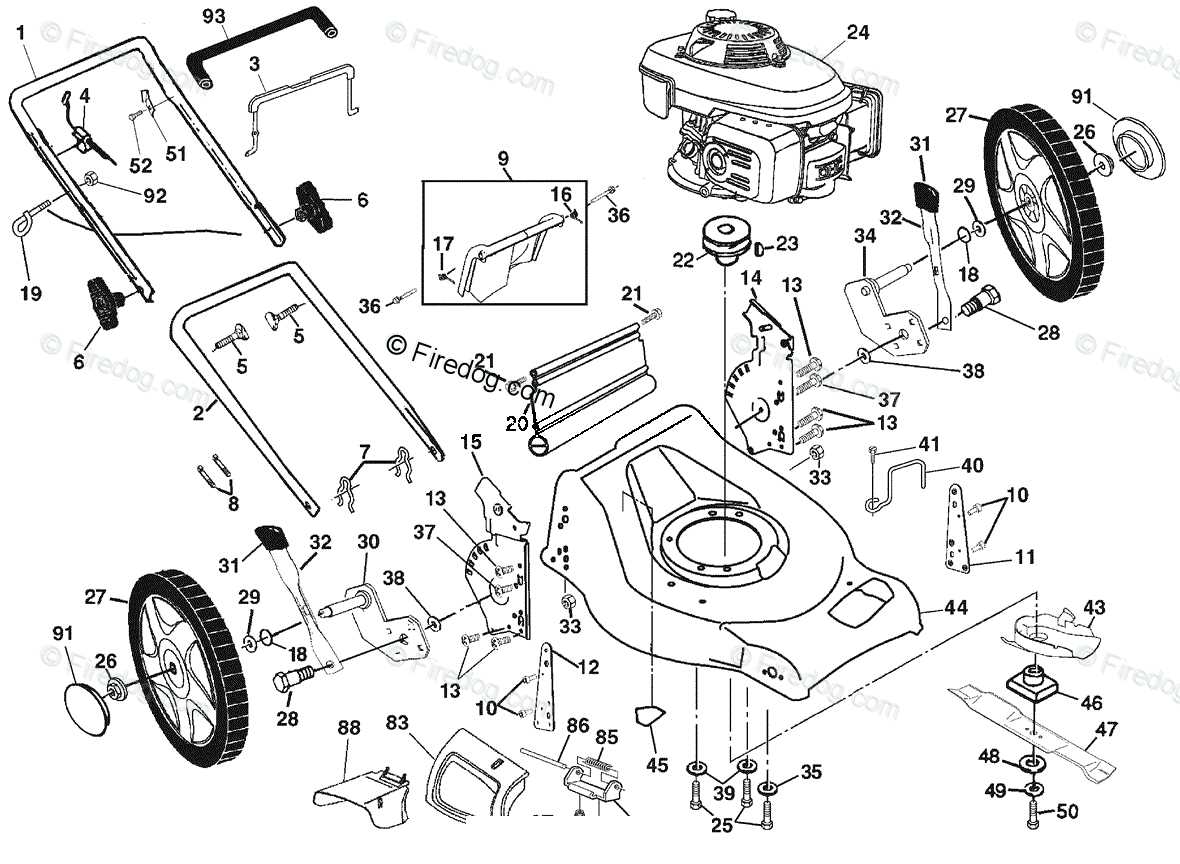

We will also provide a visual guide to the essential features of this machinery. This reference will not only assist you in identifying specific sections but also serve as a valuable tool for anyone looking to perform upkeep or modifications. By gaining insight into these components, you can approach repairs with confidence and improve your overall lawn care experience.

Understanding Husqvarna Mower Components

Grasping the various elements of outdoor equipment is essential for effective maintenance and optimal performance. Each component plays a vital role in ensuring the machine operates smoothly and efficiently, allowing users to achieve their landscaping goals with ease.

Key Elements of the Equipment

Notable components include the cutting mechanism, drive system, and engine. The cutting mechanism is responsible for achieving a clean finish, while the drive system enables effortless navigation across different terrains. The engine serves as the powerhouse, driving the overall functionality.

Importance of Regular Maintenance

Understanding these components is crucial for proper upkeep. Regular checks and timely replacements can significantly extend the lifespan of the equipment and enhance its performance, ultimately leading to a more enjoyable mowing experience.

Key Parts of Self-Propelled Mowers

Understanding the essential components of a lawn care machine is crucial for maintaining its performance and efficiency. Each element plays a significant role in the overall functionality, ensuring that the equipment operates smoothly and effectively. Familiarity with these parts helps in troubleshooting issues and facilitating repairs when needed.

Drive System

The drive system is responsible for the movement of the equipment, allowing it to navigate across various terrains with ease. This component typically includes gears, belts, and wheels that work together to provide propulsion. A well-functioning drive system not only enhances mobility but also ensures a consistent cutting experience.

Cutting Mechanism

The cutting mechanism is pivotal for achieving a neat and even lawn. This part generally consists of sharp blades attached to a rotating deck. The design and sharpness of these blades significantly influence the quality of the cut, making regular maintenance essential for optimal performance. Proper adjustment of this mechanism can prevent uneven cutting and promote healthier grass growth.

Importance of Maintenance for Longevity

- Enhances Efficiency: Regular checks and servicing help maintain peak operational effectiveness.

- Prevents Breakdowns: Routine inspections can identify potential issues before they escalate into major problems.

- Extends Lifespan: Consistent care contributes to the longevity of equipment, maximizing investment.

- Improves Safety: Well-maintained machines reduce the risk of accidents and ensure safe usage.

By prioritizing maintenance, users can delve into a more sustainable and economical approach, ultimately benefiting from their equipment for years to come.

Common Issues and Solutions

Maintaining lawn equipment can sometimes lead to unexpected challenges. Understanding these frequent problems and their remedies is essential for ensuring optimal performance. This section will explore typical issues faced by users and provide effective solutions to enhance functionality and longevity.

Problem 1: The machine won’t start. This is often due to fuel issues or a drained battery. Solution: Check the fuel level and quality; replace if necessary. Ensure the battery is charged and connections are secure.

Problem 2: Uneven cutting or poor performance. This may result from dull blades or clogged components. Solution: Sharpen or replace blades regularly and clear any debris from the cutting area.

Problem 3: Excessive vibration during operation. This could indicate a misalignment or wear. Solution: Inspect for loose parts and tighten or replace as needed to restore balance.

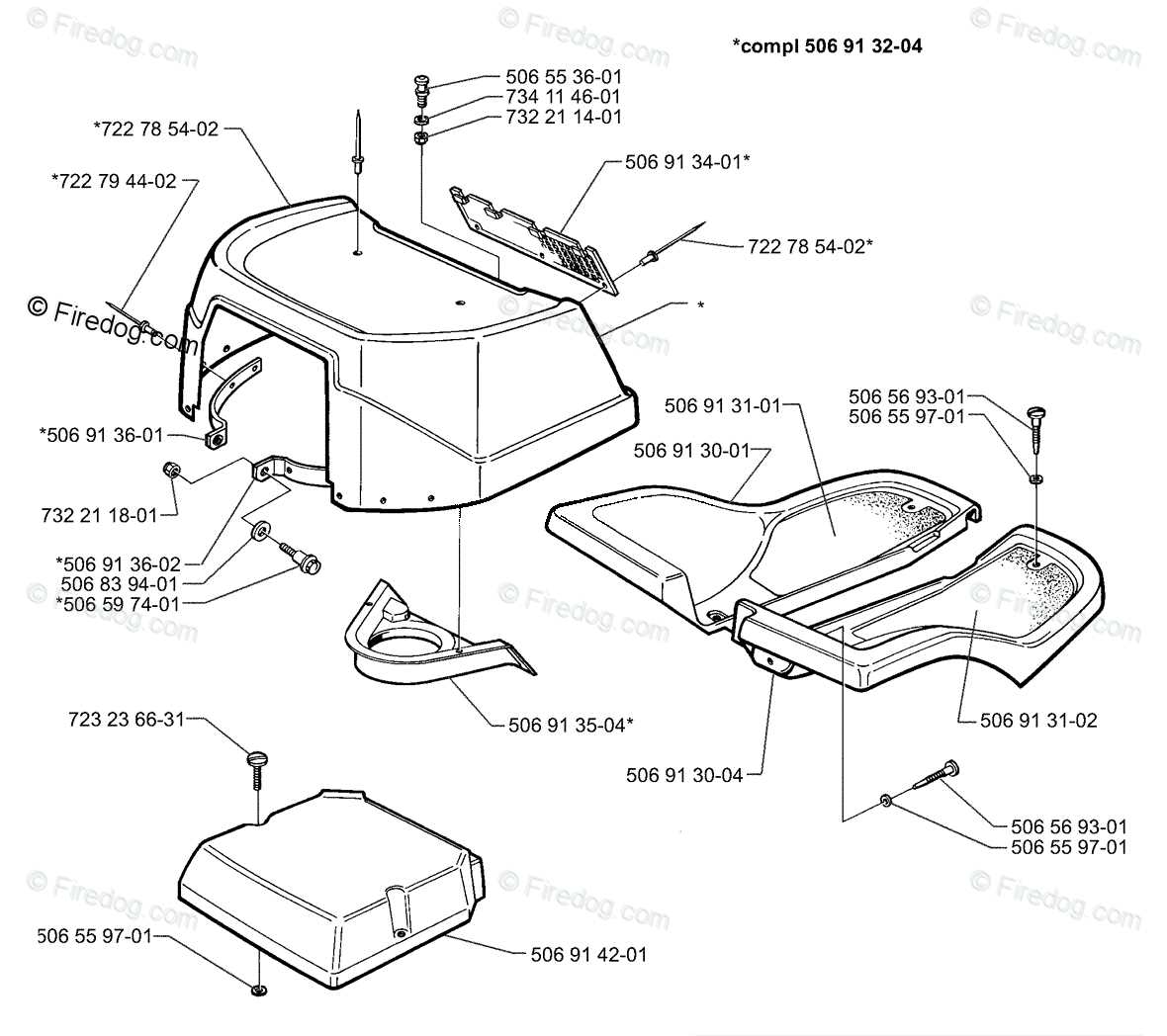

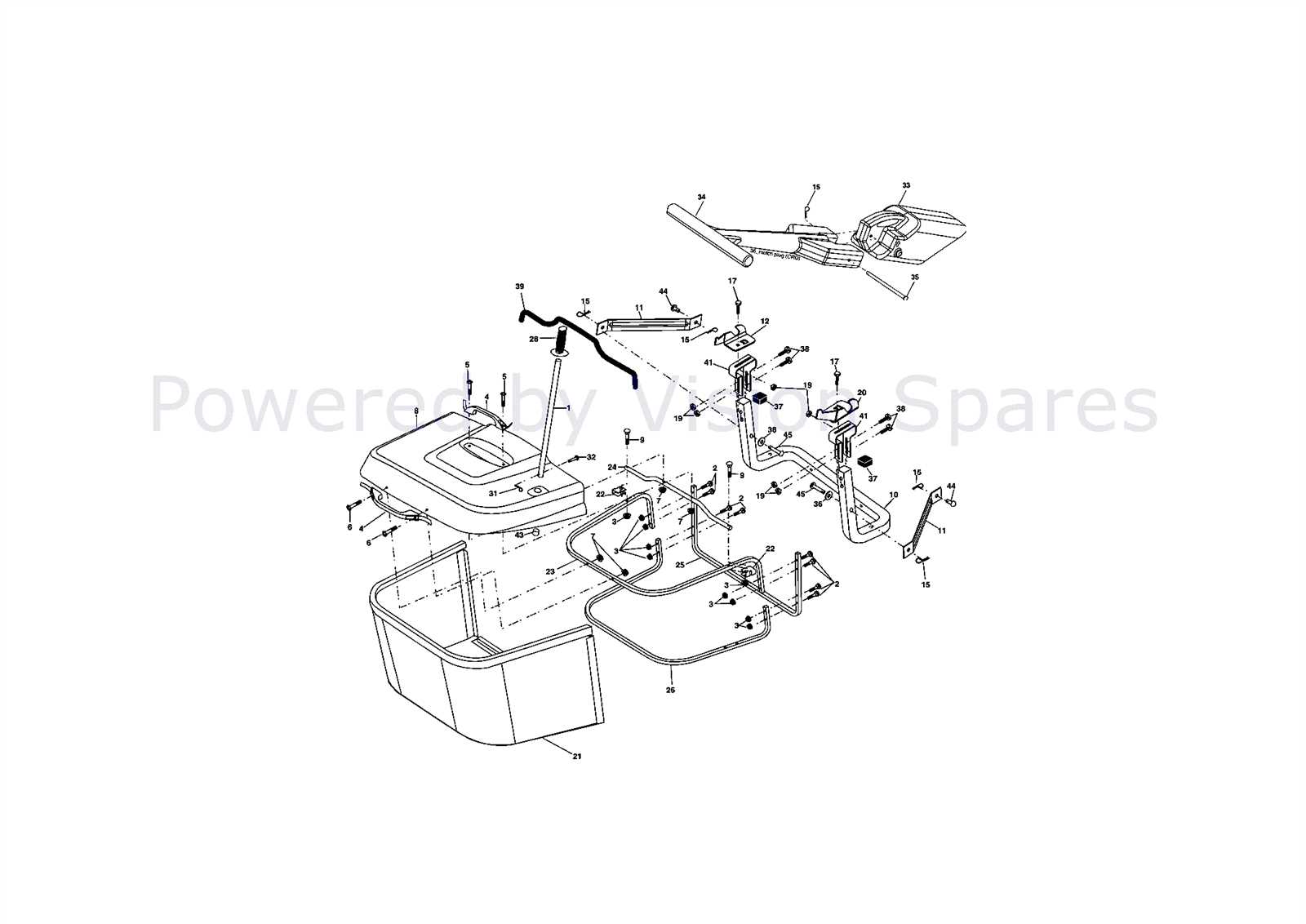

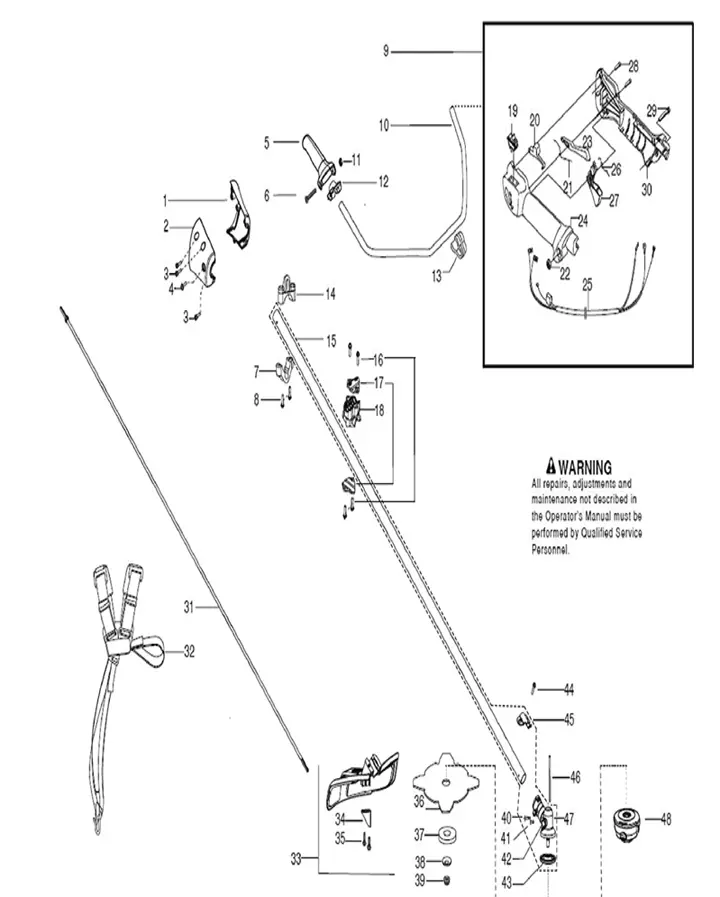

How to Read Parts Diagrams

Understanding component illustrations is crucial for effective maintenance and repairs. These visual representations provide an organized view of individual elements, helping users identify and locate various pieces. Familiarity with these diagrams can streamline the process of ordering replacements and performing repairs.

Identifying Key Sections

Begin by examining the overall layout, which typically groups related items together. Look for labels or numbers that correspond to a parts list, enabling you to match the visual with specific components. This systematic approach simplifies locating what you need.

Interpreting Symbols and Legends

Diagrams often include symbols to represent different types of items, such as fasteners or specific components. A legend will usually accompany the illustration, clarifying what each symbol signifies. Understanding these details enhances your ability to navigate the illustration effectively.

Replacing the Blade: A Guide

Maintaining the cutting edge of your lawn care equipment is essential for achieving a pristine lawn. A dull or damaged blade can hinder performance, making it crucial to replace it when necessary. This guide provides straightforward steps to ensure you can efficiently swap out the blade for optimal results.

Tools You Will Need

Before you begin the replacement process, gather the necessary tools. You will need a socket wrench, safety gloves, and a flat surface to work on. Having these items ready will streamline the procedure and enhance safety.

Step-by-Step Replacement Process

Start by disconnecting the power source to prevent any accidental activation. Once safe, flip the unit over to access the blade. Use the socket wrench to loosen the fastening bolts, carefully removing the old blade. Ensure you clean the area of debris before positioning the new blade. Secure it tightly by reattaching the bolts, making sure everything is aligned properly. Finally, return the equipment to its upright position and reconnect the power source.

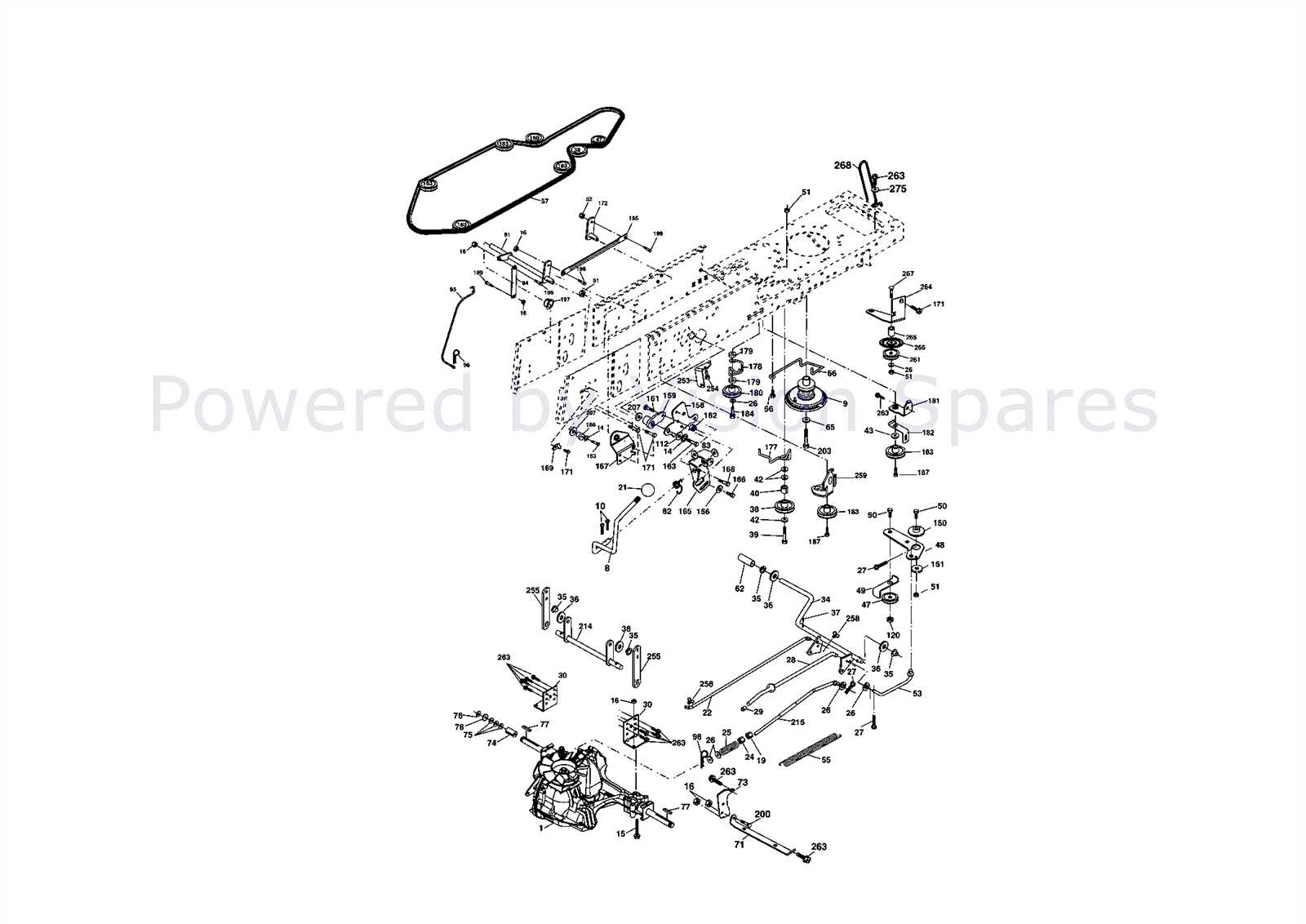

Identifying Drive System Components

Understanding the essential components of a propulsion mechanism is crucial for effective maintenance and troubleshooting. Each element plays a vital role in ensuring optimal functionality, allowing for smooth operation and reliability.

Key Components to Consider

- Transmission: Converts power from the engine to the wheels.

- Drive Belt: Transfers motion and connects the engine to the transmission.

- Wheels: Provide traction and movement across various terrains.

- Gearbox: Controls speed and torque for enhanced maneuverability.

Maintenance Tips

- Regularly inspect the drive belt for wear and tear.

- Ensure the transmission fluid is at the appropriate level.

- Check the wheels for proper inflation and alignment.

- Lubricate moving parts to prevent friction and damage.

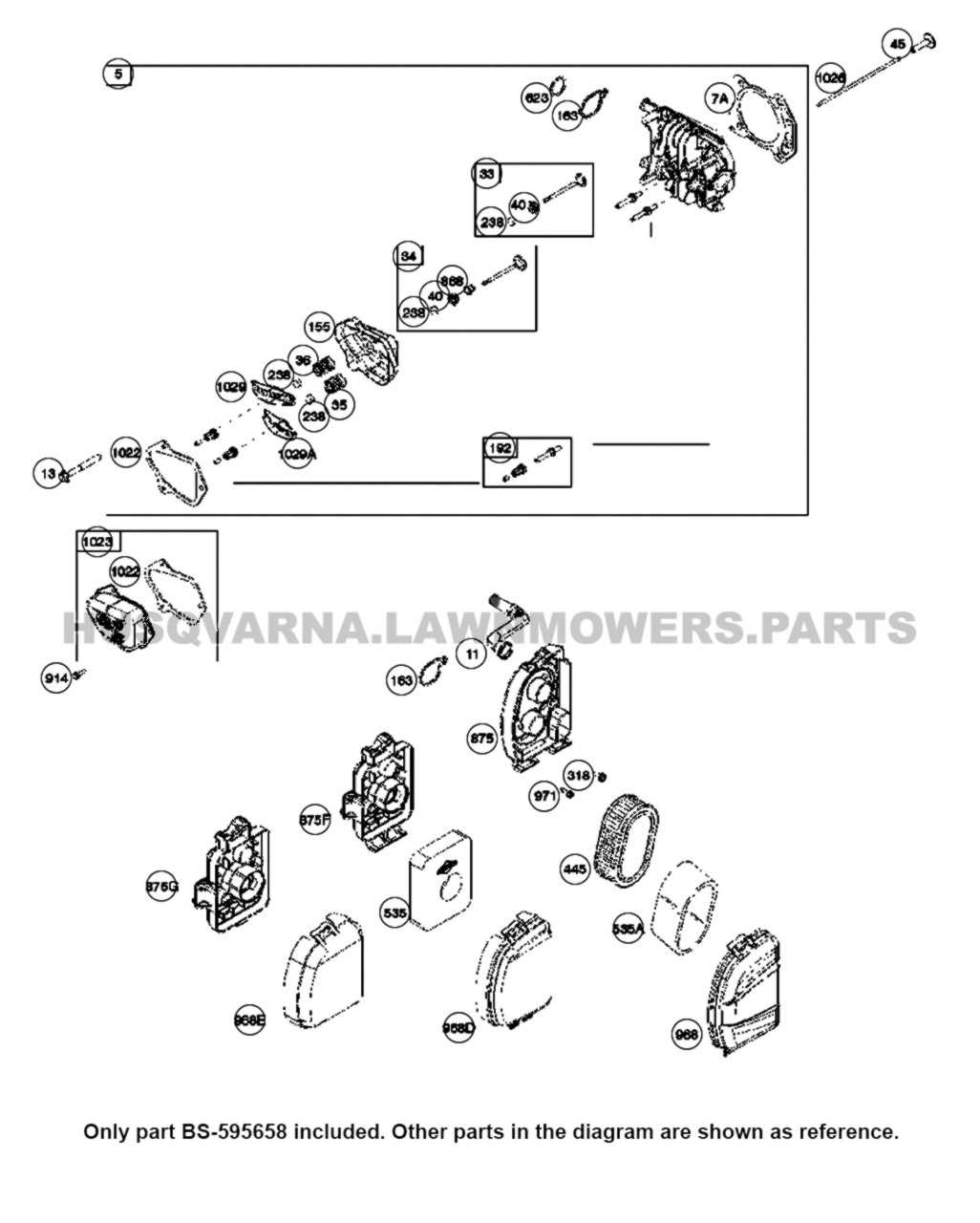

Fuel System Parts Explained

The fuel system is essential for the efficient operation of outdoor power equipment. It ensures that the engine receives the right amount of fuel at the correct pressure, allowing for optimal performance. Understanding the components involved can help in troubleshooting and maintenance, ensuring longevity and reliability of the machine.

Key Components of the Fuel System

- Fuel Tank: The reservoir that stores the fuel before it is delivered to the engine.

- Fuel Lines: These tubes transport fuel from the tank to the engine. They must be intact and free from leaks.

- Fuel Filter: This component removes impurities from the fuel, protecting the engine from potential damage.

- Carburetor: A critical device that mixes air and fuel in the correct proportions for combustion.

- Fuel Pump: Responsible for moving fuel from the tank to the carburetor, ensuring a steady flow during operation.

Maintenance Tips

- Regularly inspect the fuel tank for leaks or cracks.

- Replace the fuel filter as recommended to maintain optimal flow.

- Check fuel lines for signs of wear or damage, and replace them if necessary.

- Clean the carburetor periodically to prevent clogs and ensure efficient mixing.

- Monitor the fuel pump for proper operation and listen for unusual noises.

By familiarizing yourself with these components and their functions, you can enhance the performance and lifespan of your outdoor equipment.

Electrical Components in Mowers

Understanding the electrical elements of lawn care machines is essential for their optimal performance and longevity. These components are crucial for powering various functions, ensuring smooth operation, and facilitating user convenience. A well-functioning electrical system contributes significantly to the overall efficiency of any grass-cutting device.

Key Electrical Elements

Among the primary electrical components are the batteries, which provide the necessary power for operation. They come in various types and sizes, influencing the runtime and effectiveness of the equipment. Additionally, motors play a pivotal role in driving the cutting mechanism and other integrated features. Their efficiency directly impacts the machine’s performance and energy consumption.

Control Systems and Safety Features

The control systems serve as the brain of the apparatus, managing various functions such as speed settings and cutting height adjustments. These systems often include advanced technologies for enhanced user experience. Furthermore, incorporating safety features like emergency stop switches and overload protection is vital, ensuring user safety during operation and reducing the risk of accidents.

Choosing the Right Replacement Parts

Selecting appropriate components for your equipment is crucial for maintaining its performance and longevity. Understanding the specific requirements and compatibility of each item ensures a seamless fit and optimal functionality, ultimately enhancing the overall efficiency of your machine.

Understanding Compatibility

Before making a purchase, it’s essential to verify that the new components match the specifications of your device. Check the model number and consult the manufacturer’s recommendations to avoid mismatches that could lead to ineffective operation.

Quality Over Cost

While it may be tempting to opt for cheaper alternatives, investing in high-quality components can save you time and money in the long run. Genuine items or those from reputable brands often provide better durability and performance, reducing the likelihood of frequent replacements.

Ordering Parts from Authorized Dealers

When it comes to maintaining your equipment, sourcing components from certified vendors ensures reliability and quality. Authorized dealers offer a range of advantages, including access to original items and expert support, making the ordering process seamless and efficient.

Here are key benefits of choosing certified distributors:

| Benefit | Description |

|---|---|

| Quality Assurance | Components are manufactured to meet strict standards, ensuring durability and performance. |

| Expert Guidance | Trained staff can provide valuable advice on compatibility and installation. |

| Warranty Coverage | Purchasing through authorized channels often includes warranty protection for your investment. |

| Convenient Access | Dealers typically offer a wide range of items, making it easier to find what you need. |

In addition to these advantages, ordering from authorized sources helps support local businesses and ensures you receive the best possible service throughout your equipment ownership experience.

Understanding Warranty Coverage

Warranty coverage is essential for protecting your investment in outdoor equipment. It provides assurance that manufacturing defects and certain damages will be addressed, ensuring peace of mind for users. Understanding the specifics of what is covered can help you maximize the benefits and avoid unexpected costs.

Key Components of Warranty Coverage

Most warranties include components like parts replacement, repair services, and support for specific timeframes. It’s crucial to read the terms carefully to identify any exclusions or conditions that may affect your rights. Often, improper usage or lack of maintenance can void the warranty.

How to Navigate Claims

When filing a warranty claim, gather relevant documentation such as receipts and service records. Providing detailed information about the issue will facilitate the process. Remember to act promptly, as many warranties require claims to be made within a specific period following the problem’s discovery.

Tips for DIY Repairs and Upgrades

Engaging in do-it-yourself maintenance can be both rewarding and cost-effective. With the right approach and a few essential tools, you can enhance the functionality and longevity of your equipment. This guide provides practical insights to empower you in your repair and upgrade endeavors.

Understand the Basics

Before diving into repairs, familiarize yourself with the components and their functions. A thorough understanding of how each element operates will aid in troubleshooting and ensuring that any modifications are beneficial. Use manuals or online resources to delve deeper into the mechanics.

Tools and Safety First

Having the correct tools is crucial. Invest in quality equipment that suits your needs. Additionally, prioritize safety by wearing appropriate gear such as gloves and goggles. Always disconnect power sources before starting any work to avoid accidents.